Professional Documents

Culture Documents

Residential Regulator: Applications Description

Uploaded by

Miguel Angel Morales CastroOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Residential Regulator: Applications Description

Uploaded by

Miguel Angel Morales CastroCopyright:

Available Formats

Gas

RB 1200

Residential Regulator

Applications Description

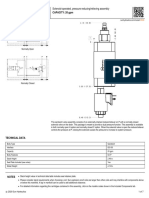

The RB 1200 regulator is designed for The RB 1200 regulator is a spring-loaded self

residential and light commercial applications. operated regulator with internal relief and a safety

Its valve design makes it specially suitable shut-off device. It is fitted with an inlet strainer.

for medium-pressure service lines where it The safety shut-off valve cuts the gas flow

accomodates large inlet pressure variations when the outlet pressure exceeds the set

while keeping very constant outlet. pressure (OPSO) or when it drops below the

The RB 1200 offers two connection styles set value (UPSO). It remains closed until the

providing flexibility for meter mounting or valve is reset manually. Its internal relief valve

integration in compact meter boxes. (SRV) avoids triggering the safety shut-off valve

in case of thermal expansion, transient surges

of pressure, and creep leaks from regulator.

Technical Features

Maximum inlet pressure 10 bar

Outlet pressure 13 mbar – 135 mbar

Accuracy & lock-up pressure Up to AC5 / up to SG10

Operating temperature -20°C to +60°C

Acceptable gases Natural gas, propane, butane, air, nitrogen

Safety devices Standard relief valve

Optional built-in safety shut-off valve:

- Over-pressure shut-off (OPSO)

- Under-pressure shut-off (UPSO)

Sizes & Connections

4 5

Sizes DN 20 combi-body or DN 32 in-line body

Connection Combi-body: internal thread ISO 7 - Rp 3/4 3

In-line body: external thread ISO 7 - Rp 1 1/4 14

2

15

Materials

Body/Actuator Die cast aluminium 1

Seals Nitrile 12

Diaphragms Nitrile

16

Option Designations 13

9

RB 1210 with SRV

RB 1211 with OPSO and SRV 10 7

RB 1212 with OPSO, UPSO and SRV

11 8

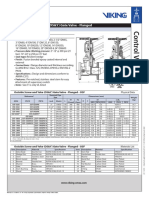

Operating Principle

The pressure reduction takes place between prevent unauthorized intervention. Optionally,

> B 1200 with built-in safety the seat and the tubular nozzle (1). The valve the rod (12) controlled by the diaphragm

shut-off valve disc position is controlled by the diaphragm (2) assembly triggers the slam shut valve when

which senses the outlet pressure on one side outlet pressure drops below a set point defined

and is loaded by the spring (3) on the other so as to overcome the load of spring (13). The

> For residential applications side. The spring load is adjustable by the nut (4). set point is factory preset and cannot be

> Angle or in-line design The cap (5) can be sealed to prevent adjusted on site.

> Built-in shut-off valve unauthorized intervention. A safety relief valve is built into the diaphragm

By design the tubular nozzle is balanced assembly. When the outlet pressure build-up over

> Internal relief

against inlet pressure differentials. the set point exceeds the load of the spring (14),

> Inlet strainer

Safety the diaphragm plate moves while the stem is

> Adjustable on site

The slam shut valve (7) shuts the gas flow off stopped, thus opening a passage between the

tight in case of excess of outlet pressure, which orifice (15) and the plug.

is sensed by the diaphragm (8). The load of Gas is released to atmosphere through the

the shut-off valve spring (9) is adjustable by breather tap.

the nut (10). The cap (11) can be sealed to A 100 μm strainer (16) protects the regulator on

w w w . i t r o n . c o m the inlet side.

Gas

Typical Regulation Curve (22 mbar set point)

26

25

24

Outlet Pressure - mbar

23

22

21

20

19 5 bar

18

17 2 bar

200 mbar 400 mbar 1 bar

16

0 5 10 15 20 25

Rate of flow - m3/h in standard conditions - 0.6 SP.GR.GAS

Outlet Pressure Range

Regulator

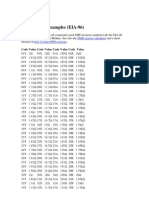

Spring Code Spring Characteristic Spring Range

Spring characteristics: d De Lo Lt

d : wire diameter (mm) (mm) (mm)

