Professional Documents

Culture Documents

Branofol M3, R3: Vci-Corrosion Protection Film

Uploaded by

Jaya RidwantoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Branofol M3, R3: Vci-Corrosion Protection Film

Uploaded by

Jaya RidwantoCopyright:

Available Formats

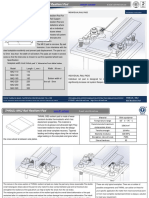

BRANOfol M3, R3

VCI-Corrosion Protection Film

Characteristics Duration of Protection

BRANOfol M3 and BRANOfol R3 are blue dyed, special Depending on climate conditions and how well the packa-

polyethylene film with double-sided active VCI corrosion

ging is sealed, BRANOfol M3, R3 can offer protection for up

protection which effectively protect metal parts from corro- to twelve months. The duration of protection can be extend-

sion during transport or storage. ed if the application, storage and transport are well known.

They are water-proof, weldable and suitable for automatic BRANOfol M3 Protects steel, cast iron (only on

packaging as well as bag production. BRANOfol M3 and - nitrite free contact), zinc plated steel, tin, alumini-

BRANOfol R3 are available from 40 to 300 µm and also - surpass test standard um, chromium, zinc, copper and its al-

available as VCI-embossing film. DIN EN ISO 6270-2 loys reliably against corrosion.

The scope of protection can be extended if the

used materials and alloys are known in detail.

BRANOfol products continuously release small amounts of

corrosion protection agents inside of the packaging (VCI: BRANOfol R3 Has been increasingly developed for the

Volatile Corrosion Inhibitors), helping to provide effective - contains nitrite iron protection. It protects steel, chromi-

(TRGS 615 compliant)

protection against corrosion for metal parts during transport um, tin, pure aluminium and cast iron

or storage. - surpass test standard against corrosion.

DIN EN ISO 6270-2

- complies with The scope of protection can be extended if the

The protecting atmosphere is, depending on the volu- TL8135-0043, level 3 used materials and alloys are known in detail.

me of the package, available after a short time. This

holds true even after having opened the package for a

short time – the protecting atmosphere will be rebuilt

immediately afterwards.

Advantages

• Environmentally friendly corrosion • Protects against humidity

protection without oiling and greasing • Non-hazardous material

• Packaging material and corrosion • High elasticity and tear strength

protection in one • Development of customized solutions

• Metal parts are ready for use immediately possible

• Time efficent packaging process

• Easy to dispose and recyclable

Current version: 08/ 2017– replaced: 08/2016

BRANOfol M3, R3

Product Information

Delivery Forms Types

Flat film, sheets, bags, half tubes, hoods, tubes, side- BRANOfol M3 M3 - standard

pleaded Tubes, pallet liners, Boxed hoods, elastic string M3 S - shrinkable

bags, zip lock bags. M3 XS - highly tear-proof

M3 SXS - highly tear-proof and shrinkable

M3 XA - dissipative, ESD-D

Storage M3 ESD - conductive, ESD-C

M3 FL - flame retardant

Cool and dry, protected from direct sunlight. Shelf-life in the M3 KL - cross-laminated

original packaging up to three years. M3 UV - UV-stable

M3 XE - extra elastic

M3 SUV - shrinkable and UV stable

Disposal BRANOfol R3 R3 - standard

R3 XS - highly tear-proof

BRANOfol M3, R3 can be recycled. Soiled film has to be R3 SXS - highly tear-proof and shrinkable

disposed through waste incineration. R3 XA - dissipative, ESD-D

Operation Safety Facts

BRANOfol M3, R3 corresponds to TRGS 615. Please see Parameter Test method Unit BRANOfol

for further information the safety information sheet.

Tensile strength DIN EN ISO MPa > 25

lengthwise/transversely 527-3/2/500

Stretching DIN EN ISO % > 600

lengthwise/transversely 527-3/2/500

Dart-Drop ASTM D1709/A g > 550

Water vapour DIN EN ISO 5106 g/m2 * d ≤1

permeability (23 °C, 85 % r. F.)

Operating temperature Temporary: max. 70 °C

Constantly: -10 °C to 40 °C

The mechanic parameters surpass the specifications

of the norm DIN 55530.

The information corresponds with typical values of BRANOfol M3.10XS/ R3.10 XS

Binding are the respective product specifications.

Please pay close attention to thickness and impermeability to water vapour when selecting your VCI films.

Both of these parameters are of decisive importance for corrosion protection and should therefore be selec-

ted with the specific application in mind.

