Professional Documents

Culture Documents

Department of Public Works and Highways: Manila

Uploaded by

Faustino AbadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Department of Public Works and Highways: Manila

Uploaded by

Faustino AbadCopyright:

Available Formats

~~ /~~~:!

REPUBLIC OF THE PHILIPPINES II> _ 1"- - ~/r/

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS

OFFICE OF THE SECRETARY

MANILA

OCT 16 2014'

DEPARTMENT ORDER ) SUBJECT DPWH Specification on the Use of

) Elasto Barchip - Synthetic Fibers in

No. 110 )

)

Portland

Pavement

Cement Concrete

Series of 201~ P. ,..I~

In line with the continuing efforts to upgrade the construction technology thru

adoption of successful research studies, this Department has approved the use of Elasta

Barchip - Synthetic Fibers as additive to concrete subject to its specifications hereto

attached. A Certificate of Conditional Approval has been issued by this Department,

allowing the use of Elasto Barchip - Synthetic Fibers in DPWH projects from October 2014

until October 2019.

This Order shall take effect immediately.

Department of Public Works and Highways

Office of the Secretary

\\ \ 1\ \I \ \\111I 1\1111111111I 111111I11\

WIN4U00977

'"

DEPARTMENT ORDER

NO. 110

SERIES OF 2014

SPECIFICATION ON THE USE OF ELASTO BARCHIP - SYNTHETIC FIBERS

IN PORTLAND CEMENT CONCRETE PAVEMENT

1.0 Description

This item shall consists of furnishing and placing of Elasto Barchip -

Synthetic Fibers in Portland Cement Concrete Pavement, with or without

reinforcement, constructed on the prepared base in accordance with this

specification and in conformity with the lines, grades, thickness and typical

cross-section shown on the Plans, or as established by the Engineer.

Elasto Barchip - Synthetic Fibers is an additive to Portland Cement

Concrete Pavement to create concrete composites that are more durable than

plain concrete. It can provide improved flexural ductility and toughness,

fatigue capacity, and abrasion and impact resistance. It impedes crack

development and slows crack growth, while it also provides increased load

capacity in pavements that have already cracked. It can be used. in areas

prone to flooding and where traffic volume is heavy. It can also reduce

spalling at contraction joints by keeping them tighter and more stable than the

regular PCCP.

2.0 Material Requirements

2.1 Elasto Barchip - Synthetic Fibers-

Elasto Barchip - Synthetic Fibers is a monofilament polypropylene

extract fiber, non-toxic and not hazardous to health and is resistant to acid

and alkali designed to enhance the overall quality of concrete.

Properties of E/asto Barchip - Synthetic Fibers

Material Polypropylene extract synthetic fiber

Design Macro monofilament

Fiber Length 48mm

Diameter 0.72 mm

Shape Rectangular - Fully embossed

Color White

Specific Gravity 0.90 - 0.92

Tensile Strength 500 MPa (min.)

Young's Modulus 10 GPa

Melting Point 159°C -179 °C

Matrix Bonding Excellent

,.

2.2 Portland Cement

It shall conform to the requirements of Subsection 311.2.1, Portland

Cement, Item 311 - Portland Cement Concrete Pavement.

2.3 Fine Aggregate

It shall conform to the requirements of Subsection 311.2.2, Fine

Aggregate, Item 311 - Portland Cement Concrete Pavement.

2.4 CoarseAggregate

It shall conform to the requirements of Subsection 311.2.3, Coarse

Aggregate, Item 311 - Portland Cement Concrete Pavement.

2.5 Water

It shall conform to the requirements of Subsection 311.2.4, Water, Item

311 - Portland Cement Concrete Pavement.

2.6 Reinforcing Steel

It shall conform to the requirements of Subsection 311.2.5, Reinforcing

Steel, Item 311 - Portland Cement Concrete Pavement

2.7 Joint Fillers

It shall conform to the requirements of Subsection 311.2.7, Joint Fillers,

Item 311 - Portland Cement Concrete Pavement.

