Professional Documents

Culture Documents

CH 18

Uploaded by

Rakesh ShahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH 18

Uploaded by

Rakesh ShahCopyright:

Available Formats

18

Marble Tiles

PRODUCT CODE : 29131 and 29132

QUALITY AND STANDARDS : IS 33161 (Revision 1974)

MONTH AND YEAR : January, 2003

OF PREPARATION

PREPARED BY : Small Industries Service Institute

Okhla Industrial Estate

Opp. Modi Flour Mills,

New Delhi-110020.

Phone Nos.: 26838118, 26838068,

26838269

Fax No. : 26838016

E-mail: sisi@del3.vsnl.net.in

INTRODUCTION hardness, durability, smoothness and

finish.

Polished marble tiles manufactured Realizing the potential of polished

out of natural marble blocks of different marble tiles, to earn substantial foreign

colours is well known as one of the most exchange, the Govt. of India included

beautiful decorative and reliable building the marble tiles industry in its list of

material. Marble tiles are used as building

export thrust sector. The major

material in hotels, hospitals and airport

importers of polished marble tiles are

terminals, architectural use for interior,

the United State of America, United

exterior and floor decoration in building,

Kingdom (U.K.), Japan, Germany,

decorative memorial stone, high

precision instrument beds and surface Singapore and Canada. India’s main

plates. Besides these, marble is in competitors in the international market

demand for table, craftwork for interior are China, South Korea, Brazil etc.

decoration, name plates etc.

B ASIS AND PRESUMPTIONS

MARKET POTENTIAL With 300 working days in a year and

The polished marble tiles are having of 8 hrs. shift per day, the unit is likely

good demand in India and abroad. In to achieve 80% of its installed capacity.

developing countries like India, the The unit shall achieve full capacity in

construction work of hotels, airport, 3 years.

railway stations, hospitals etc. is in great Labour wages has been taken

upsurge. The people have developed according to the Minimum Wages Act of

attraction for marble tiles due to its the State Government.

108 MARBLE TILES

Interest Rate desired dimensions of tiles with the help

Fixed capital 14% of edge cutting machine. Thereafter, the

Working Capital 14% tiles are sorted out size wise and packed.

Margin money 25% Quality Control and Standards

Estimate life of 10 years IS 33161 (Revision 1974).

the project

Repayment of loan 7 years. Production Capacity (per annum)

Average cost of land has been Quantity : 112500 Nos. tiles

considered as per the rate of SIDC in size 6”x12”

industrial areas. 62500 Nos. tiles,

size 24”x24”

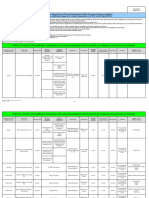

IMPLEMENTATION SCHEDULE

112500 Nos. tiles,

Sl. No. Activity Period size 12” x 12”

1. Preparing of project report 1 month Value : Rs. 68, 62, 500.

2. Selection of site 1 month

Motive Power 30 kW.

3. Registration of SSI 1 Week

4. Availability of finance/loan 1 month Pollution Control

5. Construction of building 1 month Water treatment plant is required for

6. Machinery procurement, 3 months recirculation of the water.

erection and commissioning

7. Trial Production 1 week FINANCIAL ASPECTS

8. Recruitment of labour 2 weeks A. Fixed Capital

(i) Land and Building (Rs.)

TECHNICAL ASPECTS

Land:About 500 sq. meter cost 5,00,000

Process of Manufacture will be @ Rs. 1000 per sq.mtr.

Building: Workshed: 12 x 10 sq, mtr. 3,60,000

Marble slabs of required thickness @ Rs. 3000 sq.mtr.

procured from block sawing machine Office Stores etc.: 100 sq.mtr. 4,00,000

are fed in the polishing machine for @ Rs. 4000 sq. mtr.

surface polishing and cut into the Total 12,60,000

(ii) Machinery and Equipments

Particulars Indigenous/ No. Cost

Imported (Rs.)

Automatic marble cutting machine with 13 HP Motor Indigenous 1 4,15,000

and other accessories

Edge cutting machine for edge cutting of the tiles with “ 1 3,75,000

10.5 HP motor and other accessories

Automatic polishing machine with 5 HP motor and other accessories “ 1 2,00,000

Overhead water tank cap 2500 Ltr. With water pump. “ 1 25,000

Total 10,15,000

MARBLE TILES 109

Particulars Indigenous/ No. Cost

Imported (Rs.)

Cost of power connection including transformer 30 KW 80,000

Electrification, transformer and foundation etc@ 10% 1,01,500

Cost of fixture and furniture 50,000

(iii) Pre-operative expenses 50,000

Total 12,96,500

B. Working Capital (Per Month) Other Contingent Expenses (per month) (Rs.)

Repair and Maintenance 1000

(i) Personnel (per month)

Transportation charges 5,000

Description Nos. Salary/ (Rs.)

