Professional Documents

Culture Documents

Thick Film Chip Resistors Spec Sheet

Uploaded by

Manuel VargasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thick Film Chip Resistors Spec Sheet

Uploaded by

Manuel VargasCopyright:

Available Formats

Thick Film Chip Resistors (RC Series)

Specification Sheet

□ Features

1. Small, thin and lightweight

2. High reliability

3. Applicable Both flow and reflow soldering.

4. Suitable size and package for surface mount assembly

5. RoHS Compliant.

□ Part Number Description

RC 0603 F 103 CS

Type (Series) Size : mm (inch) Tolerance Resistance Value Packing Type

General 0402 (01005) D ±0.5% CS 7” reel

RC purpose - 3-digit code

0603 (0201) F ±1.0% ES 10” reel

chip resistor (E-24,E-96 series)

1005 (0402) J ±5.0% AS 13” reel

- 4-digit code

1608 (0603) * Jumper : ‘J’ (E-96 series)

2012 (0805) - Jumper : ‘000’

3216 (1206)

3225 (1210)

5025 (2010)

6432 (2512)

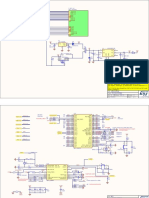

□ Structure and Dimension

[ Unit : mm ]

Size : mm L W T A B Weight(g/K)

RC0402 0.40±0.02 0.20±0.02 0.13±0.02 0.10±0.03 0.10±0.03 0.04mg

RC0603 0.60±0.03 0.30±0.03 0.23±0.03 0.10±0.05 0.15±0.05 0.15mg

RC1005 1.00±0.05 0.50±0.05 0.35±0.05 0.20±0.10 0.25±0.10 0.6mg

RC1608 1.60±0.10 0.80±0.10 0.45±0.10 0.30±0.20 0.35±0.10 2.1mg

RC2012 2.00±0.20 1.25±0.15 0.55±0.10 0.40±0.20 0.35±0.20 4.9mg

RC3216 3.20±0.20 1.60±0.15 0.55±0.10 0.45±0.20 0.40±0.20 9.5mg

RC3225 3.20±0.20 2.55±0.20 0.55±0.10 0.45±0.20 0.40±0.20 16mg

RC5025 5.00±0.20 2.50±0.20 0.55±0.10 0.60±0.20 0.60±0.20 26mg

RC6432 6.30±0.20 3.20±0.20 0.55±0.10 0.60±0.20 0.60±0.20 41mg

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

□ Applications and Ratings

Rated *MWV **MOV Tolerance T.C.R Resistance Working

Type

Power [W] [V] [V] [%] [ppm/℃] Range [Ω] Temp. [℃]

±300 1~99

RC0402 1/32 15 30

±1.0(F) ±250 100~1M

-55~125

±5.0(J) ±300 1~9.9

RC0603 1/20 25 50

±250 10~10M

RC1005 1/16 50 100

RC1608 1/10 50 100

RC2012 1/8 150 200

±0.5(D)

RC3216 ±300 1~9.9

1/4 200 400 ±1.0(F) -55~155

±100 10~10M

±5.0(J)

RC3225 1/3 200 400

RC5025 2/3 200 400

RC6432 1 200 400

1) The rated voltage should follow the formula 𝐸 = 𝑃 × 𝑅

In case the value exceeds the MWV, the MWV shall be regarded as the rated voltage

2) Moisture Level(1 Level)

3) *Max Working Voltage

4) **Max Overload Voltage

※ Please contact our sales representatives or engineers for other specifications

□ Rated Voltage

1. The rated voltage for resistor can be a DC continuous working voltage or AC(rms) voltage in

commercial line frequency wave form at rated power. It can be expressed as below.

𝐸 = 𝑃×𝑅 E : Rated Voltage[V] P : Rated Power[W] R : Nominal Resistance[Ω]

If the value calculated by the equation exceeds Max working Voltage, the rated voltage is limited

to max working voltage. In other words, the lower value is the rated voltage.

ex) For RC1608 Series [ P=0.1(W), Max working voltage = 50(V) ]

1) The rated voltage, when R=1KΩ 2) The rated voltage, when R=100KΩ

𝐸= 0.1 × 1000 = 10(𝑉) 𝐸= 0.1 × 100000 = 100(𝑉)

When the value is lower than MWV, When the value is higher than MWV,

The Rated voltage is 10(V) The Rated voltage is equal MWV, as 50(V)

2. When the rated voltage is applied to the resistor, check the ambient temperature and decrease

the lower according to the power derating curve.

