Professional Documents

Culture Documents

Fieldbus Temperature Transmitter For FOUNDATION™ Fieldbus and PROFIBUS PA Model T53.10, Head-Mounted Version

Uploaded by

Alejandro MartinezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fieldbus Temperature Transmitter For FOUNDATION™ Fieldbus and PROFIBUS PA Model T53.10, Head-Mounted Version

Uploaded by

Alejandro MartinezCopyright:

Available Formats

Temperature

Fieldbus temperature transmitter

For FOUNDATION™ Fieldbus and PROFIBUS® PA

Model T53.10, head-mounted version

WIKA data sheet TE 53.01

for further approvals

see page 5

Applications

■■ Process industry

■■ Machine building and plant construction

Special features

■■ FOUNDATION™ Fieldbus ITK version 4.61

■■ PROFIBUS® PA profile 3

■■ Automatic switch between protocols

■■ Explosion protection Ex i, intrinsically safe/FISCO

■■ Explosion protection Ex n

Fieldbus temperature transmitter, model T53.10

Description

The model T53.10 fieldbus temperature transmitter The model T53.10 fieldbus temperature transmitter has

with FOUNDATION™ and PROFIBUS® PA fieldbus a polarity-independent bus connection. Due to its small

communication is suitable for temperature measurement with dimensions, the model T53 temperature transmitter is

resistance thermometers and thermocouples. Furthermore suitable for all DIN form B connection heads.

resistance and mV measurements with or without customer-

specific linearisation are possible. Differential, average or The model T53 temperature transmitter is delivered with a

redundancy temperature measurements can be realised. factory configuration (see ordering information) or customer-

specific configuration in line with the configuration options.

The T53 is available at FOUNDATION™ Fieldbus with LAS

functionality (Link Active Scheduler) and PID regulation.

These functionalities allow for master-independent

regulations in the field instrument.

WIKA data sheet TE 53.01 ∙ 01/2019 Page 1 of 6

Data sheets showing similar products:

Field case for temperature transmitter; model TIF11; see data sheet TE 62.02

Specifications

Input, configurable

Measuring Standard α values Basic Temperature

range 1) accuracy coefficient per °C

Resistance Pt25 ... Pt1000 -200 ... +850 °C IEC 60751 α = 0.00385 ≤ ±0.1 °C ≤ ±0.002 °C

sensor Pt25 ... Pt1000 -200 ... +850 °C JIS C1604: 1989 α = 0.003916 ≤ ±0.1 °C ≤ ±0.002 °C

Ni25 ... Ni1000 -60 ... +250 °C DIN 43760 ≤ ±0.15 °C ≤ ±0.002 °C

Cu10 ... Cu1000 -50 ... +200 °C α = 0.00427 ≤ ±1.3 °C ≤ ±0.02 °C

Resistance sensor 0 ... 10 kΩ ≤ ±0.05 Ω ≤ ±0.002 Ω

Potentiometer 0 ... 100 kΩ

Measuring current during measurement typical 0.2 mA (Pt100)

Connection methods 1 sensor 2-/4-/3-wire or 2 sensors 2-/3-wire

(for further information, please refer to “Designation of connection terminals”)

