Professional Documents

Culture Documents

Mandatory Documents For Iatf

Uploaded by

dhir.ankur0 ratings0% found this document useful (0 votes)

35 views6 pagesOriginal Title

mandatory documents for iatf

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views6 pagesMandatory Documents For Iatf

Uploaded by

dhir.ankurCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 6

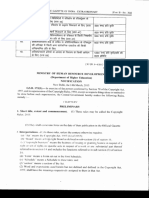

Mandatory documents and records required by IATF 16949:2016

Department Document reff. at

Sr.no Name Clause No format responsible ICL Status

1 Scope of the quality management system 4.3 Document

Documented process for the management of product safety related products and

2 manufacturing processes 4.4.1.2 Procedure

3 Quality policy 5.2 Document

4 Responsibilities and authorities to ensure that customer requirements are met 5.3.1 Document

5 Results of risk analysis 6.1.2.1 Document

Document

6 Preventive action record 6.1.2.2 /Record

Document

7 Contingency plan 6.1.2.3 /Record

Document

8 Quality objectives 6.2 /Record

Document

9 Records of customer acceptance of alternative measurement methods 7.1.5.1.1 /Record

10 Documented process for managing calibration/verification records 7.1.5.2.1 Record/doc

11 Maintenance and calibration record 7.1.5.2.1 Record/doc

Documented process for identification of training needs including awareness and

12 achieving awareness 7.2.1 Procedure

13 Documented process to verify competence of internal auditors 7.2.3 Procedure

14 List of qualified internal auditors 7.2.3 Record/doc

15 Documented information on trainer’s competency 7.2.3 Record/doc

16 Documented information on employee’s awareness 7.3.1 Record/doc

17 Documented process to motivate employees 7.3.2 Record/doc

18 Quality manual 7.5.1.1 Document

19 Record retention policy 7.5.3.2.1 record/doc

Documented process for review, distribution and implementation of customer

20 engineering standards/specifications 7.5.3.2.2 Procedure

21 Registry of customer complaints 8.2

22 Product/service requirements review records 8.2.3.2

23 Procedure for design and development 8.3.1.1 Procedure

Document/

24 Record about design and development outputs review 8.3.2 Record

Document/

25 Documented information on software development capability self-assessment 8.3.2.3 Record

Document/

26 Records about product design and development inputs 8.3.3.1 Record

Document/

27 Records about manufacturing process design input requirements 8.3.3.2 Record

28 Document a process to identify special characteristics 8.3.3.3 Procedure

Document/

29 Records of design and development controls 8.3.4 Record

Document/

30 Documented product approval 8.3.4.4 Record

Document/

31 Records of design and development outputs 8.3.5 Record

Document/

32 Manufacturing process design output 8.3.5.2 Record

Document/

33 Design and development changes records 8.3.6 Record

Document/

34 Documented approval or waiver of the customer regarding the changes in design 8.3.6.1 Record

Document/

35 Documented revision level of software and hardware as part of the change record 8.3.6.1 Record

36 Documented supplier selection process 8.4.1.2 Procedure

Documented process to identify and control externally provided processes,

37 products and services 8.4.2.1 Procedure

Documented process to ensure compliance with statutory and regulatory requirements

