Professional Documents

Culture Documents

Upadhye Pradeep Vardhaman

Uploaded by

ajijOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Upadhye Pradeep Vardhaman

Uploaded by

ajijCopyright:

Available Formats

1.

Name of the student: UPADHYE PRADEEP VARDHAMAN

2. Date of Registration: 29th September 2017

3. Whether the candidate

is attending regularly: Yes

If not, give reason:

4. Name of the guide: ASST. PROF.S.B.PATIL

5. Title of the work: REJECTION ANALYSIS AND IMPROVEMENT IN CASTING OF

PUMP COVER 0143133677 BY TAGUCHI METHODS.

6. Period of report: AUGUST 2019 – NOVEMBER 2020

7. Details of the work done: This Progress Report 1 contains the work done between the

month of December 2019 to January 2020 which was carried

out by following the guidelines given by guide and Activity

described in Activity Chart.

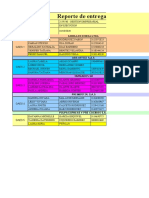

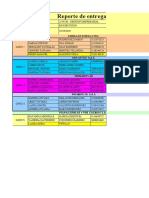

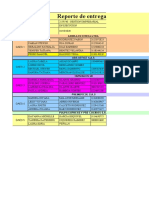

7.1 January 2020

7.1.1 Work Aimed – “To optimize the pouring Temperature of Cover 678”.

7.1.2 Activity performed –

I. Experimental Setup for different Temperature.

II. Collecting The data.

7.1.3 Experimental Set up

As per recommendation reset up experiment for the temperature between 1250°c-1350°c

7.1.3.1 Result

Sr. Group of Temperature Result After Machining of

No. 20Nos

1 1250°c -1350°c 19 Nos

7.1.3.2 Summery

So After Result we getting that the Temperature is in Between 1250°c to 1350°c is correct

and if the temperature will increases the amount of gas trapped also increases which cause the

blow hole generation in the casting surface

8.1 February 2020

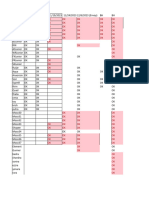

8.1.1 Work Aimed – “To Analysis and remove the Wall issue.”

8.1.2 Activity performed –

I. Collection of data where wall thickness issue occurs.

II. Implementing Corrective Action for Cure this Issue.

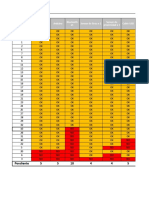

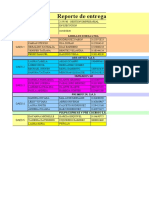

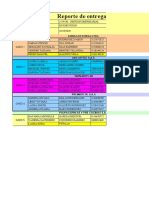

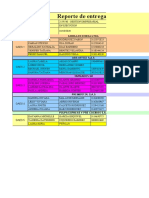

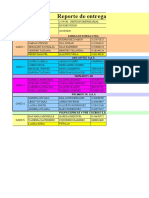

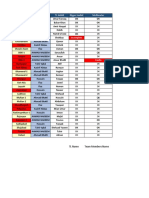

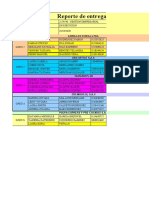

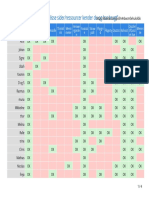

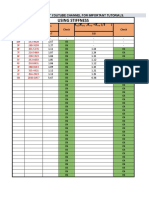

8.1.2.1 Collection of data where wall thickness issue occurs.

Give Numbering to the each Wall and Measuring 15Nos for the Tracing the Part location where

the wall thickness is off

There is 15Pointof wall thickens which is to measure where gauge is ok or not

OK = NOGO and GO will pass

NOT OK = NOGO and Go will not pass

LOCATION

PART

L-

NO. L-1 L-2 L-3 L-4 L-5 L-6 L-7 L-8 L-9 L-10 L-11 L-12 L-14 L-15

13

NOT NOT NOT NOT

1 OK OK OK OK OK OK OK OK OK OK OK

OK OK OK OK

NOT NOT

2 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT

3 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT

4 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT

5 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT NOT NOT

6 OK OK OK OK OK OK OK OK OK OK OK

OK OK OK OK

NOT NOT

7 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT

8 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT NOT NOT

9 OK OK OK OK OK OK OK OK OK OK OK

OK OK OK OK

10 OK OK OK OK OK OK OK OK OK OK OK OK OK OK OK

NOT NOT

11 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT NOT NOT

12 OK OK OK OK OK OK OK OK OK OK OK

OK OK OK OK

NOT NOT

13 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT

14 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

NOT NOT

15 OK OK OK OK OK OK OK OK OK OK OK OK OK

OK OK

8.1.3 CONCLUSION

From the data analysis we found that the location at the L-4 and L-14 are quite similar as well as