3. If higher voltage than rated voltage, the reliability condition and performance cannot be

guaranteed.

4. If pulse wave is applied, the maximum pulse power should be below the rated voltage.

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

□ Power Derating Curve

Rated power shall be the load power corresponding to nominal watt suitable for continuous use at

70±2℃ ambient temperature, In case the ambient temperature exceeds 70±2℃, reduce the load

power in accordance with the derating curve

□ Jumper Ratings

Max Resista

Rated Working

Type Overload -nce

Current[A] Temp.[℃]

Current[A] [Ω]

1005 and 0402 -55 ~

bigger sizes 0.5 1

0603 125

1005

1 2

0402, 1608

0603 Max

size 2012 2 5 0.05 -55 ~

3216 155

3225

2 10

5025

6432

□ Standard Soldering Land Pattern

[ Unit : mm ]

Size Reflow Soldering

Type mm inch A B 2A + B C

RC0402 0402 01005 0.17 0.20 0.54 0.18

RC0603 0603 0201 0.37 0.28 1.02 0.29

RC1005 1005 0402 0.60 0.50 1.70 0.50

RC1608 1608 0603 0.80 0.80 2.40 0.80

RC2012 2012 0805 0.90 1.40 3.20 1.20

RC3216 3216 1206 1.30 1.80 4.40 1.50

RC3225 3225 1210 1.30 1.80 4.40 2.40

RC5025 5025 2010 1.40 3.30 6.10 2.40

RC6432 6432 2512 1.40 4.60 7.40 3.00

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

□ Performance characteristics

Requirements Test Conditions

ITEM

Specification (JIS C 5201-1)

DC resistance value should be JIS C 5201-1 4.5

Resistance

within the specified Voltage apply within 5sec

TCR should be within the JIS C 5201-1 4.8

Temperature Characteristic

specified T.C.R +20℃ → -55℃ / +20℃ → +125℃

JIS C 5201-1 4.13

△R should be within

Short time Overload 2.5 times of rated voltage

±(1.0%+0.1Ω)

5sec, 1cycle

New solder coated more than JIS C 5201-1 4.17

Solderability

95% of termination 245+5/-0℃, 2±0.5 sec

JIS C 5201-1 4.18

ΔR should be within Flow : Max 10sec

Resistance to Solder Heat

±(1.0%+0.05Ω) (260℃, Both side dipping)

Reflow : Max 10sec(230℃↑, 30sec)

ΔR should be within JIS C 5201-1 4.19

Temperature Cycle

±(1.0%+0.1Ω) -55℃ ↔ +125℃, 100 cycle

JIS C 5201-1 4.24

ΔR should be within Rated Voltage, 40±2℃, 90~95%RH,

Moisture Resistance

±(3.0%+0.1Ω) 1,000+48hours

90mins ON, 30mins OFF

JIS C 5201-1 4.25

ΔR should be within

Load Life Rated Voltage, 70±2℃, 1,000+48hours

±(3.0%+0.1Ω)

90mins ON, 30mins OFF

ΔR should be within JIS C 5201-1 4.23

High Temperature Exposure

±(3.0%+0.1Ω) 155±2℃, 1,000+48hours

※ The reliability test condition can be replaced by the corresponding accelerated test condition.

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

□ Taping & Packing

1. Quantity per Reel

Division Size (Inch) Thickness Taping type Pitch 7” Reel 10” Reel 13” Reel

1mm - - -

0402 (01005) 0.13 mm Paper

2mm 20K - 80K

1mm - - 150K

0603 (0201) 0.23 mm Paper

2mm 15K - 60K

1005 (0402) 0.35 mm Paper 2mm 10K 30K 40K

Chip Resistor 1608 (0603) 0.45 mm Paper 4mm 5K 10K 20K

2012 (0805) 0.55 mm Paper 4mm 5K 10K 20K

3216 (1206) 0.55 mm Paper 4mm 5K 10K 20K

3225 (1210) 0.55 mm Paper 4mm 5K 10K 20K

5025 (2010) 0.55 mm Embossed 4mm 4K - 15K

6432 (2512) 0.55 mm Embossed 4mm 4K - 15K

2. Cardboard(Paper) tape : 2mm pitch

[ Unit : mm ]

