Professional Documents

Culture Documents

System Costs

Uploaded by

Tania Meza0 ratings0% found this document useful (0 votes)

25 views1 pageThis document compares and contrasts two systems of tracking manufacturing costs: process costing and job order costing. Process costing involves allocating costs across all units produced in an accounting period, while job order costing accumulates costs for each specific production order or batch. Job order costing provides more accurate unit costs but is more complex and expensive to implement, while process costing is more practical for high-volume production of similar goods.

Original Description:

Costos por proceso y costos por ordenes

Original Title

System costs

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document compares and contrasts two systems of tracking manufacturing costs: process costing and job order costing. Process costing involves allocating costs across all units produced in an accounting period, while job order costing accumulates costs for each specific production order or batch. Job order costing provides more accurate unit costs but is more complex and expensive to implement, while process costing is more practical for high-volume production of similar goods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views1 pageSystem Costs

Uploaded by

Tania MezaThis document compares and contrasts two systems of tracking manufacturing costs: process costing and job order costing. Process costing involves allocating costs across all units produced in an accounting period, while job order costing accumulates costs for each specific production order or batch. Job order costing provides more accurate unit costs but is more complex and expensive to implement, while process costing is more practical for high-volume production of similar goods.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

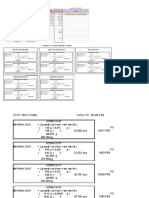

SYSTEMS OF COSTS

SYSTEMS OF COSTS BY PRODUCTION ORDERS SYSTEMS OF COSTS PROCESS

This syste is used to measure manufacturing costs during an

This system accumulates the costs for each order,batch or order that is

CONCEPT accounting period and the allocate them among the number

physically identifiable as its production progresse.

ofunits manufactures during that period.

1. Production continuous

1. Batch production 2. It is made without there being a specific order (but it can

2. Made to order exist)

CHARACTERISTICS 3. Individual control 3.Global control

4. It is not necessary to wait for the end of production to know thw unit 4.Avarage costs per operation

cost 5. It is essential to refer to a period of time to determine the

unit cost

1. The costs calculated by this system, speed up setting prices

for the sale, which allows collecting important information to

make a solid budget.

1. Provides great accuracy in the determination of unit costs

2. Thanks to the fact that similar products are calculated,the

2. provides full details of the production of each item

calculation of their unit costs is considerably facilitated.

ADVANTAGES 3. Futere estimates can be made based on costs previous

3. This cost system is more affordable for industrial companies,

4. You can know which orders have left profit and which losses

since it is economical, does not require a large investment of

5. Production in process is known without the need to estimate it

time, and does not require great technical capacitu on the part

of the staff, wich is why it is easy to implement this cost

system, in these companies.

1. This cost system is not very flexible, which can affect the

first months of the year, which are months where companies

1. Its cost of operations is very high because a great deal of work is

have changes, which can affect the cost of products, so the

required to obtain all the data in detail.

standard cost of products, so the standard cost is not safe in

2. It takes more time to obtain the costs

DISADVANTAGES the face of this situation.

3.There are serious difficulties regarding the cost of partial deliveries of

2. Due to the instruments and tools that are constantly used,

finishes products since the cost is not obtained until the completion of the

implementimg this cost system can be expensive at first.

order

3. This cost system can be better utilized by companies that

have excepcional internal control.

Process costing is used in companies that manufacture a single

Graphic arts companies, construction companies, locksimth contractors, producct or when the difference between the types of products

shoe manufactures, furniture manufactures, machine builders, can work is not substantial, that is when the products are relatively

TYPES OF ORGANIZATION

on a projecct or order basis and indicate the costs acoording to that order homogeneous. This cost system is commonly used in oil

this system is also known as of job order cost system. compannies, chemical and pharmaceutical industries, bottlers,

and auto parts manufacturers.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Corrective Action ProcedureDocument1 pageCorrective Action ProcedureZharel AhmadNo ratings yet

- Cara Hitung Pemakaian ResinDocument5 pagesCara Hitung Pemakaian ResinSalsa SalsabilaNo ratings yet

