Professional Documents

Culture Documents

Deck Profile Sheet

Uploaded by

Husen Ghori0 ratings0% found this document useful (0 votes)

87 views20 pagesDEWAS

Original Title

deck-profile-sheet

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDEWAS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

87 views20 pagesDeck Profile Sheet

Uploaded by

Husen GhoriDEWAS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 20

www.pushpakinfra.com

Steel Redefined

Pushpak

Infra Steel Private Ltd

COMPANY PROFILE

Pushpak Group of Companies

Pushpak Steel Centre Pushpak Colour Roof (I) Pvt. Ltd.

Pushpak Infra Steel Pvt. Ltd. Pushpak Infra Resources Pvt. Ltd.

Pushpak group established in 1987 is a Pune based group

specializing in Stee! Roofing Industry. Having a vast experience of more

than 30 years, the company has grown to become one of the largest

manufacture and distributors of roofing sheets and allied products.

Pushpak group has its own manufacturing unit under the name of

Pushpak Colour Roof (1) Pvt. Ltd. The company posses an installed

capacity of more than 55000 Metric Tons Per Annum. The company

has installed the best quality imported cold roll forming machines

to manufacture roofing / cladding profile sheet. “2” and “C”

purlins, Steel Deck profile sheet, tile profile sheets, Poly

Carbonate Profile Sheets, and other building accessories.

The company procures high quality raw material from

Jindal Steel Ltd, Essar Steel Ltd, Bhushan Steel Ltd,

Uttam Galva Steels and processes the same into high

quality finished goods.

The company by its experience, services and

right solutions with technology driven skilled

staff state of art manufacturing facility and

well organized back office Pushpak Group is

the most trusted brand in the field of

roofing industry.

Pushpak C & Z Purlin

——

Pushpak C & Z Purlin are Secondary members of structures which

serve as the material of construction for fast-track projects. These

purlins are characterized by high strength, yet low cost (as a result of

the high stength to weight ration) Pushpak Purlins are supplied in

required sizes and lengths with pre-punched holes for quick bolting.

We offer purlins in galvanized coated steel in 1206SM/175 GSM/275

EE

GSM coatingas per customer requirement.

"Technical and Material Specifications -—_—Benefits of C & Z Purlins “CAPSULE HOLE

Thickness 1.5mm to 2.5mm, s High strength to welght ratio 28

Material Galvanised Steel Economical

sae ite rane © Can be used for large spans 16

@ Better quality & finish |

Yield Strength ; 245 MPa to 345 MPa ek inattian

_¢ Standard Purlin Section C-Section : YS 1 & 345 MPa

of fe) Size 4 81 B2 c h t

- cio | 120 | 60 | 60 ‘40-100 [15°25

caso | 150 | 60 | 60 40-130 [15°25

cigo | 180 | 70 70

e200 | 200 | 70 70

caso} 250 | 80 80

cso | 280 | 80 80

40-160 |1.5-25

20 | 40-180 |1.5-2.5

40-230 [1.5°25

40-260 |1.5-2.5

c300_}| 300 | 80 80 40-280 |1.5-2.5

+ All dimensions in mm

‘© Standard Purlin Section Z-Section : YS - 245 MPa & 345 Mpa

Bt

g 4 | e1 | 52 E h t

“ SA z20 | 120 | 60 55 40-100 | 15°25

zso | 150 | 60 | 55 40-130 [15°25

Lk. re ee woaeo [1525

7 =| z00 | 200 | 7 | 6 | 20 | aot lasas

zo [| 250 | 80 | 75 40-230 | 15°25

ie io zo | 280 | 80 78 40-260 | 15-25

7 za00 | 300 | s | 7 40-280 | 15-25

B2 * All dimensions in mm a

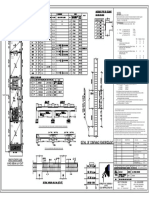

Pushpak Steel Deck P960

Introduction

Pushpak Steel Deck is used as composite floor

system. The steel deck profile sheet has a ribbed

profile with embossment to interlock with

concrete slabs, creating a reinforced concrete

slab that serves dual purpose of permanent

form and positive reinforcement.

Pushpak Deck P960 Profile

ss

aa)

sib

i" Technical Specifications

700

supply width | Covered Wieth Pitch Crest Height | Crest width

Concrete Retainer

} 960mm {+10mm)] 932mm (eSmm) | 230mm {+2mm) | Simm (:2mm) | s9mm (+2mm)

"Advantages

e An efficient and economical alternative for multi storey Steel deck reduces the concrete thickness and also the

buildings. reinforcement which in turn increase floor to floor clear

© Steel Deckis stronger than the conventional shuttering. height,

It is faster to install than conventional shuttering, © Steel Deck reduces project cost since it economizes

congestion freearea during construction gives free concrete and steel consumption.

space for parallel activities, andthis saves considerable © Deck profile sheet is offered in Zinc coated and pre

projecttime. coatedsteel, zinc ranging from 120 to 275 gsm which

© Steel Deck eliminates shuttering and de shuttering _givesbetter resistance against corrosion.

planks, and other propsand provides clear space for ® Steel Deck is widely used in multi-storey buildings.

‘working underside the rec floor. Storage facilities, industrial sheds, shopping malls, ware

© Simultaneous casting of multiple floors possible. houses.