2.8 Admixture

Air-entraining admixture shall conform to the requirements of

AASHTO M 154.

Chemical admixture, if specified or permitted, shall conform to the

requirements of AASHTO M 194.

Fly Ash, if specified or permitted as a mineral admixture and not

exceeding 20% partial placement of Portland Cement in concrete mix shall

conform to the requirement of ASTM C 618.

Admixture/s maybe added to the concrete mix to produce some

desired modifications to the properties of concrete if necessary, but not as

partial replacement of cement. If specified, monofilament polypropylene

synthetic fibers, which are used as admixture to prevent the formation of

temperature/shrinkage cracks and increase impact resistance of concrete

slabs shall be applied in the dosage rate recommended by its manufacturer.

,.

2.9 Curing Materials

It shall conform to the requirements of Subsection 311.2.9, Curing

Materials, Item 311 - Portland Cement Concrete Pavement.

2.10 Calcium Chloride

It shall conform to AASHTO M144, if specified or permitted by the

Engineer.

2.11 Storage of Cement and Aggregate

It shall conform to the requirements of Subsection 311.2.11, Storage of

Cement and Aggregate, Item 311 - Portland Cement Concrete Pavement.

2.12 Packaging, Dispensing and Storage of Elasto Barchip - Synthetic

Fibers

Barchip fibers are packaged in the desired measured quantities in

either degradable paper bags, plastic bags and/or bulka bags. Paper bags

can be put directly into the concrete track or opened and the loose fiber

dispensed. The plastic bags is not degradable and will need to be opened

before dispensing into the concrete track.

All boxes of fibers shall be stored immediately upon delivery at the site,

on a clean dry surface, under cover and in the place approved by the

Engineer.

2.13 Proportioning, Consistency and Strength of Concrete

It shall conform to the requirements of Subsection 311.2.12,

Proportioning, Consistency and Strength of Concrete, Item 311 - Portland

Cement Concrete Pavement.

3.0 Construction Requirements

3.1 Quality Control of Concrete

It shall conform to the requirements of Subsection 311.3.1, Quality

Control of Concrete, Item 311 - Portland Cement Concrete Pavement.

3.2 Equipment

It shall conform to the requirements of Subsection 311.3.2, Equipment,

I

Item 311 - Portland Cement Concrete Pavement.

,.

3.3 Preparation of Grade

It shall conform to the requirements of Subsection 311.3.3, Preparation

of Grade, Item 311 - Portland Cement Concrete Pavement.

3.4 Setting Fonns

It shall conform to the requirements of Subsection 311.3.4, Setting

Forms, Item 311 - Portland Cement Concrete Pavement.

3.5 Conditioning of Subgrade or Base Course

It shall conform to the requirements of Subsection 311.3.5,

Conditioning of Subgrade or Base Course, Item 311 - Portland Cement

Concrete Pavement.

3.6 Handling, Measuring and Batching Materials

It shall conform to the requirements of Subsection 311.3.6, Handling,

Measuring and Batching Materials, Item 311 - Portland Cement Concrete

Pavement.

3.7 Mixing Concrete

It shall conform to the requirements of Subsection 311.3.7, Mixing

Concrete, Item 311 - Portland Cement Concrete Pavement.

3.8 Addition, Mixing and Pumping of Elasto Barchip • Synthetic Fibers

in Concrete Mix

The amount of Elasto Barchip Synthetic Fiber to be added in a

concrete mix shall not be less than 1.25 kg per cubic meter of concrete. The

total fiber requirement shall be added first to the mixer with the initial batch

water to achieve optimum fiber distribution during mixing operation. The bag

will release the fiber which will be homogenously distributed throughout the

mix after five (5) minutes of mixing.

The fiber shall be pumped through 50 mm rubber hoses without

difficulty. Precaution should be taken to ensure the fibers pass freely through

the pump hopper grate.

3.9 Limitation of Mixing

It shall conform to the requirements of Subsection 311.3.8, Limitation of

Mixing, Item 311 - Portland Cement Concrete Pavement.

