Professional Documents

Culture Documents

2247

2247

Uploaded by

Roberto De Mesa P0 ratings0% found this document useful (0 votes)

17 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 page2247

2247

Uploaded by

Roberto De Mesa PCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

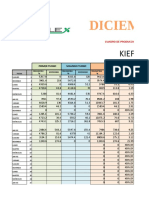

ari820%6 Dow DOWLEX™ 22476 Polyethylene Resin

Dow DOWLEX™ 2247G Polyethylene Resin

Categories: Polymer; Film; Thermoplastic; Polyethylene (PE); LLDPE

Material Next Generation DOWLEX™ 2247G Polyethylene Resin with Extra Stretch Performance (ESP) is an

Notes: ethylene-octene-1 copolymer designated for cast stretch film applications, such as industrial pallet

wrap, DOWLEX 2247G provides stretch films with superior extensibility and increased resistance to

failure around film flaws while maintaining exceptional puncture resistance and load retention,

Information provided by Dow

Vendors: No vendors are listed for this material. Please olick here if you are a supplier and would like

information on how to add your listing to this material

Physical Properties Metric English Comments

Density 0.917 g/cc 0.0331 Ib/in® ‘ASTM D792

Thickness 58.4 microns 2.30 mil

Melt Flow 2.3 g/10 min 2.3 g/10 min ASTM D1238

Mechanical Properties Metric English Comments

Film Tensile Strength at Yield, MD 9080MPa___1317 psi "ASTM D882

Film Tensile Strength at Yield, TD 8.846MPa 1283 psi ASTM D882

Film Elongation at Break, MD 432% 432 % ASTM D882

Film Elongation at Break, TD 705 % 705 % ASTM D882

Impact 321 321 [ftbflin’}; Puncture Resistance; Dow Method

2060 2060 [ft-bt/in®]; Toughness MD; ASTM D882

2653, 2653 [ft-bt/in’]; Toughness TD; ASTM D882

Elmendorf Tear Strength MD 2959 2959 ASTM D1922

Elmendor Tear Strength TD 5589 558 g ASTM D1922

Elmendorf Tear Strength, MD 5.05 g/micron 128 g/mil ASTM D1922

Elmendor Tear Strength, TD 9.55 gimioron 243 g/mil ASTM 01922

Dart Drop Test 148g 0.326 Ib Method B; ASTM D1709

Film Tensile Strength at Break, MD 50.11MPa 7268 psi ‘ASTM D882

Film Tensile Strength at Break, TD 36.9MPa 5210 psi ‘ASTM D882

Thermal Properties Metric English Comments

Melting Point 123°C 253 °F Dow Method (DSC)

Vicat Softening Point 99.0°C 210°F ASTM D1525

Optical Properties Metric English Comments

Haze 0.80 % 0.80% ‘ASTM D1003

Gloss 94.6 % 94.6% 45°; ASTM D2457

‘Some ofthe values displayed above may have been converted from thelr orginal uns andlor rounded in order daplay the information in a

consistent format. Users requiing more precse data far scientific or engineering calculations can cick on the property value fo see the arginal

Value as well as raw conversions to equvvalent unis. We advise that you only use the orginal value or one of ts raw conversions n your

Caleulations to minimize rounding ero” We also ask that you refer to MatWeb's terms of use regarding tis formation. Click have to vew all the

Property valugs for this datasheet as they were arginaly entered into MatWeb.

ip hwwrw matweb.comisoarchidatashool print asex?matguic=7200a 176-2054 tad 12bd81 41012

"

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- RAT11h-17mic UltDocument3 pagesRAT11h-17mic UltRoberto De Mesa PNo ratings yet

- Diciembre - Produccion Mensual ExtrusionDocument9 pagesDiciembre - Produccion Mensual ExtrusionRoberto De Mesa PNo ratings yet

- RobustDocument247 pagesRobustRoberto De Mesa PNo ratings yet

- Analisis Por Mes Produccion y Scrap Sellado 2012Document6 pagesAnalisis Por Mes Produccion y Scrap Sellado 2012Roberto De Mesa PNo ratings yet

- Presupuesto Luminarias MP SigmaplastDocument2 pagesPresupuesto Luminarias MP SigmaplastRoberto De Mesa PNo ratings yet

- Technical Data Sheet: Random Copolymer Esenttia 07R87Document1 pageTechnical Data Sheet: Random Copolymer Esenttia 07R87Roberto De Mesa PNo ratings yet

- ModeloDocument2 pagesModeloRoberto De Mesa PNo ratings yet

- XZ 89495.00Document2 pagesXZ 89495.00Roberto De Mesa PNo ratings yet

- Pdiol 2008dec24 Supply An 01Document3 pagesPdiol 2008dec24 Supply An 01Roberto De Mesa PNo ratings yet

- Linear Low Density Polyethylene SLL318: DescriptionDocument1 pageLinear Low Density Polyethylene SLL318: DescriptionRoberto De Mesa PNo ratings yet

- ATTANE™ 4404G: Ultra Low Density Polyethylene ResinDocument3 pagesATTANE™ 4404G: Ultra Low Density Polyethylene ResinRoberto De Mesa PNo ratings yet

- Linear Low Density Polyethylene LL318: DescriptionDocument1 pageLinear Low Density Polyethylene LL318: DescriptionRoberto De Mesa PNo ratings yet

- Exceed™ 2718CB: Metallocene Polyethylene ResinDocument2 pagesExceed™ 2718CB: Metallocene Polyethylene ResinRoberto De Mesa PNo ratings yet

- ELITE™ AT 6111: Enhanced Polyethylene ResinDocument3 pagesELITE™ AT 6111: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- Certene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneDocument1 pageCertene™ Llgf-220A: Muehlstein - Linear Low Density PolyethyleneRoberto De Mesa PNo ratings yet

- ELITE™ 5230G: Enhanced Polyethylene ResinDocument3 pagesELITE™ 5230G: Enhanced Polyethylene ResinRoberto De Mesa PNo ratings yet

- 733 2abDocument2 pages733 2abRoberto De Mesa PNo ratings yet

- Pa003en Rev05 PP5231HMDocument1 pagePa003en Rev05 PP5231HMRoberto De Mesa PNo ratings yet

- Tricolene LLB1918ADocument1 pageTricolene LLB1918ARoberto De Mesa PNo ratings yet

- 725 1NTDocument8 pages725 1NTRoberto De Mesa PNo ratings yet

- 665 7BLDocument2 pages665 7BLRoberto De Mesa PNo ratings yet

- Termo HDPE Transparente 440x50 20-04-12 Formato Ficha TecnicaDocument1 pageTermo HDPE Transparente 440x50 20-04-12 Formato Ficha TecnicaRoberto De Mesa PNo ratings yet