BRANOpac

All of the information contained herein is based on current knowledge and is not binding. Modification Solutions with System

may be necessary to suit conditions at the location of use. No claims for damages can be made in this

regard. BRANOpac GmbH

Gottlieb-Daimler-Str. 18-20

35423 Lich, Germany

More information available at:

Phone: +49 6404 9142-0

www.branopac.com

Fax: +49 6404 9142-700

www.branopedia.com

Email: info@branopac.com

www.facebook.com/BRANOpacGmbH

You might also like

- Pi Branorost Chips enDocument2 pagesPi Branorost Chips enJaya RidwantoNo ratings yet

- Vci-Anticorrosion Paper: Characteristics Ferrogard/Multiguard TypesDocument2 pagesVci-Anticorrosion Paper: Characteristics Ferrogard/Multiguard TypesJaya RidwantoNo ratings yet

- Cable Terminal Kit 3Document8 pagesCable Terminal Kit 3luiszc2988No ratings yet

- 854659-000 Product specificationsDocument2 pages854659-000 Product specificationsTAREK AWADANo ratings yet

- WR 1000Document1 pageWR 1000kirandhivya1821No ratings yet

- Ham-Let Astava Line of ManifoldsDocument24 pagesHam-Let Astava Line of ManifoldsGaurav BedseNo ratings yet

- ms-02-316 Pre-Insulated Tubing BundlesDocument12 pagesms-02-316 Pre-Insulated Tubing BundleskicsnerNo ratings yet

- ms-02-316 Pre-Insulated Tubing BundlesDocument12 pagesms-02-316 Pre-Insulated Tubing BundleskicsnerNo ratings yet

- Fire ProofDocument4 pagesFire ProofRaton121 RahmanNo ratings yet

- PSS-3000 Ba Set PDFDocument4 pagesPSS-3000 Ba Set PDFHema JoshiNo ratings yet

- Siderflex Catalogue PDFDocument12 pagesSiderflex Catalogue PDFSourindranath MaityNo ratings yet

- Protection Against Corrosion: International Packaging Solutions ... Always One Step AheadDocument8 pagesProtection Against Corrosion: International Packaging Solutions ... Always One Step AheadMohammed Al-OdatNo ratings yet

- Zerust ICT510-OPS OutdoorVCIShrink Info RevF3Document2 pagesZerust ICT510-OPS OutdoorVCIShrink Info RevF3ccorp0089No ratings yet

- GotexFibreOpticBrochure DigitalDocument2 pagesGotexFibreOpticBrochure DigitalChen KaixiangNo ratings yet

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- Durmat PTA Laser Thermal SprayDocument32 pagesDurmat PTA Laser Thermal SpraySergeyNo ratings yet

- Tridol Atf 3-3Document2 pagesTridol Atf 3-3mario.No ratings yet

- 3M™ Cold Shrink Silicone Rubber 3/C Cable Breakout Boots 8560 SeriesDocument7 pages3M™ Cold Shrink Silicone Rubber 3/C Cable Breakout Boots 8560 SeriesLizbeth Lizbeth AmesquitaNo ratings yet

- Corroban 1183 DX Protects Metal Parts from CorrosionDocument2 pagesCorroban 1183 DX Protects Metal Parts from CorrosionAbhinayKumarNo ratings yet

- Masonry Reinforcement Windposts PDFDocument16 pagesMasonry Reinforcement Windposts PDFJohn DeomampoNo ratings yet

- Bridgestone's Belt Conveyor SeminarDocument90 pagesBridgestone's Belt Conveyor Seminarmarco antonio talavera salazarNo ratings yet

- PS English Reusable Bevel ProtectorDocument1 pagePS English Reusable Bevel ProtectorEnrico ManfrinatoNo ratings yet

- ASTAVA BV Holland CatalogDocument28 pagesASTAVA BV Holland CatalogXavierNo ratings yet

- Removable Reusable Blanket Insulation: Engineering Reusable Solutions For A Sustainable PlanetDocument6 pagesRemovable Reusable Blanket Insulation: Engineering Reusable Solutions For A Sustainable Planet최승원No ratings yet

- Catalogo Casco DRAGER HPS 6100Document4 pagesCatalogo Casco DRAGER HPS 6100mabiNo ratings yet

- EYE-19-1145 Securefit Catalog P8-1 MdResDocument5 pagesEYE-19-1145 Securefit Catalog P8-1 MdResroyNo ratings yet

- 3M 2890 BrochureDocument2 pages3M 2890 BrochureMichael TadrosNo ratings yet

- Alberta-80-Fusion Self-Fusing Silicone Rubber TapeDocument2 pagesAlberta-80-Fusion Self-Fusing Silicone Rubber TapeHà Trần MạnhNo ratings yet

