Professional Documents

Culture Documents

Tanks

Tanks

Uploaded by

Akesh reddy0 ratings0% found this document useful (0 votes)

33 views60 pagesOriginal Title

Tanks (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views60 pagesTanks

Tanks

Uploaded by

Akesh reddyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 60

13.1 INTRODUCTION

- ‘ries vac. Meee

To meet the daily requirement of water by industries, campuses, localities, towns and cites various qe!

types of R.C. water tanks are used. Such tanks may be in general, classified as:

se

(i) Tanks resting on ground, 0 i

(ii) Under ground tanks, and @ e

(iii) Elevated tanks. (i

The tanks may have circular or rectangular sections. Tanks resting on ground and underground “tele

tanks have flat bottom slab while elevated water tanks may have flat bottom or conical bottom. () For

Apart from strength requirement, another essential requirement in the design of water tank is {i Fo

imperviousness. To make water tanks impervious, wider cracks should be avoided in the concrete, {compre

which may be achieved by —

(i) Use richer concrete mix, say M25 or M30. wm Rei

(ii) Give a minimum clear cover of 25 mm, —

(iii) Provide smaller diameter bars at closer intervals, Wm

(iv) Keep the tensile stresses in concrete low.

(0) Follow good constuction practices like thorough mixing, good compaction and good curing.

13.2 DESIGN REQUIREMENT

IS: 3370 is the Indian code of Practice for concrete structures for the storage of liquids. This was Sinan

Goble in December 196. I incorporated two amendments in 1997 and the same Scitht ern 7

1999, The code is available inthe following four parts: ‘ilness

%

Part I: General requirements "eh if

Part II : Reinforced concrete structures ;

Part IIL: Prestressed concrete structures, and eh

Part IV : Design tables, “Wiog

BI

Ji veid leakage problems, imit state method of design should not be used in water tanks. 18 456- cs

2000s silent about permissible stresses in direct tension, Hence from IS: 3370 (Re affirmed in 1999). ti

it is obvious that earlier version of IS: 456 guide lines should be used, which is based on working ale %

Stress method, Permissible stresses for concrete and stel ae as shown in Tables voy and 13.2. Sng.

Water Tanks [J

Table 13.1:

Permissible Stresses in Concrete

[ Grade of

Concrete Permissible Stress

in Shear in

20 Bee

a a eee 17

3S ae 19

[os ae %

M35 =

M40 a

Sees

Types of Stress

lee i | Mild Steet

1. Direct tensile stress Seg as ae

2. Tensile stress in bending == "

() On liquid retaining face 1s

(ii) On face away from liquid if itis less than 225 mm | 15

(iii) On face away from liquid, if it is 2 225 mm 125

3. Tensile stress in shear reinforcement

(i) For members less than 225 mm thick us

__ Gi) Formembers2225mmthick |

4. Compressive stress in columns subjected to direct load _| 125

Minimum Reinforcement

For thickness upto 100 mm, minimum percentage of reinforcement should be 0.3. For thicknesses

from 100 mm to 450 mm it may be reduced linearly to 0.2 per cent. Hence

Pain = 0-3 upto 100 mm thick sections

1-100

= 03-01 ———— for 1= 100 mm to 450 mm

03 0175-100

Minimum reinforcement should be ensured in both directions.

It thickness of section is more than 225 mm, z

‘Vis enough if total steel meets the minimum m

jired near both face, however

143.2 METHODS OF ANALYSIS

Te behaviour of walls of water tank is

°F cylindrical tank, bending theory ©

‘eclangular tanks, plate theory with

‘sults. The continuity with adjacent

™oments and shears. One can th

‘affirmed in 1999 gives the a

‘Ylindrical as well as rectangular

‘conomical.

Advanced R.C.C. Design eG

However there are approximate methods of analysis, commonly used in the design. In the

approximate method, it is assumed that in case of circular tanks bottom 1/3rd height or 1m, whichever

is greater, is predominantly under cantilever action where as in case of rectangular tanks bottom 4

height or | m, whichever is greater is mainly under cantilever action. Rest of the wall is resisting

water pressure by forces developed in horizontal directions. Approximate method is always on safer

side and hence design is uneconomical. However it has the following advantages:

( Ttis simple

(ia) It gives feel of the structural behaviour,

Hence designer or site engineer can always avoid disasters of mistakes of draftman or those due to

confusion of sign conventions in the analysis.

We may have lot of sophisticated methods of analysis to assess the design forces, but it is

necessary for engineers to develop feel of structural behaviour, Hence the approximation methods of

analysis should be leamt by engineering students. In this book designs are carried out after using

approximate methods for the analysis.

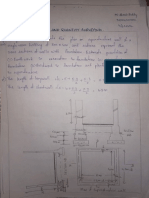

13.4 DESIGN OF CIRCULAR TANKS RESTING ON GROUND jest

Circular tanks can have flexible base or rigid base. Fig. 13.1 shows typical circular tanks. In case of

flexible joints, the wall is free to move outward when intemal water pressure is applied and hence, the

Wall is subjected to hoop forces ‘T’ only

faci

ete

Samy

‘Comer reinforcement

a1

{) Stiding base

(b) Rigid base

Fig. 13.1 Typical circular tanks

D

T=yH—

ue 2 (13.1)

where y= Unit weight of water

H= Height of tank and

D= Diameter of circular tank,

The reinforcement for hoop forces is to be given i

minimum steel is to be Provided, eae

Incase of rigid joint, lower portion i

Incas Portion is hay

mainly in hoop tension Fig. 13.2 gives the

height BD, then Cantilever moment at base

Water Tanks EE

o

=

8 wl

(a) Load sharing (b) Load for cantilever action

Fig. 13.2

A

“>, (13.2)

ad maximum hoop tension at D E

D

T=y(H-h)—

WH-H)>

For circular tanks *h’ may be taken as a or 1 m whichever is more.

Examples 13.1 and 13.2 illustrate the method of design.

13.5 DESIGN CONSTANTS

Referring to Fig. 13.3, depth of neutral axis is ‘nd’ where -

hob + ‘ Cae,

He) oye

I cS |

mos

Fig. 13.3,

n= laid

16. + Fu (13.3)

Lever arm is ‘jd’ where

jz ie

ERM) Advanced R.C.C. Design Se

Om 3 (3.

where ke 30 Jn 5

‘The equivalent concrete section

ASA, +mAg=A,t(m—1) Ag 146)

the above expressions, : : :

_— 6.4, = Permissible compressive stress in concrete in bending

che =

6, = Permissible stress in steel

and m = Modular ration = Es

= =, which is usually rounded of to nearest full number (13.7)

be

A. = Area of concrete

A,,= Area of steel

A, = Gross area of cross-section.