Shear Connection In Composite Beams

‘Shear Connector Studs are designed to tie the concrete slab to the steel beams and to resist shear loadings between the

concrete slab and steel beam in composite construction. The Shear Stud is made of steel and it is delivered with a

ceramic ferrule to ensure 2 good connection of the Stud with the beam. The shear Studs are available in different

lengths and diameters . The length of the Stud will be reduced by approximately Smm during the welding process. The

ferrules are made of clay and able to withstand heat shockas well as high temperatures without melting or breaking.

steel reinforcement

concretestab | “hearconnectors

profiled steel sheeting

DETAILS OF PROPERTIES AND LOAD CAPACITIES FOR PERMISSIBLE DEFLECTION AND STRESS

PLACEMENT: SIMPLY SUPPORTED ELD STRESS OF MATERIAL = 250 kame ]

Si] Thins [Moment] _ secon Mods Peis fla or pan

jie _|iertn/m | Tope T BoRom7 [oer] x4 mtr] 22 mtr] 13m] 14m] Smt] nem] 2.7 mr] 20m] 2s] 30mm] as mr] omer

Z[ oso [same | aaaa | aan | ao | aes [ame | aem [are [au | oe [aes | ees | ooo [arr [ame | se

2] 100 [sar | anos | aaa | ame | 2s | sno | unas | ae | 1200 | tom [os | eat | aaa | so? | as | an |

4] 310 [esa [ange] as2a” | soz | asos | 20s | ava | ases | a3ae [tugs | oem | 757 | ase | 336 | 27 | 209 |

S| 10 [ar |_zraa_| 2740 | moan | avar | anes | aes | arr | sat | tome | ana? | am | eae | es | oe | aoe

eas [race [amen | anemaear | ave | asra | ae | aes | asin [as | atea [asa | ses [ove | om | om

‘PLACEMENT; THREE SPANS CONTINUOS ELD STRESS OF MATERIAL = 2450 ke/ama

Se] Tindnes [Momento] _ sean Mods Permissible load n Kesar fr span

| nmin [inert [Yop | Beto

ote] 1ate] 120tr] 130m] x40] Sei] nt] 1.7 e] 20m] 2m] 30mm] as mr] mer

ent | oe | en

T [om [as [ter [agar | an | anor [ee | aesn | ace | aa | 0m | oes | ear | we | no | an | ame

2] oso [same | aaaa | aoa | auae [ aan | aire | ano | asoe [aoe [azn [acer [van | $00 [a7 [ase | oe

a] ton [sar | anos | aq | sr | sr | aeot | 205 | eu | sae | 120 | aioe | ome | ssa | aaa | om | ane

a] 410 [eae [aaa [aan | ame | stn | aeee | 0 | aon [aaa | sare [anno | awe [cos | eo0 | am | ae

S| 420 | sar |_araa_| a7aa | aise | zn | ama | 24m | aoe | ame | acs | oma | aor] ew? | ase | ae | se

@[ as [ree | meee [one | wore | aan | ance | ar | am | ae | ac [aera | aoee | cea | ove | a | oer

PLACEMENT SPY SUPPORTED “WELD STRESS OF MATERIAL = 3450 NG/om

| Titnes |Movet of] ScinNr Ter ad naan

Nej_inmem [inertafen{ Topzt | womom2t | ya] aa.mte| 120tc| 3:3.em| 2.4 mtc| 25m] 3.6 mc) 2.7 tr | 20%me| 25 mex| 2.0mtc| 25 mtr] 40 mt

Z[ es | ssaa | aoaa | aan | wn | aes [oer | art [rae [se [ar [aut [em [seo aes ae [oa

3| 190 | ser | mos | 230s | sara | avon | aeao | 220i | ors | urs | asiz | tame | set | cis | coo | ane | ome

a] nae] 835 | 25a | 25.24 | aza0 | aor | 25a | 2500 | anes | anea | tess | tes7 | 2060 | ors | ari] 348 | 208

S| 120 | sos7 | 2740 _z7a0_| aon | sot | aioe | aven | avn | 20m | aoe | asoe | uiso| rae | su_| ae | an?

S[tas[ yee [ase | a0am | aree [ase | ee | zea | oem | niae | ano [sess [ nave [ ves | sm | 0 | a

PLACEMENT: THREE SPANS CONTINUOS "ELD SESS OF MATERIAL = 350 Keone

4] Thine | Momento] _ Secon Modan ermibleleadn Kam for pan

Noj_inmm linertafm| Towa] @owtomat | oor] sa mtc| a2mte| 1 mt] .amtc| 15sec] 26mtr] 2.7m] 20mtr] 25 mtc| some 35 mtr] 40mte

ent [a | en?

mos ue | ies | ae [me len fae) oe) me | me | ua] |e | ae | ow | ae

aoe [saa [aoa | aoae [eave [ sete [ au [ aeeo | aaae | aoes | avon [ azve | tose | veo [ae [aera

so | ~etas | asze [2528 | samo [200 | a0 | aioe | ame | mass | aoe | ase | ams | sae | san [ear [oe

x20 | a7 | zrao | 240 | 5754 | 755 | 2505 | oon | 295 | ass7 | aze7 | vom | soe | s20 | eo | a | 99

sas [mae | eae [zea | saxo [sour [asa | asoe | aos | 26se | zee | 2000 | 19s] 956 | om | aes | a0

‘Simply Supported Multi Span Continuos

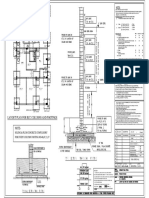

Roofing & Cladding Sheet Pushpak P1100

1025

a oe eae, oa

Pushpak P1100 Hi-Rib Profile

Technical Specifications for 245 MPa Technical Specifications for 550 MPa

‘Supply Width | ‘100mm (20mm) ‘Supply Wiath | ‘1100mm (20mm)

Covered Wiath 41025mm (#10mm) Covered With 41040mm (¢ 10mm)

Pitch 205mm (23mm) Pitch 208mm (23mm)

Crest Height 27.5mm (42mm) Crest Height 27.Smmn (2mm)

Crest Width 25mm (1mm) Crest Width 25mm (1mm)

Introduction ‘Anti Capillary groove

Pushpak 1100 Trapezoidal profiles is used for widely diverse applications.

