Professional Documents

Culture Documents

Tug8 - T24031

Tug8 - T24031

Uploaded by

bernardo0 ratings0% found this document useful (0 votes)

8 views3 pagesOriginal Title

TUG8 - T24031 (1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views3 pagesTug8 - T24031

Tug8 - T24031

Uploaded by

bernardoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

CSIR Implementation Unit

8 Mechanical Testing

Pvale Bag X28 Auckland Patk 2006 Saul Arca

‘Toh #27 11 482 1200

Fax #27 11725 6618,

Deivery Adsress: Chr Melon Road & Frost Avenue

Cotesioe 2092 vehannesburg

CERTIFICATE OF TEST

‘Three performance tests of medium duty Application Received: 18 April 2016

extended shell extruded aluminium conveyor

belt clamp set complete with PVC conveyor belt Certificate No 24031

(1200 mm belt width)

Order No: COD Dato of Test: 23 June 2016

SUBMITTED TO

Mr Greg Labuschagne

Flexco

P 0 Box 15386

HURLYVALE

1611

1. INTRODUCTION

At the request of Mr Greg Labuschagne of Flexco, one medium duty extended shell extruded aluminium

conveyor belt clamp set complete with PVC conveyor belt (1200 mm belt width) was submitted for

performance test. The test was conducted in accordance with the customer's request.

2. TEST PROCEDURE

Testing machine: 15 MN MEL tensile testing machine

Test type: Performance test in tension

Test specification: Customer request

Torque on belt clamps: 200 N.m and 163 N.m.

‘A PVC conveyor belt was installed in the clamps. An appropriate torque was then applied. The belt clamp

assembly was installed in the 15 MN MFL tensile testing machine using suitable fittings @s shown in

Figure 1. A pre-load of 10 kN was applied to the bolt clamp assembly. A gradually increasing tensile load

was applied to the assembly unti the belt clamps slipped. The clamps were loosened and returned to the

chosen position and tightened to a suitable torque, the lest was then restarted. This procedure was repeated

‘wo times for a total of three tests.

Testing Otfees:

Notic:

‘ONLY the orignal saned report must be

tragarded as the oficial document. Page: tof Engineer

Certificate #: 124001

2

Date Issued: 06 July 2016 CcSl RR

DMS Ret: COT Gen-10751.2

Figure 1. Medium duty extended shell extruded aluminium conveyor belt clamp assembly installed in

the testing machine

3. TEST RESULTS

Tho results of the performance tests carried out on the medium duty extended shell extruded aluminium

conveyor belt clamp assemblies are summarised in Table 1

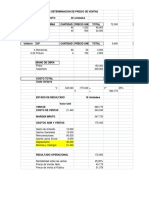

‘Table 1. Results of medium duty extended shell extruded aluminium conveyor belt clamp assemblies

Test | Maximum | Length between | Length between | Torque applied

Na. | load carried | belt clamps | belt clamps after | on clamp bolts | Observation

5 (kN) | before test (mm) | test (mm) (N.m)

1 113.0 855 870 163 The conveyor

2 924 810 860 belt clamps

3 138.0 780. 30. 200 slipped.

4, DISCLAIMER

1. The CSIR cannot be held responsible for product indifferences and cannot be held responsible for

any accidents or incidents as a result thereof,

2. Due to the limited amount of sample(s) tasted and the type of test

for the results from those specific samples tested.

All CSIR standard terms and conditions of testing apply and will be forwarded upon request.

This Certificate of Test may not be published without prior written consent of the CSIR.

‘This Certificate of Test must be reproduced in its entirety if published or reproduced by the client.

done, CSIR can only account

Notice:

‘ONLY the orginal signed report must be

regarded as the official document. Page: 2013

Gerticate #: 124031

Date fesued: 06 July 2016

DMS Ref: COT Gen:18751.2

CSIR

Certificate No.:

724031

23 June 2016

Flexco

Medium duty extended shell extruded aluminium

conveyor belt clamp set complete with PVC conveyor

belt (1200 mm belt width)

4 2 z

TAS.0KN | S21 KN | 139.0 KN

340

i

120 s sh +

10 || —t ay

80

7 —resinos

£ Test No.2

i eeeeee cee a _ —Testno:3

40

20 | ie

oe el Z Ble

0 40 42 «30 «40 «50S

Displacement (mm)

Testing otcer

Notice: i

ONLY th erigina signed report must be |

regarded asthe ofl document Page: 303 Engen?

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Diagrama de Flujo Estacion de ServicioDocument1 pageDiagrama de Flujo Estacion de Serviciobernardo100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Ejes BT Ab3 Ee FF Aj Per 1 6 Con Fin Siga SolDocument34 pagesEjes BT Ab3 Ee FF Aj Per 1 6 Con Fin Siga SolbernardoNo ratings yet

- Ejes Contab Sol 1 7Document38 pagesEjes Contab Sol 1 7bernardoNo ratings yet

- Ejes Costos Abs Inventario FaltabanDocument10 pagesEjes Costos Abs Inventario FaltabanbernardoNo ratings yet

- Ejes Costos Variab Sol FaltabanDocument2 pagesEjes Costos Variab Sol FaltabanbernardoNo ratings yet

- Ejes Costos Variab Siga Iman Sol-1Document6 pagesEjes Costos Variab Siga Iman Sol-1bernardoNo ratings yet

- Evaluacion 1 2021 AgostoDocument2 pagesEvaluacion 1 2021 AgostobernardoNo ratings yet

- Data Contabilidad Def Todos 1Document18 pagesData Contabilidad Def Todos 1bernardoNo ratings yet

- Data Costos AbsDocument21 pagesData Costos AbsbernardoNo ratings yet

- Reparación Filtro Banda #5Document5 pagesReparación Filtro Banda #5bernardoNo ratings yet

- Data Contabilidad Def Todos 2Document15 pagesData Contabilidad Def Todos 2bernardoNo ratings yet

- Vps Bimpac PlantaDocument7 pagesVps Bimpac PlantabernardoNo ratings yet

- Ficha Tecnica EZ FIX MAXDocument1 pageFicha Tecnica EZ FIX MAXbernardoNo ratings yet

- Polínes 55CVR01Document1 pagePolínes 55CVR01bernardoNo ratings yet

- Planos Polines de Filtro de BandaDocument5 pagesPlanos Polines de Filtro de BandabernardoNo ratings yet

- Ficha Tecnica Alzacintas-0Document2 pagesFicha Tecnica Alzacintas-0bernardoNo ratings yet

- Planificación NDT MDE 2021Document23 pagesPlanificación NDT MDE 2021bernardoNo ratings yet

- Ficha Tecnica Prensas TUG-0Document2 pagesFicha Tecnica Prensas TUG-0bernardoNo ratings yet

- Análisis de Consolidación y Secado de Relaves para Evaluar Mejoras deDocument268 pagesAnálisis de Consolidación y Secado de Relaves para Evaluar Mejoras debernardoNo ratings yet

- CV-06 Tramo1Document1 pageCV-06 Tramo1bernardoNo ratings yet

- Reporte Flash No Bloqueo de Correa MELDocument1 pageReporte Flash No Bloqueo de Correa MELbernardoNo ratings yet

- Estacion de Servicio (Original)Document27 pagesEstacion de Servicio (Original)bernardoNo ratings yet

- Administración de Empresas MGDocument2 pagesAdministración de Empresas MGbernardoNo ratings yet