Professional Documents

Culture Documents

2 Rineer Motors

2 Rineer Motors

Uploaded by

wilo0 ratings0% found this document useful (0 votes)

23 views10 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views10 pages2 Rineer Motors

2 Rineer Motors

Uploaded by

wiloCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

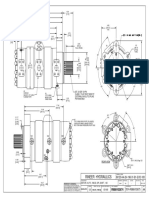

Features of the Rineer

125 Series 4-Ported Motor:

®@ 3000 PSI continuous.

™ Speed to 350 RPM continuous.

@ Up to 240HP continuous.

@ 10° diameter x 23" long package.

@ Weighs 380 Ibs.

@ Same starting, stall and low speed torque.

© Two-speed operation with some external valving.

,)

Df

WYMAN YY

T

i

ri

Performance Data: Series Circuit Parallel Circuit

LC A SO BP ED oie ec Pa

Displacement

(ou.in.frev.)

60 68 82 98 113 125 120 186 164 196 226 250

Pressure (PS!) a

‘Max. Continuous 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000 3000

‘Max. Intermittent 3500 3500 3500 3500 3500 3500 3500 3500 3500 3500 3500 3500

“Speed (RPM) oo

Mex. Continuous 350 950 300 300 900 900150180 «150150150150

Max. Itermitent 400 400 350 350950 350200 200 200 «200-200-200

Torque (ft.bs.) wes =e

‘At3O00 PSI 2000 2868 2884 9446 4012 4486 4908 4882 ©5048 7106 8274 9250

Per100PSI 696 729 961 1148 1937 1495 1436 1627 1982 2088 2758 3063

‘SERIES PARALLEL LOGIC CIRCUIT

wl

BK 4Vi

AZ. At A

z

wht AQ Al

B2] Bi — ef

ve B2 Bi

A B 8

"nae

H |

He

| jee

Technical Information

VANE CROSSING VANE

‘The Rineer patented vane crossing vane design produces

‘much higher volumetric and mechanical efficiencies than is

possible with a standard vane type design This design provides.

a sealing vane between cavities to improve mechanical and

‘volumetric efficiencies,

‘STARTING AND STALL TORQUE

The Rneer motor produces torque curves which ae virtually

flat, with starting and stall torque equal to approximately

90-94% of theoretical torque

MORE POWER STROKES PER REVOLUTION

‘The 125 Series has sik stator cates and 16 rotor vanes, Each

rotor vane works in each stator cavity once per revolution,

which results in 96 power strokes per revolution, This helps

produce higher mechanical effiency and fatter torque curves.

4-PORTED MOTOR CONFIGURATION

4-Ported motors have displacements normally ranging from

120 into 250 in? and are comprised of two rotor stator

packages separated by a mid-inlet housing, Ths allows the

packages to function individually a in parallel. Any of the

standard displacement packages may be combined to satisty

‘otal displacement requirements

4-PORTED MOTOR, DOUBLE SPLINED

‘The 126 Series 4-Ported Motor is avalable with the standard,

‘splined shaft extending through both the front and rear housings.

BEARING LOADING

‘The bearings in the 125 Series can accent radial load per the

radial capaity chart Thrust foading isnot recommended.

For thrust-type applications, contact Rineer or optional bearing

configurations.

SEALS

‘Buna N Seals are supplied standard. Viton Seals may be ordered

as an option.

CASE DRAIN AND CROSS PORT LEAKAGE

‘The combined case drain and cross port leakage of a 4-Ported

Motor is approximately 1 to 14 GPM per 1,000 PSI, This wil

‘vary with the oil viscosity and internal clearance selection.

ROTATION

The 125 Series Motor rotates eqully well neither direction

and smoothly throughout is entire pressure and speed range

Looking into the end of the shaf, rotation is clockwise when

oil is supplied tothe ports nearest the shaft output end (AY

and 2).

HORSEPOWER LIMITATION

Maximum horsepower limitation may vary with different

applications. When using the 125 Series 4-Ported Motor

above 240HP, consult a Ringer Application Engit

FILTRATION

25 micron minimum,

WEIGHT

A125 Series 4-Ported Motor weighs 380s, inal displacements.