Free Board

In all water tanks a free board of about 200 mm is to be given; in other words depth of water tanks in

kept 200 mm more than the required depth for the full capacity. However for the design depth of

water is taken as the total depth only since occasionally a stagnant water upto full height may be

stored.

Example 13.4: Design a circular water tank with flexible base resting on the ground to store 50,000

litres of water. The depth of tank may be kept 4 m. Use M25 concrete and Fe-415 steel,

Solution: .

Capacity of tank = 50,000 litres = 50 m3

Depth of tank =4m

+. If D is the diameter, then

=p? x4 =50

4

D=3.989 m

Provide 4 m diameter

Free board = 200 mm

Total height of tank H=4+0.2= 4.2 m

Unit weight of water Y= 9.8 kN/m?

Permissible tensile stress in Fe-415 steel = 150 N/mm?

Permissible tensile stress in concrete = 1.3 N/mm?

Maximum hoop tension

apie 4

T= YH =98%42x— = 82.32 kN/per meter height at base

gee

=zeeret

9, = 150 N/mm?

.. Area of steel required for taking hoop tension

A 82.32 x 1000

pe 2

150 = 548.8 mm’

Using 12 mm bars, spacing

Exi2

5488 * 1000 = 206 mm

Provide 12 mm bars at 200 mm c/c,

Awprovided = x 12? x ~ = 565.5 mm? per metre height.

Increase the spacing to 300 mm at a height 1.5 m from base.

Thickness of Wall

Maximum hoop tension T = 82.32 kN

Permissible stress in tension= 1.3 N/mm?

Modular ratio for M25 concrete

280. 280

m=——_

=a

3xO4. 3X85

If ‘r is the thickness of wall, equivalent area of concrete per metre height

= 10001+(m-1) A,

Hence

fr,

oe 10001 +(m—1A,

82.32 x 1000

~~ 10000-+ (11) x 5655

t= 57.66 mm

t= 100 mm

oO

Provide

Vertical Steet

Only minimum reinforcement is required,

* A, minimum ae

100 x 1000 = 300 mm?

: 100 * 100 x 1000. i

Using 8 mm bars,

Provide & mum bars at 150 mm ole

259)

ne

El Adtonced RC. Desi _—

it elt. Since the load gets trap,

ered with tarf gets

Base Slab

i ided with minimum reinforee, "td

ibe aid ona 75 mi 50 ey be provided with mini ‘

‘The base slab will be laid on a Ay at 1

i yminal thickn Teemen

to ground directly, a not

SLY .

both direction. ee

= 93.5 150% 1000 = 45 E

». Ay minimum

os th face

Providing half the reinforcement neat =

A,y= 225 mm’

Using 8 mm bars,

2 xg

Provide 8 mm bars at 220 mm c/c on both faces in both directions. a

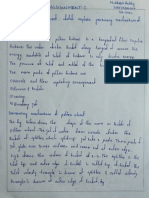

vi

Fig. 13.4 shows the details of reinforcement.

To}

Let

Let

Example 43.2: Design Note:

between wall and bases

Solution:

Dimensions of he tank: Diameter D =4 m

Total height

H=42m

Mix used: M25, Steel to

be used Fe-415

See= 8.5 Nin? and g,, = Wee

Montene eae

sll

3x85,

Design constants are

mo

n= PG

moa +0,

— Water Tanks 7%

7 iy tees 03

ie, 15-194 = 0,872

3

ke! aoe

i 3 Oete xpXn= 7% 8:5 0872 x 0.384 = 1.428

Design for Cantilever Action

The height “h’ above base upto which cantilever action exist is given by

h= or 1 m whichever is more

Cantilever moment = 3 Hx hx 2

= i xosxa2 «idx a = 13.446 KN-m

Depth of balance section

7

in (EME = [IBERHOS a

kxb 1.428 x 1000

To keep the section sufficiently under reinforced. :

la as = 4x93 = 129.7 mm

Let us keep d = 130 mm and total thickness 165 mm.

(Note: Minimum thickness of 150 mm is normally kept to avoid leakage problems).

6

a _M____13446%10" _ _ 790.8 mm?

= jd 1500872130

Using 10 mm bars,

*rovide 10 mm bars at 95

Hence let us provide 10 mn

‘0 that a spacing of 190 m

FIG Advanced R.C.C. Design _

Design of Section for Hoop Action

For this reinforcement is to be provided in horizontal ee

‘at height h =1.4 m in this case. Hoop tension is given ry

T=y(H-h)xD2

Max hoop tension is to be considereq

4

=9.8(4.2- 14) x5 = 54.88 KN

Ay = 2288%1000 365.8 mm?

5 150

Using 10 mm bars, spacing

= x10?

x1000 = 214 mm

3658

Provide 10 mm bars @ 200 mm c/e.

Check for tensile stress in concrete:

zg x10? ‘

Ag= 1000 = 392.6 mm’

Actual a4

i

ogee

Equivalent conerete area

5488 x 1000

= = 1.10 Nimm?

165% 1000+ 1=1)x3926 ~ 110 Nm

Permissible 6,, for M25 concrete = 1.3 N/mm?

Hence safe.

For bottom 1.4 m above base the spacin;

g of 100 mm may be maintained. In the remaining portion

it may be raised to 300 mm c/c.

Distribution Steel (In vertical direction)

Minimum steel required = Fax lesx 1000 = 495 mm?

+. Vertical steel for cantilever action serves this Purpose also.

Base Slab

Provide nominal thickness of 150 mm with nominal Teinforcement of in

bat aca of 8 mm bars at 220 mm o/c in

Provide 150 mm x 150 mm haunches at junction. To ensure the rividi i i

= Sena Tigidity of connection, provide

Junction reinforcement of 8 mm bars at 220 mm cf. It takes care of development jired for

cantilever steel. S length required

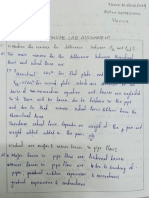

Fig. 13.5 shows the seh

Se Water Tanks Q%3

10 mm @ 96 che

8 mm @ 200 c\c on both faces

2) alld Ss

tn 150

Fig. 13.5

136 RECTANGULAR TANKS RESTING ON GROUND

Consider the design of rectangular water tank of size L x B x H, where

L— Length of tank

B— Breadth of tank

H— Total height of tank

In the approximate methods such tanks are divided into two categories:

(@ Tanks with LB < 2

(i) Tanks with L/B > 2

\) Design of tanks with L/B < 2: Similar to design of circular tanks, here also lower part is

sumed to have predominantly cantilever action and upper portion to have resistance by hortvontal

‘ston. The load taken by the two actions is shown in Fig. 13.6(a), where D is a point at a height

h = H/4 or 1 m, whichever is more

--(13.8)

Hence maximum cantilever moment on the wall

S 5vHne +-(13.9)

For horizontal action, maximum Pressure is at (H — h) m below top (at D). Hence p, = (H —h) as

shown in Fig. 13.6 (6).

