Professional Documents

Culture Documents

P3-80 Pipe Joints and Elements For HDPE Pressure Pipelines

Uploaded by

m_9250 ratings0% found this document useful (0 votes)

26 views2 pagesOriginal Title

16963_P3-80 Pipe Joints and Elements for HDPE Pressure Pipelines

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views2 pagesP3-80 Pipe Joints and Elements For HDPE Pressure Pipelines

Uploaded by

m_925Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

- upc 621.649.411.4.062-096.7422 DIN DbUb3*PTX3 60 MMH 279444 OOO4R4O 7 Mm

1621.644,2-006 : 628.1 DEUTSCHE NORMEN August 1980

Pipe Joints and tlements for High Density

olyethylene (HDPE) Pressure Pipelines

Types { and 2

Pipe Bends for Butt-welding

‘Dimensions

Rohrverbindungen und Robrleltungstelle fir Druckrohrleitungen aus Polyethylen hoher Dichto (HDPE), Typ 1 und 2;

aus Rohr goformte Rohrbogen flr Stumpfschweissung, Masse

1 Scope

‘This Standard applies to pipe bends of high density polyethylene (HOPE), type 1 and type 2, which are formed from

pipe in accordance with DIN 8074 Part 1 oF Part 2 and which are butt-welded with a heating element in accordance

with DIN 1910 Part 3 or DVS2207 to pipes of HOPE type 1 and type 2 in accordance with DIN 8074 Part 1 or Part 2.

‘The pipe bends must conform to the requirements of DIN 16963 Part 6 or Part 26").

For technical reasons the pipe bends may only be welded to pipes of the same series in accordance with DIN 8074

Part 1 of Part 2, Deviation from thisrequirement is allowed If the wall thicknesses are equal in the wolding zone.

Note: Instead of the designation “Hard polyethylene (hard PE)”, this Standard uses the designation “High density

polyethylene (HDPE)" in accordance with DIN 7728 Part 1, April 1978 edition.

The previously used short designation “Hard polyethylene (hard PE)” may, however, continua to be used during the

transitional period (e. the service life of the stamping tools for marking pipes and pipe elements).

2. Other relevant Standards

DIN 1910 Part Welding; welding of plastics, methods

DIN 8074 Part 1 Hard polyethylene (hard PE) pipes; type 1, dimensions

DIN 8074 Part 2_ High density polyethylene (HOPE) pipes; type 2, dimensions

DIN 16963 Part 5 Pipe joints and elements of hard polyethylene (hard PE) for pressure pipelines; type 1, general

ality requirements, testing

DIN 16963 Part 25 (et present stil in draft form) Pipe joints and elements of high density polyethylone (HOPE) for

pressure pipelines; typo 2, goneral quality quirements, tsting

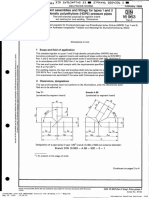

3. Dimensions, designation

“The pipe bends do not have to conform to the illustration; only the specified dimensions must be adhered to, The

ppormissible deviation from the 90° angle of bond is + 2°.

Pipe bond B2

90° bond

epraducon, renin pats ony wth he exalt pein of he DN Dasuahes er Nommung arin

Designation of a 82 pipe bend with a 80° angle and Dra 16d

‘external pipe diameter d = 400 mm of pipe series 3 and 2) gertle

type t

Bend DIN 16963 — B2—90—400—3—1 —*) Atppresent stil in draft form

Continued on page 2

oaat

fvghts of German Glanards (OW Harmon) ae wi

iaVorog anh Beango ‘DIN 16963 Tel 3 engl. Prokegr. 4

Vertr-e, 0108

DIN LbS63*PT*3 80 MM 2794446 OOON3S4L 5 me

Page 2 DIN 16963 Part 3

Further Standards and documents

DIN. 7728 Part 1

DIN 8075 Part 1

DIN 8075 Part 2

DIN 16963 Part 1

DIN 16963 Part 2

DIN 16963 Part 4

DIN 16963 Part 6

DIN 16963 Part 7

DIN 16963 Part 8

DIN 16963 Part 9

DIN 16963 Part 10

DIN 16963 Part 11

DIN 16963 Part 12

DIN 16963 Part 13

DIN 16963 Part 14

Dvs 2207

3) Obtainable from Deutscher Verlag fir Schweisstechnik GmbH (German Publishing House for We

4000 Ditsseldort

Plastics; symbols for homopolymers, copolymers and polymer compounds

Hard polyethylene (hard PE) pipes; type 1, general quality requirements, testing

igh density polyethylene (HDPE) pipes; type 2, general quality requirements, testing

Pipe joints and elements of high density polyethylene (HDPE) for pressure pipelines; types 1 and 2,

pipe bends of sogmental construction for butt-welding, dimensions

(at present still in draft form) Pipe joints and elements of high density polyethylene (HDPE) for

pressure pipelines; types 1 and 2, toe pieces and branch connections of segmental construction with

necked ends for butt-welding, dimensions

(at present still in draft form) Pipe joints and elements of high density polyethylene (HDPE) for

pressure pipelines; typos 1 and 2, bushes, flanges and seals for butt-welding, dimensions

(at-present still In draft form) Pipe joints and elements of high density polyethylene (HDPE) for

pressure pipelines; types 1 and 2, injection moulded fittings for butt-welding, dimensions