FLUID

‘We suggest premium grade fuds containing high quality rust,

‘oxidation and foam inhibtors, along with ant-wearaditives. For

best perormance, minimum viscosity shouldbe maintained at

100 $SU or higher. Fu temperture should not exceed 180° F

Elevated tid temperature will adversey affect sealife while

accelerating oxidation and fhid breakdown, Fre resistant fuids

maybe used wth eta imitations, Contac ner for adtonal

informaton,

CASE DRAIN

‘The 125 Saris 4-Ported Motors designed for enteral case dan

‘Thee case drain ports are supplied; use the port atthe highest

elevation, We recommend case drain pressure of 35 PSI or less

whan using the standard seals,

CASE DRAIN CIRCULATION

Fluid should be circulated through the case when a temperature

sifferential exists between the motor and the system in excess

of 50°F. Should this occur, contact a Rineer Application

Engineer.

MOUNTING

The mounting position is unrestricted, The shats, pilots and

‘mounting faces shouldbe within 002 TIR.

INTERMITTENT CONDITIONS

Intermittent conditions are to be less than 10% of every minut.

The 4Ported Motor canbe usedas a two-speed when combined

with external valving as ilustrated, The series paral circuit an

only be used when both cardges are of equal ispacement.

The teu using two-way of oi valves can be used with equal

‘or unequal displacement cartidges. When using te logiccrcult,

it shouldbe connected as ilustrated to insure proper mixing of

oil inthe circulating carsdge, Particular attention should be

vento the size and flow capacity of V2, as this valve must

handle the displacement ofthe circulating cartridge when inthe

high speed mode, For example: a 125 C.D. + 60 C1.D. = 185,

CL. with sped ratios of 3.08: or 1 48:1

OTHER AVAILABLE MOTORS

For information on aditional Rineer Motos, request one of

the following publications:

15 Series.

15 Series Two Sp

416 Series Wheel Moto.

45 Series Retractable Shaft

37 Series.

57 Sees...

125 Series

oto

Publication 08151003,

Publication 0151004

Publication 0371003

ublication 0571003,

ublication 0$1251003

Radial Load Capacities

500s

Ha B-10 rating is desired at other than 1,500

‘ot

z, hous, multi te radiaioadcapactyobiined

22 tam pp —} Sia lac Ht ateae any

(a the appropriate factor below.

Peg SSS Eee oI Factor

SE smom x

Ez 500 18

33 2m 1000 4

i B | 3

2 7

4 ae 0 &

Distance from mounting face of motor to radial oad 9000 | 55

Model Code

rea) A ra) ] -31

125A4 = 125 Series 4-Ported | PC Std. Clearance | Max. Displacement ) Min, Displacement | 31 ~Spined Shat

125AF4 = Double Front lange | PL=Low Clearance | Parallel Circut ouble Spined

120-120 cuin ev cuinsev,

196 cuinsev, 68 cuinsev,

‘64 cuinstev

196 cuinstev

226 = 226 cine

250 = 250 cuintev

Applications

Rineer Hydraulics warrants that, atthe time of shipment o Purchaser, our

product wil be ree of defects inthe material and wormanshp, The above

Warrant is LIMITED to defetive products returned by Parnas to Ringer

yori et prea win four unde and tv (45) days from

Cate of shipmen,o one (1) yar om dat of fist use, whichever expres

frst We wl repair eplece any prod or part thereof whith s proved to

be defective in workmanship or materal Thr sn ler warany, express

{imple and in no event stl ie rales be abl fox consequent

‘of spel danages, Dsanting the product opereton of

‘the produt beyond the published capitis ofr

utposes other han that or which the product

E was designed, shall Void ths. warrant.

331 Breesport + San Antoni, Texas 78216 « (210) 341-6839 « Fax (210) 341-1281

‘univ rineer.com + E-mail slesteck@rineer.com

with — OVERVIEW

‘optional features, Rincer Hydraulics is wniquely positioned to,

Dame ope ee ee eer

ee Mee

Rineer Hydraulics was formed in 1967 and has been supplying

hydraulic motors to the marketplace for over 30 years. Applications

in industrial, marine, and mobile industries have been the proving,

ground for our durable and adaptable high-torque motors.

