Professional Documents

Culture Documents

Flexmetprotect C-CNM-M: Technical Data Sheet

Uploaded by

minni choubeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flexmetprotect C-CNM-M: Technical Data Sheet

Uploaded by

minni choubeyCopyright:

Available Formats

TM

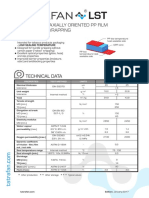

FLEXMETPROTECT C-CNM-M

Technical Data Sheet (METALLIZED CPP FILM)

Product Description: Key Features: Applications:

FLEX METPROTECTTM C-CNM-M is a metallized Low SIT Snacks & Biscuits

CPP film having metal deposit on corona treated side and Excellent Hermiticity Condiment Packaging

functional sealing layer on other side with low SIT & Broad Broad hot tack High Speed Packaging On FFS Machine

Hot Tack Good metal adhesion Specially Designed for Nitrogen Flushing Application

Seal Through Contamination

METALLIZED ON TREATED SIDE (MT) AND A FUNCTIONAL SEALING LAYER ON OPPOSITE SIDE WITH LOW SIT & BROAD HOT TACK(C-CNM-M)

TEST TYPICAL VALUE

PROPERTIES METHOD UNIT

(ASTM) 22 25 30 35

OPTICAL DENSITY 2.2 2.2 2.2 2.2

(TOLERANCE : +/- 5%) Gretag -

Micron 22 25 30 35

THICKNESS Internal

(Gauge) 88 100 120 140

FILM DENSITY D-1505 gm/cc 0.91 0.91 0.91 0.91

2

GRAMMAGE Internal gm/m 20.02 22.75 27.30 31.85

YIELD Internal m2/kg 49.95 43.96 36.63 31.40

in2/lb 35191 30968 25807 22120

TREATMENT LEVEL D-2578 dyne/cm 36 36 36 36

MD* 750 800 825 850

TENSILE STRENGTH AT BREAK D-882 Kg/cm2

TD* 275 300 320 340

MD 500 550 575 600

ELONGATION AT BREAK D-882 %

TD 800 800 850 900

0

HEAT SEAL INITIATION TEMPERATURE Internal C 110±3 110±3 110±3 110±3

HEAT SEAL STRENGTH Internal gm/25mm 2000 2400 2600 2800

W.V.T.R.(380C & 90%RH) F-1249 gm/m2/day <1.5 <1.4 <1.3 <1.2

0

O.T.R. (23 C & 0%RH) D-3985 cc/m2/day <150 <140 <130 <120

'Ref no QAD UFLI S/17 - MC 5/1

*MD = MACHINE DIRECTION *TD = TRANSVERSE DIRECTION

STORAGE & HANDLING

FLEXMETPROTECTTM does not require special storage conditions. It is recommended to storage below 30°C in order to avoid any deterioration of the film surface properties. It is advisable to

use the material on FIFO basis. The film should be kept at operating environment for 24 hours before processing. FLEXMETPROTECTTM is best suitable for use up to 3 months from date of

dispatch.

FOOD CONTACT

FLEXMETPROTECTTM complies with EC and FDA regulations. Specific document and MSDS are available on request.

DISCLAIMER

It is the responsibility of our customer to determine that their use of our product(s) is safe, lawful, and technically suitable in their intended applications.The Values given in the technical data

sheet represent typical values based on the best of our knowledge as on date when the data was compiled. It is offered solely to provide possible suggestions for your own experimentation and not

as a guarantee for the material supplied. The user is solely responsible for the end use of the product and needs to perform their own tests to confirm the product suitability / compatibility in all

respects. Flex Gives no warranty or accept liability for any loss and fitness of the product for any specific purpose. Flex reserves the right to change the technical data sheet at any time for

enhancing the quality of the products without prior information

**TDS issued on 16-02-2017.

Website: www.flexfilm.com

You might also like

- B-TVL-M: Standard Barrier Metallized BOPP FilmDocument2 pagesB-TVL-M: Standard Barrier Metallized BOPP FilmSayed FathyNo ratings yet

- B-THL: Standard Transparent Heat Sealable BOPP FilmDocument2 pagesB-THL: Standard Transparent Heat Sealable BOPP FilmSayed FathyNo ratings yet

- B-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmDocument2 pagesB-TDM-M: Decorative Grade Non Heat Sealable Metallized BOPP FilmSayed FathyNo ratings yet