Max. lead resistance 50 Ω each wire

Thermocouple Type J (Fe-CuNi) -100 ... +1,200 °C IEC 60584 ≤ ±0.5 °C ≤ ±0.01 °C

Type K (NiCr-Ni) -180 ... +1,372 °C IEC 60584 ≤ ±0.5 °C ≤ ±0.01 °C

Type L (Fe-CuNi) -200 ... +900 °C DIN 43710 ≤ ±0.5 °C ≤ ±0.01 °C

Type E (NiCr-Cu) -100 ... +1,000 °C IEC 60584 ≤ ±0.5 °C ≤ ±0.01 °C

Type N (NiCrSi-NiSi) -180 ... +1,300 °C IEC 60584 ≤ ±0.5 °C ≤ ±0.01 °C

Type T (Cu-CuNi) -200 ... +400 °C IEC 60584 ≤ ±0.5 °C ≤ ±0.01 °C

Type U (Cu-CuNi) -200 ... +600 °C DIN 43710 ≤ ±0.5 °C ≤ ±0.01 °C

Type R (PtRh-Pt) -50 ... +1,760 °C IEC 60584 ≤ ±1 °C ≤ ±0.025 °C

Type S (PtRh-Pt) -50 ... +1,760 °C IEC 60584 ≤ ±1 °C ≤ ±0.025 °C

Type B (PtRh-Pt) 400 ... 1,820 °C IEC 60584 ≤ ±1 °C ≤ ±0.025 °C

W3 0 ... 2,300 °C ASTM E988-90 ≤ ±1 °C ≤ ±0.025 °C

W5 0 ... 2,300 °C ASTM E988-90 ≤ ±1 °C ≤ ±0.025 °C

mV sensor -800 ... +800 mV ≤ ±10 µV ≤ ±0.2 µV

External CJC (cold junction compensation) -40 ... +135 °C

Connection methods 1 sensor 2-, 3- or 4-wire

2 sensors: 2 x 2-wire (RTD/TC) or 1 x 2-wire (RTD/TC) with 1 x 3-wire (RTD)

(for further information, please refer to “Designation of connection terminals”)

Max. lead resistance 5 kΩ each wire

Error of cold junction compensation (CJC) ≤ ±0.5 °C

1) Other units e.g. °F and K possible

Factory configuration

Sensor Pt100

Connection method 3-wire connection

Output limits 0 ... 100 °C

Output FOUNDATION™ Fieldbus PROFIBUS® PA

Version ITK version 4.61 EN 50170 vol. 2 / profile 3

Functionality Basic or LAS

Function blocks 2 analogue and 1 PID 2 analogue

Execution time, PID controller < 200 ms

WIKA data sheet TE 53.01 ∙ 01/2019 Page 2 of 6

Case (for head mounting, incl. spring-loaded mounting screws)

Material Plastic, PBT, glass-fibre reinforced

Ingress protection

■■ Case IP68 per IEC/EN 60529

■■ Connection terminals IP00 per IEC/EN 60529

Connection cross-section of terminals 0.14 ... 1.5 mm²

Weight approx. 0.05 kg

Explosion protection, power supply

Model Approvals Permissible ambient/ Safety-related maximum values Power supply

storage temperature for UB 2) / current

(in accordance with the

Current loop Sensor

consumption

relevant temperature

(connections 1 + 2) (connections

classes)

3 - 6)

T53.10.OIS EC-type examination certificate: -40 … +85 °C (T4) Ui = DC 30 V Ci = 2 nF Uo = 5.7 V DC 9 … 32 V/

KEMA 06ATEX0148X -40 … +75 °C (T5) Ii = 120 mA Li = 1 µH Io = 8.4 mA < 11 mA

-40 … +60 °C (T6) Pi = 0.84 W Po = 12 mW

Zone 0,1: II 1G Ex ia IIC T4/T5/T6

-40 … +75 °C (T4) Ui = DC 30 V Ci = 2 nF Co = 40 µF

Zone 0,1: II 1D Ex iaD

-40 … +65 °C (T5) Ii = 300 mA L = 1 µH Lo = 200 mH

i

■■ CSA approval 1807316 -40 … +45 °C (T6) Pi = 1.3 W

Intrinsically safe version: -40 … +85 °C (T1 ... T4) Ui = DC 17.5 V Ci = 2 nF

Class I, division 1, group A, B, C, D -40 … +60 °C (T5) (FISCO) Li = 1 µH

-40 … +45 °C (T6) Ii = 250 mA

■■ FM approval 3027564 Pi = 2.0 W

(Inst. Drg: 11175631)

Intrinsically safe version: -40 … +85 °C (T1 ... T4) Ui = DC 15 V Ci = 2 nF

Class I, division 1, group A, B, C, D -40 … +60 °C (T5) Ii = 900 mA Li = 1 µH

-40 … +45 °C (T6) Pi = 5.32 W

Non-incendive version:

Class I, division 2, group A, B, C, D

T53.10.OIS EC-type examination certificate: -40 … +85 °C (T1 ... T4) Linear barrier Ci = 2 nF