Current production motors

include 6 through 250+ cubic inch

displacements, with a variety of

shaft and bearing arrangements to

fit most requirements. The unique,

patented design of the Rineer motor

creates the optimum power to

weight ratio available for a given

displacement.

Our major effort is devoted to

providing our customers with a

reliable and performance proven

product, while working in concert

with them to solve unusual or

difficult applications. We are driven

Made in USA

to find a better solution for our

customers, and as a part of that

Process we are continuously

improving and broadening our

product line.

All major components of the

Rineer Motor (i.e., housings, valve

plates, shafts, etc.) are produced in-

house on modern production

machines assuring control over

tolerances and quality. Each motor

is assembled and dynamometer

tested to insure it will perform to

the high expectations our customers

have come to depend upon for theit

demanding applications.

Research & Development

‘We constantly strive to improve

‘our motors, testing a diverse range

of ideas and materials. A team of

dedicated engineers working with

a state-of-the-art CAD System

responds quickly to customer

requests. Once a design

modification is completed,

drawings are forwarded to a

separate manual department for

‘machining. Upoa completion, units

are sent to the R&D Lab for

extensive mechanical and hydraulic

testing. The lab is equipped

with computer monitored

dynamometers with capabilities

exceeding 1000 horsepower.

Coupled with numerous special

devices, we can perform a wide

array of testing. Customers are

welcome to share ideas with our

staff in order to assure complete

satisfaction,

A Few of Our Options...

© 2-speed versions

* Double motors for higher

torque and high speed

* Through-hole shafts

© High load radial &

thrust bearings

* Drill motor versions

w/API threads

* Displacement choices

beyond catalog listings

+ High Performance series for

increased pressure and speeds

features o

At the heart of the Rineer motor

is a patented vane crossing vane

design, a unique idea in fluid power

transmission. This design allows

for low speed high torque and high

speed high torque, making it one

of the most versatile motors in the

industry.

The Rineer motor is a bi-

rotational rotary power converter

utilizing working vanes in the

rotating member (rotor) and sealing

vanes in the stationary member

(stator), see figure below. These

vanes are hydraulically and spring

loaded, and are radiused on their

15 Series rotor-stator package

Stator

Stator Vane

Rotor Vane

Rotor

Key:

Refer to text

crossing edges. The rotor vanes,

when acted upon by a differential

pressure, exert rotational force on

the rotor. As oil enters the “A”

ports, the rotor turns clockwise

towards the “B” ports. As each

rotor vane is finishing its work cycle

in a cavity, the next vane starts its

work cyele in that cavity.

There are four rotor vanes

working at any given time. For

example, as the two vanes marked

“C” have just started their work

cycle and are continuing to “cam

out? the two vanes marked “D” are

just past the midpoint of their work

cycle and are camming back. This

results in approximate constant

vane extension therefore the output,

approaches constant torque

regardless of radial location,

Each rotor vane works

once per cavity per

revolution resulting

in 40 power strokes

ina four-cavity (10

rotor vane] motor.

As the rotor vanes

approach the

stator vanes, only

the radius of the

vane tips come into

contact, allowing

each vane to ride past

the other. Rotor and

stator vanes have the same

system pressure behind them,

advan

tages

The stator vanes function as

high pregsure to low pressure seals

betweela adjacent inlet and outlet

ports. This the

incorporation of more working

enables

cavities in less area, thus improving

both the mechanical and volumetric

efficien

The PC Advantage

(Presstere Balanced)

‘New versions of the Series 37,

57 and 125 motors, called “PC?

have been introduced to replace

the original design. With this

recently patented feature, the

timing, plates are hydraulically

balanced with approximately

equal force towards the rotor to

beter control crossport and case

leakage.

