Professional Documents

Culture Documents

Manage Performance with KPIs

Uploaded by

awadallaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manage Performance with KPIs

Uploaded by

awadallaCopyright:

Available Formats

Key Performance Indicators (KPIs)

Selecting the Proper KPIs

KPI Tree

Operational Definition

Balanced Scorecard

Common KPIs

KPIs & Continuous Improvement

Performance management is an approach used to manage performance of an

organization. It can play an important role in the success or failure of a business. It can

be applied to measure the performance of an organization, a business unit, a single

department, a project, an employee, and even the process to build a product or service.

It includes activities that will help to ensure goals are consistently being met in an

effective manner. Those activities include planning and setting expectations, developing

the capacity to perform, continually monitoring performance, periodically rating

performance in a summary fashion, and rewarding good performance.

Performance indicators are measurements that define and assess the performance

and the success of an organization. They are objectives to be targeted in order to add

the most value to a business. They are means to periodically assess the performance of

an organization, its departments and the people working there. Performance indicators

are developed to impact the entire organization. Accordingly, choosing the right

performance indicators relies upon a good understanding of what is important to the

organization.

An organization may use performance indicators to assess its success as well as the

success of an operational goal or a particular activity. Performance indicators are either

result oriented or process oriented. Result oriented indicators focus on the key

outputs of a process and related to the critical success factors (e.g. customer

complaints from key customers and return on investment). While process oriented

indicators focus on the inputs to a process (e.g. time to process customer

order and late deliveries to key customers).

Performance Indicators are Used to:

Help an organization to understand its performance levels and set realistic

performance goals.

Help aligning daily work to the organization’s strategic goals.

Help an organization monitoring its progress on a real-time basis.

Help an organization to understand its weaknesses and establish

improvement priorities.

Determine whether an improvement is being made and maintained.

Help benchmark internally and externally.

Identify if staff are doing well and to help them if they are not.

Provide a basis for recognizing team and individual performance.

Selecting the Proper Performance Indicators:

Performance indicators are often developed based on the critical success factor.

CSFs are the elements that are necessary for a strategy to be successful and for an

organization to achieve its mission. CSFs selection is a very subjective exercise and

requires active leadership by senior management. Examples of CSFs are: delivery on-

time and in-full, providing superior customer service, short time to market new

products, management commitment and staff orientation.

For example, if one of your goals is to deliver product on-time in-full, then a

performance indicator may be the percentage of deliveries that are received by

customers not on-time in-full. By monitoring this, you can improve your delivery

performance by directly measure how well your organization is meeting its long-term

goal of providing an on-time in-full delivery to customers.

Performance indicators need also to reflect the Voice of the Customer. By

understanding the Critical-to-Quality characteristics (CTQs) features of your customer,

you can use them as a basis to select your performance indicators. Customer

satisfaction level, customer retention rate, the number of key customer visits, and the

profitability of customers are among the indicators that may be measured. In order to

calculate those performance indicators, raw data needs to be collected from customers.

KPI Tree:

An ideal situation is where performance indicators cascade down through an

organization. A KPI Tree is a visual method of displaying a range of measures in an

organization or related to a project. This helps people work in such a way that their

activities are aligned with the organization strategy, and helps individual work areas

contribute to overall business performance. It helps bringing together a range of

measures and provides a visual representation for which measures contribute to other

measures.

A successful KPI tree is the one that contains a balance of measures covering

efficiency, effectiveness, quality, delivery and cost. You might find that sometimes you

have to develop some new measures to achieve this balance. Effectiveness

performance indicators measure processes in the eyes of the customer. They measure

customer satisfaction such as quality, on-time delivery, cost, accuracy, ease of use, etc.

Efficiency performance indicators measure processes from business perspective, and

are of interest to the internal customers. They measure the amount of resources used

by a process and are thus likely to have close links with the 8 Wastes. Examples

are: processing time, waiting time, cycle time, inspection cost, repair cost and material

usage.

Example:

The following is an example of a KPI Tree that was constructed during the

implementation of a customer satisfaction research improvement project.

Operational Definitions:

An operational definition is a clear and detailed description of a performance indicator.

The need for operational definitions is fundamental when collecting data. The data

collection will be meaningless if there is an inconsistency in understanding a measure, a

specification, a requirement, or a procedure. Operational definitions ensure consistent

data collection, eliminate ambiguity, and ensure standards are applied in the same

manner.