3.10 Placing Concrete

It shall conform to the requirements of Subsection 311.3.9, Placing

Concrete, Item 311 - Portland Cement Concrete Pavement.

,.

3.11 Test Specimens

It shall conform to the requirements of Subsection 311.3.10, Test

Specimens, Item 311 - Portland Cement Concrete Pavement.

3.12 Strike-off of Concrete and Placement of Reinforcement

It shall conform to the requirements of Subsection 311.3.11, Strike-off

of Concrete and Placement of Reinforcement, Item 311 - Portland Cement

Concrete Pavement.

3.13 Joints

It shall conform to the requirements of Subsection 311.3.12, Joints,

Item 311 - Portland Cement Concrete Pavement.

3.14 Final Strike-off (Consolidation and Finishing)

It shall conform to the requirements of Subsection 311.3.13, Final

Strike-off (Consolidation and Finishing), Item 311 - Portland Cement

Concrete Pavement.

3.15 Surfaces Test

It shall conform to the requirements of Subsection 311.3.14, Surfaces

Test, Item 311 - Portland Cement Concrete Pavement.

3.16 Curing

It shall conform to the requirements of Subsection 311.3.15, Curing ,

Item 311 - Portland Cement Concrete Pavement.

If steam curing at a temperature in excess of 160°C is to be used,

polypropylene fibers should not be used.

3.17 Removal of Forms

It shall conform to the requirements of Subsection 311.3.16, Removal

of Forms, Item 311 - Portland Cement Concrete Pavement.

3.18 Sealing Joints

It shall conform to the requirements of Subsection 311.3.17, Sealing

Joints, Item 311 - Portland Cement Concrete Pavement.

t 3.19 Protection of Pavement

It shall conform to the requirements of Subsection 311.3. 18, Protection

of Pavement, Item 311 - Portland Cement Concrete Pavement

,.

3.20 Concrete Pavement

It shall conform to the requirements of Subsection 311.3.19, Concrete

Pavement - Slip Form Method, Item 311 - Portland Cement Concrete

Pavement.

3.21 Acceptance of Concrete

It shall conform to the requirements of Subsection 311.3.20,

Acceptance of Concrete, Item 311 - Portland Cement Concrete Pavement.

3.22 Opening to Traffic

It shall conform to the requirements of Subsection 311.3.21, Opening

to Traffic, Item 311 - Portland Cement Concrete Pavement.

3.23 Tolerance and Pavement Thickness

It shall conform to the requirements of Subsection 311.3.22, Tolerance

and Pavement Thickness, Item 311 - Portland Cement Concrete Pavement.

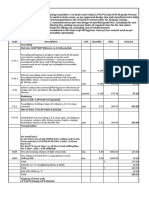

4.0 Method of Measurement

The area to be paid for under Item 311 shall be the number of square

meters (m2) of concrete pavement placed and accepted in the completed

pavement. The width for measurement will be the width from outside edge to

outside edge of completed pavement as placed in accordance with the Plans

or as otherwise required by the Engineer in writing. The length will be

measured horizontally along the center area of concrete pavement measured.

Elasto Barchip - Synthetic Fiber will be measured in kilogram (kg)

5.0 Basis of Payment

The accepted quantity, measured as prescribed in Section 4, shall be

paid for at the contract unit price for Portland Cement Concrete Pavement

and Elasto Barchip - Synthetic Fibers, which price and payment shall be full

compensation for preparation of roadbed and finishing of shoulders, unless

otherwise provided by the Special Provisions, furnishing all materials, for

mixing, placing, finishing and curing all concrete, for furnishing and placing all

joint materials, for sawing weakened plane joints, for fitting the prefabricated

center metal joint, for facilitating and controlling traffic, and for furnishing all

labor, equipment, tools and incidentals necessary to complete the item.