KEMA 06ATEX0148X -40 … +65 °C (T5) Ui = 30 V Li = 1 µH

-40 … +45 °C (T6) Ii = 120 mA

Zone 0,1: II 2G (1)G Ex ib [ia] IIC T4/T5/T6 Pi = 0.84 W

■■ CSA approval 1807316

Intrinsically safe version: -40 … +85 °C (T1 ... T4) Trapezoid barrier Ci = 2 nF

Class I, division 1, group A, B, C, D -40 … +75 °C (T5) Ui = 30 V Li = 1 µH

-40 … +60 °C (T6) Ii = 300 mA

■■ FM approval 3027564 Pi = 1.3 W

(Inst. Drg: 11175631)

Intrinsically safe version:

Class I, division 1, group A, B, C, D

Class I, zone 0, Ex ia IIC or AEx ia IIC

Class I, zone 1, Ex ib IIC or AEx ib IIC

Class I, division 2, group A, B, C, D

T53.10.ONI EC-type examination certificate: -40 … +85 °C (T1 ... T4) Ui = DC 32 V Ci = 2 nF

KEMA 06ATEX0149X -40 … +75 °C (T5) FNICO (FISCO) Li = 1 µH

-40 … +60 °C (T6) Ui = DC 17.5 V

Zone 2: II 3GD Ex nA [nL] IIC T4/T5/T6

Zone 2: II 3GD Ex nL IIC T4/T5/T6

Zone 2: II 3GD Ex nA [ic] IIC T4/T5/T6

Zone 2: II 3GD Ex ic IIC T4/T5/T6

■■ CSA approval 1807316

FM approval 3027564

(Inst. Drg: 11175631)

Non-incendive version:

Class I, division 2, group A, B, C, D

Class I, zone 2, Ex nA IIC

Class I, zone 2, AEx nA IIC

2) Depending on the safety-relevant upper limit values for the current loop circuit (for this, also see the type examination certificate).

WIKA data sheet TE 53.01 ∙ 01/2019 Page 3 of 6

Ambient conditions

Ambient and storage temperature range -40 ... +85 °C

Maximum permissible humidity 95 % r. h., non-condensing

Vibration resistance per DIN EN 60068-2-6 2 ... 100 Hz, 4 g

Other

Insulation voltage, test / operation AC 1.5 kV / AC 50 V

Response time (programmable) 1 ... 60 s

Updating time < 400 ms

Execution time, analogue input block < 50 ms

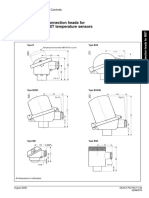

Dimensions in mm

2099288.02

Screw M4

approx. 30 mm;

spring-loaded

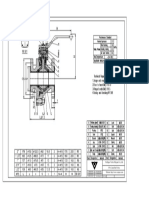

Designation of connection terminals

1 sensor

2099318.02

2 sensors

Potentiometric sensor

Terminal 1 and 2: Connection

FOUNDATION™ Fieldbus or PROFIBUS® PA

(protected against reverse polarity)

WIKA data sheet TE 53.01 ∙ 01/2019 Page 4 of 6

Accessories

Model Description Order number

Adapter ■■ Suitable for TS 35 per DIN EN 60715 (DIN EN 50022) or 3593789

TS 32 per DIN EN 50035

■■ Material: Plastic / stainless steel

■■ Dimensions: 60 x 20 x 41.6 mm

Adapter ■■ Suitable for TS 35 per DIN EN 60715 (DIN EN 50022) 3619851

■■ Material: Steel, tin-plated

■■ Dimensions: 49 x 8 x 14 mm

Approvals

Logo Description Country

EC declaration of conformity European Union

■■ EMC directive

EN 61326 emission (group 1, class B) and interference immunity (industrial application)

■■ RoHS directive

■■ ATEX directive

Hazardous areas

FM USA

Hazardous areas

CSA Canada

■■ Safety (e.g. electr. safety, overpressure, ...)

■■ Hazardous areas

EAC Eurasian Economic Community

■■ EMC directive

■■ Hazardous areas

GOST Russia

Metrology, measurement technology

KazInMetr Kazakhstan

Metrology, measurement technology

- MTSCHS Kazakhstan

Permission for commissioning

BelGIM Belarus

Metrology, measurement technology

UkrSEPRO Ukraine

Metrology, measurement technology

DNOP - MakNII Ukraine

■■ Mining

■■ Hazardous areas

NEPSI China

Hazardous areas

WIKA data sheet TE 53.01 ∙ 01/2019 Page 5 of 6

Manufacturer‘s information and

certifications

Logo Description

- China RoHS directive

Certificates (option)

■■ 2.2 test report

■■ 3.1 inspection certificate

■■ DKD/DAkkS calibration certificate

Approvals and certificates, see website

Ordering information

Model / Explosion protection / Configuration / Options

© 05/2004 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specifications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modifications to the specifications and materials.