PC motors operate with

increased efficiency over the

entire performance range relative

to the original design. They

retain the excellent low-speed

torque efficiency of the original,

but have improved overall

efficiency.

e

description

BY SERIES |

Our Standard Motors are designed for 3000 psi continuous and 3500 psi intermittent. Torque

ratings are actual @3000 psi. All motors are Dynamometer tested to insure performance.

e

15 Series: Brochure D§ 151001. Fight fixed displacements ranging from 6 to 15 CID with torques from

216 ft Ibs. 0 $60 fe. Ibs. Speeds to 2600 RPM. Conforms to SAE “C” moun,

15 Series Two Speed: Brochure DS 151002. Has the same displacement choices as the 15 series with the

added feature of shifting from full to partial displacement via an integral valve.

15 Series Wheel Motor: Brochure DS 151003.

Incorporates large roller bearings that accommodate both radial and axial loads. Available in both single and

2-speed versions.

15 Series Retractable: Brochure DS 151004.

A unique concept that allows the shaft of the motor to be disengaged from the mechanism being driven.

125 Ser

2154 ft. Ibs

as 9245 ft. Ibs.

125 Series

configurations, including API.

QQUVILss

For durable hydraulic motors that meet

Brochure DS 1251003. Six fixed disy

$7, Series: Brochure DS 371003. Six fixed displacements ranging from 12 to 37 CID with torques of

424 ft Ibs, to 1383 f. Ibs. Speeds to 1200 RPM. Conforms to SAE “D® mount.

57 Series: Brochure DS 571003. Two fixed di

isplacements, 48 and 55.5 CID with torques of 1776 ft. Ibs, and

2076 ft. Ibs. Speeds to 600 RPM. Hyb:

rid SAE “D” mount (longer pilot and larger shaft).

37/57 Series 4-Port: Brochure DS 37/571009. Combines any two displacements from the 37 andlor 57 series

choices in a 4-port configuration. Allows for 2 or 3-speed operation using external valving.

placements ranging from 60 to 125 CID with torques from

to 4625 ft. Ibs. Speeds to 350 RPM. By combining any two displacements, torque can be as much

Port: Brochure DS 1251009. Combines any two displacements from 60 to 125 CID in a

4-port configuration for up to 250 CID. Allows for 2 or 3-speed operation using external valving

Drill Motors: Available in 37, 57, and 125 Series as 2 or 4-port models with numerous bearing and shaft

your demands, specify RINEER.

For over 30 years, we have specialized in only one thing ~ engineering the right motor ft your needs.

Rineer delivers the performance you can count on,

Limited Warranty Policy

ine Hydaulies warrants that, tthe time of shipment to Purchaser, our

oduct wl be free of detects in the material ané workmanship. The above

\aranty is LIMITED to defective products retuned by Purchase to inaar

yaaa, freight prepaid win for hundred and tye 485) days om

dae of shipment, or one (1) yar fom date of fist use, whichever expires

fist We wll epi or repiace any product or part hereo whic is proved to

be defect in workmanship or matel. Theres no other waranty, exressed

‘OF 4Yp,q. OF implied, and in no event shal Rieer Hydraulics be Viable

s 24 ,_ {or consequential or special damages. Dismantling the

“_foduct, operon ofthe praduct beyond the published

“capabilites or for pupcses oer han tat or which

+ the product was designed, shal Void this warranty

Distributed By:

381 Breesport« San Antonio, Texas 78216 » (21 0) 341-6833» Fax (210) 341-1231

‘wwwuerineer.com + E-mail: salesteck@ringer.com

Stall & Starting Torque

The torque curves are virtually flat

with maximum torque output at start

and stall conditions.

More Power Strokes

Per Revolution

The 15, 37 and 57 Series have four

stator cavities and 10 rotor vanes

while the 125 Series has six stator

cavities and 16 rotor vanes. Since each

rotor vane works in each stator cavity

‘once per revolution, the 15, 37 and

57 Series have 40 power strokes per

revolution; the 125 Series has 96

power strokes per revolution.

Smaller & Lighter than

Typical Motors

The Rineer design results ina

smaller and lighter envelope

package for a given displacement.

For example, a 15 cubic inch

motor weighs only 43 pounds and

the 125 cubic inch motor weights

only 225 pounds.