38 of purchased processes, products and services 8.4.2.2 Procedure

39 Documented process and criteria for supplier evaluation 8.4.2.4 Procedure

Document/

40 Records of second-party audit reports 8.4.2.4.1 Record

Document/

41 Characteristics of product to be produced and service to be provided 8.5.1 Record

Document/

42 Control plan 8.5.1.1 Record

Document/

43 Total productive maintenance system 8.5.1.5 Record

44 Records of traceability 8.5.2.1 Procedure

Document/

45 Records about customer property 8.5.3 Record

Document/

46 Production/service provision change control records 8.5.6 Record

47 Documented process to control and react to changes in product realization 8.5.6.1 Procedure

48 Documented approval by the customer prior to implementation of the change 8.5.6.1 Procedure

49 Documented process for management of the use of alternate control methods 8.5.6.1.1 Procedure

Document/

50 Record of conformity of product/service with acceptance criteria 8.6 Record

Document/

51 Record of expiration date or quantity authorized under concession 8.7.1.1 Record

52 Documented process for rework confirmation 8.7.1.4 Procedure

Document/

53 Record on disposition of reworked product 8.7.1.4 Record

54 Documented process for repair confirmation 8.7.1.5 Procedure

Document/

55 Record of customer authorization for concession of the product to be repaired 8.7.1.5 Record

Document/

56 Notification to the customer about the nonconformity 8.7.1.6 Record

57 Documented process for disposition of nonconforming product 8.7.1.7 Procedure

Document/

58 Record of nonconforming outputs 8.7.2 Record

Document/

59 Monitoring and measurement results 9.1.1 Record

Document/

60 Internal audit program 9.2 Record

Document/

61 Results of internal audits 9.2 Record

62 Documented internal audit process 9.2.2.1 Procedure

Document/

63 Results of the management review 9.3 Record

Document/

64 Action plan when customer performance targets are not met 9.3.3.1 Record

Document/

65 Results of corrective actions 10.1 Record

66 Documented process for problem solving 10.2.3 Procedure

67 Documented process to determine the use of error-proofing methodologies 10.2.4 Procedure

68 Documented process for continual improvement 10.3.1 Procedure

Documented process for the management of product safety related products and manufacturing processes (clause 4.4.1.2

Quality policy (clause 5.2)

Responsibilities and authorities to ensure that customer requirements are met (clause 5.3.1)

Results of risk analysis (clause 6.1.2.1)

Preventive action record (clause 6.1.2.2)

Contingency plan (clause 6.1.2.3)

Quality objectives (clause 6.2)

Records of customer acceptance of alternative measurement methods (clause 7.1.5.1.1)

Documented process for managing calibration/verification records (clause 7.1.5.2.1)

Maintenance and calibration record (clause 7.1.5.2.1)

Documented process for identification of training needs including awareness and achieving awareness (clause 7.2.1)

Documented process to verify competence of internal auditors (clause 7.2.3)

List of qualified internal auditors (clause 7.2.3)

Documented information on trainer’s competency (clause 7.2.3)

Documented information on employee’s awareness (clause 7.3.1)

Documented process to motivate employees (clause 7.3.2)

Quality manual (clause 7.5.1.1)

Record retention policy (clause 7.5.3.2.1)

Documented process for review, distribution and implementation of customer engineering standards/specifications (clau

Registry of customer complaints (clause 8.2)

Product/service requirements review records (clause 8.2.3.2)

Procedure for design and development (clause 8.3.1.1)

Record about design and development outputs review (clause 8.3.2)

Documented information on software development capability self-assessment (clause 8.3.2.3)

Records about product design and development inputs (clause 8.3.3.1)

Records about manufacturing process design input requirements (clause 8.3.3.2)

Document a process to identify special characteristics (clause 8.3.3.3)

Records of design and development controls (clause 8.3.4)

Documented product approval (clause 8.3.4.4)

Records of design and development outputs (clause 8.3.5)

Manufacturing process design output (clause 8.3.5.2)

Design and development changes records (clause 8.3.6)

Documented approval or waiver of the customer regarding the changes in design (clause 8.3.6.1)

Documented revision level of software and hardware as part of the change record (clause 8.3.6.1)

Documented supplier selection process (clause 8.4.1.2)

Documented process to identify and control externally provided processes, products and services (clause 8.4.2.1)

Documented process to ensure compliance with statutory and regulatory requirements of purchased processes, products

Documented process and criteria for supplier evaluation (clause 8.4.2.4)

Records of second-party audit reports (clause 8.4.2.4.1)