- Proofex Torchseal 3P and 4P UAEDocument2 pagesProofex Torchseal 3P and 4P UAEhbangash2022No ratings yet

- Monoflange AstavaDocument12 pagesMonoflange AstavaPriyanka rajpurohitNo ratings yet

- Comfort and Ingenuity: Waterproof Foam and Removable Strap CoatingDocument2 pagesComfort and Ingenuity: Waterproof Foam and Removable Strap CoatingZamriNo ratings yet

- 100% OUTDOOR: No Metal PartDocument2 pages100% OUTDOOR: No Metal PartHenrique CorreiaNo ratings yet

- Thermal Insulation Products - Jacketing & CladdingDocument15 pagesThermal Insulation Products - Jacketing & CladdingSreekumar K SNo ratings yet

- Nitocote sr3000Document4 pagesNitocote sr3000VJ QatarNo ratings yet

- Passive Corrosion Prevention For Flanges and Valves: Product InformationDocument3 pagesPassive Corrosion Prevention For Flanges and Valves: Product InformationAnant RubadeNo ratings yet

- D3 Spray Nozzle PDFDocument6 pagesD3 Spray Nozzle PDFwahyuNo ratings yet

- High Vacuum Storage ContainersDocument2 pagesHigh Vacuum Storage ContainerspcbstepNo ratings yet

- Protect Bolts & Nuts From Damage and Corrosion: Thread & Nut Protection Improved MaintenanceDocument12 pagesProtect Bolts & Nuts From Damage and Corrosion: Thread & Nut Protection Improved MaintenanceJo KingsNo ratings yet

- 11 SS Type Hydrophone CableDocument2 pages11 SS Type Hydrophone CableMathew Manoj ThyvelikakathNo ratings yet

- Product Brochure: Passive Fire ProtectionDocument16 pagesProduct Brochure: Passive Fire ProtectionValentin A.No ratings yet

- tds_armo_grid_sr_eu_en_ver202301Document2 pagestds_armo_grid_sr_eu_en_ver202301abdo abjNo ratings yet

- Schiavi Enc Met Page096Document1 pageSchiavi Enc Met Page096Adel AdelNo ratings yet

- Insulators and load-bearing technical dataDocument1 pageInsulators and load-bearing technical dataAdel AdelNo ratings yet

- GD 5000 Technical Data Sheet Rev2 (Jan 22)Document1 pageGD 5000 Technical Data Sheet Rev2 (Jan 22)HKC EQUIPEMENTSNo ratings yet

- Gundle Insulation Brochure PDFDocument8 pagesGundle Insulation Brochure PDFnadji habibiNo ratings yet

- Creusabro MDocument4 pagesCreusabro MhealgoseNo ratings yet

- MasterSeal 930 TDSDocument3 pagesMasterSeal 930 TDSAdrian SerbanNo ratings yet

- 362127-000 Product Specifications Heat ShrinkDocument2 pages362127-000 Product Specifications Heat ShrinkStanley MasekoNo ratings yet

- SalisburyDocument6 pagesSalisburyjorge_moralesmNo ratings yet

- Cable Terminal KitDocument10 pagesCable Terminal KitJohn ThomasNo ratings yet

- PR 6130 Cable Junction Boxes PR 6135, PR 6136 Installation CablesDocument4 pagesPR 6130 Cable Junction Boxes PR 6135, PR 6136 Installation CablesNovia SariNo ratings yet

- Information On Belt Selection and Storage: Reporting Reference: LBT-CP031204Document8 pagesInformation On Belt Selection and Storage: Reporting Reference: LBT-CP031204haziqNo ratings yet

- Caplugs Hose ProtectionDocument24 pagesCaplugs Hose ProtectionOsva E DiezNo ratings yet

- Crane Rail Pads MK2Document2 pagesCrane Rail Pads MK2Mukty BaktiarNo ratings yet

- Primacord PDFDocument5 pagesPrimacord PDFWolf Lilly100% (1)

- Steel Cord Conveyor BeltingDocument10 pagesSteel Cord Conveyor BeltingnicolasNo ratings yet

- FusesDocument34 pagesFusesMohd Arjhit AliNo ratings yet

- Counter Sniper Manual - The Official US Army ManualFrom EverandCounter Sniper Manual - The Official US Army ManualNo ratings yet