Republic of the Philippines

DEPARTMENT OF PUBliC WORKS AND IDGBWAYS

OFFICE OF THE SECRETARY

Product Accreditation

This is to certify that

te

o

,~'S§pplied"by:

Ez e OceaTi Chemt7:ade"Inc. ",-'

2/:r 1260 Juan Luna St., 'T'ondO,Manifa ':'

~

is duly accredited for use in DPWH projects as an additive to paving concrete

': 1;. - ~,--.,- ~ . t- - '. ,-

:.:- ' .••••• - , ~. ~

.-

subject to its'speciftca ons (hereto'attached} pursuant to· the provisions-of;

/,- :!':., :'.;-, ;.. ,"- ..•. ' .'~, !."-' ,t ":.~. r", ~r·""';' ,....~~~

.. " ..•.

DPWH Departm~nt Order No. is?, senes of 2002. ,.' "

'::'" .,,_T~i..accreditation shall remain, in force untif expiry prlnteq7below, 4~~

.;< subject to~its compliance" Wi'; t'e' requirements of",tl e~af()rementioned

Departrilent Order.""

Conditional Approval Nlimbei:

Date Issued

Expiry Date ".~'"

" ." ',-

r,-';,·~;~~,:",'"

You might also like

- Pavement Design DPWHDocument8 pagesPavement Design DPWHSwerthson Wasawas83% (6)

- What Is PQC PDFDocument19 pagesWhat Is PQC PDFLASA VADODARANo ratings yet

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringFrom EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringRating: 4 out of 5 stars4/5 (5)

- MCHW Vol 1 Series 2600 Web PDFDocument8 pagesMCHW Vol 1 Series 2600 Web PDFalejandraoy9No ratings yet

- Do 029 S2019Document6 pagesDo 029 S2019ZA TarraNo ratings yet

- DPWH Concrete SPECIFICATIONSDocument6 pagesDPWH Concrete SPECIFICATIONSShe Timbancaya100% (1)

- DPWH Approves Forta-Ferro Fibers for Concrete PavementDocument10 pagesDPWH Approves Forta-Ferro Fibers for Concrete PavementSimeon James Defeo VillacrusisNo ratings yet

- D.O. 126, S 2017Document6 pagesD.O. 126, S 2017ZA TarraNo ratings yet

- Is 1489 1 1991Document19 pagesIs 1489 1 1991vijay kNo ratings yet

- Concrete Lab ManualDocument20 pagesConcrete Lab ManualkelmazodroNo ratings yet

- Ce312 - Chapter 03.1 - Road MaterialsDocument16 pagesCe312 - Chapter 03.1 - Road MaterialswindellacsonNo ratings yet

- 7 JUN 20t&: Department of Public Works and HighwaysDocument14 pages7 JUN 20t&: Department of Public Works and HighwaysFaustino AbadNo ratings yet

- Portland-Pozzolana Cement - Specification: Indian StandardDocument12 pagesPortland-Pozzolana Cement - Specification: Indian Standardrahulrai711No ratings yet

- Ijs DR 191415Document11 pagesIjs DR 191415Ricky RickxNo ratings yet

- X-X-X-X-X-X-X - X-X: Department of Public Works and HighwaysDocument7 pagesX-X-X-X-X-X-X - X-X: Department of Public Works and HighwaysMark OlandresNo ratings yet

- O 4 Mar2016Document23 pagesO 4 Mar2016jaymarNo ratings yet

- 2374 - Technical Specification of Flooring Works PDFDocument17 pages2374 - Technical Specification of Flooring Works PDFKarthikeyan PanchatcharamNo ratings yet

- Department of Public Works and Highways: 09' FebruaryDocument2 pagesDepartment of Public Works and Highways: 09' FebruaryKenneth AustriaNo ratings yet

- Mechanical Properties of Self Compacting Concrete Reinforced With Polypropylene FibresDocument11 pagesMechanical Properties of Self Compacting Concrete Reinforced With Polypropylene Fibresmudasar205No ratings yet

- Department of Public Works and Highways: Republic of The PhilippinesDocument7 pagesDepartment of Public Works and Highways: Republic of The PhilippinesRyan FelipeNo ratings yet

