100% found this document useful (1 vote)

2K views7 pagesCircuit Description: ECM 5V VC VTA Throttle Position Sensor

1) The document discusses diagnostics for the throttle position sensor in a Toyota Corolla from 2003.

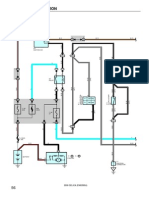

2) The throttle position sensor detects the throttle valve opening angle and sends a voltage signal to the ECM. A voltage of 0.3-1.0V indicates the throttle is closed, and 3.2-4.9V means it is fully open.

3) Faults in the throttle position sensor circuit that cause the voltage signal to be outside the normal 0.1-4.9V range will cause the ECM to set diagnostic trouble codes P0120, P0122, or P0123.

Uploaded by

jeremih alhegnCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

2K views7 pagesCircuit Description: ECM 5V VC VTA Throttle Position Sensor

1) The document discusses diagnostics for the throttle position sensor in a Toyota Corolla from 2003.

2) The throttle position sensor detects the throttle valve opening angle and sends a voltage signal to the ECM. A voltage of 0.3-1.0V indicates the throttle is closed, and 3.2-4.9V means it is fully open.

3) Faults in the throttle position sensor circuit that cause the voltage signal to be outside the normal 0.1-4.9V range will cause the ECM to set diagnostic trouble codes P0120, P0122, or P0123.

Uploaded by

jeremih alhegnCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

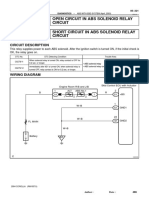

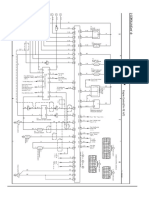

- Throttle Pedal Position Sensor Circuit Description: Describes the circuit for the throttle position sensor, including operating principles and component interactions.

- Monitor and Strategy Description: Explains the monitoring method and the ECM's strategy for using throttle position data for engine control.

- Wiring Diagram: Presents a wiring diagram illustrating connections and layouts for the throttle position sensor.

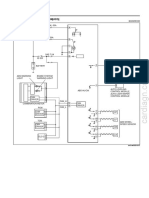

- Hand-held Tester Procedure: Provides step-by-step instructions on using a hand-held tester to check and calibrate the throttle valve opening percentage.

- Harness and Connector Check Procedure: Details procedures for inspecting and verifying the connections between the throttle position sensor and ECM.