De : external diameter 20564241 1.5 30 80 9.5 13 - 20 mbar

Lo : height 20564141 1.6 30 80 9.5 18 - 29 mbar

20564243 1.7 30 80 7.5 27 - 46 mbar

Lt : no. of spires 20564142 1.8 30 80 8.5 31 - 52 mbar

20564050 1.8 30 100 10 45 - 60 mbar

20564051 2 30 100 11.5 60 - 85 mbar

Standard conditions: 20564044 2.2 30 80 9 82 - 135 mbar

• Absolute pressure of 1.013 bar

• Temperature of 15°C Safety Shut-off Valves

Over Pressure Shut-off Springs (OPSO)

Spring Code Spring Characteristic Spring Range

Correction factor for d De Lo Lt

(mm) (mm) (mm)

non-natural gas applications: 20561915 0.9 18 25 6.5 30 - 41 mbar

The flow rates are indicated for a 0.6 specific 20562018 1 18 25 6.5 38 - 56 mbar

20562015 1 18 30 6.5 55 - 80 mbar

gravity gas. 20562020 1.1 18 30 6.5 70 - 120 mbar

To determine the volumetric flow rate for 20562019 1.2 18 25 5.5 115 - 135 mbar

gases other than natural gas, multiply or

calculate the values in the capacity tables Under Pressure Shut-off Springs (UPSO)

using the sizing equations with a correction The set point of the under-pressure shut-off valve is not adjustable and is preset at the factory.

factor. The differential pressure between the regulator and UPSO set points is indicated in the following table.

The level of pressure differential - low, medium, high - can be selected to suit the application.

The table below lists correction factors for

Reg Spring Differential (mbar) Reg Spring Differential (mbar)

some common gases:

Code Low Med High Code Low Med High

Gas type Specific Correction 20564241 8 15 20 20564050 20 25 30

gravity factor 20564141 10 20 25 20564051 40 50 55

20564243 25 35 40 20564044 55 65 70

Air 1.00 0.77 20564142 20 30 35

Butane 2.01 0.55

Carbon dioxide (dry) 1.52 0.63 Relief Valve

Carbon monoxide (dry) 0.97 0.79

Spring Code Relief Set Pressure*

Natural gas 0.60 1.00

955-203-36 10 mbar over set point

Nitrogen 0.97 0.79

Propane 1.53 0.63 * Other settings available on request

Propane-Air mix 1.20 0.71

Specific gravity or relative density Flow Capacity

(air = 1, non-dimensional value)

RB 1200 set at 22 mbar - model with built-in SSV

Use the following formula to calculate the I nlet Pressure Capacities (m3/h)

at Standard Conditions

correction factor for gases not listed above.

200 mbar 7

In the formula, d is the specific gravity of 400 mbar 10.5

the gas. 1 bar 14

2 bar 20

Correction factor = 0.6

d 4 bar 30

Capacities at 4 mbar droop.

Overall Dimensions & Fittings Ø 150

Various additional fittings are available for inlet and outlet connections as shown below. Other

possibilities can be provided on request.

180

Rp 3/4

DN

DN

50

40 A A A 89 36

125

> Fig 1 > Fig 2 > Fig 3

> Mod. 1211-1212 - Weight 1.1 Kg

Inlet fitting type See Fig A (mm)

Three-piece coupling welded on DN 20 pipe 1 104

Three-piece coupling welded on DN 25 pipe 1 113

DN 20 sphero-conical coupling 2 110

DN 25 sphero-conical coupling 2 115

130

External thread ISO Rp-3/4 3 107

Outlet fitting type

Gas meter union G 1 1/4

External thread ISO R7 Rp 3/4

> Mod. 1210 - Weight 1 Kg

Installation

Gas must flow through the valve body in the

same direction as the arrow cast on the body.

The RB 1200 regulator can be mounted in

any position. The set point must be adjusted

slightly if the regulator is positioned so that

the loading spring is not vertical and pointing

upwards.

When changing the connection style (in-line or

angle), ensure there are no leaks and that all

connections are tight.

> Typical meter box installation

Information to be specified

when ordering:

- Regulator type code

- Minimum and maximum inlet

pressures

- Outlet pressure range

- Outlet pressure setting

- Connection type

• OPSO setting*

• UPSO setting*

* (if requested)

About Itron Inc.

Itron Inc. is a leading technology provider to the global energy and water industries. Our company is the world’s leading provider of metering, data collection and utility software solutions,

with nearly 8,000 utilities worldwide relying on our technology to optimize the delivery and use of energy and water. Our products include electricity, gas and water meters, data collection

and communication systems, including automated meter reading (AMR) and advanced metering infrastructure (AMI); meter data management and related software applications; as well

as project management, installation, and consulting services. To know more, start here: www.itron.com

For more information, contact your local sales representative or agency.