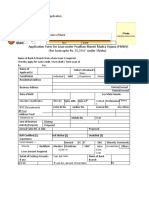

The following is an example of a form that can be used to present the operational

definitions of performance indicators.

Balanced Scorecard and Dashboard Reporting:

A very common way to manage and monitor performance indicators is to apply a

management framework such as the balanced scorecard. A scorecard is simply a

report that displays a collection of performance indicators. The balanced scorecard has

evolved from its early use as a simple performance measurement framework to a full

strategic planning and management system. It helps align business activities to the

vision and strategy of the organization and monitor performance against strategic goals.

Click to enlarge

Performance dashboards are used to easily monitor the performance in an

organization. They are often a series of graphics, charts, gauges and other visual tools

that can be easily interpreted and analyzed. They allow to see if the performance

indicators are being met based on the goals in place. If not, they will visually alert that

corrective actions should be made. They are typically limited to show summaries,

comparisons and trends. A good dashboard:

Is simple and easy to understand.

Conveys important information at a glance.

Contains minimal distractions and visually appealing.

Displays real-time information.

Should be displayed on the shop floor using a screen or a bulletin boards.

Common Key Performance Indicators:

Here are some of the common KPIs to measure and monitor per business function:

Manufacturing and Producti on

Spoilage / rejecti on rate

Re-work rate

Time spent on product re-work

Total units manufactured

Units per day

Units per labor hour

Line effi ciency

Producti on capacity

Capacity uti lizati on

First ti me right rati o

Rolled throughput yield (RTY)

Average changeover ti me

Material usage

Purchasing and Inventory

Cancelled purchase requests

Purchase orders completed

Purchase order cycle ti me

Emergency purchase rate

Rejected receipt rate

Late deliveries from suppliers

Changes in approved suppliers

Unloading ti me

Stock level

Inventory days coverage

Re-work on procured inventory

Sales, Marketi ng and Shipping

Time to process customer orders

Time to resolve customer claims

Visits to key customers

New customers rate

Customer retenti on rate

Sales forecast accuracy

Market share growth

Marketi ng expenses

Product availability

Loading ti me

Not on-ti me in-full (NOTIF)

Finance and Accounti ng

Net profi t margin

Cost of goods sold

Operati ng income

Cost per unit

Working capital

Accounts receivable turnover

Inventory turnover rati o

Return on investment (ROI)

Budget variance

Capital expenditure (CAPEX)

Monthly department expenses

Maintenance

Response Time to Breakdown

Mean Time Between Failures

Mean Time to Repair

Spare Parts Inventory Turnover

Work Orders Completed

Preventi ve Maintenance Completed

Repair Cost

Repair Cost per Unit

Maintenance / Repair Downti me

Human Resources

Staff turnover rati o

Employee sati sfacti on index

Exit interview sati sfacti on rati o

Internal promoti on rate

Labor uti lizati on rate

High performing employees

Training hours rati o

Training att endance rati o

Absenteeism rate

Part-ti me employees

Disabled staff rati o

Environment, Health & Safety

Recorded safety observati ons

Workplace inspecti on audits

Risk assessments implemented

Lost work days

Signifi cant injury cases

Near miss cases

First aid treatment cases

Environmental incidents

Safety circles conducted

Sati sfacti on with ergonomics

EHS training hours

Quality

Customer complaints

Returns from key customers

Customer sati sfacti on index

Customer surveys conducted

Defects at customer site

Defects per million opportuniti es

Defects per unit

Cost of non quality

Quality circles conducted

Audits performed on schedule

Lean

Value added ti me

Takt ti me

Operator / machine cycle ti me

Order processing cycle ti me

Net available ti me

Work in process ti me

Value stream rati o

Process Cycle effi ciency

Upti me rati o

Overall equipment eff ecti veness

Muda-free cost

KPIs and Continuous Improvement:

Performance indicators are key to the continuous improvement process. They are used

to establish improvement priorities and track the progress of improvement projects. The

following are examples of indicators that are used to measure continuous improvement

activities:

Chartered improvement projects

Project charters approved and signed off

SOPs developed after improvement projects

Completed improvement projects

Financial department involvement in improvement projects

Processes perform at 4.5 Sigma or higher

Staff trained in Lean Six Sigma

Savings resulting from improvement implemented by employee suggestions

Time to respond to suggestions

Idea conversion rate

Kaizen events conducted

Cross-industry benchmarking studies conducted

Utilizing Performance Indicators:

The following steps will help you understand how to establish and best utilize your

winning performance indicators:

Review the quality of the current data collection methods (are you collecting

data unnecessarily?).

