Professional Documents

Culture Documents

Capex For Plant 1 Condenser

Uploaded by

dbp90500 ratings0% found this document useful (0 votes)

13 views4 pagesCapex

Original Title

Capex for Plant 1 Condenser

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCapex

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views4 pagesCapex For Plant 1 Condenser

Uploaded by

dbp9050Capex

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Capex No. AOPLIMBRI19-20/0/g | PLANT - 01

y Replacement and Installation of Condenser at Plant - 01 |

Replacement and Installation of Condenser at Plant

Prepared By:

Projects Department, Baroda

Date of Preparation-1 1/07/2019

Prepared By Reviewed By et By

es

| a

|

| Vaibhav

| Mayank Patel Passi Ashok Pathy | Dr Sunil Bawane Manish Doshi

+ | -

Dy. Manager AGM cM | President | 8

Mi |

Engg. & Projects | Engg. & Projects Operation | API

Page 1 of 4

|

)

|

|

|

|

alo

AOPLIMBR/19-20/ 0\@/ PLANT - 01

Replacement and Installation of Condenser at Plant - 01

Index

| Particulars Page No.

| Project Name ae ieee ats

| Index ; Zs : a 2 |

| Objective = Le ee Sel |

| Major Equipments requirements : 3 |

| Justification 7 = | 3

| Cost Estimate | on

Capex Implementation i: | 4 a

2 eae

| Pay back

Page 204

AOPLIMBR/19-20/9\@ / PLANT = 01

Ni Replacement and Installation of Condenser at Plant - 01

1. Objective:-

+ To replace shell & tube condensers of R-102 and R-115 to meet the present process

requirements for distbutton. Ay’) gh on

2. Major Equipments Requirement:-

= 10m? SS ~ Condenser — 02 nos. (R - 102 & R ~ 115 Primary Condenser)

« 08m? SS ~ Condenser — 02 nos. ( R - 102 & R - 115 Secondary Condenser)

3. Justificatior

* Present Condition:

R_— 102: During distillation and recovery of solvent, there is vapor loss and the

recovery of toluene is at 80 %.Due to this distillation and recovery time is more

This is due to insufficient capacity (< 8m? area) of condenser in R - 102 which is old

and under capacity.

R= 115° This reactor was unused since last - 4 years. It is now rejacketed and

planned to utilize for atorva stage - |. Existing condenser is old and under size/ive(” >

Distillation time is more due to improper cooling,

* Proposed Condition:

R — 112 & R — 115 will have improved recovery of toluene. Expected increase in

recovery by 2% to 4% for toluene used in sertraline and Atoravastatin. Distillation /

Recovery time will reduce by 20% to 25%.

Page 3 of 4

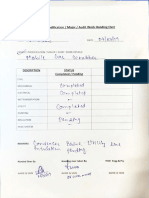

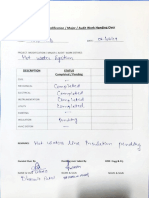

Capex No. AOPLIMBR/19-20/ ©) / PLANT - 01

OL!

N Replacement and Installation of Condenser at Plant — 01

4. Cost Estimate:-

Piping Cost (20%) 1.76

Insulation Cost (15%) | 1.32

Labor charges (20%) 1.76

(including Dismantling & Erection charges)

Grand Total

1, SK Cost |

No. | Description (Lacks) |

1 Equipment Cost 10m2 condenser 02 nos. | 5.20

2 | Equipment Cost 08m2 condenser 02 nos. | 3.60_|

Total 8.80 |

|

13.64 | INR

5. Capex Implementation:-

8 weeks

6. Pay Back:-

« Improved solvent recovery, reduced cycle time and EHS compliance:

Page 4 of 4

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Kilo Lab - 3Document1 pageKilo Lab - 3dbp9050No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Kilo Lab - 2Document2 pagesKilo Lab - 2dbp9050No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Welding Defects PDFDocument61 pagesWelding Defects PDFمحمد امين شريفNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Kilo LabDocument3 pagesKilo Labdbp9050No ratings yet

- Online Helicopter Ticket Details for Shri Mata Vaishno Devi ShrineDocument5 pagesOnline Helicopter Ticket Details for Shri Mata Vaishno Devi Shrinedbp9050No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Gmail - Job - Urgent Opening in API MFG Production Dept.Document3 pagesGmail - Job - Urgent Opening in API MFG Production Dept.dbp9050No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- PDFDocument2 pagesPDFdbp9050No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Curriculum Vitae ' Sr. Boiler Attendant / Technical AssistantDocument3 pagesCurriculum Vitae ' Sr. Boiler Attendant / Technical Assistantdbp9050No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Cooling TowerDocument17 pagesCooling TowerFaisal ShahzadNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Rates of Income Tax for AY 2017-18Document70 pagesRates of Income Tax for AY 2017-18dbp9050No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Turnkey ProjectDocument12 pagesTurnkey Projectdbp9050No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)