L-5 and L-10 also similar so we conclude that wall thickness issue will occure from the core

sliding in the moluld

You might also like

- Kalimba. 37 Simple Songs from Around the World: Play by NumberFrom EverandKalimba. 37 Simple Songs from Around the World: Play by NumberNo ratings yet

- Master Inspection Data Sheet YCTDocument2 pagesMaster Inspection Data Sheet YCTboby RachmanNo ratings yet

- Avance Jesus UnmsmDocument1 pageAvance Jesus UnmsmJesus Adderly Calle Flores YarlequeNo ratings yet

- Copia de Inventario RobotsDocument5 pagesCopia de Inventario RobotsRoberto Carlos CaraballoNo ratings yet

- Lista de Chequeo TH3Document3 pagesLista de Chequeo TH3kthe MontoyaNo ratings yet

- Aprendiz No. Evidencias Por Entregar Informe Foro Tematico Folleto PromocionalDocument3 pagesAprendiz No. Evidencias Por Entregar Informe Foro Tematico Folleto Promocionalkthe MontoyaNo ratings yet

- Produtividade Do DiaDocument3 pagesProdutividade Do DiaDrunk Funny 2020No ratings yet

- QA-R-32 MSA (Attribute Study)Document2 pagesQA-R-32 MSA (Attribute Study)Raja DuraiNo ratings yet

- RUT Nombre Completo Cargo Turno 1 2 3 4 5 6 7 8 9 10 11 13 14 15 16 17 18 19 20 21 22 23 24 25Document8 pagesRUT Nombre Completo Cargo Turno 1 2 3 4 5 6 7 8 9 10 11 13 14 15 16 17 18 19 20 21 22 23 24 25Carolina Valeska Gallegos JerezNo ratings yet

- Cedula Nombre Completo ProcudaduriaDocument2 pagesCedula Nombre Completo ProcudaduriaBRAYAN ALEXIS ARIAS LOAIZANo ratings yet

- 03/2018 Report Prova in Nebbia Salina (In Accordo Con UNI ISO 9227) Salt Spray Test Report (According To UNI ISO 9227) ISO 9227Document3 pages03/2018 Report Prova in Nebbia Salina (In Accordo Con UNI ISO 9227) Salt Spray Test Report (According To UNI ISO 9227) ISO 9227Rinaldo BompieriNo ratings yet

- Cuadro de Contabilidad ActualizadoDocument5 pagesCuadro de Contabilidad ActualizadoTatiana MerchanNo ratings yet

- Cuadro de Contabilidad ActualizadoDocument5 pagesCuadro de Contabilidad ActualizadoTatiana MerchanNo ratings yet

- Cuadro de Contabilidad ActualizadoDocument5 pagesCuadro de Contabilidad ActualizadoTatiana MerchanNo ratings yet

- Cuadro de Contabilidad ActualizadoDocument5 pagesCuadro de Contabilidad ActualizadoTatiana MerchanNo ratings yet

- Cuadro de Contabilidad ActualizadoDocument5 pagesCuadro de Contabilidad ActualizadoTatiana MerchanNo ratings yet

- C-3 Gadgets Detail NOV-21 .Document5 pagesC-3 Gadgets Detail NOV-21 .Muhammad Arslan AfzalNo ratings yet

- Nomor Soal Kunci Jawaban: Analisis Soal Uts Semester Ii: - TP 2017 - 2018Document2 pagesNomor Soal Kunci Jawaban: Analisis Soal Uts Semester Ii: - TP 2017 - 2018doreeeNo ratings yet

- Cuadro de Contabilidad Actualizado1Document7 pagesCuadro de Contabilidad Actualizado1Tatiana MerchanNo ratings yet