- HF515Document1 pageHF515P Singh KarkiNo ratings yet

- B-TVS-M: Metallized BOPP FilmDocument2 pagesB-TVS-M: Metallized BOPP FilmSayed FathyNo ratings yet

- Geomembrane HDPE Smooth Black PDFDocument1 pageGeomembrane HDPE Smooth Black PDFandriarisetiawan0% (1)

- TDS HMTDocument1 pageTDS HMTKarthiNo ratings yet

- UmaPET EC104 - 140Document2 pagesUmaPET EC104 - 140Luz Angela GuerreroNo ratings yet

- Product Data: Titanlene Ldf200GgDocument1 pageProduct Data: Titanlene Ldf200GgchinchotarngNo ratings yet

- B-PVL-M: White Voided Metallized BOPP FilmDocument2 pagesB-PVL-M: White Voided Metallized BOPP FilmSayed FathyNo ratings yet

- B-TVB-M: Sandwich Grade Heat Sealable Metallized Bopp FilmDocument2 pagesB-TVB-M: Sandwich Grade Heat Sealable Metallized Bopp FilmSayed FathyNo ratings yet

- Product Data: Titanlene Ldf250YzDocument1 pageProduct Data: Titanlene Ldf250YzchinchotarngNo ratings yet

- LDF201FG R01Document1 pageLDF201FG R01Oscar Tan IIINo ratings yet

- UmaPET - TFDocument3 pagesUmaPET - TFLuz Angela GuerreroNo ratings yet

- KXNEDocument2 pagesKXNEJan GawełNo ratings yet

- Technical Information: Coextruded Biaxially Oriented Polypropylene FilmDocument1 pageTechnical Information: Coextruded Biaxially Oriented Polypropylene FilmAlzena badzlinNo ratings yet

- T-Pet: Product Data SheetDocument1 pageT-Pet: Product Data SheetHamdy AkkadNo ratings yet

- UmaPET - AODocument1 pageUmaPET - AOñeNo ratings yet

- Tds - Macgrid BiaxialDocument1 pageTds - Macgrid BiaxialLiliana Ribeiro100% (2)

- Properties: Test Conditions Units Properties Test Conditions Units Typical ValuesDocument1 pageProperties: Test Conditions Units Properties Test Conditions Units Typical ValueszaherNo ratings yet

- Sarafil CFL101 Grade Clear Polyester Film Is Designed As Base Film For High Clarity Industrial Applications LikeDocument2 pagesSarafil CFL101 Grade Clear Polyester Film Is Designed As Base Film For High Clarity Industrial Applications LikeJay AhmadNo ratings yet

- LLBF 218aDocument1 pageLLBF 218aYefrain J. ArzolayNo ratings yet

- Global Synthetics Proliner HDPE Smooth DatasheetDocument1 pageGlobal Synthetics Proliner HDPE Smooth DatasheetMatt GhanaviNo ratings yet

- Innoplus (GC Marketing) LL7835ADocument1 pageInnoplus (GC Marketing) LL7835AOscar Tan IIINo ratings yet

- Coextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataDocument2 pagesCoextruded Biaxially Oriented PP Film For Tobacco Wrapping: Technical DataJan GawełNo ratings yet

- DMC - Prasentation1Document8 pagesDMC - Prasentation1Selva BabuNo ratings yet

- SV1055Document1 pageSV1055akankshas06No ratings yet

- FILMON® BX TDS JNF Apr 2021Document1 pageFILMON® BX TDS JNF Apr 2021Donny SinagaNo ratings yet

- Torayca Carbon T1100G-Technical-Data-Sheet-1 PDFDocument2 pagesTorayca Carbon T1100G-Technical-Data-Sheet-1 PDFd25932373No ratings yet

- Lldpe 20100326-165732-Tds-02-Uf1810t-1Document1 pageLldpe 20100326-165732-Tds-02-Uf1810t-1Addison FregilNo ratings yet

- Highshrink PT814Document1 pageHighshrink PT814Hemant Kumar PathakNo ratings yet

- LL7410D1Document1 pageLL7410D1Nitin MaheshwariNo ratings yet

- LLDPE - Lotrene Q1018N PDFDocument2 pagesLLDPE - Lotrene Q1018N PDFNilay TanrıverNo ratings yet