Size

A B W F E P1 P2 P0 D t

(Inch)

0402 0.24 0.45 0.31

(01005) ±0.03 ±0.03 ±0.02

0603 0.38 0.68 8.00 3.50 1.75 2.00 2.00 4.00 φ1.50 0.42

+0.10

(0201) ±0.05 ±0.05 ±0.10 ±0.05 ±0.10 ±0.05 ±0.05 ±0.10

/-0.03

±0.05

1005 0.65 1.15 0.43

(0402) ±0.10 ±0.10 ±0.07

※ According to normal size, we fill out A, B in the table above. The data may be varied with

special size tolerance.

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

3. Cardboard(Paper) tape : 4mm pitch

[ Unit : mm ]

Size

A B W F E P1 P2 P0 D t

(Inch)

1608 1.00 1.90 0.60

(0603) ±0.20 ±0.20 ±0.10

2012 1.65 2.40 0.75

8.00 3.50 1.75 4.00 2.00 4.00 φ1.50

(0805) ±0.20 ±0.20

±0.10 ±0.05 ±0.10 ±0.10 ±0.05 ±0.10 +0.10/-0.00

±0.10

3216 2.00 3.60 0.75

(1206) ±0.20 ±0.20 ±0.10

3225 2.90 3.60 0.75

(1210) ±0.20 ±0.20 ±0.10

※ According to normal size, we fill out A, B in the table above. The data may be varied with

special size tolerance.

4. Embossed(Plastic) tape

[ Unit : mm ]

Size

A B W F E P1 P2 P0 D t1 T0

(Inch)

5025 2.90 5.40 1.00 0.30

(2010) ±0.10 ±0.10

12.00 5.50 1.75 4.00 2.00 4.00 1.50 ±0.10 ±0.20

6432 ±0.20 ±0.05 ±0.10 ±0.10 ±0.05 ±0.10 ±0.10

3.30 6.60 1.00 0.30

(2512) ±0.10 ±0.10 ±0.10 ±0.20

※ According to normal size, we fill out A, B in the table above. The data may be varied with

special size tolerance.

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

5. Reel Dimensions

[ Unit : mm ]

Symbol Tape Width A B C D E W t

8mm φ180+0/-3 φ60±1.0 φ13.3±0.3 4±0.2 2.0±0.5 9±0.5 1.2±0.2

7” Reel

12mm φ180+0/-3 φ60±1.0 φ13.3±0.3 4±0.2 2.0±0.5 13±0.5 1.2±0.2

8mm φ258±3.0 φ81±1.0 φ13±0.3 4±0.2 2.0±0.5 9±0.5 1.8±0.2

10”Reel

12mm φ258±3.0 φ81±1.0 φ13±0.3 4±0.2 2.0±0.5 13±0.5 1.8±0.2

8mm φ330±2.0 φ100±1.0 φ13±0.5 4±0.2 3.3±0.5 9±0.5 2.2±0.2

13”Reel

12mm φ330±2.0 φ80±1.0 φ13±0.5 4±0.2 3.3±0.5 13±0.5 2.2±0.2

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

□ Precautions for Product Safety

1. The products are designed and produced for general electronic devices applications.

User must contact our sales in-charge before using our products, if there is a risk to occur critical

issues, such as casualties due to breakdown or malfunction of devices from application on products

demanding high reliability or other safety devices, also for complicated products such as

medical equipment, transportation equipment, an aircraft/spacecraft, an atomic energy

controller, a fuel controller, automobile equipment, military equipment, disaster/crime preventive

equipment.

2. The products are designed for use in the standard environment. Do not use products in specific

environment that can affect a product performance. If you need to use products in the

following conditions, please contact our sales in-charge in advance.

① Various types of liquid including water, oil, organic solvent and other chemicals.

② Direct sunlight, outdoors, or atmosphere with an amount of dusts.

③ An amount of corrosive gases such as sea breeze, Cl2, H2S, NH3, SO2, NO2, and etc.

④ Strong static electricity or electromagnetic waves

⑤ Heat-producing components or inflammable materials are close.