- Cuadro de Contabilidad Actualizado1Document7 pagesCuadro de Contabilidad Actualizado1Tatiana MerchanNo ratings yet

- Cuadro de Contabilidad Actualizado1Document7 pagesCuadro de Contabilidad Actualizado1Tatiana MerchanNo ratings yet

- Cuadro de Contabilidad Actualizado1Document7 pagesCuadro de Contabilidad Actualizado1Tatiana MerchanNo ratings yet

- Digital Resources Survey Results (Students) in DenmarkDocument4 pagesDigital Resources Survey Results (Students) in DenmarkKarmele LOPEZ DE ABETXUKONo ratings yet

- Encuesta Todos Recursos DanesesDocument4 pagesEncuesta Todos Recursos DanesesKarmele LOPEZ DE ABETXUKONo ratings yet

- Cuadro de Contabilidad Actualizado1Document5 pagesCuadro de Contabilidad Actualizado1Tatiana MerchanNo ratings yet

- Cuadro de Contabilidad Actualizado1Document5 pagesCuadro de Contabilidad Actualizado1Tatiana MerchanNo ratings yet

- 12th Floor Cheaklist2Document2 pages12th Floor Cheaklist2ankit GajjarNo ratings yet

- Soft Storey Check DecodeDocument18 pagesSoft Storey Check DecodePrinc XhikaNo ratings yet

- Controle de VisitasDocument42 pagesControle de VisitasRosana Alves LaudelinoNo ratings yet

- 10 Al 19 de Agosto Advertising and Web Page FP Aa7 E5 Export And/Or Import Fe Aa10 E8Document2 pages10 Al 19 de Agosto Advertising and Web Page FP Aa7 E5 Export And/Or Import Fe Aa10 E8jaseth peñateNo ratings yet

- QWRQWRDocument2 pagesQWRQWRjoep42000No ratings yet

- Relatorio UnidadesDocument3 pagesRelatorio UnidadesMarcos SouzaNo ratings yet

- Demi Journée de Travail..09!07!2022 Entre 8H Et 16HDocument9 pagesDemi Journée de Travail..09!07!2022 Entre 8H Et 16HMPUNGINo ratings yet

- UP OK Down UP OK UP OK OK UP Not Ok UP UP OKDocument5 pagesUP OK Down UP OK UP OK OK UP Not Ok UP UP OKBiswajit SahooNo ratings yet

- Curtos: Conteúdos Curriculares Aval. Externa Arte Atualizado Em: Links Das AtividadesDocument12 pagesCurtos: Conteúdos Curriculares Aval. Externa Arte Atualizado Em: Links Das AtividadesThalita GabrielaNo ratings yet

- Inspection Result: 13 3/8" 68# LB. FT K55 ButtressDocument1 pageInspection Result: 13 3/8" 68# LB. FT K55 ButtressRicardo Hurtado HernándezNo ratings yet

- Pre-Marital Counselling Class 22 Attendence List-2Document1 pagePre-Marital Counselling Class 22 Attendence List-2Davids BlackNo ratings yet

- Cuadro de Contabilidad ActualizadoDocument5 pagesCuadro de Contabilidad ActualizadoTatiana MerchanNo ratings yet

- Cuadro de Contabilidad ActualizadoDocument5 pagesCuadro de Contabilidad ActualizadoTatiana MerchanNo ratings yet

- Inventario (Data Mapper 2021)Document93 pagesInventario (Data Mapper 2021)GustavoNo ratings yet

- Block 1: Condominios Sociales Block 1-2-3 Rene SchneiderDocument12 pagesBlock 1: Condominios Sociales Block 1-2-3 Rene SchneiderDaniel Mauricio Arriagada ParraNo ratings yet

- PWSIRENSDocument1 pagePWSIRENSIsmed RizalNo ratings yet

- Controle de VisitasDocument42 pagesControle de VisitasManutençãoNo ratings yet

- Relatório de Execução Torres Edificio JamelDocument16 pagesRelatório de Execução Torres Edificio JamelGui TavernaroNo ratings yet

- 2.1.4.2 Jadwal Pemeliharaan Prasarana DurganDocument6 pages2.1.4.2 Jadwal Pemeliharaan Prasarana DurganKursaniNo ratings yet