EEq] Advanced RC.C. Design = is

sed frame ac he frame being symmetric, analys

ame actio a D y:

Jjosed fra

This is resisted by cl

‘end moment at A are

BAL Bi

Pr pm a 3.19)

nts may be balanced,

the momet

Using moment distribution ; :

: e long wall supports short wall and short wall supports long wall, horizontal tension de

Since long wall s ssh nd short

in the walls. At D, horizontal forces developed are

elope

T= HW) (311g)

L

ee, Tp nH-m) A311)

The effect of horizontal tensile forces is to reduce the net moment in walls to an extend Tx, where

xis distance of tensile reinforcement from the centre of wall. Thus final horizontal design moment is

=M-Tr (13.12)

The bending moment reduces towards top above ‘h’. Hence spacing may be increased towards the

top. However minimum reinforcement requirement should not be violated.

It may be noted that, near corners bending tension is on inner face and near centre it is on outer

side.

(ii) Design of tanks with L/B 2 2: In such cases, long walls behave like cantilevers of height H.

Thickness of walls may be decided on the basis of cantilever moments in long wall. The horizontal

i ; iB. eli :

Steel required in the long wall is to resist direct tension T, = (Hi — fh). Designer will find this

requirement is automatically satisfied by providing minimum reinforcement of 0.3 per cent,

Lower portion of short wall of height ‘h’ is resisting the load by cantilever action and top H-h

resist the load by horizontal frame action, as

discussed in case (i), Hence cantilever moment in shot

2

walls is Wai.

J 2

Pue to horizontal fame action, bending moment may be taken equal to Y= WB" both avends

16

tre it is on outer face. Though long walls a

end 1 m may be considered as supported by

and centre. At ends, tension is

predominantly tesisting the I

short walls

on inner face and at cen

load by cantilever action,

Tg =y(H-h)x1

This will reduce the design moment by T, i i i

$ : i where x is the distan from centt

of section. The reinforcement is calculated for bending and direct an ee stelis

Provided in horizontal directioy . aoe a

The design procedure is illustrated with two examples below:

Water Tanks EE

ple 13.3: Design a rectangular water tank of size 5m x 4m x3 m deep resting on firm

round. Use M2S concrete and mild steel,

Solution:

Size of tank =5mx4mx3m, deep

Grade of concrete M25

Gey = 8.5 N/m?

280.

3x85

6,,= 115 N/mm?

Design constants are

m=

pe ae MKS

Moye +O 11X8.5+115

Cae sh

3

i JoerciN= 5X8.5X0850X 0488 = 1.619

In this problem,

g23 =2=125<2

Hence both long and short el resist the load by cantilever action for height h = 1 m and by

horizontal action resist the load in the top H-h = 3 — 1 = 2 m. In such water tanks, moment due to

horizontal action is considerable and it governs the selection of thickness of walls. Hence horizontal

frame action is first considered.

Horizontal Frame Action

The critical section is at a height h = a or | m whichever is more. Hence in this

caseh=1m

Pa = WH - h) = 9.8(3 - 1) = 19.6 KN/m>

“. Fixed end moments are

= 40.833 kN-m, in long wall

_ ppl? _19.6xS?

ial 12

PB?

Advanced R.C.C. Design 2 Pane

-

Member

Short wall

5

en t distribution as shown in tab)

Due to symmetry one balancing will take care of moment dis He belo:

4 0.444 Long wal}

Short wall 05:

=26.133 40.883

- 8.20 Bue

ee 34.333

Perens anesn = 34.333 KN-m, tension outside.

Effective thickness required for balance section is

7

Fe 34333%105 46 am

kb \1.619 x1000

Section is to be kept sufficiently under reinforced. Hence let us keep overall thickness of 200 mn,

with effective cover of 35 mm,

: d= 200 ~ 35 = 165 mm

Pirect pul on long and short walls are given by

T= mAx5=196x4 = 39.2 kN

ib

and THe PAX 7=196%5 = 49 4

Eccentricity of Teinforcement from centre of wall

200

Beeson

+. Design moment at comer Me

=M-Tx

b = 34.333 — 399 x 9,

i 2 x 0.065 = 31.795

Hence at comer, horizontal reinforce : -785 KN-m_

It *

‘ment required for bending resistance

Ag = 3E785x106 31785 x 198 ;

oj. =

ii for direct tension wt Uisx0850x 165 ea

4b

392x110

- Water Tanks FH o

;, Total Ay = 2311 mm?

Using 20 mm bars, spacing required is

n 9?

s= 4 x1000 = 136 mm

211

provide 20 mm bars at 130 mm c/e, Itis to be provided on water face.

Reinforcement at middle of long walls:

. v

Bending moment = 4 ~ — Moment at corner

2

= 96x -34333 = 26.917 kN-m

Design moment =M-Tyx

= 26.917 — 39.2 x 0.065 = 24.369 kN-m

24.369 x 108

= oe = 1511 mm?

“= Ti5x0850x165

_ 39.2x 1000

Bis WMS

E Ag = Aga + Aga =1852 mm

Using 20 mm bars, spacing

= 341 mm

x20"

= 1000 = 169 mm

aesesD

These bars are to be provided at outer face.

Here also bars may be provided at 130 mm c/c, so that bars may be bent and used.

Reinforcement for Short Wall

M = 34.333 — Tyr = 34.333 - 49 x 0.065

= 31,148 kN-m

_ 3148x108

* 15x 0850x165

49 x 1000

Avy = ——

2 Pa

Total Ay= 2357 mm”

T

pe

2357

Aw = 1931 mm”

= 426 mm?

‘Using 20 mm bars, spacing =

EQ) Advanced R.C.C, Design ek ee an

Provide 20 mm bars at 130 mm c/c.

Bending moment at centre of wall

2

B

= y(H-h)— - Moment at ends

= Hl)

2

= 9,8(3-1)x Te 34.333 = 4.867 KN-m

{tis quite small. It is taken care by minimum reinforcement. Bend alternate bars Provided fy

moment ata distance Ge 1m from each end and continue remaining half throughout. Hen,

CE at centre

of wall reinforcement consist of 20 mm bars at 260 mm c/c,

Reinforcement in Vertical Direction

2 2

Cantilever moment =yn4 98x3x—

6

4.9 kN-m

M 49x10°

Ag= = __49x108 2

"Gy jd 115%x0850x165 = 3904 mm

Minimum. Teinforcement =

03

0% 200 x 1000 = 600 mm?