Train staff on CTFs, KPIs, empowerment and process improvement methods.

Start by a few easily understood performance indicators.

Relate to critical success factors and reflect the voice of the customer.

Allow teams to define and select their own performance indicators.

Have your performance indicators approved by senior management.

Measure and report only what matters.

Monitor performance using dashboards.

Display at workplace (on screens or public display boards).

Use performance indicators as a basis for team meetings and decision

making.

Identify and pursue improvement goals.

You might also like

- ThemeGallery Company ProfileDocument20 pagesThemeGallery Company ProfileNatasa Maric SekulicNo ratings yet

- Manufacturing Process Audit: Example ReportDocument25 pagesManufacturing Process Audit: Example ReportJawad rahmanaccaNo ratings yet

- How To Create An Effective Standard Operating ProcedureDocument56 pagesHow To Create An Effective Standard Operating ProcedureMemona YasmineNo ratings yet

- Developing Operational Review Programmes For Managerial and Audit UseDocument38 pagesDeveloping Operational Review Programmes For Managerial and Audit UseRoxanne CerioNo ratings yet

- ProtivitiDocument24 pagesProtivitivipul.sachdeva6947No ratings yet

- FPT Software's Financial Report and AnalysisDocument39 pagesFPT Software's Financial Report and AnalysisHuy Nguyễn NgọcNo ratings yet

- Strategic Planning Ebook HR 2018 1Document31 pagesStrategic Planning Ebook HR 2018 1Lanfan BariNo ratings yet

- Server Refresh Planning Guide PDFDocument20 pagesServer Refresh Planning Guide PDFK Kunal RajNo ratings yet

- Accenture Outlook From Analog To Digital How To Transform The Business ModelDocument6 pagesAccenture Outlook From Analog To Digital How To Transform The Business ModelMoybul AliNo ratings yet

- Erp White PaperDocument18 pagesErp White PaperJayaprakash ThonnakkalNo ratings yet

- ErpNext Consulting IEEE PHDocument3 pagesErpNext Consulting IEEE PHNathaniel JoshuaNo ratings yet

- Best Practices For Ensuring A Successful ITSM ImplementationDocument23 pagesBest Practices For Ensuring A Successful ITSM ImplementationErdem Enust100% (1)

- Capstone ProjectDocument16 pagesCapstone ProjectApeksha YadavNo ratings yet

- IT Roles + Responsibilities + KPIsDocument7 pagesIT Roles + Responsibilities + KPIsfredelNo ratings yet

- ITIL Core Concepts Summary PDFDocument31 pagesITIL Core Concepts Summary PDFRafael SolisNo ratings yet

- Business Process Analysis and Optimization - A Pragmatic Approach To Business OperationsDocument36 pagesBusiness Process Analysis and Optimization - A Pragmatic Approach To Business OperationsParvez AlamNo ratings yet

- Measuring ITSM - Are Your Processes Making The GradeDocument17 pagesMeasuring ITSM - Are Your Processes Making The GradeMoe SulimanNo ratings yet

- Hoc Practices, To Formally Defined Steps, To Managed Result Metrics, To ActiveDocument5 pagesHoc Practices, To Formally Defined Steps, To Managed Result Metrics, To ActiveSwati ShettyNo ratings yet

- Establishing and Improving Manufacturing Performance MeasuresDocument6 pagesEstablishing and Improving Manufacturing Performance MeasuresIslamSharafNo ratings yet

- Getting There and Enjoying The Trip: Using Roadmaps To Turn EA Into ResultsDocument28 pagesGetting There and Enjoying The Trip: Using Roadmaps To Turn EA Into ResultsChristopher StanleyNo ratings yet

- KPI-based Performance Measurement FrameworkApproach For Lean Implementation in Mining IndustryDocument4 pagesKPI-based Performance Measurement FrameworkApproach For Lean Implementation in Mining IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Strategic Planning: S M A R TDocument5 pagesStrategic Planning: S M A R Tms60codNo ratings yet

- Problem Management Overview: PM Process, KPIs, BenefitsDocument26 pagesProblem Management Overview: PM Process, KPIs, Benefits1buckeyeNo ratings yet

- PM Performance and Value List of MeasuresDocument44 pagesPM Performance and Value List of MeasuresnobitaenokiNo ratings yet

- ITSM Measurement PDFDocument12 pagesITSM Measurement PDFSwadhin PalaiNo ratings yet