Pushpak 1100 Trapezoidal Profile is supplied in different thickness lengths as per

requirement dimensions. This profileis suitable for roof and wall panels.

Pushpak 1100 Trapezoidal Profile is for industry or trade, Stadia, Ware House,

Airport Hanger, Railway station, Under construction Building Boundaries etc.

‘OVERLAPPING

Curved Sheet

Curved Sheets are available from Pushpak 1100 profile, Curving through computerized, PLC controlled

crimping machine. The minimum length of curve is 300 mm, start lead is 50mm & end lead is 350mm thereby making

length of curved sheet possible as 800mm, length restrictions apply to curved sheets. Curved sheet in high tensile

metal is supplied at customers risk.

__ PRE PAINTED GALVANISED IRON (PPG!)

© Coa

gon

© Thickness:

* ZnCoating (65M)

» Paint Systems

* Yield Strength

« Primer Service Coat

+ Top Coat [Expossed Surface)

+ Bottom Coat

Roofing & Cladding Sheet Pushpak P1100

MATERIAL SPECIFICATIONS _

~ PRE PAINTED GALVALUME STEEL SHEETS (PPGL)

£AS1397,

Hot Dip Galvanised ron

Standard 0.50mm

(Optional o.40mmto0.80mm)

2n90,29120,2n275

Regular Modified Polyster Paint (RMP)

Optional (SMP & PVEF2)

245 MPa optional 345MPa, $50 MPa)

‘Smicrons Epoxy

15t020microns

Sto7 microns.

‘© Material Confirm to

© Coatingon

Thickness

© AL-ZnCoating (GSM)

VieldStrength

old Rolled Stee!

+ Standard Thickness of .47mmTCT.

Az 150

+ 550MPa (optional 345 MPa)

© Material Conformto

© Coating

«Thickness

+» 2nCoating (GSM)

PaintSystems

* YieldStrength

«© PrimerService Coat

= TopCoat Exposed Surface)

© Bottom Coat

Galalume

Standard 0.50mm

{(Optional.4omm to 0.80mm)

2AZ150

+ Regular Modified Polyster Paint (RMP)

‘Optional (SMP & PVdF)

'55OMPa (optional 345MPa, 245MPa)

: Smicrons Epoxy

20t025Microns

: Sto7Microns

‘Supplied in maximum length up to 13 mtrs.

Base Meta

Prime Costing

op (Finish) Coating

Chromate Coating

Zine Au Zine Coating

(Cold Roted ste! sheet)

Zine Au Zine Coating

Chromate Coating

Bottom Finch) Coating

DETAILS OF PROPERTIES AND LOAD CAPACITIES FOR PERMISSIBLE DEFLECTION AND STRESS

PLACEMENT : THREE SPANS CONTINUOS 1100 Profile (FY-250) Thk. = 0.4mm to 0.8mm.

Thindnes: | Moment ot | Secon aodiie Ferrio Kham oan

ene | The ot os al

== = eae} peer torn 12m tam | adm | asm | tem | 17m an | 19m 20m

= [aa 40 as [eae ae ee ee ae a

2 | 04s si) ase [7a | ae | am | mm | a |e | a | mo | ue | us) oe

3 [30 ser[ am_| 795 | a7 | 209 | me [am [ues | a@ [ae | ae | me] aoe

s | om en [an [90 | 6 [oa [a3 [as | mo [as fom [ass [os |e

«| 07 z_| am | tose [sm _|96_| o0e | an_|osa_|_ms | is7_| ve | 6] uw

7 | om a7 [aso | sez0 [os [eer [am [a Pe [ast | a | ase | ee] ao

PLACEMENT : THREE SPANS CONTINUOS — 1100 Profile (FY-550) Thk. = 0.4mm to 0.8mm

Seno] Thnaren | Momento! | _ Seon odie Permisbie nen Kalan spon

tomm | _werie | sovat [eotomzt | om | iam | tam] tam | asm ] ism | 17m | 14m | 19m | 20m

KO aco as ee

=| as0 Se ama 7ae [of ee ae fae] |e

=| 055 a2 | 30 | a7 | oor |e | sea | sas | | ors || ae

5 [ee ma 3a [ea dome | |e eas ae ||| ee

© | 070 7 | aa | som | us? | an | ma | ou] ss | ami | os | oa | oa | nie

7 [oss ams [ a0 | seae [amo [ ses [moo | ma eee] won| rae]

Thermal and Acoustic Insulation

Thermal and Acoustic insulation is crucial in today’s construction. Pushpak Insulation offers industrial shed

‘owners an extremely durable high performance insulation medium that resists rodents, insests, mould etc. and

can be washed as required. Insulation controls heat flow, prevents condensation, and controls noise. Depending

on the facing, some insulation could increase the efficiency and effectiveness of lighting fixtures.Insulation slows

the movement of heat and keeps it inside the building, where it belongs in the winter. In summer, it does the

opposite, keeping heat outside. The heat transfer rate throughout the building is controlled, reducing energy

usage. Pushpak thermal and acoustic insulation is highly effective and extremely easy to install, durability and

waterproof qualities make it unchallenged by conventional insulation mediums.

_ Pushpak Thermoguard Roofing sheet

Introduction :

The simplest and easiest

way of adding shed insulation is

PushpakThermoguard sheet. It is a

durable, lightweight and resilient

‘material for fast track projects.tt works by

trapping heat due to the Polyethylene

foam. Thermoguard sheet has property of

shock absorption and vibration damping. It has

reflective aluminium foil which reduces heat

transfer by radiation. This is one of the cheapest

methods of insulation and best solution for costly

Sandwich Puff Roof panel. Thermoguard sheet is

reliable under every circurnstance andit can easily deal

with tropical temperatures as well asthe frosty cold.