- MAS-170110 Waterproofing Membrane (Hot-Type & Self Adhesive) Rev. 0Document7 pagesMAS-170110 Waterproofing Membrane (Hot-Type & Self Adhesive) Rev. 0Doan Ngoc DucNo ratings yet

- PDF Kingboard KB 6160A Data SheetDocument2 pagesPDF Kingboard KB 6160A Data SheetAlex Prim NavajasNo ratings yet

- UmaPET - EHS100Document3 pagesUmaPET - EHS100Wan Fyzzul HabibonNo ratings yet

- MSDS Titanlene-801YYDocument1 pageMSDS Titanlene-801YYSyuhadaNo ratings yet

- PCT 1 (DL) Mo Bopp InsulationDocument1 pagePCT 1 (DL) Mo Bopp Insulationjuan herreraNo ratings yet

- Terra Felt TF70 PDFDocument1 pageTerra Felt TF70 PDFDeden IlmannudinNo ratings yet

- Macformer Tublar Type Mfm-IIIDocument1 pageMacformer Tublar Type Mfm-IIIDeny SuryantoNo ratings yet

- Dow Elite 5400G TDSDocument2 pagesDow Elite 5400G TDSAli RazuNo ratings yet

- Technical Datasheet LF0190: 1) Product DescriptionDocument1 pageTechnical Datasheet LF0190: 1) Product DescriptionjavadmohammadiNo ratings yet

- Bopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesDocument2 pagesBopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesMatteo DMNo ratings yet

- TDS BOPP Blanco LSG57 y 60 - EUDocument2 pagesTDS BOPP Blanco LSG57 y 60 - EUEmmanuel AlvarezNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- Yemchio Transparente PDFDocument1 pageYemchio Transparente PDFSantiago López AlarcónNo ratings yet

- LLBF 122FDocument1 pageLLBF 122FYefrain J. ArzolayNo ratings yet

- Meltio-Nickel-718 Material Datasheet PDFDocument2 pagesMeltio-Nickel-718 Material Datasheet PDFJakNo ratings yet

- LF410 (영문)Document1 pageLF410 (영문)coordinador.comercialNo ratings yet

- Special Characteristics:: Innoplus Ll7420DDocument1 pageSpecial Characteristics:: Innoplus Ll7420DFahad MohamedNo ratings yet

- Lldpe 22501aa22501kjDocument2 pagesLldpe 22501aa22501kj李万福No ratings yet

- SCG D777CDocument1 pageSCG D777Cbhoopendra singhNo ratings yet

- Datasheet LTM-2125 PDFDocument1 pageDatasheet LTM-2125 PDFjavadmohammadiNo ratings yet

- AC410Document1 pageAC410P Singh KarkiNo ratings yet

- T700S Technical Data Sheet PDFDocument2 pagesT700S Technical Data Sheet PDFjairoNo ratings yet

- High Density Polyethylene GF4950: DescriptionDocument1 pageHigh Density Polyethylene GF4950: Descriptioncesar1scribdNo ratings yet

- TDS LC670 Eng 220216Document1 pageTDS LC670 Eng 220216AthonioMourinhoNo ratings yet

- Equate EGDA 6888Document2 pagesEquate EGDA 6888akshayNo ratings yet

- T800S Technical Data Sheet 1 PDFDocument2 pagesT800S Technical Data Sheet 1 PDFAmal AvNo ratings yet

- Proforma Invoice - Raw Material Feeding System - (16!07!21) UFLEXDocument1 pageProforma Invoice - Raw Material Feeding System - (16!07!21) UFLEXminni choubeyNo ratings yet

- Russian Salad: Choose Any 3 Salads ChineseDocument4 pagesRussian Salad: Choose Any 3 Salads Chineseminni choubeyNo ratings yet

- Exam Details: PrintDocument3 pagesExam Details: Printminni choubeyNo ratings yet

- Gmat Handbook: Everything You Need To Know and Agree To When Scheduling Your GMAT ExamDocument17 pagesGmat Handbook: Everything You Need To Know and Agree To When Scheduling Your GMAT ExamGirish SeshadriNo ratings yet

- IELTS - Complete GuideDocument11 pagesIELTS - Complete GuideAkash Acky Arya100% (1)

- GMAT Preparation Tips PDFDocument2 pagesGMAT Preparation Tips PDFminni choubeyNo ratings yet

- Nmat by Gmac™ Practice ExamDocument105 pagesNmat by Gmac™ Practice ExamKshiteej Tiwari100% (1)