Characteristics of product to be produced and service to be provided (clause 8.5.1)

Control plan (8.5.1.1)

Total productive maintenance system (clause 8.5.1.5)

Records of traceability (clause 8.5.2.1)

Records about customer property (clause 8.5.3)

Production/service provision change control records (clause 8.5.6)

Documented process to control and react to changes in product realization (clause 8.5.6.1)

Documented approval by the customer prior to implementation of the change (clause 8.5.6.1)

Documented process for management of the use of alternate control methods (clause 8.5.6.1.1)

Record of conformity of product/service with acceptance criteria (clause 8.6)

Record of expiration date or quantity authorized under concession (clause 8.7.1.1)

Documented process for rework confirmation (clause 8.7.1.4)

Record on disposition of reworked product (clause 8.7.1.4)

Documented process for repair confirmation (clause 8.7.1.5)

Record of customer authorization for concession of the product to be repaired (clause 8.7.1.5)

Notification to the customer about the nonconformity (clause 8.7.1.6)

Documented process for disposition of nonconforming product (clause 8.7.1.7)

Record of nonconforming outputs (clause 8.7.2)

Monitoring and measurement results (clause 9.1.1)

Internal audit program (clause 9.2)

Results of internal audits (clause 9.2)

Documented internal audit process (clause 9.2.2.1)

Results of the management review (clause 9.3)

Action plan when customer performance targets are not met (clause 9.3.3.1)

Results of corrective actions (clause 10.1)

Documented process for problem solving (clause 10.2.3)

Documented process to determine the use of error-proofing methodologies (clause 10.2.4)

Documented process for continual improvement (clause 10.3.1)

You might also like

- Design History File - Final PDFDocument5 pagesDesign History File - Final PDFDarcy Chadwick Sheerin100% (1)

- AS9100D List of Mandatory Documents Whitepaper enDocument12 pagesAS9100D List of Mandatory Documents Whitepaper enAnkur DhirNo ratings yet

- AS9100 Mandatory RecordsDocument3 pagesAS9100 Mandatory Recordsocardenas9160No ratings yet

- ISO 9001 Quality ManualDocument33 pagesISO 9001 Quality Manualramrom100% (4)

- ISO 13485-2016 Implementation and Compliance With MyEasyISO - R01 - 01062017Document5 pagesISO 13485-2016 Implementation and Compliance With MyEasyISO - R01 - 01062017kaushal_sutariaNo ratings yet

- Asq Presentation Iso 13485Document48 pagesAsq Presentation Iso 13485dhir.ankur100% (1)

- Document Control Procedure AB-DOC-21-012.0Document13 pagesDocument Control Procedure AB-DOC-21-012.0SALES AL ABERNo ratings yet

- MDR Classification DocumentDocument17 pagesMDR Classification Documentdhir.ankurNo ratings yet

- IATF 16949 Gap Assessment ChecklistDocument7 pagesIATF 16949 Gap Assessment ChecklistBharath100% (1)

- Bsi MD Risk Management For Medical Devices QaDocument10 pagesBsi MD Risk Management For Medical Devices Qadhir.ankurNo ratings yet

- Checklist of Mandatory Documentation Required by Iso 13485 2016Document3 pagesChecklist of Mandatory Documentation Required by Iso 13485 2016Ami Jariwala100% (1)

- IMS Internal Audit Check ListDocument5 pagesIMS Internal Audit Check ListAIM ConsultancyNo ratings yet

- Document Management Guidance ExampleDocument6 pagesDocument Management Guidance ExampleISO 9001 Checklist100% (6)

- Cipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Document8 pagesCipc-Pro-L2-002 - Control of Tool and Customer Property Procedure Rev 05 2Marvin CubeNo ratings yet

- List of Mandatory Records For ISO 9001Document2 pagesList of Mandatory Records For ISO 9001NC Rigor Luis100% (2)