⑥ A resistor is sealed or coated with materials such as synthetic resin, and etc.

⑦ Water or water-soluble detergent is used for cleaning free soldering or flux coating after

⑧ Condensation phenomenon occurs on the object.

⑨ Out of the range from -55 °C to +155(125) °C

3. The products have no radiation resistance.

4. It is a must to notify the person in charge of sales of issues on product safety at any time.

In addition, a regular monitor for product safety should be conducted by customers.

□ Precautions regarding the use of products.

1. Product characteristics must be evaluated on a board mounted.

2. When transitory load is used in which short-time load is applied such as pulse, a resistor should

be tested on a board mounted. If load is higher than rated voltage under the load conditions at

continuous steps, it causes damages on characteristics or reliability of the resistor. Therefore,

when load exceed the rated voltage, it is not allowed to apply.

3. It is not recommended to use halogen products such as chlorine (Cl), bromine (Br), etc. or

fluxes that are highly active due to the residue that is able to affect the characteristics or

reliability of a resistor.

4. Be careful with the soldering condition to avoid the Ag-solder penetration problems.

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

5. When soldering manually, do not touch a resistor body with the edge of soldering iron directly.

When working with a soldering iron at high temperature, please be done with the work as

quick as possible.

6. Physical shocks to the resistor can cause the breaking of protective layers of the product and

affect its characteristic adversely. Therefore, use caution when picking and moving Chip-R with

hard instruments such as metal tweezers in order to avoid damages on a resistor or

degradation of product performance degradation.

7. Do not soak the resistor in a solvent for a long time. Also, the effect of solvent must be

checked prior to use.

8. Place products carefully to keep the standard temperature range in the category, otherwise

increasing temperature caused by adjacent heat-generating components can exceed the

temperature range. In addition, do not place or install heat-emitting components or flammable

materials such as plastic coating wires near these products.

9. Safety can be guaranteed only when average power is lower than rated power, and if power

exceeding the rated power is applied, please make sure to make an inquire on surge voltage or

a current waveform for a short time.

□ Recommendation for temperature/humidity

Even taping and packaging materials are designed to endure a long-term storage, they should

be stored with a temperature of 0~40°C and an RH of 0~70% otherwise, too high temperatures

or humidity may deteriorate the quality of the product rapidly.

As oxidization is accelerated when relative humidity is above 70%RH, the lower the humidity is,

the better the solderability is.

As the temperature difference may cause dew condensation during the storage of the product,

it is a must to maintain a temperature control environment.

□ Shelf life

An allowable storage period should be within 6 months from the outgoing date of delivery in

consideration of solderability.

It can be stored for a long time in vacuum at room temperature, but if vacuum condition is not

available, it is recommended to be stored in a dry condition inside desiccator.

As for products in storage over 6 months, please check solderability before use.

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

Thick Film Chip Resistors (RC Series)

1. The product specifications are subject to change, modify or suspend at any time without prior

notice by our company. Hence, it is a must to get approval of the product specifications before

making orders for products. For more inquires on the product specifications, please contact

our sales in-charge or engineer (AE).

2. Without our permission, any copies, duplications, use or transmission of contents or

information contained in this specification (catalog) for any purpose are prohibited.

3. No responsibility shall be held for any claims, disputes, damages or liabilities arising from or

related to the misuse of the Products and or information contained in this Specification

(Catalog). In addition, regarding the use of the products and information contained in this

Specification (Catalog), no liability shall be held for any claims, disputes, damages or liabilities

relating to our or any third party ’ s intellectual property rights or other related rights.

4. Bilateral discussions shall be required in case there are unmarked or uncertain parts in the

specification (catalog).

Samsung Electro-Mechanics. All rights reserved. ww w. Samsungsem.com

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- RC_Series_dsDocument6 pagesRC_Series_dsAda LakNo ratings yet

- rc_series_20150401_1Document7 pagesrc_series_20150401_1Владимир ТимофеевNo ratings yet

- Component Identification ElectronicsDocument23 pagesComponent Identification ElectronicsManjunatha Swamy VNo ratings yet

- WW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Document8 pagesWW25W, WW20W, WW10W, WW12W, WW08W, WW06W 1%, 5%Fazli WadoodNo ratings yet

- General Purpose Multilayer Ceramic CapacitorsDocument26 pagesGeneral Purpose Multilayer Ceramic CapacitorsparapNo ratings yet