Provide 304 mm?

area on each face so that required distribution Steel is also available.

ae

Using 10 mm bars, me

Go ae ONS

pce: a re

pase Slab

provide nominal base slab of thickness 150 mm with 8 mm bars at 220 mm c/c in both direction at top

ani bottom of slab. A lean concrete bed of 100 mm may be provided on which bottom slab can rest.

Details of reinforcement are shown in Fig. 13.8,

‘Section plan bent line this

Fig. 13.8

ample 13.4: Design an open rectangular tank of size 3 m x 8 m x 3 m deep resting on a firm

found, Use M25 grade concrete and Fe 415 steel. Approximate method may be used. for the analysis.

Solution:

Size of the tank 3 mx 8 mx 3 m deep

Grade of concrete: M25, Grade of steel Fe-415

a Gye = 8.5 N/mm? and 6,, = 150 N/mm?

ps RO

3x85

Modular ratio nT

Advanced R,C.C. Design Nas gaa

L 8

Now, ie

Hence long wall predominantly acts as cantilever of height H = 3 m

smemeremeagnee

Design of Long Wall

.

YH 9g 3 2 44.1 kNem

w= WE moan

Equating moment of resistance to bending moment, for balanced section we get

kbd? = M |

M _ | 44.1x10°

mie ee aoa

. 4 Vip ~ Viax3x 1000 ~17°™

Provide 220 mm total thickness with effective cover 35 mm. Hence d= 220-35 = 185mm

.. Reinforcement for cantilever action (vertical on water side)

M____ 441x108

Using 16 mm bars, spacing is

Exe

s=—=——— x 1000 = 110.3 mm

1823

Provide 16 mm bars at 110 mm c/c in vertical direction near innerface of the tank.

Curtailment of bars: Moment is given by y° at any depth ‘h’ below top. Hence ‘“h’ the distance

from top where alternate bars can be curtailed is given by

Rw

or h = 2.38 m from top or 0.62 m from base. However the above value is only theoretical.

As per code requirement actual curtailment should be at

= 0.62 + 12 x diameter of bar

16

= 0.62 + 12x —— =0;

+ * F000 0.812 m

Hence curtail alternate bars at 0.9 m from base.

Reinforcement in Long Wall in Horizontal Direction

Direct tensile force transferred by short wall on long wall

B

TL= H-h)> = 980-13 = 29.4 kN

Water Tanks ii

:, Horizontal reinforcement required

150

Minimum reinforcement to be provided

= 196 mm’, too small

03

i x 220 x 1000 = 660 mm?

Hence 330 mm” area may be provided on each face. Using 8 mm bars,

= x8?

=4

s= =

330 1000 = 152 mm

:. Provide 8 mm bars at 150 mm c/c near each face in horizontal direction.

Design of Short Wall

Reinforcement in vertical direction:

2 2

oq WHALE _98%3x1" _ 49 iN-m

6 6

___4.9x10°

~ 150% 0.872 x 185

Too small, Provide minimum reinforcement of 8 mm bars at 150 mm c/c near each face.

Ag = 202 mm?

Reinforcement In Horizontal Direction

Water pressure at h =1 m above base

Pp = 9.8 x (3 1) = 19.6 KNim?

B? _ 19.6x3*

.. Bending moment at ends may be taken as aa = BOSS = 14.7 Nm

Actual tension due to 1 m length of long wall

Tp = WH - fh) x1 = 9.83 - 1) x1 = 19.6 KN

ae 14.7%10° = 607 mm?

#1 150 x 0.872 x 185

19.6 x 1000

oS ae

= 130 mm?

Using 12 mm bars

7.35 10° 2

tl 150 x 0.872 x 185

( Note : It is ; of A,, required at =)

Hence provide 12 mm bars at 300 c/c.

Base Slab

Provide nominal base slab. Reinforcement details are shown in Fig. 13.9.

84 @ 150 cc a

‘Sectional plan at bare Ses

‘Section through short

(Section -y) wall

Fig. 13.9

13.7 UNDERGROUND TANKS

In water supply system to towns underground water tanks are used to store water received from

mains. The tanks may be circular or rectangular. For larger capacities circular tanks are preferabl

0 = 4 capacities circular le,

since forthe same capacity they consume less material. As the cost of shutering foro bas

per unit areas large, rectangular tank work out cheaper fr small capacities. Under ground

to be designed to sustain the following two cases: a es

Case (i) Tank full and no earthfill.

Case (ii) Tank empty and active earth

et atereiaisl

plained for tanks resting on ground. In case (ii), external pressure

Design for case (i) is same as ex;

depends upon the type of back fill

(a) Active earth pressure due to dry soll or wet cohestonless soil

ee KA WH |

(a) Dry or back fil (b) Submerged saturated sand fill

of cohesioniess soil mh sf

Fig. 13.10

The active earth pressure acting on wall varies linearly (Ref. Fig. 13.10) and its maximum value is

Py=Ky,H (13.13)

where, K— Rankines coefficient of earth pressure :

Y, — Unit weight of soil

H— Total depth of tank.

Rankines coefficient of earth pressure is given by

x= esing

+sind

where, 9 is angle of repose.

(b) If back fill is saturated sandy soil

It consist of active earth pressure due to saturated backfill (y’,) and due to water pressure from

outside. This situation for water table upto top of tank is also shown in Fig. 13.10. In this case

maximum pressure from outside is

Py = Ky’ H+ YH (13.14)

where’, — Unit weight of saturated sandy soil

and %y — 9.8 N/m’ is unit weight of water.

Designer has to adjust the reinforcements judiciously to take care of both loading cases discussed

above, Apart from designing the walls bottom slab also needs the design. It is designed for uplift

Pressure from saturated soil below. The tank should not get lifted due to this uplift pressure. Hence

bottom slab is projected beyond the walls so that weight of soil on this projected portion helps in

adding downward load to resist upward water pressure,

Underground tanks need roof slab to keep water clean. Hence the designer must design the roof

slab, which is similar to design of slabs in buildings.

The example below illustrate the desig e

of circular tanks also may be tal

horizontal plane where as r¢

Advanced R.C.C. Design 2 __._ ae

Example 23.5: Design an underground water tank of size 3m x 8 m x3 m for the following darq,

Type of soil: Submerged sandy soil, with

Y= 16 kN/im’, $= 30°

Water table can rise upto ground level.