- Approved List 101109Document16 pagesApproved List 101109tudaya_rajNo ratings yet

- About MaharashtraDocument20 pagesAbout MaharashtraPrasad RahateNo ratings yet

- Compensation Structure in Pharmaceutical SectorDocument14 pagesCompensation Structure in Pharmaceutical Sectordprshi50% (2)

- Supplier Score Card Training March 2016Document10 pagesSupplier Score Card Training March 2016umtNo ratings yet

- Im ProblemsDocument6 pagesIm Problemsbushra asad khanNo ratings yet

- Ethiopia ASSESSMENT OF FERTILIZER CONSUMPTIONDocument23 pagesEthiopia ASSESSMENT OF FERTILIZER CONSUMPTIONbinyamgmaryam1624100% (1)

- The History and Evolution of Rickshaw in PDFDocument14 pagesThe History and Evolution of Rickshaw in PDFMIGUEL TORRES MORENONo ratings yet

- Arabelle™ Steam Turbine For Nuclear Power Plants: Performance To Boost Your Nuclear ReactorDocument16 pagesArabelle™ Steam Turbine For Nuclear Power Plants: Performance To Boost Your Nuclear ReactoraniekanNo ratings yet

- Activity 9Document13 pagesActivity 9MinzaNo ratings yet

- BOAT Strategyblueprint - v2Document88 pagesBOAT Strategyblueprint - v2Fejiro GbagiNo ratings yet

- Attachement JDocument23 pagesAttachement JMehari Temesgen50% (2)

- Unit 17: Negotiating Delivery-Timing and LocationDocument26 pagesUnit 17: Negotiating Delivery-Timing and LocationNgân ThanhNo ratings yet

- African Growth and Opportunity Act English LODocument3 pagesAfrican Growth and Opportunity Act English LODika GodanaNo ratings yet

- Tanzania-Spices Roadmap - FinalDocument71 pagesTanzania-Spices Roadmap - Finalfwaks100% (1)

- LOCAL TAXATION SummaryDocument17 pagesLOCAL TAXATION SummaryZairah Nichole PascacioNo ratings yet

- Labor Market InformationDocument60 pagesLabor Market InformationHershell ContaNo ratings yet

- GRP 2 - Eumind Entrepreneurs - w2g - FinalDocument14 pagesGRP 2 - Eumind Entrepreneurs - w2g - Finalapi-538632185No ratings yet

- Dwnload Full Selling Building Partnerships 9th Edition Castleberry Test Bank PDFDocument35 pagesDwnload Full Selling Building Partnerships 9th Edition Castleberry Test Bank PDFkeathleyjessiavipfx100% (9)

- India-UAE CEPA Report 2022Document46 pagesIndia-UAE CEPA Report 2022Vivek BaranwalNo ratings yet

- Vertical Farming Breathing High RisesDocument70 pagesVertical Farming Breathing High RisesGurpal KaurNo ratings yet

- Harpreet Lotey W.F ResumeDocument3 pagesHarpreet Lotey W.F ResumeParminder KaurNo ratings yet

- Beware 16062020 09Document2 pagesBeware 16062020 09Sephiwe MafilikaNo ratings yet

- Geely Goes GlobalDocument4 pagesGeely Goes GlobalE D Melinsani Manalu100% (1)

- Third and HollywoodDocument2 pagesThird and HollywoodMatthew JaffeeNo ratings yet

- Raipur Factories ListDocument53 pagesRaipur Factories ListPravesh Sharma100% (10)

- Fm-npd-16 (Temp. Change Request Note)Document1 pageFm-npd-16 (Temp. Change Request Note)akash.vd.1603No ratings yet

- Bid Proposal Template: About UsDocument3 pagesBid Proposal Template: About UsHeni Zbloody EbahNo ratings yet

- Hospital Pharmacy Nadeem Irfan BukhariDocument101 pagesHospital Pharmacy Nadeem Irfan BukhariEngurd Langin0% (3)