Insurance 5,000

month

Sales expenses 10,000

Manager-cum-supervisor 1 8,000 8,000

Consumable Stores 800

Typist-cum-clerk 1 4,000 4,000

Advertisement and Publicity 2000

Accountant 1 4,000 4,000

Sales-man 1 4,000 4,000 Misc. Expenses 5000

Skilled workers 2 4,000 8,000 Total 30,600

Un-skilled workers 4 2,500 10,000 (v) Total Recurring Expenditure (per month) (Rs.)

Peon 1 2,000 2,000 Salaries and wages 48,300

Watchman 1 2,000 2,000 Raw materials 2,91,000

+ 15% perquisites 6,300 Utilities 17,000

Total 48,000 Misc. expenses 30,600

(ii) Raw Material (per month) Total 3,86,900

Description Indige- Qty. Rate Amount (vi) Total Working Capital (Rs.)

nous/ Sq. m. (Rs.) (Rs.) (On three months basis) 11,60,700

Marble Slab Ind 1600 135 sq.m. 2,16,000

C. Total Capital Investment

Diamond saw Ind. L.S. 50,000

and Spares Total fixed investment Rs. 25,56,500

Lubricants, Ind. L.S. 25,000 Total working capital Rs. 11,60,700

chemical

and Misc. Total Rs. 37,17,200

Total 2,91,000 or Say Rs. 37,17,000

(iii) Utilities (per month) (Rs.) FINANCIAL ANALYSIS

Electricity L.S. 16000 (1) Cost of Production (per annum) (Rs.)

Water L.S. 1,000

Total recurring cost 46,42,800

Total 17,000

Depreciation on building @ 5% 38,000

(iv) Other Contingent Expenses (per month) (Rs.) Depreciation on machinery

and equipment @ 10% 1,19,650

Postage and Stationery 800

Depreciation on furniture and

Telephone 1,000 fixtures @ 20% 10,000

110 MARBLE TILES

Cost of Production (per annum) (Rs.) B.E.P. = Fixed Cost x 100

Fixed cost + Net Profit

Interest on total investment

@ 14% 5,20,380 = 11,02,750 X100

11,02,750+15,31,670

Total 53,30,830

= 41.9%

(2) Turnover (per year)

Addresses of Machinery Suppliers

1,12,500 Nos. tiles of size 6”x12” 13,50,000

@ Rs.12 per tile 1. M/s. M.I. Shah and Co.

1,12,500 Nos. tiles of size 12”x12” 27,00,000 (Machinery) Pvt. Ltd.,

@ Rs.24 per tile

Lotus House, 5th Floor, 33, A,

62,500 Nos. of tiles of size 24”x24” 28,12,500 New Marine Line,

@ Rs.45 per tile

Mumbai-400020

Total 68,62,500

2. M/s. Veenedyt

(3) Net Profit (per year) 3, Girish, 224, Katni Road,

= Sales – cost of production Matunga (West),

= Rs. 68,62,500 – 53,30,830

Mumbai-400016

= Rs. 15,31,670 3. M/s. Rajasthan Udyog

13, Heavy Indl. Area,

(4) Net Profit Ratio Jodhpur.

= Net profit per year x 100 4. M/s. Karam Chand Mansion

Turn over per year

Barrack Road,

= 15,31,670 x100 Behind Metro Cinema,

68,62,500

Mumbai-400020.

= 22%

5. M/s. Grant Tools Pvt.Ltd.

(5) Rate of Return 53, 19th Main, 25th Cross,

= Net Profit per year X 100 5 Block Rajaji Nagar,

Total Investment Bangalore-560010.

= 15,31,670x100 6. M/s. Surfix Polix

37,17,000

2-430, A, Naraina Village,

= 41%

New Delhi-110028.

(6) Break-even Point 7. M/s. Ved Saso Mechanical

Opp. Lohil Machine Tools,

Fixed Cost (per annum) (Rs.)

Panki Ind. Area, Kanpur.

Depreciation on machinery 10% 1,19,650

Depreciation on building 5% 38,000 Raw Material Suppliers

Depreciation on fixture and 10,000 1. M/s. Andhra Pradesh Mining

furniture 20%

Corporation

Interest on Total Investment @14% 5,20,380

Panjagutta,

40% of salary and wages 2,31,840 Hyderabad-500024

40% of other Contingent expenses 1,22,880 2. M/s. Maharastra Steel Mining

(excluding insurance)

Corporation

Insurance 60,000

Abbyanakar Nagar,

Total 11,02,750 Nagpur-440010

You might also like

- Smart Industrial ParkDocument15 pagesSmart Industrial ParkRakesh ShahNo ratings yet

- Invites: For Pre-Booking of Industrial PlotsDocument1 pageInvites: For Pre-Booking of Industrial PlotsRakesh ShahNo ratings yet

- Covid19 Diagnosticproducts List enDocument74 pagesCovid19 Diagnosticproducts List enRakesh ShahNo ratings yet