Grade of concrete

(i) For tank M25

(ii) For roof slab: M20

Grade of steel : Fe-415

Unit weight of water = 9.8 kN/m?

Live load on roof slab = 2 kN/m?

Solution:

Design of Roof Slab

Size3mx8m

Ly

B

Hence it may be designed as one way slab. It may be designed by working stress method with

higher permissible stresses (230 N/mm? for Fe-415 steel or 140 N/mm? for mild steel) since there is

no leakage problem for this element. One can use limit state method also. Concrete of grade M20 is

Preferred from the consideration of economy.

Let

J, _ 3000

= > = 120mm

2525)

Let us select d = 120 mm and overall depth D = 150 mm

Using M20 concrete and Fe-415 steel, the slab will be designed

Self weight = 0.15 x 1x 1 x 25 =3.75 kN/m2

Liveload =2.0 kN/m?

Finishing load =0.5 kN/m?

ane

Total = 6.25 kN/m?

annette

3

M=625x y= 703 KN-m

M,= 1.5 x 7.03 = 10.55 KN-m

My tim = 0.138 fy bd”

= 0.138 x 20 x 1000 x 120?

= 39.744 x 10° N-mm

39.744 KN-m > M,

Hence under reinforced secon, Equating momento moment of resistance,

Asics

= 087f,A,d\1-—* x

M, ie 4 ba 1 wes

Water Tanks

A 41s

10.55 x 10° = 0.8" eK

7 x 415 x Ay, x 120] 1 F000 1a aa

A

: 243.5 afi. Hi )

e s 578313,

ra Ay? - $783.13 A, + 243.5 x 5783.13 = 0

Ag = 254.7 mm?

Minimum to be provided = 2 1000 x 120 = 144 mm?

Using 10 mm bars,

a x10? ‘

= x =

$= Seq * 1000 = 308 mm

Provide 10 mm bars at 300 mm c/e

Distribution steel = 0.12% = 144 mm?

Using 8 mm bars,

ix 3 F

= 1000 = 349

Saree mm’

Provide 8 mm bars at 300 mm c/c.

Design of Walls

* These are to be designed with working stress method with lower values of Permissible stresses to

avoid leakage problem. Using M25 concrete and Fe-415 steel,

Gepe = 8.5 kKN/m™ sm=i11 G,,= 150 N/mm?

= Ode. _1KBS_ _ gg,

10,4, +6, 11X85+150 ~

jot-$n1-9 - 0872

Kes 5Oaenj=X85x 0384x0872 = 1.423

In such tanks usually cantilever moment

Hence let us first consider the design of

, when tank is empty, governs the choice of thickness,

wall

si nn

Advanced R.C.C. Design

Yy = 9.8 kNim!

2

Pre dy 62%3498%3 = 35.6 kN/m’

3

3

, Hl 356x3x = = 53.4 KN-m

Ma XSSSXH XT 3 3

+ Depth of balanced section

Provide d =195 mm and D = 195 + 35 = 230 mm

6

he nota

"150 x 0.872 x 195 :

Using 20 mm bars, spacing required is

Ex 20? (

=4__ x 1000 = 150 mm

2094

Provide 20 mm bars at 150 mm c/c near outer face of the wall.

Alternate bars may be curtailed where bending moment is half that at base i.e. at a depth

1

ie ( )

w=5) A=|=)3=238m

wD 2

i.e., at a height 3 — 2.38 = 0.62 m from base.

‘The above value is theoretical value, As per code requirement add 12 x diameter of bars to above |

value. Hence the bars are to be curtailed at a height = 620 + 12x 20 = 860 mm from base. Hence |

Curtail alternate bars at 0.9 m from base.

(b) When tank is full and no earth pressure

Ph=Yy H=9.8 x3 = 29.4 KN/m?

# Here canievermomen M= 1.29433 x3 = 66.15 kN-m

5 66.15 10°

i be [eee ese (OTL 5

i 150% 0.872 x195 ~ 2594 mm

Using 16 mm bars,

Bag

ss “7594 1000 =77.51 mm

Provide 16 mm bars at 75 mm.

Cte on inne face in vertical dretion,

| Horizontal Bars in Long Walls

Water Tanks YR

Since thickness of wall is more than 225 mm, minimum percentage of steel to be provided is

= 03-01230= 100

F50=100 = 0.263

0.263

Ay= a 230 x 1000 = 604 mm?

Steel required on each face = 302 mm?

Using 8 m bars, spacing required

= 300 * 1000 = 166 mm

Provide 8 mm bars at 160 mm c/c. They hold the vertical steel provided for cantilever action due to

the two loading cases considered,

Check for Direct Tension

T= Y4(H-W)5 = 98G-1)x3 = 29.4 KN

«. Area of steel required

= BAXTO00 ~ 196 mm? < 604 mm?

-. Distribution steel takes care of this tensile force.

Design of Short Wall

Design of lower portion for cantilever action (Vertical reinforcement)

nae or 1 m whichever is more

= 1m, in this problem

‘When tank is empty and outside sandy soil is saturated

Pp = 35.6 kN/m?

= Sxas6xixd = 5.933 kN-m

__M____5933x10®

Gy, jd 150x 0872x195

Direct compression due to load on 1 e long

Ay = 232 mm?

Concrete alone can resist

When the tank is full a

BR) Advanced R.C.C. Design _ _ ——--

which is 8 mm bar at 160 mm c/e as foung

Provide minimum reinforcement in vertical direction,

earlier, It is to be provided near both faces.

Design of top H-h=3-1=2m portion

y= ky’, (H-h) + ¥,(H - h)

= |x (16-98) (3-1) +9.8(3=1) = 23.73 kN/m?

3

23,73 x3*

Moment at support eae = 17.8 kN-m

6.

Nga ATM 60 at?

150 x 0872 x 195

At mid span bending moment is half of 17.8 KN-m

Hence A,,= 399 mm?

At support, using 10 mm bars spacing required is

ax 10?

se 1000 = 112

Gog * 1000 mm

Provide 10 mm bars at 110 mm c/c (near outer face).

At middle portion alternate bars may be bent inside.

