Professional Documents

Culture Documents

Symbol Name On Drawing Tolerance Zone Gauging: Straightness

Uploaded by

inbhachOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Symbol Name On Drawing Tolerance Zone Gauging: Straightness

Uploaded by

inbhachCopyright:

Available Formats

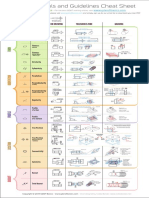

GD&T Symbols and Guidelines Cheat Sheet

Provided by GD&T Basics - For the best GD&T training online, visit www.gdandtbasics.com

If you would like a free copy of this cheat sheet please visit www.gdandtbasics.com and simply sign up for our email list to download your free PDF

All drawings made in

first angle projection

SYMBOL NAME ON DRAWING TOLERANCE ZONE GAUGING

Two parallel lines

0.03 apart

0.03

Straightness

(Surface)

10±0.050 Cylindrical Tolerance Zone

0.03 when Part ∅ = 10.05 Cylinder Gauge ID = M +

0.03 M

M Straightness 0.13 when Part ∅ = 9.95

Gauge ID =

(Derived Median Line w/ M ) 10.08

Two parallel planes

0.030 apart

Flatness

0.03

(Surface)

FORM

Planar Tolerance Zone Gauge spacing

Flatness

10±0.05 at Virtual Condition

0.03 M M + = 10.08

M (Derived Median

Plane w/ M )

Two concentric circles

0.03 0.03 apart

Circularity

Two concentric cylinders

0.03 0.03 apart

Cylindricity

Two parallel planes

0.03 apart

0.03 A

Parallelism

ORIENTATION

Flat datum block

A (Datum A)

Datum A

0.03 A

Perpendicularity

Two parallel planes

0.03 apart Flat datum block

(Datum A)

A

(Feature) 90°

Datum A

Gauge pin Pin Gauge OD = M −

10±0.05 inserted

0.03 M A Axis perpendicular Pin Gauge ∅ = 9.92

M

Perpendicularity Bonus tolerance Tolerance Zone

at M

to datum

90°

(9.95 - 0.03)

(Feature of Size w/ M )

A Datum A

Two parallel planes

0.03 apart

0.03 A

Angularity 60° A Gauge

Block

60 60°

60°

Datum A °

Uniform Linear Boundary About True Profile Datum B

0.03 A B

Profile B A

0.03 apart

Gauge must

follow true profile.

of a line Basic dimensions

Profile is usually

measured with a CMM.

PROFILE

(not shown) must be used Datum A

to define the True Profile

0.03 A B Uniform Surface Boundary About True Profile Datum B

Profile B A

0.03 apart Gauge must

follow true profile.

of a surface Profile is usually

measured with a CMM.

Basic dimensions

(not shown) must be used Datum A

to define the True Profile

10±0.05 Measure X and Y location and compare to the true position.

Part (actual) position

0.03 A B C

2X √ (Actual X - True X)2 + (Actual Y - True Y)2

B Y

This formula must be less than

True Position 20.0 True

Actual

Actual Y

the ∅ True Position tolerance

0.03 True Y

30.0

True

center

C A X

True X Actual X

FUNCTIONAL

Actual GAUGING

Pin Position Part Part Tolerance Zone

10±0.05

of Pin Gauge

0.03 M A B C

True Position

True

position For an For an True

B position

External Internal

M (Maximum Material 25.0 Tolerance Zone Feature Feature

Actual

Condition) of Hole Gauge

Hole Position

LOCATION

25.0 C A Gauge Gauge

0.03 A The following is usually

Measured axis Datum axis done with a CMM:

1. Determine

Concentricity Datum axis

2. Measure referenced

surface

A

Datum A

3. Determine if central

Tolerance Zone axis falls in TZ

A

A A

0.03 A

A The following is

Datum A usually done

Plane with a CMM:

Symmetry 1

1. Determine

Datum plane

2. Measure both

surfaces of features

3. Determine if

Two parallel planes midpoints fall in TZ

0.03 apart

0.03 A

Datum A

Datum A Fixed + Rotated

A

A

Fixed axially

Runout + Rotated

A

RUNOUT

0.03 A Datum A

Datum A Fixed + Rotated

A

A Fixed axially

Total Runout A

+ Rotated

Copyright © 2014 GD&T Basics - www.gdandtbasics.com - Chart designed by Andrea Barbieri <www.andreabarbieri.net>