- CCSDBE - QMS EstablishmentDocument7 pagesCCSDBE - QMS EstablishmentvyerramallaNo ratings yet

- ISM Audit Handbook GuideDocument26 pagesISM Audit Handbook GuideTri TranNo ratings yet

- Elements of Digital Dashboards: Effective Dashboard DesignDocument8 pagesElements of Digital Dashboards: Effective Dashboard DesignUmer RafiqNo ratings yet

- Wal MartDocument8 pagesWal MartNazish SohailNo ratings yet

- Abigail Santos Boutique, Financial Statement For MerchandisingDocument9 pagesAbigail Santos Boutique, Financial Statement For MerchandisingFeiya Liu100% (1)

- Metrics For IT Outsourcing Service Level AgreementsDocument9 pagesMetrics For IT Outsourcing Service Level Agreementsapi-19828209No ratings yet

- Service Delivery and ITDocument6 pagesService Delivery and ITRomaBMNo ratings yet

- Your Payment ReceiptDocument1 pageYour Payment ReceiptAnonymous XHThIrbDNo ratings yet

- ITIL, COBIT and EFQM - Can They Work Together PDFDocument12 pagesITIL, COBIT and EFQM - Can They Work Together PDFNiicolâs AndresNo ratings yet

- Best Practices For IT Strategic Planning en PDFDocument32 pagesBest Practices For IT Strategic Planning en PDFAnonymous iMq2HDvVqNo ratings yet

- World Class ManufacturingDocument16 pagesWorld Class ManufacturingedercassettariNo ratings yet

- How to Build a Service Catalog in 40 CharactersDocument10 pagesHow to Build a Service Catalog in 40 Charactersamramin1963No ratings yet

- ITIL V3 Planning, Protection and OptimizationDocument167 pagesITIL V3 Planning, Protection and OptimizationCarol Nzui100% (5)

- Business Process Reengineering (A Prerequisite For Process Model Design)Document31 pagesBusiness Process Reengineering (A Prerequisite For Process Model Design)Milind GadhaviNo ratings yet

- Business Process Management Systems: Madonna Nagy Ashraf AbdelraoufDocument55 pagesBusiness Process Management Systems: Madonna Nagy Ashraf AbdelraoufDona NagyNo ratings yet

- Optimize Software License Revenue WhitepaperDocument9 pagesOptimize Software License Revenue WhitepaperFlexeraSoftwareNo ratings yet

- Metrics Framwork RolloutDocument6 pagesMetrics Framwork RolloutAashirtha SNo ratings yet

- Testing Process ImprovementDocument29 pagesTesting Process Improvementapi-3699222No ratings yet

- Itil Process Assessment FrameworkDocument42 pagesItil Process Assessment FrameworkaminaNo ratings yet

- Designing and Managing Valuable Service ProcessesDocument34 pagesDesigning and Managing Valuable Service ProcesseszeraNo ratings yet

- T&H Shopfitters Corp v. T&H Shopfitters Corp Workers UnionDocument2 pagesT&H Shopfitters Corp v. T&H Shopfitters Corp Workers UnionJonas CruzNo ratings yet

- Analyzing Investing Activities Chapter 5Document29 pagesAnalyzing Investing Activities Chapter 5Anggita LianiNo ratings yet

- Identification of Key Performance Indicators inDocument18 pagesIdentification of Key Performance Indicators inMaria Aparecida Almeida AlvesNo ratings yet

- Configure Service Desk PDFDocument48 pagesConfigure Service Desk PDFreparraNo ratings yet

- Basel - Four Lines of DefenseDocument29 pagesBasel - Four Lines of DefenseShankar RavichandranNo ratings yet

- Deployment of Software Metrics Measurements Techniques Within Software Development ProcessDocument5 pagesDeployment of Software Metrics Measurements Techniques Within Software Development ProcessJournal of ComputingNo ratings yet

- A Starter Set of ITSM Guiding PrinciplesDocument96 pagesA Starter Set of ITSM Guiding PrinciplesalawawdsNo ratings yet

- L2 Demand ManagementDocument19 pagesL2 Demand ManagementEmaNo ratings yet

- SWOT AnalysisDocument11 pagesSWOT AnalysisWill Panchaud0% (1)

- A Self-Assessment Tool For Estimation of IT MaturityDocument1 pageA Self-Assessment Tool For Estimation of IT MaturityVanessa García PinedaNo ratings yet

- Service Catalog EmailDocument14 pagesService Catalog EmailAlberto Pazmiño ProañoNo ratings yet