Bottom Stab

Assuming thickness of bottom slab = 0.2 m,

H=3+02=3.2m

+. Upward pressure when sandy soil is saturated

=9.8 x 3.2 = 31.36 kN/im? a

The bottom slab is to be projected beyond walls of tank so that soil over it helps in avoiding

Se Hence first the required project is to be determined, Let it be x metres as shown in

‘ig. 13.11. ¢ x:

Water Tanks

Downward Loads

(a) Weight of top slab = 0,15 (8 + 2 0,23) (3+ 2% 0,23) x25 = 109,77 KN

(b) Weight of long walls = 2x 0.23 (8 + 2% 0.23) x 3% 25 291,9 KN

(c) Weight of short walls = 2 x 0,23 y 3% 3% 25 = 103.5 KN

(d) Weight of bottom slab = (8.46 + x) (3.46 + 4) 0,2 % 25 m 1464 + 59.6% + 5x2

(e) Weight of soil on the Projection of bottom slab

= [(8.46 + 2x) (3.46 + 2x) ~ 8.46 x 3.46) 3% 16

= (23.84 x + 40) x 48 © 114432. 4192.2

Uplift force on bottom slab

= 31.36 (8.46 + 2x)(3.46 + 2x)

= 917.96 + 747.62x 4125.44

Equating upward force to total downward force, minimum x required can be obtained,

917.96 + 747.62x + 125.44? = 109.77 + 291.9 + 103.5 + 1464 + 59.6% +5174 1144,32x + 192.2

11.56x? + 456.3 x ~ 266.39 = 0

ce 4563 + 456.3? + 4x 71.56 x 26639 = 0.538 m

2x 71,56 e

Hence provide a projection of 0.6 m alll around, The base slab is to be

The loads acting on this slab is shown in Fig. 13.12,

[sae | ei

eran rey Tt

soil

neces

designed as one way slab,

™

ee

panced R.C.C. Design :

| Advanced R.C.C. Design _ pward pressure to be Considereg fy

soil. Hence uy

Self weight of slab directly get transferred t0

bending moment calculation is 2

=31.36-0.2x1x1 x 25 = 26.36 KN/m'

Weight of soil on projected portion

= 163 = 48 kN/m?

3

ing at 240.2 = 1.2m

Roar icaloa walle 5 .X3= ; 356x3 = 534 KN acting at 5

Cantilever moment at the face of the wall

2 48x06" :

= 2636x2S 4 s34x12— SOUS

Moment at Centre of Slab

Load transferred by wall per meter length of base slab

= weight of 1m long wall + ; weight of roof slab per meter length

702313 x25 45 x(.0+2%023) x02.x25 = 25.9 kN

-+ Moment at centre of slab

3.46 + 1.2)

= 26.36 x EE sua 12-48x06x (E+ 58) -259(5 403)

2

= 25.2 KN-m, Producing tension at bottom.

Moment at centre of slab is crit

1 3

== os

peeves =

44.1 kN

+. Moment at centre of slab (see Fig. 13.12 b)

: 3.46412)

= 263 ¢

Oras zen 9 po sostl

=~ 50.23 kN-m q

= 50.23 kN,

s+ Thickness of

Bg tension at top

Provide d = 215 mm and D = 250 mm

A. = — 6018 10°

“150 x0872 x 215

= 2139 mm?

Using 16 mm bars,

x16

= = x 1000 =

s= 39 * 1000 = 94 mm

Provide 16 mm bars at 90 mm c/c near bottom face for the cantilever moment.

In the middle portion, reinforcement required at top is

50.23 x 108

~ 150 x0872.x 215

Continue cantilever reinforcement throu

At bottom

st

= 1786 mm?

ighout i.e., 16 mm bars at 90 mm e/c,

= __252x10°

>

a

150x0872x215 ~ 896 mm

Using 12 mm bars, spacing required is

Ag

= x12

896

Provide 12 mm bars at 120 mm c/e,

s=

1000 = 126 mm

Distribution Steel

250295

= 03~ 2507225 _ 929

% of steel 03 B=2

Ag= 922 x 050x100 = 572 mm?

100 a ,

A,, on each face =

Using 8 mm bars

Advanced R.C.C, Design

in Fig. 13.13.

Reinforcement detail is shown in Fig.

(@) Section along x-x

20 6 @ 150

8e@ic0

Se

*t

10¢@ 110_—

209 @ 150 reo" He

1250

86@170 12 @ 120

(€) Section along y.y

Fig. 13.13

13.8 OVERHEAD WATER TANKS

Various overhead tanks being useq may be classified as

(a) Rectangular over

(®) Circular overhead tanks, and

(©) Intz type tanks,

Water Tanks PER]

are used to store large quantity of water. Intz tanks of capacity one million liters are commonly used

in water supplies in cities,

All overhead water tanks need top slab cover and also. staging to support them. When top slab is

provided, the top edge of tank wall may be treated as hinged. Walls are always monolithic with base

slab. Hence walls may be treated as having edges fixed at base, and hinged at top.

In case of circular tanks, dome is preferred to top flat slab. Many times bottom flat slab is replaced

by dome.

The exact analysis of over head tanks is not simple since all structural elements (top slab, walls

bottom slab and beam supporting bottom slab) are built monolithic. The continuity analysis is required.

The attempt of Jai Krishna and O.P. Jain (Ref.3) for continuity analysis is note worthy, However

since now a days finite Element Analysis packages are available one can think of using them to get

better results. Approximate analysis based on assumed boundary conditions and membrane theories

may be practiced, provided detailing is made to take care of edge disturbances in the form of edge

moments,

In this book designs are made by approximate methods.

13.9 RECTANGULAR OVER HEAD WATER TANKS

Top slab may be designed by limit state method or by working stress method in which permissible

stress in mild steel = 190 N/mm? and for Fe-415, 6,,= 230 N/mm?. Live load on tank may be taken

as 2 KN/m?,

The walls may be designed by approximate method as discussed in this chapter earlier or one can

make use of moment shear coefficients given in IS: 3370 (Part IV) (reaffirmed in 1999),

Base slab is heavily loaded when tank is full. Hence it is designed for the water pressure when tank

is full, taking edges as fixed. The base slab is supported along its edges by wall or beams and some

time additional beams may be there in the middle also. Beams are Supported by columns of the s

For the design of tank and base slab working stress method with

Stresses in steel should be used, since in these element: sj

leakage problem.

taging.

13.10 CIRCULAR OVER HEAD WATER

As stated earlier circular water tanks are

Provided with dome as top cover. The inves

has shown that the rise of spherical dom

Advanced R.C.C. Design

Fig. 13.14

D= Diameter of Dome

R= Radius of curvature of dome

h= Rise of dome, =th Dz

t= Thickness of dome usually minimum of 75 mm and maximum of 100

5 KN/m?. Finishing load may be added to get tot

area of surface. If ‘w’ is load on the surface Per unit are

following expression:

Meridional thrust T=

— Per unit length

A

a ml)

Circumferential force, = wa

Maximum values of above forces occur when o=6

} per unit length

, ie,

» at junction with top ring beam.

ircumferential directions.

n top ring beam. Top ring beam is Subjected to load from meridional thrust T,

in top ring beam is given by

Hence hoop tension

Water Tanks FE]

Hence maximum tension in wall

_YHD

a

Reinforcement is to be provided for the above forces on appropriate side. Provide minimum

reinforcement on the other side. To ensure the continuity in actual structure bars on inner face of tank

should be looped at comer and anchorage length is ensured.