Itron GmbH.

Hardeckstraße 2

D-76185 Karlsruhe

Germany

Phone: +49-721 5981 0

Fax: +49-721 5981 189

www.itron.com

© Copyright 2010, Itron. All Rights Reserved. - Itron reserves the right to change these specifications without prior notice. GA-RB-1200-EN-V1.2-2010.05

You might also like

- RB 2000 ActDocument6 pagesRB 2000 ActArbaz KhanNo ratings yet

- 1264 Dival507ct Eng Apr16Document12 pages1264 Dival507ct Eng Apr16raquel.mc2No ratings yet

- Model Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPMDocument7 pagesModel Solenoid Operated Ventable Relief Assembly: CAPACITY: 30 GPManandsubbiahNo ratings yet

- STAUFF One - Diagtronics - ENDocument2 pagesSTAUFF One - Diagtronics - ENJANANI ASSOCIATESNo ratings yet

- WMR (G) / NL: Residential RegulatorDocument4 pagesWMR (G) / NL: Residential RegulatorMiguel Angel Morales CastroNo ratings yet

- Pressure Regulators: Type FLDocument20 pagesPressure Regulators: Type FLRinnoNo ratings yet

- Danfoss RTDocument12 pagesDanfoss RTSerge Yannick MimboeNo ratings yet

- Camozzi 951-000Document8 pagesCamozzi 951-000Mohammad Adeel KhanNo ratings yet

- Gas Pressure Regulator RS 250 / RS 251: Product InformationDocument24 pagesGas Pressure Regulator RS 250 / RS 251: Product InformationNaseer HydenNo ratings yet

- 038 Pozicioner RTX 1200 EngDocument16 pages038 Pozicioner RTX 1200 EngICE MEDIA CONCEPTNo ratings yet

- Prince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyDocument15 pagesPrince Hydraulics - Sectional Body Series 20 Offered by PRC Industrial SupplyPRC Industrial Supply100% (1)

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- 800D SeriesDocument3 pages800D Seriesvkeie0206No ratings yet

- NZ/NZ-M and NZOS/NZOS-M Series: Pressure Reducing RegulatorsDocument49 pagesNZ/NZ-M and NZOS/NZOS-M Series: Pressure Reducing Regulatorsmohana priyaNo ratings yet

- Data Sheet S7 - 2020 - ENG - Light - CavagnaDocument12 pagesData Sheet S7 - 2020 - ENG - Light - CavagnaWND PRTMNo ratings yet

- FP 400e-6dDocument4 pagesFP 400e-6dRICHINo ratings yet

- 0050en Vfa Im LRDocument8 pages0050en Vfa Im LRnitsabhiNo ratings yet

- Model 2400 D: Pneumatic Indicating RelayDocument4 pagesModel 2400 D: Pneumatic Indicating Relayzinstr1No ratings yet

- Banco Con Control Electrico Proporcional L218Document60 pagesBanco Con Control Electrico Proporcional L218Agustín TorresNo ratings yet

- Ir 3 5 DN 32 100Document9 pagesIr 3 5 DN 32 100henddikNo ratings yet

- Pneumatic Directional Control Valves: Type 451-4Document4 pagesPneumatic Directional Control Valves: Type 451-4Francisco Mones RuizNo ratings yet

- Gas Pressure Regulator RS 250 / RS 251: Product InformationDocument28 pagesGas Pressure Regulator RS 250 / RS 251: Product InformationAdilson Melo de MouraNo ratings yet

- +GF+ Pressure Retaining Valve Type 586Document4 pages+GF+ Pressure Retaining Valve Type 586ROMNANo ratings yet

- Val-Presion de AlivioDocument2 pagesVal-Presion de AlivioCristian CanteroNo ratings yet

- Medenus Safety Shut Off Valve PI - S104 - EN - FP3 - KleinDocument20 pagesMedenus Safety Shut Off Valve PI - S104 - EN - FP3 - Kleinanas ins10No ratings yet

- Robuschi Data Sheet RoboxDocument21 pagesRobuschi Data Sheet RoboxMAZENNo ratings yet

- MAT-p eDocument4 pagesMAT-p eedark2009No ratings yet

- PCT 267836Document2 pagesPCT 267836Sonu KushwahaNo ratings yet

- Rpd-Rps-En-0503 RPD-RPS CatalogueDocument28 pagesRpd-Rps-En-0503 RPD-RPS Catalogue4122acaNo ratings yet

- Related Products: Auto Drain Valve: PrecautionsDocument10 pagesRelated Products: Auto Drain Valve: Precautionsteknik otomotifNo ratings yet