‘Thermo guard gives you the best quality of roof

profile sheet with customised metal properties like thickness, GSM, Yield strength etc. It overcomes the discomfort

and environmental damage brought by glass fibre and epispastic materials it also resist ultraviolet radiation that can

penetrate through sheet iron, concrete, wood and other common heatinsulation materials.

1025

Pushpak P1100 Hi-Rib Profile

Technical Specifications for 245 MPa Technical Specifications for 550 MPa

‘Supply Wiath ‘100mm (+20mm) | | Supply Width 100mm (+20mm)

Covered Width 1025mm (#10mm) | | Covered Width 1040mm (+ 10mm)

Pitch 205mm (3mm) Pitch 208mm (3mm)

Crest Height 27.6mm (2mm) Crest Height 27.5mm (2mm)

Crest Width 25mm (1mm) Crest Width 25mm (1mm)

Technical Properties Specifications

Material PPGI/PPGL Sheet with PE foam

{one sided aluminum foil)

PPGI/PPGL sheet Thickness 0.40mm, 0.45 mm, 0.50 mm TCT

Foam Thickness 6.00 mm,

Volume 325 em?

Density 0.503 g/cc

Emissivity 3-5%

Reflectivity 95-97%

Thermal Conductivity 0.02998 W/ mk

Fire Retardant Yes

Operating Temperature -40'C to 115°C

Noise reduction 7t0 848

Corrosion Resistance No visible sign of corrosion

Features:

1) Easy to install. Minimizes labor fatigue

And increases productivity.

2) Increases machine life by reducing heating.

3) Dust, odor, moisture free. Fire retardant.

4) Anti-radiation and anti-vibration. Corrosion resistant.

5) High reflectivity reflects about 97 % of radiant

heat and UV rays.

6) Heat and Sound insulation. Chemically unreactive

Applications :

1) Cold rooms.

2) Pharma Companies,

textile companies.

3) Underdeck insulation.

4) Manufacturing units and

industrial shades.

Pushpak Tile Profile Introduction

Pushpak tile profile blends the classic look of architecture

with modern material. This metal roofing sheet has low

‘maintenance cost, superior weather resistance and long

life. It is ideally suited to commercial buildings, resorts,

farm houses, hotels, residential houses and other

public area residential use. It helps save money by

1160

5 ° reducing assembling time and workmanship by

ras | not breaking, cracking or leaking and being

a environmentally-friendly.

Pushpak Tile Profile

Technical Specifications

supplywath | covered wisth | Pitch Crest Height

60mm (+ Sem) | 1036mm (250m) | 26mm (e4mm) | 28mm (22mm)

ta

Eave Gutter

Root Panel : PP _-down Tako Pos

Putin ont rome

Rater wee

(Deck Profile Sheet).

Gable Tim Lower

Wall Panel Ze

Rollup Door

Conner Fisehing ‘

cand

uy Bottom Flashing

Canopy Trim

Right Frame Columa

Wall Bracing

Concrete Foor ‘Gross Bracing

=

Introduction Poly Carbonate Profile Sheet / Sky Light

Polycarbonate is a polymer with a unique

blend of desirable properties. This polymer

can be given shape by different processes,

which include injection moulding, blow

moulding, extrusion - and thermoforming.

Polycarbonate roof sheets are manufactured by the

process of extrusion. Polycarbonate roof sheets are

commonly called transparent steel due to their

wonderful impact resistance and glass like clarity.

Following are a few salient properties of corrugated roof

sheets.

Polycarbonate sheets possess superb impact strength

(Virtually Unbreakable).

2. Excellent flexural strength hence can be cold curved or even cold

bent into simple shapes

Very high light transmission of up to 90%.

|. Superlative fire performance ( Self extinguishing) and TAC approved.

Light in weight hence easy to handle & install

. Available in tailored lengths, hence minimum wastage.

Excellent thermal and electrical insulation properties.

(from -40°C to +130°C).

Polycarbonate sheets are extensively used in Industrial Applications. These are used for Industrial Sky

Lights and North-Light Glazing to provide daylight solutions in Industrial and Commercial Structures. These

polycarbonate roof sheets are available in a variety of

profiles matching to commonly used industrial roofing

sheets that include asbestos cement sheets & metal

corrugated sheets, corrugated roof sheets and plastic

corrugated roofsheets.

Being an engineering thermoplastic, polycarbonate sheets can be

thermoformed to make them suitable for a host of different applications

where high performance is sought in combination with transparency/

translucency. These plastic corrugated roof sheets can also be engineered to suit various innovative applications in the

future,

Polycarbonate Louver

Pushpak Bubble Insulation

This s another effective material for insulating roof

as well as wall. it prevents the temperature trap

because the air bubble confined good insulator. The

air inside the bubble helps resist against the

temperature changes. is a line of reflective insulation

featuring Polyethylene bubble film sandwichedbetween

two protective sheets, one or bath of which are composed of

astrong metalized aluminum polyester film. This Foil Insulation

filmprovides a reflective surface that blocks up to 95 percent of

radiant heat,dramatically improving thermal performance and

energy efficiency while keepingenergy costs lower and interior spaces

more comfortable.

Thickness 4.00 mm '8.00 mm /10.00mm | 12.00mm

Material PE Bubble PE Bubble PE Bubble PE Bubble

{both sided uminom ot) | (ith sided luminiom fi) | oth side lamin fol) | (both sided alumi

Emissivity 5% 3% 3% | 3%

Reflectivity | 95% 97% 97% 97%

Fire retardant | Yes ‘Yes Yes | Yes

Operating Temp.| -80" to 100° 40" to 100°C 80" to 100° ¢ 40" to 100°C

Noise Reduction | 348A 4dBA SdBA | SdBA

size 1.250% 40 mtr —_|1.250X 40 mtr__| 1.250X 40 mtr 1.250K 40 mtr

Features:

1) Prevention of heet and noise.