WIKA data sheet TE 53.01 ∙ 01/2019 Page 6 of 6

01/2019 EN

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Tel. +49 9372 132-0

Fax +49 9372 132-406

info@wika.de

www.wika.de

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mill Test Certificate - ExampleDocument1 pageMill Test Certificate - ExampleAlejandro Martinez100% (4)

- APPLIED BUSINESS TOOLS AND TECHNOLOGIES SyllabusDocument12 pagesAPPLIED BUSINESS TOOLS AND TECHNOLOGIES SyllabusGlayd Loren100% (3)

- Drager Babytherm 8004 8010 Error ListDocument31 pagesDrager Babytherm 8004 8010 Error Listbioserviceltda2022100% (1)

- The Vulnerability Economy - Zero-Days, Cybersecurity, and Public PolicyDocument11 pagesThe Vulnerability Economy - Zero-Days, Cybersecurity, and Public PolicyAyejuyole SolaNo ratings yet

- Annex II - A - Design ReportDocument281 pagesAnnex II - A - Design ReportAlejandro MartinezNo ratings yet

- Diaphragm SealsDocument2 pagesDiaphragm SealsAlejandro MartinezNo ratings yet

- Connection Heads - DanfossDocument2 pagesConnection Heads - DanfossAlejandro MartinezNo ratings yet

- Property (Unit) Typical Value Test MethodDocument2 pagesProperty (Unit) Typical Value Test MethodAlejandro MartinezNo ratings yet

- Safety Data Sheet: 1. IdentificationDocument9 pagesSafety Data Sheet: 1. IdentificationAlejandro MartinezNo ratings yet

- COR - InjectionSampling 344998 RevC - 2Document2 pagesCOR - InjectionSampling 344998 RevC - 2Alejandro MartinezNo ratings yet

- Check Valves: Bronze Lift Check Valve PN32Document1 pageCheck Valves: Bronze Lift Check Valve PN32Alejandro MartinezNo ratings yet

- 04 Psi Pikotek R 2018 enDocument14 pages04 Psi Pikotek R 2018 enAlejandro MartinezNo ratings yet

- 014 - 030 Single Reduction Worm IntroductionDocument17 pages014 - 030 Single Reduction Worm IntroductionAlejandro MartinezNo ratings yet

- Digital Power Meter: Data Acquisition Node For Basic Power MetricsDocument4 pagesDigital Power Meter: Data Acquisition Node For Basic Power MetricsAlejandro MartinezNo ratings yet

- PFA Ball Valve Drawing PDFDocument1 pagePFA Ball Valve Drawing PDFAlejandro MartinezNo ratings yet

- Route (ZMR G3) : Use ManualDocument24 pagesRoute (ZMR G3) : Use ManualAlejandro MartinezNo ratings yet

- Instructions For Installation Use and Maintenance Spare Parts General CatalogueDocument22 pagesInstructions For Installation Use and Maintenance Spare Parts General CatalogueAlejandro MartinezNo ratings yet

- SheetDocument6 pagesSheetAlejandro MartinezNo ratings yet

- CH-PVDF-1018: Socket FittingsDocument7 pagesCH-PVDF-1018: Socket FittingsAlejandro MartinezNo ratings yet

- Kkl-Kml5-A-Dv Kkl-Kct5-A-Dv KKL-KML5.5-A-DV Kkl-Kml6-A-Dv KKL-KML7.7-A-DVDocument1 pageKkl-Kml5-A-Dv Kkl-Kct5-A-Dv KKL-KML5.5-A-DV Kkl-Kml6-A-Dv KKL-KML7.7-A-DVAlejandro MartinezNo ratings yet

- Lect02 - Complex Functions and MappingDocument55 pagesLect02 - Complex Functions and MappingMuhamamd IdreesNo ratings yet