Design of base slab depends on how it is supported. Fig. 13.15 shows different methods of

supporting base slab.

and cantilever moment is prmad.,

|

|

LLL

VILLEILITLITD

[Fae

(0) Section

BLD) Advanced R.C.C. Design

at lesser heights, circular

ted on wall: In smaller diameter Set pom design a

Bisa eens the tank along its rey ens The end condition may be assy :

we f ee eet ; tial moments are

circ a bjected to water pressure -adial and circumferent S are giy,

San Saran circular plate theory we know radial Biven

by the expressions

q an al

M, = £3+n)(@ -r’)

a

r

-—(1+3p)

16

= Load per unit area = y,, H + self weight

= Radius of bottom slab

H= Poissons ratio

2

Mo=4°-(3+H)

where

= Radial distance where values are required.

Radial and circumfe,

with appropriate steel,

(5) Tank supported

base slab with a rin,

ential reinforcement for the base slab may be designed. Tank wall is Provideq

on ring beam: In case of larger tanks it is econo

g beam of diameter 07

ported by a number of colu

by the arc between any two consecutive c

mical to support Circular

9 of the diameter of tank as shown in Fig. 13.14 (6). The

ins spaced at regular intervals. If 6 is the angle subtended

olumns at the centre of ring beam, then

Let support moment

Mid-span moment

and

Maximum torsional Moment = &” wR? o

© = The angle at which maximum twisting moment

moment occurs.

Then structural analysis (Ref, Structural Si :

of k, KY, k” and o, f

: ysis, Vol. II by i ing waited

‘OT various number of Columns used to en = eee eo

si a Si

aa aa tari.

ae a aWateriionieneias

Table 13.2 Coefficient for Bending Moment, Torsional Moments and Location of Point of Maximum

Torsion in Ring Beams

No. of Column ¢ k ke ike, @ for Maximum

__ Supports | (Degre Torsion

90 . 0.070 | 0.021 “19.25

5 72 0.108 0.054 0.150 15.25

6 60 0.089 0.045 0.009 12.75

8 45 0.066 0.030 0.005 9.33

10 36 0.054 0.023 0.003 7.50

12 36 0.045 0.017 0.002 6.25

It is to be noted that the section at which torque is maximum bending moment is zero and at

support there is no torsional moment.

In such case, slab may be analyzed by plate theory. Fig. 13.16 shows load on slab which consists

of total weight of dome, top ring beam and wall transferred at the edge of base slab and uniformly

distributed load of ¥,, H plus self weight. The slab is resting on ring beam of radius b. The total load on

ting beam from slab may be found which consists of total load on slab. Let it be W. Then slab is

analyzed as

Load from wall

Weight of water

ction from ring beam

Fig. 13.16

: : iphery by walls and subjected to y,, H plus self weight.

(® Circular slab simply supported at outer periphery “ :

(ii) Circular slab simply supported at outer periphery by walls and subjected to total ring load W at

a concentric circle of radius b.

In plate theory the expressions for moment for the above

Case I:

two cases are given below:

FED Advanced RC.6, Design —_

and

For case UH:

Forr)

m= Hlamet—(2) «(2)

2 2

aw Cs *) +2-(2)

and y= Main ( a

Note that in this case

M,=0 at r=a.

(©) Slab supported on four beams as shown in Fig. 13.15 (c)

© The slab between the beams has size

L= 2asin 45° = 3 a,

The square slab of size JZ

down. Sufficient reinforcem:

ax V2 ais designed as a two way slab with comers held

ent is provided in the beams to take up negative moment,

Gi) If Wis the total load of water and self weight of slab, each beam Carries a load of e ‘The

load is triangular in shape with maximum ordinate at mid span of beam. Hence maximum

moment in the beam is x x ew

hemes The beam is designed as a T-beam.

(d)

the slab and it acts as a T-beam.

The tank wall acts as a curved

and hence needs additional steel at top and bottom oft

(©) Slab supported on a number of be

in Fie

slab needs support from Several beams, arr: it of beams is shown st

(13.15. ¢). Each pane! of slab between: istics, Eccnione slab. The beams‘

designed as continuous beams subjected to ‘iangular loading. The tank wall is

additional steel to act as a beam.

a 2 Water Tanks PTD}

example 13.6: Design a flat bottom circular elevated water tank of diameter 10 m and total height

4 which is'0 be Sspporied by ring beam Of m Glameters The Ying beam Jet be support aoe

columns ee Placed. Use M25 concrete and Fe-413 steel. Design the following components of

water tan

(a) Top dome

(b) Top ring beam

(c) Olindrical walt

(d) Bottom slab

(e) Bottom ring beam.

Solution:

Diameter of tank = 10 m Radius a= 5m

H=4m.

Diameter of bottom ring beam =7.5 m

Radius b = 3.75 m

Concrete Mix:M 25 Steel: Fe-415

Design of Top Dome

Referring to Fig. 13.14,

D=10m 7 Dr say h=1.5 m.

R = radius of dome

2

Then QR -hyh= (3)

QR - 15) 15 =5?

2 2

Rare 9.083 m.

3 Se a+). 9083-15 0,

Semi central angle 8 = cos G+ cos 9083 = 33.4°.

Assuming thickness of dome 75 mm,

Self weight of dome = 0.075 x 1 x 1 x 25 = 1.875 kN/m?

Live load = LS kN/im?

Finishing load = 0.5 kN/m*

Total w= 3.875 kN/m*

Max, meridional thrust = "8 = 3825% 9.083 19.13 anim,

1+cos® 14005334

Maxi ‘ocunieausianee

\

i

p

EE) Advanced R.C.C. Design z a

1

= 3875 sonoma rie si]

= 10.202 kN/m.

18.93 x1000 9,959 N/mm?

1000 x 75

concrete in compression = 6 N/mm*, Hence safe.

. Maximum stress

Permissible stress in M25 c

-. Provide only nominal reinforcement of 8 mm dia at 180 mm c/c in both circumferentay

. :

meridional directions.

Design of Top Ring Beam

D

Hoop Tension = T, cos 8 =18.93 c0538.4 xe = 79.02 KN. !

|

79.02 1000 ; 1

150 7527 ma

Provide 6 bars of 12 mm.