- SR12X2201FTLDocument9 pagesSR12X2201FTLnguyen.nguyennguyuyenNo ratings yet

- Avxc S A0002375768 1Document12 pagesAvxc S A0002375768 1Belen Dall OglioNo ratings yet

- Ucr E-1139189Document8 pagesUcr E-1139189João JoséNo ratings yet

- Ucr E-1815979Document8 pagesUcr E-1815979João JoséNo ratings yet

- SMD - Resistors: Pulse Withstanding Thick Film Chip ResistorDocument9 pagesSMD - Resistors: Pulse Withstanding Thick Film Chip ResistormasakpNo ratings yet

- MT Series: SpecificationsDocument2 pagesMT Series: SpecificationsEnrique Sanchez (KicKeWoW)No ratings yet

- DatasheetDocument1 pageDatasheetStuxnetNo ratings yet

- ASC - General - Purpose - Capacitor For HallsensorDocument19 pagesASC - General - Purpose - Capacitor For HallsensorLusiNo ratings yet

- Walsin Tech Corp 0402B473K160CT - C338148Document20 pagesWalsin Tech Corp 0402B473K160CT - C338148Fazli WadoodNo ratings yet

- NIC Components NCC SeriesDocument3 pagesNIC Components NCC SeriesNICCompNo ratings yet

- Cyntec - Resistors CatalogDocument15 pagesCyntec - Resistors CatalogJaime Misael JalifeNo ratings yet

- Capacitors SMD TableDocument15 pagesCapacitors SMD TableEdgar DauzonNo ratings yet

- Resistencias SMD WIN-1524917Document4 pagesResistencias SMD WIN-1524917Ignacio Barriga NuñezNo ratings yet

- Current Sense Low Value Resistors: Part Number StructureDocument3 pagesCurrent Sense Low Value Resistors: Part Number StructureraveendraNo ratings yet

- DatasheetDocument16 pagesDatasheetErick MauricioNo ratings yet

- Multilayer Chip Capacitors X7R/B Characteristic: FeaturesDocument17 pagesMultilayer Chip Capacitors X7R/B Characteristic: FeaturesLupita Motta TobíasNo ratings yet

- TAJ Series: Standard TantalumDocument5 pagesTAJ Series: Standard TantalumPankaj MaithaniNo ratings yet

- Metal Film Precision MELF Resistor AEC-Q200 Qualified for AutomotiveDocument13 pagesMetal Film Precision MELF Resistor AEC-Q200 Qualified for AutomotivecutoNo ratings yet

- Chip Resistors Guide: Dimensions, Specs & ApplicationsDocument6 pagesChip Resistors Guide: Dimensions, Specs & ApplicationsmanivelcNo ratings yet

- TR1210B100RP0550ZDocument9 pagesTR1210B100RP0550Znguyen.nguyennguyuyenNo ratings yet

- NIC Components NRE-LW SeriesDocument5 pagesNIC Components NRE-LW SeriesNICCompNo ratings yet

- Film Resistors MR Series: Metal Film: FeaturesDocument1 pageFilm Resistors MR Series: Metal Film: FeaturesGeorge Ribeiro Lucas GeorgeNo ratings yet

- Resistor SMD SizesDocument11 pagesResistor SMD Sizescarlos.antouryNo ratings yet

- Surface Mount PowerDocument5 pagesSurface Mount PowerM UMAR ABBASINo ratings yet

- Type CRGP Series: SMD Precision Pulse Thick Film Chip ResistorDocument10 pagesType CRGP Series: SMD Precision Pulse Thick Film Chip Resistorm3y54mNo ratings yet

- SMDC01005 ElectronicDocument10 pagesSMDC01005 ElectronicMariaNo ratings yet

- Resistor DatacsheetDocument4 pagesResistor DatacsheetNhan NguyenNo ratings yet

- Cap 220pF 2kVDocument12 pagesCap 220pF 2kVJoão Oliveira BentesNo ratings yet

- Performance EMI Filter: Single-Phase FiltersDocument4 pagesPerformance EMI Filter: Single-Phase FiltersbobmarllyNo ratings yet

- TAJ Series: Standard TantalumDocument5 pagesTAJ Series: Standard TantalumFaraz ElectronicNo ratings yet