- LED Cube 4x4x4Document18 pagesLED Cube 4x4x4blackberry_gloryNo ratings yet

- Auth0 Provider: Example UsageDocument43 pagesAuth0 Provider: Example UsageBala SubramanyamNo ratings yet

- Homework Assignment 3: Name: Paul GudgelDocument12 pagesHomework Assignment 3: Name: Paul GudgelPaul GudgelNo ratings yet

- The Rules To Organizing A TEDx EventDocument17 pagesThe Rules To Organizing A TEDx EventYasmineHNo ratings yet

- Igus® Motion Plastics: Dryve D1, ST-DC - EC/BLDC-Motor Control SystemDocument195 pagesIgus® Motion Plastics: Dryve D1, ST-DC - EC/BLDC-Motor Control Systemdenix49No ratings yet

- Brosur CCTV & Server Dahua PT Mitra LimaDocument32 pagesBrosur CCTV & Server Dahua PT Mitra LimaTasya SalsabilaNo ratings yet

- SNA Assignment - Centrality: Harshit Kumar Singh 19BM63058Document6 pagesSNA Assignment - Centrality: Harshit Kumar Singh 19BM63058Harshit Kumar SinghNo ratings yet

- DECP FY'23 Hiring Job DescriptionDocument2 pagesDECP FY'23 Hiring Job DescriptionShubham patelNo ratings yet

- SAP Cloud ALM For Implementation - Process ManagementDocument45 pagesSAP Cloud ALM For Implementation - Process ManagementpravalikakaranNo ratings yet

- Wireless Control System For DC Motor To Position A Dish Antenna Using MicrocomputerDocument7 pagesWireless Control System For DC Motor To Position A Dish Antenna Using MicrocomputerPradeep KumarNo ratings yet

- Fronius Primo: The Communicative Inverter For Optimised Energy ManagementDocument4 pagesFronius Primo: The Communicative Inverter For Optimised Energy ManagementUser_docsNo ratings yet

- Netstat Liste NewDocument26 pagesNetstat Liste NewCsabiNo ratings yet

- COM-POWER-NSX-690V (Web) Siste Versjon 30nov 2012Document52 pagesCOM-POWER-NSX-690V (Web) Siste Versjon 30nov 2012Tri KusworoNo ratings yet

- 019 Farinograph EDocument4 pages019 Farinograph EJan Joseph Moscoso CárdenasNo ratings yet

- LogDocument72 pagesLogcarinojerrymarcNo ratings yet

- Oracle HCM Fast FormulaDocument22 pagesOracle HCM Fast FormulaMohammad NavazNo ratings yet

- ANL303 - JAN - 2019 - Exam PaperDocument6 pagesANL303 - JAN - 2019 - Exam PaperSuwandi LieNo ratings yet

- DIVQ.E212323 - Circuit Breakers, Molded Case and Circuit-Breaker Enclosures - UL Product IQDocument1 pageDIVQ.E212323 - Circuit Breakers, Molded Case and Circuit-Breaker Enclosures - UL Product IQRahul Kumar Singh (IPR and Product Safety Compliance)No ratings yet

- Subnet by Network RequirementDocument24 pagesSubnet by Network RequirementCemee Faith Muleta EscarillaNo ratings yet

- CS501 Highlight Handout Advanced Com ArchitectureDocument442 pagesCS501 Highlight Handout Advanced Com ArchitectureHuma AnwarNo ratings yet

- KARPOS Resume TemplateDocument2 pagesKARPOS Resume TemplateAivan Dominique RodriguezNo ratings yet

- Parent Letter Hampton Inn Lake Worth Milwaukee FHCDocument1 pageParent Letter Hampton Inn Lake Worth Milwaukee FHCTom CarterNo ratings yet

- Guest CycleDocument6 pagesGuest CycleMimy Bui67% (3)

- Flow Measuring Technology For Liquids, Gases and Steam: Products and Services at A GlanceDocument64 pagesFlow Measuring Technology For Liquids, Gases and Steam: Products and Services at A GlanceMaksatNo ratings yet

- Attendance Management Software User Manual V1.8Document203 pagesAttendance Management Software User Manual V1.8Viviana ZambranoNo ratings yet

- Modeling Class X AIDocument24 pagesModeling Class X AIAYUSH DEYNo ratings yet