- Electrically Operated Pressure Reducing Cartridge, Size 16: Seated Pilot Stage, Spool Type Main Stage Series WDRVPA 5 ..Document5 pagesElectrically Operated Pressure Reducing Cartridge, Size 16: Seated Pilot Stage, Spool Type Main Stage Series WDRVPA 5 ..Roberto Blazquez SevillanoNo ratings yet

- Flanged Gate Valves With Soft Seals: Operation and Maintenance Manual ForDocument9 pagesFlanged Gate Valves With Soft Seals: Operation and Maintenance Manual ForJustin ReyesNo ratings yet

- Technical Data Sheet C2..QPT-..: Type OverviewDocument5 pagesTechnical Data Sheet C2..QPT-..: Type OverviewJNo ratings yet

- Deluge Valve Installation ManualDocument7 pagesDeluge Valve Installation Manualrahull.miishraNo ratings yet

- RDDA Es Metric A4Document1 pageRDDA Es Metric A4Daniel GómezNo ratings yet

- Series 42 Self-Operated Regulators ANSI Version: T 3010 EN Type 42-10 RS Check Valve (Backflow Protection)Document8 pagesSeries 42 Self-Operated Regulators ANSI Version: T 3010 EN Type 42-10 RS Check Valve (Backflow Protection)Yesid RodríguezNo ratings yet

- Valvulas BendixDocument6 pagesValvulas BendixJohny SierraNo ratings yet

- Mooney Flowgrid Manual PDFDocument16 pagesMooney Flowgrid Manual PDFFernando FernandezNo ratings yet

- Alfa Laval Sru Rotary Lobe Pump Ese00274enDocument7 pagesAlfa Laval Sru Rotary Lobe Pump Ese00274enleosalleNo ratings yet

- Plitstr250 Rev F SS741MGDocument20 pagesPlitstr250 Rev F SS741MGArc HieNo ratings yet

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADocument2 pagesModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNo ratings yet

- Series 11: Seat 7/8-14 UNF-2B (SAE - 10) Bar Max L/minDocument2 pagesSeries 11: Seat 7/8-14 UNF-2B (SAE - 10) Bar Max L/minVendas HidrautrônicaNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- 876-32 Model SDA Direct-Dial Pilot.Document11 pages876-32 Model SDA Direct-Dial Pilot.Naveed AliNo ratings yet

- XRIM Full en Us LetterDocument7 pagesXRIM Full en Us LetterMay Perez RNo ratings yet

- VS6M Solenoid Operated Directional Control Valve Form 1019381 Rev. 09 14Document8 pagesVS6M Solenoid Operated Directional Control Valve Form 1019381 Rev. 09 14francis_15inNo ratings yet

- KTM Actuator CatalogueDocument12 pagesKTM Actuator CatalogueRahimNo ratings yet

- Vsng6 Solenoid Control Valve WebDocument8 pagesVsng6 Solenoid Control Valve WebLucas Vinícius CostaNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- BRC Geral SD 0100-2E02Document3 pagesBRC Geral SD 0100-2E02eduardogss100% (1)

- RQM - P: Series 60 Subplate Mounting RQM3-P ISO 6264-06 RQM5-P ISO 6264-08 RQM7-P ISO 6264-10Document4 pagesRQM - P: Series 60 Subplate Mounting RQM3-P ISO 6264-06 RQM5-P ISO 6264-08 RQM7-P ISO 6264-10Jorge MendozaNo ratings yet

- My Flowmax Regulator Iom Gea19584a English PDFDocument32 pagesMy Flowmax Regulator Iom Gea19584a English PDFElias ElHossariNo ratings yet

- Regulator Iom EnglishDocument32 pagesRegulator Iom EnglishShaoranNo ratings yet

- Jet Range PRVDocument4 pagesJet Range PRVneiljonesNo ratings yet

- 2199 TBDocument3 pages2199 TBJaner BeltranNo ratings yet

- RDJA Full en Metric LetterDocument2 pagesRDJA Full en Metric LetteressamNo ratings yet

- RQM5 P5 A 24CCDocument4 pagesRQM5 P5 A 24CCajlandaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- G25 and G40: Diaphragm MetersDocument4 pagesG25 and G40: Diaphragm MetersMiguel Angel Morales CastroNo ratings yet

- G65 and G100: Diaphragm MetersDocument4 pagesG65 and G100: Diaphragm MetersMiguel Angel Morales CastroNo ratings yet

- Quantometer Delta QD: Description ApplicationsDocument2 pagesQuantometer Delta QD: Description ApplicationsMiguel Angel Morales CastroNo ratings yet