- Brokerlist 20211125185015 CompressedDocument194 pagesBrokerlist 20211125185015 CompressedRakesh ShahNo ratings yet

- Universal Granimarmo CatalogueDocument24 pagesUniversal Granimarmo CatalogueRakesh ShahNo ratings yet

- Medical Devices and Diagnostics Industry Capability ReportDocument52 pagesMedical Devices and Diagnostics Industry Capability ReportRakesh Shah100% (1)

- SteelFab 2019Document4 pagesSteelFab 2019Rakesh ShahNo ratings yet

- Members List: ElcomaDocument3 pagesMembers List: ElcomaRakesh ShahNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Olongapo City Executive Summary 2017Document8 pagesOlongapo City Executive Summary 2017Hi ShineNo ratings yet

- Full Download Test Bank For Jazz 2nd by Deveaux PDF Full ChapterDocument18 pagesFull Download Test Bank For Jazz 2nd by Deveaux PDF Full Chaptercotiserampirenocx100% (20)

- Dwnload Full Financial Accounting 8th Edition Harrison Test Bank PDFDocument20 pagesDwnload Full Financial Accounting 8th Edition Harrison Test Bank PDFescout.stoopvr5nbf100% (12)

- Bitcoin For Blockheads by Tasheme ThomasDocument55 pagesBitcoin For Blockheads by Tasheme ThomasSengottu VeluNo ratings yet

- Solution Ch05Document14 pagesSolution Ch05sovuthyNo ratings yet

- Literature Review Promotional StrategiesDocument6 pagesLiterature Review Promotional Strategiesea884b2k100% (1)

- J17 DipIFR - AnswersDocument8 pagesJ17 DipIFR - Answers刘宝英No ratings yet

- Od428020695557784100 1Document1 pageOd428020695557784100 1Rájñîsh MôñdālNo ratings yet

- Business PlanDocument11 pagesBusiness PlanSamir BhandariNo ratings yet

- FM RL 1.1.1Document10 pagesFM RL 1.1.1anandakumarNo ratings yet

- Test Bank For Cornerstones of Managerial Accounting 5th EditionDocument24 pagesTest Bank For Cornerstones of Managerial Accounting 5th EditionDebraWrighterbis100% (47)

- TVET Accreditation Handbook CompressedDocument102 pagesTVET Accreditation Handbook CompressedMartinNo ratings yet

- Law and Practice of BankingDocument34 pagesLaw and Practice of BankingAbdullah Al ShaqureNo ratings yet

- Acc Finalpracticalfile Class12Document30 pagesAcc Finalpracticalfile Class12Kartik RawatNo ratings yet

- Canada Case Study Edited - EditedDocument4 pagesCanada Case Study Edited - EditedTalvir SinghNo ratings yet

- Internship ReportDocument54 pagesInternship Reportrajeshthakran1998No ratings yet

- List of Executive DirectorDocument5 pagesList of Executive DirectorYogesh ChhaprooNo ratings yet

- Project Management Analysis in The Internet Forecasting IndustryDocument14 pagesProject Management Analysis in The Internet Forecasting IndustryNiranjan NidadavoluNo ratings yet

- Business Accounting Quiz 2 (Answers) Updated.Document7 pagesBusiness Accounting Quiz 2 (Answers) Updated.Hareen JuniorNo ratings yet

- Part 6: Delivering ValueDocument8 pagesPart 6: Delivering ValueJames Carl Lambayan StiflerNo ratings yet

- CEIMDocument4 pagesCEIMAbhishek BharteNo ratings yet

- Residents Say "Exciting" Development Not Welcome: Part 7 - Short ReadingsDocument13 pagesResidents Say "Exciting" Development Not Welcome: Part 7 - Short ReadingsQuân VõNo ratings yet

- Mergers and AquisationsDocument10 pagesMergers and AquisationsNeeraj KumarNo ratings yet

- Whocares Who Does 2022 CDocument35 pagesWhocares Who Does 2022 CTran Nguyen Anh TramNo ratings yet

- Nube VS PemaDocument2 pagesNube VS PemaNina Grace G. ArañasNo ratings yet

- Meena Bhatt - ResumeDocument3 pagesMeena Bhatt - Resumehemanth vNo ratings yet

- Assignment On: Case StudyDocument7 pagesAssignment On: Case Studyimran mahmudNo ratings yet

- Effect of Currency Redesign and Cashless Policy On Academic Performance of Students in Nigerian UniversitiesDocument43 pagesEffect of Currency Redesign and Cashless Policy On Academic Performance of Students in Nigerian UniversitiesWillis LavisNo ratings yet

- Philippine Nurses Licensure Examination Results Released in Ten (10) Working DaysDocument5 pagesPhilippine Nurses Licensure Examination Results Released in Ten (10) Working DaysRapplerNo ratings yet

- Glenn Resume FinalDocument1 pageGlenn Resume FinalRea Angela PurisimaNo ratings yet