- Checklist of Mandatory Documentation Required by ISO 9001:2015Document11 pagesChecklist of Mandatory Documentation Required by ISO 9001:2015Annalyn Wong100% (1)

- Top 25 Lean ToolsDocument2 pagesTop 25 Lean ToolsAnonymous dv2IR074100% (1)

- Iatf ActivitiesDocument6 pagesIatf ActivitiesWizard tube and Engineered componentNo ratings yet

- Audit Checklist 9001 13485 21 CFR 820Document66 pagesAudit Checklist 9001 13485 21 CFR 820Zoli0984100% (5)

- AS9100 Rev D List of Mandatory DocumentsDocument12 pagesAS9100 Rev D List of Mandatory DocumentsLakshyaKumarNo ratings yet

- Process Performance Qualification ProtocolDocument7 pagesProcess Performance Qualification Protocolsandeep sharmaNo ratings yet

- List of Documents IATF 16949 Documentation Toolkit EN PDFDocument4 pagesList of Documents IATF 16949 Documentation Toolkit EN PDFRahul SharmaNo ratings yet

- List of Documents IATF 16949 2016 Documentation Toolkit enDocument4 pagesList of Documents IATF 16949 2016 Documentation Toolkit enOscar Solis MartirNo ratings yet

- Dismantling Cost StudyDocument64 pagesDismantling Cost StudyGIGsanton100% (1)

- DS-04-01 R0 Competency Requirements of Internal AuditorsDocument2 pagesDS-04-01 R0 Competency Requirements of Internal AuditorsDhinakaranNo ratings yet

- ISO 9001 2015 Documented Information ListDocument5 pagesISO 9001 2015 Documented Information ListkrishitechNo ratings yet

- Clause Matrix Iatf 16949Document10 pagesClause Matrix Iatf 16949ikesh mNo ratings yet

- List of Documents ISO 13485Document3 pagesList of Documents ISO 13485Priya DasNo ratings yet

- Mandatory Documentation IATF 16949 enDocument20 pagesMandatory Documentation IATF 16949 enrajaNo ratings yet

- 1.2 Patent Rules 1970 - 11 March 2015Document95 pages1.2 Patent Rules 1970 - 11 March 2015dhir.ankurNo ratings yet

- ISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKDocument20 pagesISO Checklist of Mandatory Documentation Required by IATF 16949 en YES OKroelly100% (2)

- IATF 16949 DocumenDocument1 pageIATF 16949 Documenpunitg_2No ratings yet

- Checklist MDRDocument162 pagesChecklist MDRdhir.ankurNo ratings yet

- ISO9001-2015 Standard Audit Documents Checklist PDFDocument4 pagesISO9001-2015 Standard Audit Documents Checklist PDFmerrwon100% (1)

- List of Documents ISO 13485 Documentation ToolkitDocument4 pagesList of Documents ISO 13485 Documentation ToolkitGreeshma Certvalue100% (3)

- Checklist of Mandatory Documents Required by ISO IEC 17025 2017 EN PDFDocument14 pagesChecklist of Mandatory Documents Required by ISO IEC 17025 2017 EN PDFkheng chanbormeiNo ratings yet

- List of Mandatory Documents Required by IATF 16949-2016Document3 pagesList of Mandatory Documents Required by IATF 16949-2016Oscar Solis MartirNo ratings yet

- How To Mix A Lead VocalDocument2 pagesHow To Mix A Lead VocalAntónio LopesNo ratings yet

- Landing Gear Shock Absorber ModelingDocument46 pagesLanding Gear Shock Absorber ModelingkhaziNo ratings yet

- What Is APQPDocument2 pagesWhat Is APQPshanramaNo ratings yet

- Development of Underground Land in MalaysiaDocument17 pagesDevelopment of Underground Land in MalaysiaNorAisyahJamalludinNo ratings yet

- List of Documents ISO 9001Document3 pagesList of Documents ISO 9001xenophontosxenNo ratings yet