- Guidelines For The Design and Construction of Ultra Thin White ToppingDocument6 pagesGuidelines For The Design and Construction of Ultra Thin White ToppingsoumenNo ratings yet

- Porous Concrete Pavement ReportDocument23 pagesPorous Concrete Pavement ReportSunanda Desai Ramteerth100% (1)

- 1489 2 PDFDocument15 pages1489 2 PDFshashikant gaurNo ratings yet

- Perlite Insulating Concrete Installation GuideDocument6 pagesPerlite Insulating Concrete Installation Guideshabnam58No ratings yet

- 311Document73 pages311mira01No ratings yet

- CC SPW 01000 02Document34 pagesCC SPW 01000 02kandy saidNo ratings yet

- Is 1489 (Part-1) Portland-Pozzolana Cement Specification (FLDocument14 pagesIs 1489 (Part-1) Portland-Pozzolana Cement Specification (FLRamarraju Kalidindi80% (15)

- Method Statement For Concrete RepairingDocument13 pagesMethod Statement For Concrete RepairingMihirdutta100% (3)

- FiberReinforcedConcrete - Mixage Des FibresDocument2 pagesFiberReinforcedConcrete - Mixage Des Fibresserhrouchni nourelhoudaNo ratings yet

- EEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFDocument6 pagesEEE-Speaker3 - Engr. CLEMENTE - Full Paper-2022 PICE MNCTC PDFShy AbuizaNo ratings yet

- S Severely Exposed BrickworkDocument16 pagesS Severely Exposed BrickworkAllahjurioNo ratings yet

- Special Foundation Works - CursDocument149 pagesSpecial Foundation Works - CursCarina PopescuNo ratings yet

- AASHTO M6-08 Fine Aggregate for cement concreteDocument8 pagesAASHTO M6-08 Fine Aggregate for cement concreteDucnguyenNo ratings yet

- Is 1489 (Part-2) Portland-Pozzolana Cement Specification (CADocument15 pagesIs 1489 (Part-2) Portland-Pozzolana Cement Specification (CARamarraju KalidindiNo ratings yet

- Portland-Pozzolana Cement - Specification: Indian StandardDocument11 pagesPortland-Pozzolana Cement - Specification: Indian Standardshashikant gaurNo ratings yet

- PFRCDocument24 pagesPFRCSean HarshaNo ratings yet

- Irc FRC PD2Document27 pagesIrc FRC PD2Ankur ChauhanNo ratings yet

- The Manuf. of Paver BlockDocument4 pagesThe Manuf. of Paver BlockMirtunjay KumarNo ratings yet

- Efficient Technology of Basalt Fiber-Reinforced CoDocument6 pagesEfficient Technology of Basalt Fiber-Reinforced CoAditya SutarNo ratings yet

- Comparative Study of Polymer Fibre Reinforced Concrete With Conventional Concrete PavementDocument5 pagesComparative Study of Polymer Fibre Reinforced Concrete With Conventional Concrete PavementesatjournalsNo ratings yet

- New Bohol Airport PCC Pavement ProjectDocument24 pagesNew Bohol Airport PCC Pavement ProjectJustine Ralph Zata100% (1)

- Gulf Perlite Ready Mixed Perlite ConcreteDocument4 pagesGulf Perlite Ready Mixed Perlite Concreteosama feilatNo ratings yet

- Research MethodologyDocument19 pagesResearch MethodologyAbiodun AmusatNo ratings yet

- Project Report On Polymer Fibre Reinforced Concrete PavementsDocument41 pagesProject Report On Polymer Fibre Reinforced Concrete PavementsShilankarMurti82% (17)

- Mat RequirementsDocument114 pagesMat RequirementsTakdir Satria NandaNo ratings yet

- IRS Guidelins HPCDocument12 pagesIRS Guidelins HPCsaritasohamNo ratings yet

- Characteristics - Foam - Concrete - With - Polypropylene - Fiber and StyrofoamDocument8 pagesCharacteristics - Foam - Concrete - With - Polypropylene - Fiber and StyrofoamAnonymous 8kRPSXXTZ7No ratings yet