2) No odor and toxicity.

3) Dust, odor, moisture free. Fire retardant.

4) Anti-radiation and anti-vibration. Corrosion resistant.

5) High reflectivity reflects about 97 % of radiant heat and UV rays.

6) Heat and Sound insulation. Chemically unreactive.

Applications :

1) Existing Shed insulation

2) Cold room and Pharma Companies, textile companies.

3) Underdeck insulation. Fall cealing

Roof Panels

Crown-type overlapping joint. Provides excellent weatherproof

cladding, Outward-facing profile overlaps the adjacent panel.

Unique fitting arrangement to prevent water leakage from the

roof. Thickness available : 20 mm, 30 mm, 40 mm, 50mm, 75

mm, 100 mm and 120 mm

‘Tongue and groove type joint System. Visible

fasteners. Perfect finish. Snug insulation. Ideal for

industrial buildings / blast freezers / cold sorage and

chiller rooms. Thickness availble : 30mm, 40mm,

50mm, 60mm, 75mm, 80mm, 100mm, 120mm, &

150mm.

This is the advanced technology of

insulation provided by a fluffy and woolly material

made from rocks, namely Rockwool insulation. Rock

‘woo! is any fibrous material formed by spinning or

drawing molten mineral or rock materials such as slag

and ceramics. It is very good for blocking the transfer of

heat. As these fibres have a very high melting point, they are

spread to prevent fire. As the Rockwool system is made from

rock fibres, itis not at all combustible and therefore can workas a

shield to resist fire. Although it is made from rock, it is not hard and

can easily fitinto any construction.

Features and Applications

Itis also used to keep the home temperature under control. Used

inbuilding construction, automotive applications and industrial plants.

Material causes absolutely no harm to health, does not cause cancer or

anyother threat tothe respiratory organs. Totallynon-combustible.

Rockwool insulation has a better acoustic value than the plastic

systems it is much more durable than the other traditional

insulating systems.

Thickness : 40mm, 50mm, (one sided aluminium foil)

Density —: 40 kg/ cubic meter, 48 kg/ cubic meter, 64 kg/ cubic meter

Size 1.10 metre X 10 metre

Glass wool is an insulating material made from fibres

of glass arranged using a binder into a texture similar to wool.

Glass wool consist of fine, long, inorganic fibers bonded together

by high temperature binder. Glass fibres in a mass resembling wool

and being used especially for thermal insulation. Glass wool is a kind

of fibrous material made from the melted glass raw materials orcullet.

Features and Applications:

Light weight, high tensile strength and exceptional resilience.

Temperatures ranging up to 250c. Glass wool is chemically inert and

has no impurities such as sulphur and chloride. The product is non-

corrosive to metal. is environmental friendly in every stage.

Vibration resistance, moist proof and odourless

Thickness: 40mm,50mm, (one sided aluminium foil)

Density: 40 ke/ cubic meter, 48 kg/ cubic meter,

64 kg/ cubic meter 5 =

Size : 1.10 metre X 10 metre

y

Water Insulation

Water Insulation (Water proofing) is very important as it helps keep shed dry. It helps

reduce humidity inside the shed and thereby protects things inside your shed from damage caused.

due to humidity or water exposure.

Pushpak Foam Closure

The Foam Closure is one of the most extensive and

complete shed closure lines in the industry. Roof yy \’Gy ey wee

closure strips are sections made of flexible foam that

are used to seal the spaces left along the edges ofa -—___« ____a___«4

roof by corrugated metal roofing. Foam closure ee eae

strips are made to fill the gaps between two

sheets.

Features and Applications:

eee ae These strips seal out animals, birds and insects. They wil

also stop wind, rain and other weather-related problems.

Foam Closure shrinkage, moisture absorption, vapour

nan Vs ‘transmission, and noise migration issuesare virtually

eliminated. This is long lasting material having high

strength and rigidity.

Pushpak Butyl Tape

Buty! Tape is self-fusing butyl rubber for making water

and humidity resistant seals. It is a high quality sealant with

excellent adhesion to metal, other roofing and other insulating

materials. itis flexibility to temperatures as low as '0' DegreeF.

It gives a weatherproof seal with excellent resistance to

environmental factors such as water, condensation, dust,

UVand sunlight over a range of temperatures.

Featuresand Applications :

Tamper Proof, Water Proof, Corrosion

Resistant. It does not flow under heat and shows No

ll Migration. Used to sealing and joining materials,

such as glass, steel, polycarbonate, wood,

Aluminium, PVC, industrial roofing, pipes, cable,

refrigeration and many other domestic

applications.

=

Pushpak Louvers

Take fresh air with wall louvers. Specifically designed for pre-

‘engineered building wall panels, wall louvers allow air to flow

through a wall, while remaining weather resistant. We

manufacture louvers for proper air flow in and out of your

metal building. Help to maintain a comfortable indoor

atmosphere. Our wall louvers allow air to flow through,

while their weather-resistant designs keep moisture,

snow, ice, insects outdoors where they belong.

no

—_

—

—

Pushpak Ridge Vent

Steel building vents are top quality, weatherproof

and efficient. They provide a low-cost, passive way to

ventilate your steel building, helping to keep the interior

fresh and cool without needing power. These vents can be

installed on any steel building, and you can choose the color.

A properly engineered ventilation system

using continuous ridge ventilators controls the

movement of fresh air through the building

removing hot, stale airand air contaminated by

manufacturing or production processes. Summer heat is

released naturally through gravity ridge ventilators. During

winter proper ventilation can assist in the control of

condensation and other moisture problems, such as rust and

deterioration of insulation or the damage to stored products.