A, provide = 6x Fi x12? = 678 mm?

280

m = modular ratio =

3x85

+. Area of concrete required is given by

79.02 1000 _

A. +11x678

EA A.= 53327 mm’,

Provide 250 mm x 300 mm top ring beam with 6 bars of 12 mm main reinforcement. Nominal

stirrups of 6 mm at 225 mm c/c are to be provided in the beam.

Design of Tank Wall

Depth of water tank =4m

and diameter of water tank =10m

~, Maximum hoop tension in the wall

—YhD_ 10

s Se = 196 kN/m

A. = 196x1000

150

= 1306 mm?

A,, on each face

= ee = 653

Using 12 mm bars spacing required is

nt 2

ali:

4

653 1000 = 173 mm.

Provide 12 mm bars at 170 mm c/c near base, on eacl

173xXh _173x4

300 300 =2.3 m below the top. In the top 2.3 m maintain 300 mm spacing.

h face. It may be gradually increased to 300

mm spacing at

Ext?

+ Ay provided at base = 4

x = 2

170 1000 = 665 mm‘

Let thickness of wall be #, Then to keep direct tension in wall within limiting value

1961000 _

10001 + 11 x 665

t= 188.7 mm.

Provide 200 mm thickness,

13

Vertical Steel

Bottom < = 1.333 m is under cantilever moment

2 2

Cantilever moment - me = Sextet = 11.61 kN-m

For M25 concrete and Fe-415 steel.

eye = 8.5 Nimm? m=11 6, = 150

n= 0.384 j=0872 and K= 1.423,

Effective depth d= 200-35 = 165

11.61x 10°

* =. = $3

Au 50x 08723165 7538 mm

E x10?

Using 10 mm bars s= 4 x1000 = 145 mm,

FEB Advanced R.C.C. Design

Ber

+ Minimum steel on each face = 300 mm?

T x10?

Using 10 mm bars ss an x 1000 = 261 mm.

Hence provide 10 mm bars at 130 mm e/c in the lower 1.3 m on inner face. Curtail alternate bees

On outer face provide 10 mm bars at 260 mm c/c.

Design of Base Slab

: D

Total load from dome =) sin 0x 2n >

= 19.18 sin 33.4 x 2m x 5 = 331.7 KN

Weight of ring beam = 0.25 x 0.30 x 2m x 5 x 25 = 58.90 kN

Weight of wall = 0.20 x (4 - 0.3) x 2m x 5.2 x 25 = 604.4 KN

Total weight = 995 kN

2 2

Weight of water =yHn np 98x41 so7aR KN

On edge of slab

Self-weight of slab: Assuming slab thickness

t

= = 0.29 m, say 300 mm.

Self-weight of slab =0.3X 11x25 =7.5 kNim

-- Total self-weight (Note, total slab diameter = 10 + 2 x 0.2 = 10.4 m)

= 15x 4x 104 = 637.1 KN.

Finishing load = 06x2 x10? = 47.1 kN.

+, Total downward load = 995 + 3078.8 + 637.1 + 47.1

= 4758 kN

“. Total upward force from ring beam = 4758 KN.

3763 kN

995 kN

102m

__Water Tanks FEE]

Fig.13.17 shows free body diagram of base slab in which total loads are indicated.

Now the slab may be treated as freely supported by walls and subjected to

( Uniformly distributed downward load of g = —3763_

~ = 46.05 kN/m?.

=x 102?

ax

(i) Upward ring load of W = 4758 kN,

For case (i) loading

2

= Sai a — 34a? qr’

M,= 76 (a? ~r?) and My = 16 16

where @ = 2 5.1m

:. Moments at critical Points are as listed below:

rinm 0 1.875 3.75 5.1

M,inkN-m 294.6 194.2 103.2 0

MjinkKN-m 224.6 214.5 184.1 149.7

In Case II,

For r < 3.75

For r > 3.75 :

ope) +]

Ww a (by by

= <|2log=-|"] 49_(2

me sree’-(2) +2-(2)

Noting that a = 5.1 m and bogs.

Moment at critical points are as listed below:

(Note: W upward. Hence may be taken as —ve)

rinm 0 1.875

M,inkN-m 201.4

-201.4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- WRE Precipitation Sums 2-12-2020Document8 pagesWRE Precipitation Sums 2-12-2020Akesh reddyNo ratings yet

- 2 Room EstimateDocument3 pages2 Room EstimateAkesh reddyNo ratings yet

- Air Quality and Emission StandardsDocument7 pagesAir Quality and Emission StandardsAkesh reddyNo ratings yet

- WRE 2 Assignment 1Document29 pagesWRE 2 Assignment 1Akesh reddyNo ratings yet

- Wre2 Assignment 2Document20 pagesWre2 Assignment 2Akesh reddyNo ratings yet

- 4 - 6 Civil EngineeringDocument7 pages4 - 6 Civil EngineeringAkesh reddyNo ratings yet

- EE Assignment 1Document43 pagesEE Assignment 1Akesh reddyNo ratings yet

- WRE Precipitation Sums 2-12-2020Document8 pagesWRE Precipitation Sums 2-12-2020Akesh reddyNo ratings yet

- FM 3 Assignment 2Document18 pagesFM 3 Assignment 2Akesh reddyNo ratings yet

- Rcs 2 Assignment 1 PDFDocument7 pagesRcs 2 Assignment 1 PDFAkesh reddyNo ratings yet

- Transportation Engineering Lab ManualDocument52 pagesTransportation Engineering Lab ManualAkesh reddyNo ratings yet

- Atginmu Cofoxnnin - Balaxn Qaugn Tawlslaphealk: DetinslepabuveDocument8 pagesAtginmu Cofoxnnin - Balaxn Qaugn Tawlslaphealk: DetinslepabuveAkesh reddyNo ratings yet

- FM 2 Lab Assignment PDFDocument15 pagesFM 2 Lab Assignment PDFAkesh reddyNo ratings yet

- GTE Assignment 2Document9 pagesGTE Assignment 2Akesh reddyNo ratings yet

- TE Assignment 2Document9 pagesTE Assignment 2Akesh reddyNo ratings yet

- GTE Assignment 7Document2 pagesGTE Assignment 7Akesh reddyNo ratings yet

- GTE Assignment 8Document4 pagesGTE Assignment 8Akesh reddyNo ratings yet

- GTE Assignment 4Document4 pagesGTE Assignment 4Akesh reddyNo ratings yet

- GTE Assignment 5Document4 pagesGTE Assignment 5Akesh reddyNo ratings yet