- Fibre Reinforced ConcreteDocument6 pagesFibre Reinforced ConcreteFranklyn GenoveNo ratings yet

- Ternary Blended Cement2Document10 pagesTernary Blended Cement2juandlc3368No ratings yet

- DO - 133 - s2016 PCCPDocument1 pageDO - 133 - s2016 PCCPCarol SantosNo ratings yet

- Memo 097.7 - 122719 - Item 451 Tunnel ShotcreteDocument9 pagesMemo 097.7 - 122719 - Item 451 Tunnel ShotcreteBai Alleha MusaNo ratings yet

- 2023-BRL-05-XX-SP-C-1010 - Pavement - P01Document39 pages2023-BRL-05-XX-SP-C-1010 - Pavement - P01François Le RouxNo ratings yet

- DO - 160 - s2016 Item 416 - Carbon Fiber SheetDocument6 pagesDO - 160 - s2016 Item 416 - Carbon Fiber Sheetfredelino jumbasNo ratings yet

- Ms. Jenny TanMobile: +63 917 833 6666Email: jenny@blueoceanchemtrade.comWebsite: www.barchip.comDocument45 pagesMs. Jenny TanMobile: +63 917 833 6666Email: jenny@blueoceanchemtrade.comWebsite: www.barchip.comrekcah ehtNo ratings yet

- Irc 060-1976Document12 pagesIrc 060-1976harivennelaNo ratings yet

- 8'!? / .or'WHDocument5 pages8'!? / .or'WHFaustino AbadNo ratings yet

- Ms 0777Document65 pagesMs 0777sandipbharNo ratings yet

- ATTACHMENT A - FAA Specification P-606: Airport Construction Standards (AC 150/5370-10) AirportsDocument5 pagesATTACHMENT A - FAA Specification P-606: Airport Construction Standards (AC 150/5370-10) AirportsMussa ElbarraniNo ratings yet

- Flyash ConcreteDocument3 pagesFlyash ConcretefranknikkersonbNo ratings yet

- Influence of Polymer On The Performance of Bentonite As A Drilling FluidDocument6 pagesInfluence of Polymer On The Performance of Bentonite As A Drilling FluidLutfur RahmanNo ratings yet

- An Investigation On Design Procedure and Operations of Polymer Fibre Reinforced Concrete Pavements by S. Panda & N.H.S.rayDocument12 pagesAn Investigation On Design Procedure and Operations of Polymer Fibre Reinforced Concrete Pavements by S. Panda & N.H.S.rayijr_journalNo ratings yet

- BP 344 - DPWHDocument11 pagesBP 344 - DPWHJabriellaSanMiguelNo ratings yet

- DO 053 s2016 PDFDocument2 pagesDO 053 s2016 PDFRay RamiloNo ratings yet

- MAY 1 3 201ft : Office of The SecretaryDocument2 pagesMAY 1 3 201ft : Office of The SecretaryFaustino AbadNo ratings yet

- Do - 049 - s2018 Bridge Aesthetics GuidelinesDocument67 pagesDo - 049 - s2018 Bridge Aesthetics GuidelinesBrian PaulNo ratings yet

- X-X-X-X-X-X - X-X-) : Office of The SecretaryDocument2 pagesX-X-X-X-X-X - X-X-) : Office of The SecretarySheryl MH-PradaNo ratings yet

- Guidelines on shoulder paving and pedestrian safetyDocument4 pagesGuidelines on shoulder paving and pedestrian safetyCzar RosuelloNo ratings yet

- DO 027 S2019stream Flow Manual PDFDocument147 pagesDO 027 S2019stream Flow Manual PDFNowell PenoniaNo ratings yet

- PCCP Minimum StandardDocument3 pagesPCCP Minimum StandardJanssen Gerardo Valbuena100% (4)