Fully protected bird mesh galvanized hardware material.

Galvalume finishis standard, and other colors are available.

Self tapping screws are specially developed for various

ro) f)ecre applications. They provide high pullout strength, shear

strength and maximum thread engagement and positive

fastening in structural steel. These screws reduce the installation

eae time and are drilled using screw guns.They are available in various

sizes ranging from 25mm up to 68mm.

Pushpak Turbo Ventilator

Ventilators is an Inexpensive, reliable and

Effective Ventilation Solution.

Roof Ventilator is a natural air ventilation

system. It is a free spinning roof exhaust which

works by tilizing the Velocity Energy of wind to induce

air flow by Centrifugal Action. The Centrifugal Force can

used by the spinning vanes creates a region of low

pressure area which draws and throws out air from below

and causes fresh cool air from the outside to come in.

Features and Applications :

Round the year effective ventilation at no running cost

Runs on Wind Power / Leakage proof . Entitled for depreciation at an

accelerated rate under present tax laws. Mechanically strong and light

weight construction available in superi

grades of Stainless Steel and Aluminum, Adaptable to any kind of roofing

Economical & environment friendly. Standard sizes include 24" and 22". Maintenance free, Noise free, Highly durable

Weather & Storm Proof

Ventilator Vanes 0.50 mm Industrial Hi-Grade Aluminum (Hindalco)

Ventilator Top Plate Stainless Stee (050 mm)

Ventilator Bottom of Ring Stainless Steel (0.50 mm)

‘Weight of Ventilator 6.5 ke. + 0.2 Kg.

Height of Ventilator 410 mmt5 mm

Center Width of Ventilator = 735 mmt 5mm

Dia of Top Plate 500 mm+S mm

Dia of Bottom Ring 600 mm +15 mm

Nos of Vanes 42 Nos Die Pressed

Thickness of Vanes 0.50 mm £0.02 mm

7 Nos of Bearing 02 Nos.

Bearing Type 6001 2Z Permanently Lubricated & Sealed

Rivets Alumium Alloy with Washer

Packing Box 3/5 Ply, 750 x 750 x 425 mm Approx.

s

Cage nor) Pushpak Polycarbonate Base Plate

(technical Specification) (iene cnn)

Perec ea ae Material Used Poly Carbonate Granules

jermosetting polyester Resin, (Bayer make!

Material Used Hardener (MEKP - AO - 9%) eeine)

Accelerator (Cobalt Octate - 3%) Profile Design Customised as per your requirement

Profile Design Customised as per your requirement a STE

Length Standard-1700 mm#10 mm\cantecstories) ‘Throat Diameter 598 mm mm (canbe ustonsed)

Throat Diameter 598 mm+5 mm Thickness 1.5 mm to 2.0mm

Thickness 1.5 mm to 2.0mm Weight 4.7 Ke:£02 Ke.

‘Weight 6.2 Kg. £0.2 ke.

. *

ro

o

Top Ridge

5 8 .

eo

20

ol

Barge Board

® *

170

50

s

Bottom Flashing

B 5

200]

200

Reverse "L" Flashing

17.380

30 *

60

2

af

Gable Flashing (c)

21

50 x

120 20

20 20

‘Window Border Flashing

kindicates top coat surface

. 108 *

Gable Flashing

6 218 *

Jas

20

0

a0) 45

20

Barge Board

0.10 Bi

00

20)

20

Canopy Flashing

4 wo »

160) | 150

ro}

Valley Gutter

18. _ 310

L260

25|

25

Barge Board (c)

22,

300

‘300

Reverse "L" Flashing

40

Bottom Flashing

uw

90 *

Hoo

20]

Canopy Flashing

15,

zs *

+

°

b

fc

e

Eave Gutter

19

300 *

40

i

B

Bottom Flashing (d)

23, 66

2h] *

6s 6

we

Down Spout Pipe

455

iss

30

aol

Comer Flashing

s x

140

40

140

B

Bottom Flashing

2

100] *

“0

40

B

Canopy Bottom Flashing

16.

f2s0

»

af

Corner Flashing (b)

20.

20

or

7 k

a

7

Down Spout Pipe

24,

Slab

Height

30

ed

100

Conerete Retainer

PUSHPAK INFRA STEEL PVT. LTD.

‘steps to protect precoated metal sheets against moisture befor ination ae important to prevent rusting oxdatlon) ofthe metal substrate. When metal sheets,

hich af strackee casey together or emateria ae Exposedto moisture and heat, Oxatlon ousting af themeta substrate can bep, Ongaaized ste! Substrates,

‘thenormalsasiicalreacion ofthe zinecoaing wil oceu, forming awhitepewéer This ype onldaion can occur beneatthe paint i

1. Minimizeexterorstoragetimeatthejobstewheneverpossible.

2 Postion coverpanal and sand bundles of metal sheets to insure proper drainage of Rainwater or condensed wate vapor Eliminate sagging when mostute could

Collect and pool Remove outer wrappingto preventmastureffomcondensngin panel bundles.

3. Don tusemosue-rappingplastcto cover panels orcas

4 Reduce temperature bsld-up by protecting bunbes or cll rom direct sunlight exposure. Proper handling and stacking during tans an help prevent abrasion

damage. A common Cause of abrasion domage, which can easly be avoded the degging of whole shecs, edges Or cormersof metal ponels against other panels

‘rstalation.fbath he paint and Galarzedcoatingare cut hou, feasting wl be rear Se by the saci acon ofthe ax Coating, but enough damage the

surface pearance can stiloccurtomake a touch-up Operation necessary.