- Fruits of ThailandDocument51 pagesFruits of Thailandtenzenmen100% (1)

- GE1451 NotesDocument18 pagesGE1451 NotessathishNo ratings yet

- Defence Services Staff College, Wellington: (To Be Filled in Capital Letters As Per Matriculation (Or) X STD Mark Sheet)Document3 pagesDefence Services Staff College, Wellington: (To Be Filled in Capital Letters As Per Matriculation (Or) X STD Mark Sheet)Siddharth MuthukumarNo ratings yet

- Syllabus Mathematics (Honours and Regular) : Submitted ToDocument19 pagesSyllabus Mathematics (Honours and Regular) : Submitted ToDebasish SharmaNo ratings yet

- ACS880 IGBT Supply Control Program: Firmware ManualDocument254 pagesACS880 IGBT Supply Control Program: Firmware ManualGopinath PadhiNo ratings yet

- 2 CSS Word FileDocument12 pages2 CSS Word Fileronak waghelaNo ratings yet

- BL of SorianoDocument185 pagesBL of SorianoJericho Pedragosa57% (7)

- The Achaeans (Also Called The "Argives" or "Danaans")Document3 pagesThe Achaeans (Also Called The "Argives" or "Danaans")Gian Paul JavierNo ratings yet

- ASVAB Core ReviewDocument208 pagesASVAB Core Reviewstanley100% (1)

- Bupa Statement To ABCDocument1 pageBupa Statement To ABCABC News OnlineNo ratings yet

- Sharp Lc-26sb25e S Ru Lc-32sb25e Lc-42sb55s e RuDocument172 pagesSharp Lc-26sb25e S Ru Lc-32sb25e Lc-42sb55s e RuПетя СтойчеваNo ratings yet

- Periyava Times Apr 2017 2 PDFDocument4 pagesPeriyava Times Apr 2017 2 PDFAnand SNo ratings yet

- Shahid Change ManagementDocument1 pageShahid Change Managementtanveer azamNo ratings yet

- (PPT) Types of Paper-And-Pen TestDocument47 pages(PPT) Types of Paper-And-Pen TestJustin Paul VallinanNo ratings yet

- Wheelandaxleupload 113020Document15 pagesWheelandaxleupload 113020api-278325436No ratings yet

- Lesson 5 - 8ae AbsorptionDocument12 pagesLesson 5 - 8ae AbsorptionarnavprajeetNo ratings yet

- Sustainable Development - Wikipedia, The Free EncyclopediaDocument22 pagesSustainable Development - Wikipedia, The Free EncyclopediaŚáńtőśh Mőkáśhí100% (1)

- Module 6:market Segmentation, Market Targeting, and Product PositioningDocument16 pagesModule 6:market Segmentation, Market Targeting, and Product Positioningjanel anne yvette sorianoNo ratings yet

- Answers To Workbook Exercises: Cambridge University Press 2014Document3 pagesAnswers To Workbook Exercises: Cambridge University Press 2014M BNo ratings yet

- 938e4INDEMNITY BOND BY PARENTS PDFDocument1 page938e4INDEMNITY BOND BY PARENTS PDFudit satijaNo ratings yet

- Department of EducationDocument4 pagesDepartment of EducationLYr EHsNo ratings yet

- First Conditional Advice Interactive WorksheetDocument2 pagesFirst Conditional Advice Interactive WorksheetMurilo BaldanNo ratings yet

- Global ScriptDocument4 pagesGlobal ScriptAubrey Andrea OliverNo ratings yet

- Mini Lecture Morphology of Skin LesionDocument48 pagesMini Lecture Morphology of Skin LesionAlkaustariyah LubisNo ratings yet

- Supplementary: Materials inDocument5 pagesSupplementary: Materials inEvan Siano BautistaNo ratings yet

- NewsWriting HizonDocument18 pagesNewsWriting HizonCrisvelle AlajeñoNo ratings yet

- The Global Workforce Crisis BCG PDFDocument28 pagesThe Global Workforce Crisis BCG PDFdakintaurNo ratings yet

- Chapter 5 Decision TheoryDocument43 pagesChapter 5 Decision TheoryTamiru BeyeneNo ratings yet

- Forrester Hybrid Integration PlatformDocument17 pagesForrester Hybrid Integration PlatformrtNo ratings yet

- Roman Empire Revived TheoryDocument173 pagesRoman Empire Revived TheoryBrenoliNo ratings yet