- Data Sheet: Lead Free Chip ResistorsDocument8 pagesData Sheet: Lead Free Chip ResistorsDarwin SipayungNo ratings yet

- Bourns SDR0302-471KLDocument2 pagesBourns SDR0302-471KLJoseph Abou El OulaNo ratings yet

- Radial Lead Varistor (MOV) : 10 - D - XXX - K - X - X - XDocument6 pagesRadial Lead Varistor (MOV) : 10 - D - XXX - K - X - X - XYCCA 2015No ratings yet

- And LC1205-T005Document1 pageAnd LC1205-T005honda freedNo ratings yet

- 180 - 12000uf, 6.3V - 35VDocument5 pages180 - 12000uf, 6.3V - 35VPadmajan YesodharanNo ratings yet

- Capacitor 4700uf 63VDocument13 pagesCapacitor 4700uf 63VEdwar OrtegaNo ratings yet

- Multilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs ComplianceDocument9 pagesMultilayer Ceramic Capacitors Soft Termination High Voltage Series (SH) X7R Dielectric 0805 To 1812 Sizes, 500V To 3Kv Rohs CompliancerezaNo ratings yet

- Thick Film Chip Resistors: NEW 01005 Case SizesDocument5 pagesThick Film Chip Resistors: NEW 01005 Case SizesNICCompNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- RC1005F561CSDocument2 pagesRC1005F561CSDarwin SipayungNo ratings yet

- Reinforced concrete shear design parametersDocument1 pageReinforced concrete shear design parametersMyat Thu Zar KhineNo ratings yet

- Thick Film Chip Resistors: FeatureDocument3 pagesThick Film Chip Resistors: Featurecodap90056No ratings yet

- Varistors Data SheetDocument11 pagesVaristors Data SheetEdilsonMatiasdeCastroNo ratings yet

- CDE [smd] AVRF SeriesDocument3 pagesCDE [smd] AVRF Seriesjghjkhgkh87No ratings yet

- Precision Metal Film Fixed Resistor Axial Leaded: FeaturesDocument21 pagesPrecision Metal Film Fixed Resistor Axial Leaded: FeaturesJonathan Llewellyn AndradaNo ratings yet

- TAJ Series: Standard TantalumDocument7 pagesTAJ Series: Standard TantalumrmNo ratings yet

- Beryl (Radial Thru-Hole) JE SeriesDocument2 pagesBeryl (Radial Thru-Hole) JE Seriesester853No ratings yet

- Taj 776811Document8 pagesTaj 776811balajiboss005No ratings yet

- RDE Vitrohm PDFDocument2 pagesRDE Vitrohm PDFtecnico4 tecnico4No ratings yet

- RDE Vitrohm PDFDocument2 pagesRDE Vitrohm PDFtecnico4 tecnico4No ratings yet

- C7025 (英文) ver1 6Document11 pagesC7025 (英文) ver1 6顏健軒No ratings yet

- Inductor Automotive Decoupling mlz2012 enDocument12 pagesInductor Automotive Decoupling mlz2012 enFurkan Berk KayaNo ratings yet

- TE SeriesDocument8 pagesTE SeriesANIL ŞENNo ratings yet

- Ref - Manual - rm0367 Ultralowpower stm32l0x3 Advanced Armbased 32bit Mcus StmicroelectronicsDocument1,043 pagesRef - Manual - rm0367 Ultralowpower stm32l0x3 Advanced Armbased 32bit Mcus StmicroelectronicsManuel VargasNo ratings yet

- MB1136Document4 pagesMB1136laurentiu.melinteNo ratings yet

- dm00104451 Cortexm0 Programming Manual For stm32l0 stm32g0 stm32wl and stm32wb Series Stmicroelectronics PDFDocument110 pagesdm00104451 Cortexm0 Programming Manual For stm32l0 stm32g0 stm32wl and stm32wb Series Stmicroelectronics PDFxvehicleNo ratings yet

- STM32L053R8Document136 pagesSTM32L053R8Armando BaronNo ratings yet

- Buc Fet 11314LDocument2 pagesBuc Fet 11314LAltab HussainNo ratings yet

- BLUESUN Specification BSM-3500 5500LV Off Grid InverterDocument1 pageBLUESUN Specification BSM-3500 5500LV Off Grid InverterFadi RamadanNo ratings yet