Smooth Output Over a

Wide Speed Range

The increased number of power

strokes per revolution, plus the flat

torque curve, generates a smooth

operation from less than 10 rpm to

2000 rpm and beyond, depending

on the series.

Improved Efficiencies

The use of stator vanes plus the overall

smaller package size improves the

volumetric efficiency. Mechanical

@liciency is enhanced due to more

working Potor vanes coupled with

low breakaway pressures). 2

THE RINEER VANE-CROSSING-VANE DESIGN

Inaddition to our

2-Speed Motors heyed

Available

15'Series motors are available in and splined shaft

‘2-speediversions. The rear housing

incoepoegies a spool valve which shits "mf" we fferspecial

between fulland partial displacement. mounts, shafts, and

2or Sspecd canbe achieved with 37, fearing designsto si the

‘57, and 125 series 4-port models.

needs of the OEM.

External valving is required to shift

from one or two cartridge mode.

Dynamic Braking 8

‘The motor is constructed)of hardened materials and does not include

any non-ferrous metals. This is a plus when designing for dynamic

braking and overrunning loads, The cavitation that typically occurs

in these cisenitg%Seldom affects the integrity of the motor.

Rineer Hydraulics has over 30 years experience designing and manufacturing

hydraulic motors for a wide variety of applications. Ui

ce most other hydraulic

manufacturers, we are dedicated solely to the production of hydraulic motors.

‘Whether your industry is the oil field, marine,

forestry, agriculture, transportation, construction

‘or communications, we provide thorough application

and design expertise. Tough jobs are the norm.

Unlike most othee hydraulic morors, the distinctive

design ofthe Rineer Rotating Element lends itself

toa wide vacety of special applications. Drill heads

hhave become a nacural extension of the produet line

due to through-hole capability of the shaft. Rineer

deilheads are custenty in service on underground

mining, water Well, blast hole, and horizontal

directional drill. The through-hole shaft also used

in our unique coaxial style motors. This producti

comprised of wo motors with one shaft being driven

through the enter of the other: The two motors are

independent ofeach other and shafts may be roared

aX diferent speeds and dcections. Another variation

ofthis hollow shafe motor isthe piggyback. In this,

design, rwo independent motors are combined by

plugging one motor directly into the shaft ofthe

other These unique through-hole shaft morors ean

be customized to fit your application

15 Series motors are available with a retractable

shaft design which allows the shaft ro be dissengaged

from a gearbox or drive train. These motors are

available with manual or hydraulic shift. The

15 Series is also available as a combination

motoriflow divider used to synchronize speeds of

independent actuators. In this design, inlet flow is

divided with a portion of the flow powering the

mocor. The remaining flow is diverted to a thied

port supplying oil to a second actuator.

‘The new 4-port motor is now available in the

37, $7, and 125 Series. These motors are made up

(of two rotary elements separated by a center

housing. Equal or dissimilar displacements may be

combined to attain desired total CID. When supplied

‘with external valving, they can be used as either

2 or 3-speed motors.

Our new high-performance motor (5000 PSI 8

higher speeds) is currently available for prototype

applications. Models include 37, 57, 8 125 Series,

Its impossible ols ll styles and applications in this overviews If you havea rnigue application or

would like to learn more about the Rineer Motor Line, please feelifree to contact the factory at:

(210) 241-6933, oF vie the internet at worwatineerdai

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Manual de ServicioDocument102 pagesManual de ServiciowiloNo ratings yet

- Manual Bba Triplex BD-85 BopDocument47 pagesManual Bba Triplex BD-85 BopwiloNo ratings yet

- 7874 R986V03675Document1 page7874 R986V03675wiloNo ratings yet

- Rineer Hydraulics: GeneralDocument2 pagesRineer Hydraulics: Generalwilo100% (1)

- 3TDP0186 - Rev BDocument43 pages3TDP0186 - Rev BwiloNo ratings yet

- Hydraulic Displacement Control - PV Series 90: BLN-95-9039-1 Issued: December 1992Document6 pagesHydraulic Displacement Control - PV Series 90: BLN-95-9039-1 Issued: December 1992wiloNo ratings yet