IMPROPER CUTTING & DRILLING

Improper cutting andling of precosted meta shes: con aso cause unsightly ust spoting. Het chips from dling, saws or cutting des can get embedded inthe

paint fash and create premature rusting. making it seem thatthe surfaces are corroding. Chips rom Adjacent tel work can embed inthe pant surtace of unprotected

‘metal sheets nearby Eliminate this problem by shearing whenever posable, Protect the pant srtacetemporaiy witha late cover hen sa driller cutting disks aren

‘se around it Turning over prepante shects white cutting tham so that chips wl fall on the inside surface alse helps Werkers shoul take care to avoid stepping on oF

‘xetingpressure against any tel hips whuch could embed the chipsnthe ait fim. mmerlatly rush tel chips of the pant surtaco, usingastifber brush they ve

ready becore embedded dislodge them by Meharical means. stalled sheets should never be placed in contact with si andseishould never be pushedagnstinstaled

Sheotstorfinal gracing Alpes, cir. igerpintsor ay other contaminants shouldbe remove fer staltonto ensure proper service fromthe pan fi,

| CLEANING COATED SURFACE

‘Athough Meta color polyester factory apples fishes are extremely curable, 2 Perce clearing to remove bult-ups of resins and other resi is a good idea to

‘extendCoatng ie simple washing with lan water ving hoses or pressure spray equipments usualy Aéequate. When heavy depos of itor other contarinats dul

surfaces, heavy-duty dry powdered laundry detergent sucha TidWheel mike 1/3 cup wth water may be used. Along handed soft bile brush wilt make cesring

‘ose Fllowingceaning operatonvith a dear waterrine. In area subject thigh hums levels mildew an cceurPe-cotedFinshes are inherent mildew estan

{reandsporedeposts can permit mildew Growthto ocea Thefolowing solution recommended toremevernidew when necessary:

1/3cupdrypowderedlaundry detergent suchasTde")

2/3-upts sodium phosphateor 73? suchasSolae*)

1alsodiumhypochianiteS solution suchas Goro), Sats water

|voidstrongsolvent and abrasive type cleaners Remove caulk compounds lease rs, way andsimitar substances bywipingith

cloth soakecin minerals Wipe Onl contaminatedaeasellowuith detergent clearing andeins thoroughly

"Not following the storage instructions of Pre-painted colls/trap sheet Stee! may lead to serious

products quality issues (paint peel of stains, blistering, corrosion, color changes, etc.) veer ony

1 Durability ofcsted ste! products i aio dependent on ervronment conditions, handling, andstorage nd instalstionprctices.Referto our above deed brochure

fn"Generalcare, Haning & Storage of Coated Stee Materals

2. Safety wares ike helmet handover, shoes should be wornby matealhandingpersoanel

3. Onreceipt of materia observe thecols whe ontruckinaseceivedconiton. "The tarpaulin covering”, "notwacollsincortactofeachather ‘and nophyskcal damage

are prerequisites for material to be OK Deviation to these conditionsin the form of photographs required to consider any cam. These deviations shuld aso be

recordedin Rony.

4. Contd ste products shouldbe handled with proper equlpment during ading & ofeadng ofthe material. Tels comingin contact with matral should have pang

toavoiddamageposstle because of otherwise direct contact. Manding shouldbe verysmooth withoutanyapidshorkdurngliftng&placingon Moor. Colsshoud not

beralledontaon

5. During wansporation, coated stel material should be suitably placed on truck aller Noor wth pallet, propery lashed with edge protector & covered with stable

6. ven paced coated steel materia shouldbe nes stacked in as received condition lar of round, gore vertical calls tobe sacked singly, bore harzonta olson

Sods with rubber pad and sheet packs sacked at on angle 18st drainage of any water ingress Materals tobe stared unde shed or with suitable protective cover

toprotec ifm ainand aise

2. Plseeintall coated sheet early and within? day of eeip at site. Any coated material packwith water lgrest shouldbe opened immediatly wiped ofthe water and

tsedonimmediatebas

{8 Thematerilsusedforpackngcoatedstel shouldbe suitably disposed of without effecting the environmentasperocallaw enforce.

9. During usge, equipment shouldbe cleansothat any olereae or foreignpartce does notcomeincontact withthe comeastee surface Sheotsshouldnotbe dragged

overothersheet or surfaces,

10 incasecostedsteelisproceseduithprotectivefin, the fm shouldbe removed atthetimeofnetalation

11. To avoid swat staining (rust stain on coated surac), debris or surplus ites suchas fasteners, ron dil pats must be removed each day after completion of

instalation work.

Pushpak is the most trusted & preferred brand in the field of roofing industry. Our Client base

has been the key to our success and growth. We have a Long-term association with all our clients

and most of the new clients are referred by our existing clients. Our client base comprises of

Leading Corporation to Government organization, directly or through registered contractors, few

of which are listed below:

Shapoorji Pallonji & Co. Ltd.

Larsen & Toubro Ltd.

Unity Infraprojects Ltd.

Thermax Ltd.

Raheja Developers Ltd.

Lafarge India

J Kumar Infraprojects Ltd

eee

Government Projects

Indian Railways

Maharashtra State Warehousing Corporation Ltd.

The Anganwadi Project (TAP) Maharashtra Government

Military School Satara

Nuclear Power Corporation of india Ltd.

Indira Gandhi International Airport - New Delhi

Pune International Airport

Pune Mahanagar Parivahan Mahamandal Ltd.

NTPC (National Thermal Power Corporation Ltd.) Raymond Luxury Cottons Ltd.

D'Decor Home Fabrics Pvt. Ltd

Banswara Syntex Ltd.

Grasim Industries Ltd.

Octaga Green Power and Sugar Co. Ltd.

Action Ispat and Power Ltd.

Pioneer Gas Power Ltd

ACB ( India ) Ltd.