You might also like

- GD T Basics Wall ChartDocument1 pageGD T Basics Wall ChartallaboutfreeNo ratings yet

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- 11) Design For Manufacturing-PDDDocument34 pages11) Design For Manufacturing-PDDinbhachNo ratings yet

- Iem 2723307Document2 pagesIem 2723307inbhachNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TigerPMS CM63Document19 pagesTigerPMS CM63Mohamed BahaaNo ratings yet

- Hydraulic ExcavatorDocument20 pagesHydraulic ExcavatorArvind HarryNo ratings yet

- CADA QP-Ktunotes - in PDFDocument3 pagesCADA QP-Ktunotes - in PDFsachinNo ratings yet

- FMC1278Document132 pagesFMC1278Herick Douglas PereiraNo ratings yet

- Refrigeration and Air Conditioning Servi PDFDocument24 pagesRefrigeration and Air Conditioning Servi PDFGeovane JavelosaNo ratings yet

- Business Systems Analyst Information Technology in NYC Resume Len KhatsernovDocument3 pagesBusiness Systems Analyst Information Technology in NYC Resume Len KhatsernovLenKhatsernovNo ratings yet

- Jinma 284 ManualDocument35 pagesJinma 284 ManualJuan Garcia100% (1)

- 2009MANITOUCATALOGUEDocument22 pages2009MANITOUCATALOGUEGoodBikes0% (1)

- Die Design ProgramDocument5 pagesDie Design ProgramSundar KaruppiahNo ratings yet

- The Autosweep RFID System Can Be Used in The Following ExpresswaysDocument2 pagesThe Autosweep RFID System Can Be Used in The Following ExpresswaysJhez EstuariaNo ratings yet

- en 30 - Sub Supplier - ManagementDocument2 pagesen 30 - Sub Supplier - ManagementAMB SpainNo ratings yet

- Volume 4, Issue 2 (2017) Tropical Plant ResearchDocument173 pagesVolume 4, Issue 2 (2017) Tropical Plant ResearchTropPlResNo ratings yet

- Lanscaping LightsDocument124 pagesLanscaping LightsAlejandra BlancoNo ratings yet

- Chopper Based Speed Control of DC Motor-1260Document6 pagesChopper Based Speed Control of DC Motor-1260Tan Chuan ChetNo ratings yet

- Crane Rails Fastening SystemsDocument37 pagesCrane Rails Fastening SystemsjulianoNo ratings yet

- Conn BrocDocument3 pagesConn BrocbenhealyNo ratings yet

- Alfa VapDocument2 pagesAlfa Vapkresimir.mikoc9765No ratings yet

- Installation Guide: Connecting Workstations Problem SolvingDocument2 pagesInstallation Guide: Connecting Workstations Problem Solvingjuan_mxNo ratings yet

- LPG Household Prices in Metro Manila: Date Monitored: October, 2019Document9 pagesLPG Household Prices in Metro Manila: Date Monitored: October, 2019Lemon AdeNo ratings yet

- Employment NewsDocument48 pagesEmployment NewsananahmedNo ratings yet

- P0748Document3 pagesP0748kreyhonNo ratings yet

- Gas Turbine ManualDocument48 pagesGas Turbine ManualShivam Kumar100% (3)

- 5Document22 pages5juan carlos zavalaNo ratings yet

- 5 KW OFF GRID & Grid Tie Quotation 31-03-2021Document3 pages5 KW OFF GRID & Grid Tie Quotation 31-03-2021ImranFazalNo ratings yet

- Lifting Lug Calculation - Concrete BucketDocument3 pagesLifting Lug Calculation - Concrete Bucketali akbarNo ratings yet

- Maag Gear Shaper CutterDocument3 pagesMaag Gear Shaper CutterBrandoNo ratings yet

- CNC Guillotine Shears HandoutDocument5 pagesCNC Guillotine Shears HandoutHarminder KumarNo ratings yet

- 1662 SMC Ds tcm228-701431635Document12 pages1662 SMC Ds tcm228-701431635cersanedNo ratings yet

- Yamaha 8HP ManualDocument66 pagesYamaha 8HP ManualGiovanni Norbedo100% (3)

- Fatigue Stress Analysis PDFDocument4 pagesFatigue Stress Analysis PDFAR HassanNo ratings yet