- Offering Content GuideDocument86 pagesOffering Content GuideGanesh IyerNo ratings yet

- Ernest - Adding Value To The It Organization With The CBM - 1Document17 pagesErnest - Adding Value To The It Organization With The CBM - 1tessioyudi2070No ratings yet

- Business Process ReengineeringDocument6 pagesBusiness Process ReengineeringigoeneezmNo ratings yet

- Process Improvement Calculations ToolsDocument65 pagesProcess Improvement Calculations ToolsNevets Nonnac100% (1)

- ITIL 4 Big Picture - Value InsightsDocument1 pageITIL 4 Big Picture - Value InsightsRodrigo AzevedoNo ratings yet

- Service Continuity Service Delivery AssessmentDocument28 pagesService Continuity Service Delivery Assessmenttom smithNo ratings yet

- KPIs in ServiceDocument19 pagesKPIs in ServiceBojan JanjatovicNo ratings yet

- Oracle Support Escalation GuideDocument1 pageOracle Support Escalation GuideNitin SharmaNo ratings yet

- Winning in A Business 4 0 World PDFDocument56 pagesWinning in A Business 4 0 World PDFLap Pham100% (1)

- Infrastructure MGMT ServicesDocument5 pagesInfrastructure MGMT Servicesshivanagendra koyaNo ratings yet

- Nature of Modern Internal AuditingDocument15 pagesNature of Modern Internal Auditinganon_323651754No ratings yet

- Further Scope of The Study Regarding Investment BankingDocument3 pagesFurther Scope of The Study Regarding Investment BankingMehedi HassanNo ratings yet

- Mba 302Document256 pagesMba 302Denim KakaNo ratings yet

- 6091fcbbdded96002ad5430d 1620180284 Big Picture C AR ManagementDocument8 pages6091fcbbdded96002ad5430d 1620180284 Big Picture C AR ManagementChi BellaNo ratings yet

- Financial ManagementDocument14 pagesFinancial ManagementsangeethamadanNo ratings yet

- Application Form For Mudra Loan ShishuDocument2 pagesApplication Form For Mudra Loan ShishuSree DigitalNo ratings yet

- Toma, Pepsi Juices-Tropicana PolandDocument1 pageToma, Pepsi Juices-Tropicana Polandbigstar42No ratings yet

- Office Communication and Interpersonal SkillsDocument6 pagesOffice Communication and Interpersonal SkillsRanjan MayanglambamNo ratings yet

- C.V Mohamad SafwanDocument2 pagesC.V Mohamad Safwanmohd addinNo ratings yet

- Safari - 03-Oct-2023 at 10:27 AMDocument1 pageSafari - 03-Oct-2023 at 10:27 AMVijay BhaskarNo ratings yet

- 1 D 1 DF 41 D 6 F 8 C 8 G 5Document5 pages1 D 1 DF 41 D 6 F 8 C 8 G 5Kia PottsNo ratings yet

- Solution To Problems - Chapter 9Document25 pagesSolution To Problems - Chapter 9GFGSHSNo ratings yet

- Vision and MissionDocument3 pagesVision and MissionPaulo Arwin BaduriaNo ratings yet

- Trips AgreementDocument3 pagesTrips Agreementsreedevi sureshNo ratings yet

- Availability As of December 1, 2020: Classification Phase LOT Area List Price Exclusive of Vat & Oc Allocation StatusDocument7 pagesAvailability As of December 1, 2020: Classification Phase LOT Area List Price Exclusive of Vat & Oc Allocation StatusMia NungaNo ratings yet

- How COVID-19 Will Change The Geography of CompetitionDocument5 pagesHow COVID-19 Will Change The Geography of CompetitionGan YunshanNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument7 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceGagan DhingraNo ratings yet

- Ch. 13 Notes: Financial Statement Analysis BreakdownDocument9 pagesCh. 13 Notes: Financial Statement Analysis BreakdownLê Tuấn AnhNo ratings yet

- Islamic Crowd Funding Platform Grows in SE AsiaDocument7 pagesIslamic Crowd Funding Platform Grows in SE AsiaKetoisophorone WongNo ratings yet

- Full Download Bcom Canadian 1st Edition Lehman Test BankDocument17 pagesFull Download Bcom Canadian 1st Edition Lehman Test Banksmallmanclaude100% (33)

- Press Release - 24 Aug 2023Document2 pagesPress Release - 24 Aug 2023rock6hard7No ratings yet