- Nomina SemanalDocument9 pagesNomina SemanalHenry MuñozNo ratings yet

- Quantitative Aptitude and Reasoning (PDFDrive)Document1,029 pagesQuantitative Aptitude and Reasoning (PDFDrive)vikash kushwahaNo ratings yet

- Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok OkDocument8 pagesOk Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok Ok OkManuel MuñozNo ratings yet

- SL - NO Date No Location Remarks Pipe/ StructureDocument3 pagesSL - NO Date No Location Remarks Pipe/ StructureMaheshNo ratings yet

- L3 Meca-1Document4 pagesL3 Meca-1DANIEL KABWENo ratings yet

- Tecnologo Adsi Ficha 2348486: InduccionDocument6 pagesTecnologo Adsi Ficha 2348486: Induccionbrayan hernandezNo ratings yet

- Laporan ArisanDocument8 pagesLaporan ArisanSinergi Interior ProjectNo ratings yet

- SOAL UJIAN TENGAH SEMESTER Rev 1Document2 pagesSOAL UJIAN TENGAH SEMESTER Rev 1RAFLI RAMADHANNo ratings yet

- Pengukuran Suhu Dan Kelembapan Di Ruang OperasiDocument2 pagesPengukuran Suhu Dan Kelembapan Di Ruang OperasiRizky Ari LolaNo ratings yet

- Description: Stellar StatusDocument13 pagesDescription: Stellar StatusPaul CansinoNo ratings yet

- Code Opening FormDocument119 pagesCode Opening Formmuhammad ali umarNo ratings yet

- Soft Storey CheckDocument6 pagesSoft Storey CheckJunayed KhanNo ratings yet

- Kpi ReportDocument1 pageKpi ReportLegend FaridiNo ratings yet

- Inspección de TrampasDocument26 pagesInspección de Trampasmiguel muniveNo ratings yet

- Nomina SemanalDocument12 pagesNomina SemanalHenry MuñozNo ratings yet

- Theoretical & Experimental Analysis of Bike Handle BarDocument8 pagesTheoretical & Experimental Analysis of Bike Handle BarajijNo ratings yet

- ProjectDocument30 pagesProjectajijNo ratings yet

- A Literature Review On Supply Chain Management Barriers in Manufacturing OrganizationDocument17 pagesA Literature Review On Supply Chain Management Barriers in Manufacturing OrganizationajijNo ratings yet

- Study of Supply-Chain Management in The Automotive Industry: A Bibliometric AnalysisDocument17 pagesStudy of Supply-Chain Management in The Automotive Industry: A Bibliometric AnalysisajijNo ratings yet

- Supplier Quality Management For Component Introduction in The Automotive IndustryDocument10 pagesSupplier Quality Management For Component Introduction in The Automotive IndustryajijNo ratings yet

- Assessment of Supplier Quality Cost in Automobile IndustryDocument21 pagesAssessment of Supplier Quality Cost in Automobile IndustryajijNo ratings yet

- Upadhye Pradeep VardhamanDocument16 pagesUpadhye Pradeep VardhamanajijNo ratings yet

- Optimization of Process Parameters of Green Sand Casting in Small Scale FoundryDocument9 pagesOptimization of Process Parameters of Green Sand Casting in Small Scale FoundryajijNo ratings yet

- Optimization of Casting Parameters Using Taguchi MethodDocument12 pagesOptimization of Casting Parameters Using Taguchi MethodajijNo ratings yet

- Final ReportDocument36 pagesFinal ReportajijNo ratings yet

- Connorm Edid6507-Assign 2Document27 pagesConnorm Edid6507-Assign 2api-399872156No ratings yet

- Community Tourism Assessment Handbook PDFDocument169 pagesCommunity Tourism Assessment Handbook PDFElena Bianca Pripoaie100% (2)

- Statement of The Problem - Docx PartDocument5 pagesStatement of The Problem - Docx PartLavinia MerceneNo ratings yet

- Arie Rimmerman-Family Policy and Disability-Cambridge University Press (2015) PDFDocument226 pagesArie Rimmerman-Family Policy and Disability-Cambridge University Press (2015) PDFWederson SantosNo ratings yet