- Cost-Effective Concrete Bridge Designs for Short SpansDocument1 pageCost-Effective Concrete Bridge Designs for Short Spanscarl_orbeNo ratings yet

- DPWH - Do - 034 - S2012 - Guidelines On The Implementation of Pedestrian Refuge Island Along National RoadsDocument6 pagesDPWH - Do - 034 - S2012 - Guidelines On The Implementation of Pedestrian Refuge Island Along National RoadsN.a. M. TandayagNo ratings yet

- DO - 160 - s2016 Item 416 - Carbon Fiber SheetDocument6 pagesDO - 160 - s2016 Item 416 - Carbon Fiber Sheetfredelino jumbasNo ratings yet

- Do 15Document4 pagesDo 15Fahmie PagayawanNo ratings yet

- Do - 008 - s2016 Uniform Transition Joints For RoadsDocument5 pagesDo - 008 - s2016 Uniform Transition Joints For RoadsrubydelacruzNo ratings yet

- Do - 155 - s2016 Carbon Fiber PlateDocument6 pagesDo - 155 - s2016 Carbon Fiber PlateCarol SantosNo ratings yet

- Department of Public Works and Highways: ManilaDocument6 pagesDepartment of Public Works and Highways: ManilaZA TarraNo ratings yet

- Design Standards for Tourism and Farm to Market RoadsDocument5 pagesDesign Standards for Tourism and Farm to Market RoadsWira PutrantoNo ratings yet

- (JD - II1'1I": Department of Public Works and Highways .U.Document6 pages(JD - II1'1I": Department of Public Works and Highways .U.jonathanNo ratings yet

- Do - 149 - s2017 Expansion Joint SystemDocument6 pagesDo - 149 - s2017 Expansion Joint SystemCarol SantosNo ratings yet

- DPWH Updates Road Sign SpecificationsDocument6 pagesDPWH Updates Road Sign SpecificationsLowie Torres TonioNo ratings yet

- DO - 146 - s2017 - Item 615 - Noise BarrierDocument7 pagesDO - 146 - s2017 - Item 615 - Noise BarrierFaustino AbadNo ratings yet

- Department of Public Works and Highways: ManilaDocument6 pagesDepartment of Public Works and Highways: ManilaZA TarraNo ratings yet

- DO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeDocument5 pagesDO - 147 - s2017 - Item 706 - Concrete, Clay, Plastic & Fiber PipeFaustino AbadNo ratings yet

- DO - 140 - s2017 - Item 627 - Weigh-In Motion System & Automatic Traffic Counter - Classifier EquipmentDocument16 pagesDO - 140 - s2017 - Item 627 - Weigh-In Motion System & Automatic Traffic Counter - Classifier EquipmentFaustino AbadNo ratings yet

- DPWH Standard Specification for Bearing DevicesDocument8 pagesDPWH Standard Specification for Bearing DevicesFaustino AbadNo ratings yet

- DPWH Standard Specification for Bearing DevicesDocument8 pagesDPWH Standard Specification for Bearing DevicesFaustino AbadNo ratings yet

- Anti Stripping Agent DO - 144 - S2014 PDFDocument4 pagesAnti Stripping Agent DO - 144 - S2014 PDFادزسر بانديكو هادولهNo ratings yet

- Department of Public Works and Highways: Republic of The PhilippinesDocument9 pagesDepartment of Public Works and Highways: Republic of The PhilippinesFaustino AbadNo ratings yet

- DO 134 s2017 0 PDFDocument24 pagesDO 134 s2017 0 PDFRodel Millondaga VenegasNo ratings yet

- P Remanand Kocheri: Professional Summary SkillsDocument2 pagesP Remanand Kocheri: Professional Summary SkillsADITYA KOCHERI-4BB18CS014No ratings yet

- Charoong Thai Wire & Cable Public Company Limited: Ctw-AcsrDocument6 pagesCharoong Thai Wire & Cable Public Company Limited: Ctw-AcsrAchint KumarNo ratings yet