- Prodoral® R 6 Prodoral® R 6-1: Coating SystemsDocument6 pagesProdoral® R 6 Prodoral® R 6-1: Coating SystemsMiguel Angel Morales CastroNo ratings yet

- Ingles IDocument17 pagesIngles IMiguel Angel Morales CastroNo ratings yet

- 4 Contamination Control 2Document61 pages4 Contamination Control 2Vijay RajaindranNo ratings yet

- Gulfco Fleet Premium: Heavy Duty Gas Engine Oil For Mobile ApplicationDocument1 pageGulfco Fleet Premium: Heavy Duty Gas Engine Oil For Mobile ApplicationAlisson Marcela ContrerasNo ratings yet

- 80010360Document2 pages80010360mdisicNo ratings yet

- Operating System Concepts 8th Edition Chapter 1 SummaryDocument2 pagesOperating System Concepts 8th Edition Chapter 1 SummaryAlfred Fred100% (1)

- Pavement Evaluation and Overlay Des - DR MSA - LatestDocument103 pagesPavement Evaluation and Overlay Des - DR MSA - LatestSreedhar BhuduruNo ratings yet

- 16PPE723Document2 pages16PPE723DrArun KaliappanNo ratings yet

- On The Gaussian Error Function (1935) : Robert J. KolkerDocument4 pagesOn The Gaussian Error Function (1935) : Robert J. KolkerSanthosh KulandaiyanNo ratings yet

- Brother Dr420 Drum ResetDocument1 pageBrother Dr420 Drum ResetJaime RiosNo ratings yet

- MV Reg CleanDocument32 pagesMV Reg CleanJose Alberto CostaNo ratings yet

- Piping Handbook Hydrocarbon Processing 1968 PDFDocument140 pagesPiping Handbook Hydrocarbon Processing 1968 PDFbogdan_chivulescuNo ratings yet

- SMD Resistor ExamplesDocument5 pagesSMD Resistor Examplesmarcbuss100% (1)

- Toshiba 42pw33q - S Ch. Pw33 SchematicsDocument18 pagesToshiba 42pw33q - S Ch. Pw33 SchematicstodorloncarskiNo ratings yet

- USS ProtocolDocument77 pagesUSS Protocolreza2131No ratings yet

- 048Document6 pages048kokykarkarNo ratings yet

- HP40 NBDocument13 pagesHP40 NBTarun ChandraNo ratings yet

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimNo ratings yet

- Carpentry: Exploratory CourseDocument25 pagesCarpentry: Exploratory CourseJohn Nelson Picones100% (3)

- Debug 1214Document3 pagesDebug 1214Anonymous B4WiRjNo ratings yet

- Jaybird Bluebuds X ManualDocument1 pageJaybird Bluebuds X Manualeduardi7720No ratings yet

- 545 ELP-ES-2011 - Catálogo de DisipadoresDocument24 pages545 ELP-ES-2011 - Catálogo de DisipadoresrichkidNo ratings yet

- Passive Cooling of The Green Roofs Combined With Night-Time Ventilation and Walls Insulation in Hot and Humid RegionsDocument25 pagesPassive Cooling of The Green Roofs Combined With Night-Time Ventilation and Walls Insulation in Hot and Humid Regionsshailesh gautamNo ratings yet

- EST 2011B v1.0 Configuration 10/28/2018 7:43 AMDocument2 pagesEST 2011B v1.0 Configuration 10/28/2018 7:43 AMbagusNo ratings yet

- EOT CRANE - Rev 2Document6 pagesEOT CRANE - Rev 2Koushik BhaumikNo ratings yet

- Pre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationDocument3 pagesPre - Use Inspection Qualification: Date: Equipment Welding Machine Serial Number Model: LocationEugenio Jr. MatesNo ratings yet

- Investigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProDocument4 pagesInvestigate The Natural Time Period, Base Shear, Displacement, Story Drift, Story Stiffness by Etabs and Staad ProEditor IJTSRDNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument2 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesMark Louie GuintoNo ratings yet

- Project Title: Hotel Management Software Project: PurposeDocument3 pagesProject Title: Hotel Management Software Project: PurposesuryaNo ratings yet

- Astm A769 PDFDocument5 pagesAstm A769 PDFCristian OtivoNo ratings yet

- VNX Unified Storage ManagementDocument3 pagesVNX Unified Storage ManagementNicoleNo ratings yet

- Update Notifikasi Depkes FEB 18Document6 pagesUpdate Notifikasi Depkes FEB 18pratistanadia_912023No ratings yet