- Brochure Commerciale Studer Next 3Document12 pagesBrochure Commerciale Studer Next 3SINES FranceNo ratings yet

- BT138FDocument7 pagesBT138FMiloud ChouguiNo ratings yet

- DC Flashover Characteristics of A Polymeric InsulatorDocument7 pagesDC Flashover Characteristics of A Polymeric InsulatorKostas GekasNo ratings yet

- EE Assignent No. 2Document11 pagesEE Assignent No. 2Noor FatimaNo ratings yet

- DC Drive Installation and Operating ManualDocument12 pagesDC Drive Installation and Operating ManualStherzitha SaOtNo ratings yet

- Telcordia Qualification and Beyond Reliability ofDocument12 pagesTelcordia Qualification and Beyond Reliability ofmwuestNo ratings yet

- 230V Central Battery System: Installation Programming UseDocument39 pages230V Central Battery System: Installation Programming UseThanosEleftheroudisNo ratings yet

- List of Derivations Part-1 XiiDocument2 pagesList of Derivations Part-1 XiiTanishq VermaNo ratings yet

- (John Norrish) Advanced Welding Processes (BookFi) - Pages-85-91Document7 pages(John Norrish) Advanced Welding Processes (BookFi) - Pages-85-91Yusuf DarellNo ratings yet

- Volex Accessories PDFDocument1 pageVolex Accessories PDFNithin M NambiarNo ratings yet

- 1 MHZ Bandwidth, Galvanically Isolated Current Sensor Ic in Small Footprint Soic8 PackageDocument18 pages1 MHZ Bandwidth, Galvanically Isolated Current Sensor Ic in Small Footprint Soic8 PackageIvana PrezimeNo ratings yet

- PDF Aviation& Electronic Parts Lookup NSN Parts LookupDocument104 pagesPDF Aviation& Electronic Parts Lookup NSN Parts LookupnsnpartslookupNo ratings yet

- Coil Press Machine CP-400Document6 pagesCoil Press Machine CP-400Mikhail YudhiantaraNo ratings yet

- LM-D2360 D2560aDocument66 pagesLM-D2360 D2560aanon_30516784No ratings yet

- Sliding Contact DeviceDocument32 pagesSliding Contact DevicebaliamajhiNo ratings yet

- Challenges of CMOS Technology - FarhanaDocument12 pagesChallenges of CMOS Technology - FarhanaaliffpadziNo ratings yet

- Expandable Intermediate Relay for Reliable Signal Transmission and Electrical IsolationDocument2 pagesExpandable Intermediate Relay for Reliable Signal Transmission and Electrical IsolationdkshtdkNo ratings yet

- Instruction Manual Fisher 4200 Electronic Position Transmitters en 124158Document44 pagesInstruction Manual Fisher 4200 Electronic Position Transmitters en 124158Peter RhoadsNo ratings yet

- Trio-20.0-27.6 ErrorDocument9 pagesTrio-20.0-27.6 ErrorRUCNo ratings yet

- UntitledDocument12 pagesUntitledFidya Eka PrahestiNo ratings yet

- Checking battery control unitDocument3 pagesChecking battery control unitjuanNo ratings yet

- Poornima College of Engineering Submitted To Submitted BYDocument16 pagesPoornima College of Engineering Submitted To Submitted BYrs sNo ratings yet

- Classifying Amplifiers by Configuration and OperationDocument8 pagesClassifying Amplifiers by Configuration and OperationElaine BicolNo ratings yet

- Electromagnetic Propagation PDFDocument27 pagesElectromagnetic Propagation PDFAbed ShaarNo ratings yet

- Ecd Final PJT ReportDocument7 pagesEcd Final PJT ReportZain UddinNo ratings yet

- Lab 4 OpAmps1Document5 pagesLab 4 OpAmps1Hafsa ZahidNo ratings yet

- JZC 33f PDFDocument1 pageJZC 33f PDFMamour brshimNo ratings yet

- Speed Control of A Separately Excited DC MotorDocument2 pagesSpeed Control of A Separately Excited DC MotorKashyap SrishaNo ratings yet

![CDE [smd] AVRF Series](https://imgv2-2-f.scribdassets.com/img/document/727235082/149x198/c18e6e118b/1714248450?v=1)