- Waste Resources Recycling in Achieving Economic and Environmental Sustainability: Review On Wood Waste IndustryDocument10 pagesWaste Resources Recycling in Achieving Economic and Environmental Sustainability: Review On Wood Waste IndustryElena Raluca DraguNo ratings yet

- DestructionDocument87 pagesDestructionHeina GalvezNo ratings yet

- Clause 14.4. ServicesDocument2 pagesClause 14.4. ServicesranggabarmanaNo ratings yet

- CHAPTER 7 (Form 5)Document20 pagesCHAPTER 7 (Form 5)Imelda Nyaun100% (3)

- Ammo 67Document22 pagesAmmo 67Eric Mak100% (1)

- Diapers and The Environment: N E A R T ADocument8 pagesDiapers and The Environment: N E A R T AVanmala SubramaniamNo ratings yet

- Examples of Humorous EssaysDocument8 pagesExamples of Humorous Essaysb6yf8tcd100% (2)

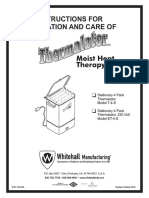

- Whitehall ThermalatorDocument17 pagesWhitehall ThermalatorBong Kek Chiew100% (1)

- Pardo - Mexican American Women Grassroots CommunityDocument8 pagesPardo - Mexican American Women Grassroots CommunityOlga 'Ligeia' ArnaizNo ratings yet

- Wastewater TreatmentDocument44 pagesWastewater TreatmentGiancarlo SantosNo ratings yet

- List of Plastic Waste Recycler UnitDocument7 pagesList of Plastic Waste Recycler Unitarun505080No ratings yet

- Energy Efficiency and CO Emissions From The Global Cement IndustryDocument12 pagesEnergy Efficiency and CO Emissions From The Global Cement IndustrymsajanjNo ratings yet

- Alkaline Flushing ProcedureDocument107 pagesAlkaline Flushing ProcedureSarah FrazierNo ratings yet

- Nep Civil Final 13.02.2023Document262 pagesNep Civil Final 13.02.2023manjubhargav phdNo ratings yet

- Annual Report 2005 Navin FluorineDocument82 pagesAnnual Report 2005 Navin Fluorinesvnrao123No ratings yet

- Impact of Disposable Products On The EnvironmentDocument2 pagesImpact of Disposable Products On The EnvironmentLiny LingamenNo ratings yet

- 14Document49 pages14Deanna BarrettNo ratings yet

- Smart Dustbin Using ArduinoDocument11 pagesSmart Dustbin Using ArduinoNiana Bliss Cepada MangaronNo ratings yet

- Sirafan SpeedDocument5 pagesSirafan SpeedProsenjit76No ratings yet

- Marijuana Security BlackbookDocument34 pagesMarijuana Security BlackbookGabriel GabarramNo ratings yet

- 100 TOP MOST POWER PLANT Engineering - Electrical Engineering Objective Type Questions and AnswersDocument1 page100 TOP MOST POWER PLANT Engineering - Electrical Engineering Objective Type Questions and Answersrose maryNo ratings yet

- EDITING Inglés 7° - Unit 4 Green Issues - Worksheet 1Document7 pagesEDITING Inglés 7° - Unit 4 Green Issues - Worksheet 1Anelis Del Carmen Leal ContrerasNo ratings yet

- Ic ReactorDocument73 pagesIc ReactorPrashant RukmangadNo ratings yet

- 1.2 Statement of ProblemDocument1 page1.2 Statement of Problemyonas DestaNo ratings yet

- DLL - Science 4 - Q1 - W4Document6 pagesDLL - Science 4 - Q1 - W4Raqueliza Molina VillapaNo ratings yet

- Cree MoreDocument3 pagesCree MoreJC AlfonsoNo ratings yet

- Facilities & Equipmemt in SwineDocument29 pagesFacilities & Equipmemt in SwineAlliah Dela RosaNo ratings yet

- Machinery Vibration Analysis Predictive MaintenanceDocument267 pagesMachinery Vibration Analysis Predictive MaintenanceKowalski KrzysztofNo ratings yet

- Seminar Nasional Hasil Penelitian dan Pengabdian Masyarakat 2016, ISBN 978-602-14917-2-0Document6 pagesSeminar Nasional Hasil Penelitian dan Pengabdian Masyarakat 2016, ISBN 978-602-14917-2-0Era KuNo ratings yet

- Chemicals Zetag MSDS Organic Coagulants Magnafloc LT 7997 - 0710Document6 pagesChemicals Zetag MSDS Organic Coagulants Magnafloc LT 7997 - 0710PromagEnviro.comNo ratings yet