(Preliminary Standard) Pipe joints and elements of high density polyethylene (HDPE) for pressure

pipelines; types 1 and 2, injection moulded fittings for resistance-welding, dimensions

Pipe joints and elements of high density polyethylene (HDPE) for pressure pipelines; types 1 and 2,

Injection moulded elbows for socket-welding, dimensions

Pipe joints and elements of high density polyethylene (HOPE) for pressure pipelines; types 1 and 2,

Injection moulded tee pieces for socket-welding, dimensions

ipe joints and elements of high density polyethylene (HDPE) for pressure pips

Injection moulded sockets and caps for socket-welding, dimensions

Pipe joints and elements of high density polyethylene (HOPE) for pressure pipelines; types 1 and 2,

bushes, flanges and seals for socket-welding, dimenions

(Preliminary Standard) Pipe joints and elements of high density polyethylene (HDPE) for pressure

pipelines; types 1 and 2, injection moulded reducing sockets for joining resistance-welded fittings,

dimensions

Pipe joints and elements of high density polyethylene (HDPE) for pressure pipelines; types 1 and 2,

turned and pressed reducing sockets for butt-welding, dimensions

(at present still in draft form) Pipe joints and elements of high density polyethylene (HDPE) for

pressure pipelines; types 1 and 2, injection moulded reducing sockets and nipples for socket-welding,

dimensions

Welding thermoplastic plastics, hard PE (hard polyethylene) pipes and elements for gas and water

Pipelines 3)

rypes 1 and 2,

ing), Postfach 2725,

cormnsonr i998 Dik pEvrecNES inetitut Pur Normng ¢.¥.~ Engiich

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- P4-88 Pipe Joint Assemblies and Fittings For HDPE Pressure PipesDocument8 pagesP4-88 Pipe Joint Assemblies and Fittings For HDPE Pressure Pipesm_925No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Mario Campos CV 2018Document6 pagesMario Campos CV 2018m_925No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- P9-80 Pipe Joints and Elements For HDPE Pressure PipelinesDocument3 pagesP9-80 Pipe Joints and Elements For HDPE Pressure Pipelinesm_925No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- P1-80 Pipe Joints and Elements For HDPE Pressure PipelinesDocument3 pagesP1-80 Pipe Joints and Elements For HDPE Pressure Pipelinesm_925No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- AWWA C208 Fabricated Steel Pipe Fittings PDFDocument28 pagesAWWA C208 Fabricated Steel Pipe Fittings PDFm_925No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- AVEVA E3D - ClashesDocument5 pagesAVEVA E3D - Clashesm_925No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- P2-83 Pipe Joint Assemblies and Fittings For Types 1 and 2 HDPE Pressure PipesDocument4 pagesP2-83 Pipe Joint Assemblies and Fittings For Types 1 and 2 HDPE Pressure Pipesm_925No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Documento Cliente 25940295Document5 pagesDocumento Cliente 25940295m_925No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Bol 485570827Document1 pageBol 485570827m_925No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Bol 483983505Document1 pageBol 483983505m_925No ratings yet

- BOL483983506Document1 pageBOL483983506m_925No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Comp Rob AnteDocument2 pagesComp Rob AnteIsmael ValenzuelaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- BOL484196494Document1 pageBOL484196494m_925No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BOL484322007Document1 pageBOL484322007m_925No ratings yet

- AVEVA Everything3D™ 2.1.0.22 Fix Partial Fix Release 52891 Windows 7 / Windows 8.1Document191 pagesAVEVA Everything3D™ 2.1.0.22 Fix Partial Fix Release 52891 Windows 7 / Windows 8.1m_925100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Marian: Attribute-Based Commodity CodesDocument14 pagesMarian: Attribute-Based Commodity Codesm_925No ratings yet

- Cabaña Panguipulli Iluminación Y Enchufes: Planta Enchufes Planta AlumbradoDocument1 pageCabaña Panguipulli Iluminación Y Enchufes: Planta Enchufes Planta Alumbradom_925No ratings yet

- BOL485570827Document1 pageBOL485570827m_925No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Bol 483983505Document1 pageBol 483983505m_925No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- PDMS Diff 12.1 - HelpDocument21 pagesPDMS Diff 12.1 - Helpm_925No ratings yet

- 6 1 5 5 3SP9 DeltaDocument78 pages6 1 5 5 3SP9 Deltam_925No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Marian: Smartplant-Marian Integration User'S GuideDocument21 pagesMarian: Smartplant-Marian Integration User'S Guidem_925No ratings yet

- Marian: Open Requisition Interface (ORI)Document32 pagesMarian: Open Requisition Interface (ORI)m_925No ratings yet

- Impact of Computer Advanced VisualizatioDocument234 pagesImpact of Computer Advanced Visualizatiom_925No ratings yet

- Informe Visita Las TórtolasDocument28 pagesInforme Visita Las TórtolassezenitNo ratings yet

- 5-5-3-GEN-New 42CDocument36 pages5-5-3-GEN-New 42Cm_925No ratings yet

- Impact of 4 D Visualization On The Cognitive Process of Detecting The Logical Errors in The Construction ScheduleDocument10 pagesImpact of 4 D Visualization On The Cognitive Process of Detecting The Logical Errors in The Construction Schedulem_925No ratings yet

- MoveDocument1 pageMovem_925No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Plancha Antiabrasiva 500 BrinellDocument2 pagesPlancha Antiabrasiva 500 Brinellm_925100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)