- Combined Plans 3 Storey ApartmentDocument13 pagesCombined Plans 3 Storey ApartmentTrending JuanNo ratings yet

- Adaptive Reuse of Silo Buildings With ADocument7 pagesAdaptive Reuse of Silo Buildings With AArpit MalhotraNo ratings yet

- Batching Plant MT 1.0 Brochure enDocument6 pagesBatching Plant MT 1.0 Brochure enajaykumarsingh22817No ratings yet

- Project Implementation LP06Document69 pagesProject Implementation LP06Wan Mohamad Noor Hj IsmailNo ratings yet

- House Plans - Floor Plans - Custom Home Design ServicesDocument14 pagesHouse Plans - Floor Plans - Custom Home Design Serviceshanif azriNo ratings yet

- A Case Study of The Design of A Basketball Steel Covered Court in Cavite State UniversityDocument60 pagesA Case Study of The Design of A Basketball Steel Covered Court in Cavite State UniversityKarl TimtimNo ratings yet

- 2.2 JKR 28 Vacuum Brick Production LineDocument5 pages2.2 JKR 28 Vacuum Brick Production LinechrisofomaNo ratings yet

- Elevation 1 Elevation 2: Typical Classroom KidsDocument1 pageElevation 1 Elevation 2: Typical Classroom KidsKYC BIM010No ratings yet

- Cosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationDocument15 pagesCosfb - Composite Slim-Floor Beam: Experimental Test Campaign and EvaluationDima OvsiiNo ratings yet

- Price List 2022Document2 pagesPrice List 2022dewi juniarNo ratings yet

- Gani Marble Tiles 003Document31 pagesGani Marble Tiles 003Furqan sahabNo ratings yet

- Drain CoverDocument2 pagesDrain CoverNirajan MarwaitNo ratings yet

- Underwater Concreting Report 2Document8 pagesUnderwater Concreting Report 2Amey KadulkarNo ratings yet

- Chatupara HP1N X 1000Document4 pagesChatupara HP1N X 1000marsplanning108No ratings yet

- Qatar PlasterDocument8 pagesQatar PlasterlingamkumarNo ratings yet

- DSR 2011-2012 (Final)Document401 pagesDSR 2011-2012 (Final)shivaji.sarvadeNo ratings yet

- Davco K11 FlexDocument2 pagesDavco K11 Flexjet toledoNo ratings yet

- HoA3 (5. Engineer - Architects)Document11 pagesHoA3 (5. Engineer - Architects)003. M.priyankaNo ratings yet

- Electrical Symbols Legend and AbbreviationsDocument5 pagesElectrical Symbols Legend and AbbreviationsjorgeNo ratings yet

- Modulation Option On R90-160 Installation InstructionDocument23 pagesModulation Option On R90-160 Installation InstructionLiviu HogeaNo ratings yet

- Technical Specifications (STRUCTURAL)Document16 pagesTechnical Specifications (STRUCTURAL)Lenielle AmatosaNo ratings yet

- Deflection Control in Composite Building by Using Belt Truss and Outriggers SystemsDocument6 pagesDeflection Control in Composite Building by Using Belt Truss and Outriggers SystemsharishNo ratings yet

- 2) Method Statement For Plain Cement ConcreteDocument5 pages2) Method Statement For Plain Cement ConcreteMukesh PrajapatNo ratings yet

- Space Frame: BMCT Assignment 4 S.Krishnachandrika 3801610009Document22 pagesSpace Frame: BMCT Assignment 4 S.Krishnachandrika 3801610009Krish AnuNo ratings yet

- Jsa For Cold Box in Process AreaDocument5 pagesJsa For Cold Box in Process AreaMohammed MinhajNo ratings yet

- Philippine slaughterhouse condemnation pit construction projectDocument24 pagesPhilippine slaughterhouse condemnation pit construction projectJopheth RelucioNo ratings yet

- 19-09-24 Preparatory Work Method Statement MobilizationDocument2 pages19-09-24 Preparatory Work Method Statement MobilizationShahab Khan100% (2)