Steel Authority of India Ltd.

Monnet Ispat & Energy Ltd.

Electrosteel Steels Ltd.

Hindalco Industries Ltd. (Aditya Birla Group)

Baliraja Sakhar Karkhana Ltd.

Harinagar Sugar Mills Ltd

M/s. Nira Bhima Ssk Ltd.

Shivaji Cane Processors Ltd.

Shetkari Sakhar Karkhana Chandapuri Ltd.

Shri Datta Sakhar Karkhana

Shraddha Energy & Sugar Pvt Ltd.

Merck Ltd.

BASF India Ltd.

Goa Carbon Ltd.

Coromandel International Ltd.

Sabero Organics Gujarat Ltd.

Unit 1:

Chakan M..0.C,, Khalumbre,

Pune (Maharashtra)

Unit 2:

Handewadi

Pune (Maharashtra)

Corporate Office

Office No. 506, Suyog Center, Email : sales@coloursteel.com

. Gultekdi, Marketyard, Web : www.pushpakinfra.com

Push pa k Pune - 411 037. www.pushpakinfra.in

www.pushpakinfra.net,

Infra Steel Private Ltd

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Design of Structures TCE PDFDocument87 pagesDesign of Structures TCE PDFmanojmorye100% (1)

- Reverse L Shaped Cantilever RETAINING WALLDocument6 pagesReverse L Shaped Cantilever RETAINING WALLHusen Ghori100% (2)

- Delivery PassDocument1 pageDelivery PassHusen GhoriNo ratings yet

- Delivery InvoiceDocument1 pageDelivery InvoiceHusen GhoriNo ratings yet

- Sakib Ismail Naikwadi: ObjectiveDocument2 pagesSakib Ismail Naikwadi: ObjectiveHusen GhoriNo ratings yet

- Delivery InvoiceDocument1 pageDelivery InvoiceHusen GhoriNo ratings yet

- Construction Pass (10) - 01-18Document1 pageConstruction Pass (10) - 01-18Husen GhoriNo ratings yet

- Delivery InvoiceDocument1 pageDelivery InvoiceHusen GhoriNo ratings yet

- Service Kitchen Quartz Drawings-06-03-2024Document1 pageService Kitchen Quartz Drawings-06-03-2024Husen GhoriNo ratings yet

- P.O. BOX 030040 Fort Lauderdale, FL, 33303: 1/4" Thick & Heavier Classed As PlatesDocument2 pagesP.O. BOX 030040 Fort Lauderdale, FL, 33303: 1/4" Thick & Heavier Classed As PlatesAshar HassanNo ratings yet

- C2 Footing DetailsDocument1 pageC2 Footing DetailsHusen GhoriNo ratings yet

- REINFORCEMENT NOTESDocument1 pageREINFORCEMENT NOTESHusen GhoriNo ratings yet

- Maruti Suzuki footing design analysisDocument3 pagesMaruti Suzuki footing design analysisHusen GhoriNo ratings yet

- Adv - Ajay Pathak-GF PLANDocument1 pageAdv - Ajay Pathak-GF PLANHusen GhoriNo ratings yet

- Venkateshwara Hatcheries PVT LTDDocument3 pagesVenkateshwara Hatcheries PVT LTDHusen GhoriNo ratings yet

- Layout Plan For RCC Columns and FootingsDocument1 pageLayout Plan For RCC Columns and FootingsHusen GhoriNo ratings yet

- Maruti Suzuki footing design analysisDocument3 pagesMaruti Suzuki footing design analysisHusen GhoriNo ratings yet

- Kazi KK A4 ColorDocument1 pageKazi KK A4 ColorHusen GhoriNo ratings yet

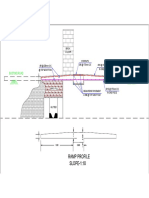

- Gate Ramp Design 27-07-2021 FulewadiDocument1 pageGate Ramp Design 27-07-2021 FulewadiHusen GhoriNo ratings yet

- Design By: Saadam Ghori Mobile: 08793596857Document3 pagesDesign By: Saadam Ghori Mobile: 08793596857Husen GhoriNo ratings yet

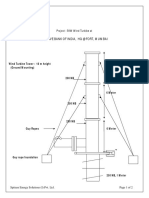

- C11 Pillar: Round Pipe. OD 152, 12thkDocument1 pageC11 Pillar: Round Pipe. OD 152, 12thkHusen GhoriNo ratings yet

- Design By: Saadam Ghori Mobile: 08793596857Document3 pagesDesign By: Saadam Ghori Mobile: 08793596857Husen GhoriNo ratings yet

- Ramp Profile SLOPE-1:10: Existing Road Open PlotDocument1 pageRamp Profile SLOPE-1:10: Existing Road Open PlotHusen GhoriNo ratings yet

- C11 Pillar: Schedule of R.C. Columns & FootingsDocument1 pageC11 Pillar: Schedule of R.C. Columns & FootingsHusen GhoriNo ratings yet

- Back Side: SHS 50X50X4mmDocument1 pageBack Side: SHS 50X50X4mmHusen GhoriNo ratings yet

- Tower & Foundation - RBI - 5KW WT - 2020Document2 pagesTower & Foundation - RBI - 5KW WT - 2020Husen GhoriNo ratings yet

- Ajit Gijare - Structural Engineer: Job ConfirmationDocument2 pagesAjit Gijare - Structural Engineer: Job ConfirmationHusen GhoriNo ratings yet

- Ijcerv5n4spl 17Document6 pagesIjcerv5n4spl 17Virubinnya ViruNo ratings yet

- Existing Building Existing Building: Ground Floor Plan 1St Floor PlanDocument1 pageExisting Building Existing Building: Ground Floor Plan 1St Floor PlanHusen GhoriNo ratings yet