- HSPQ ResearchDocument187 pagesHSPQ ResearchnesumaNo ratings yet

- Portfolio Assessment Criteria 2019Document4 pagesPortfolio Assessment Criteria 2019asnanfarooqNo ratings yet

- Logi 5Document44 pagesLogi 5Äbřîśh Łìj MęŘãNo ratings yet

- FULLTgdsfgsds XT01Document103 pagesFULLTgdsfgsds XT01Ali RayyaNo ratings yet

- Pakistan Engineering Council: Sample Mcqs Mechanical Engineering (Control Engineering)Document7 pagesPakistan Engineering Council: Sample Mcqs Mechanical Engineering (Control Engineering)YacineNo ratings yet

- The Data Journalism Handbook 2Document270 pagesThe Data Journalism Handbook 2Yuxi WangNo ratings yet

- PV ToolkitDocument117 pagesPV ToolkitKumar Patil100% (1)

- Critical Tau.... Arulanandan 1980 PDFDocument107 pagesCritical Tau.... Arulanandan 1980 PDFAsad HafudhNo ratings yet

- Communications of The ACM 06/2009 Vol. 52 No. 06Document108 pagesCommunications of The ACM 06/2009 Vol. 52 No. 06UW Change100% (2)

- D77673-Discovery Lab (1 D Motion)Document5 pagesD77673-Discovery Lab (1 D Motion)genanubisNo ratings yet

- Chapter - Vii VII VII VII Bibliography Bibliography Bibliography BibliographyDocument8 pagesChapter - Vii VII VII VII Bibliography Bibliography Bibliography BibliographyS.SeethalakshmiNo ratings yet

- 532 PDFDocument170 pages532 PDFphylosophysNo ratings yet

- Behavior Science PerspectivesDocument446 pagesBehavior Science PerspectivesLuc FglNo ratings yet

- Pengaruh Kreativitas Kedisiplinan Kompensasi Dan Komunikasi Interpersonal Terhadap Kinerja Karyawan Di Pdam Kota PadangDocument12 pagesPengaruh Kreativitas Kedisiplinan Kompensasi Dan Komunikasi Interpersonal Terhadap Kinerja Karyawan Di Pdam Kota PadangMhd FauzanNo ratings yet

- Marketing Strategy of Commercial Vehicle Industry A Study On SML Isuzu LTDDocument11 pagesMarketing Strategy of Commercial Vehicle Industry A Study On SML Isuzu LTDAjay VermaNo ratings yet

- Thesis On Waffle SlabDocument177 pagesThesis On Waffle SlabNasredeenAhmadNo ratings yet

- Rhetorical AnalysisDocument6 pagesRhetorical Analysisapi-299723979100% (1)

- GeneralDocument43 pagesGeneralRichard SarominesNo ratings yet

- Itai Ivtzan and Christopher C. French - Testing The Validity of Tarot Cards: Can We Distinguish Between A Real and A Control Reading?Document3 pagesItai Ivtzan and Christopher C. French - Testing The Validity of Tarot Cards: Can We Distinguish Between A Real and A Control Reading?SorrenneNo ratings yet

- Critical To Customer RequirementsDocument29 pagesCritical To Customer RequirementsVaibhav SinghNo ratings yet

- Literature Review Doctoral DissertationDocument7 pagesLiterature Review Doctoral Dissertationpym0d1sovyf3100% (1)

- Chapter 1 To 3 Perception On The Effects of Retention Policy FinalDocument26 pagesChapter 1 To 3 Perception On The Effects of Retention Policy Finalmarc john jaudianNo ratings yet

- (Student) (University) (Instructor) (Submission Date)Document4 pages(Student) (University) (Instructor) (Submission Date)Alex WafulaNo ratings yet

- PHD Guidelines EMSApproved 2nov2018Document6 pagesPHD Guidelines EMSApproved 2nov2018Alemayehu CEromo ADNo ratings yet

- Research 3 Quarter 3 - MELC 1 Week 1-2 Inferential StatisticsDocument39 pagesResearch 3 Quarter 3 - MELC 1 Week 1-2 Inferential StatisticsHanna nicole JapsayNo ratings yet

- Exploring and Assessing Effectiveness of English Medium Instruction Courses: The Students' PerspectivesDocument8 pagesExploring and Assessing Effectiveness of English Medium Instruction Courses: The Students' PerspectivesGatun LockNo ratings yet