- Dokumen Wajib Dalam ISO 13485Document2 pagesDokumen Wajib Dalam ISO 13485WQA ISO CENTERNo ratings yet

- Tools ISO 9001Document3 pagesTools ISO 9001Miftakhul Nurdianto100% (1)

- Iso 9001:2008 To Iso 9001:2015 Cross Reference Chart 436850307Document21 pagesIso 9001:2008 To Iso 9001:2015 Cross Reference Chart 436850307avinash_k007No ratings yet

- List Dokumen ISO 13485Document3 pagesList Dokumen ISO 13485chance of improvement100% (1)

- IATF 16949 Required Documentation For TransitionDocument2 pagesIATF 16949 Required Documentation For TransitionAnkurNo ratings yet

- 9001-2008 To 9001-2015 To IATF 16949Document21 pages9001-2008 To 9001-2015 To IATF 16949Ankur Dhir100% (2)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- Checklist of ISO 22301:2019 Mandatory Documentation: - All Rights Reserved. 1Document12 pagesChecklist of ISO 22301:2019 Mandatory Documentation: - All Rights Reserved. 1Jjc Chennai100% (3)

- Nucleo L152REDocument46 pagesNucleo L152REdiralarkNo ratings yet

- IATF IA CHecklistDocument2 pagesIATF IA CHecklistDamodaran RajanayagamNo ratings yet

- List of B Grade JournalsDocument4 pagesList of B Grade JournalsLovechocolateeNo ratings yet

- Iso37001 Implementation Guide en MyDocument12 pagesIso37001 Implementation Guide en MylovishNo ratings yet

- Dokumen Wajib Dalam ISO 13485Document3 pagesDokumen Wajib Dalam ISO 13485WQA ISO CENTER100% (1)

- Process ControlDocument5 pagesProcess ControlTuan Anh100% (1)

- Documents Specified by ISO - TS 29001 But Not by ISO 9001Document1 pageDocuments Specified by ISO - TS 29001 But Not by ISO 9001Natgas Farmer0% (1)

- F906 Food I9 Auditing Techniques v1, 27.09.2022Document30 pagesF906 Food I9 Auditing Techniques v1, 27.09.2022Lutviana EmaNo ratings yet

- List of Mandatory Documented InformationDocument2 pagesList of Mandatory Documented Informationge120120No ratings yet

- CopyDocument4 pagesCopyFamitha KamroonNo ratings yet

- Medical Device Standard: Documented Requirements by SectionDocument2 pagesMedical Device Standard: Documented Requirements by SectionyusranarifNo ratings yet

- ISO 9001 Documentation Toolkit ListDocument3 pagesISO 9001 Documentation Toolkit Listdumisani ManentsaNo ratings yet

- ISO 9001:2008 TO ISO 9001:2015 CROSS REFERENCE Chart 343874980Document21 pagesISO 9001:2008 TO ISO 9001:2015 CROSS REFERENCE Chart 343874980ivanNo ratings yet

- A9R1wavcwr 1oltzi5 7h0.tmp PDFDocument1 pageA9R1wavcwr 1oltzi5 7h0.tmp PDFSuresh KumarNo ratings yet

- 12 Chemistry Notes Ch01 The Solid StateDocument22 pages12 Chemistry Notes Ch01 The Solid StateVitesh TyagiNo ratings yet

- Aptiv Customer Specific RequirementsDocument41 pagesAptiv Customer Specific RequirementsHemant GuptaNo ratings yet

- Ba Re SyllabusDocument18 pagesBa Re Syllabuschee pin wongNo ratings yet

- Rec A4Document7 pagesRec A4Imam halim mursyidinNo ratings yet

- ISO 9001 Required Documentation and StepsDocument3 pagesISO 9001 Required Documentation and StepsganandmailNo ratings yet

- Section 8.3 - Design and DevelopmentDocument4 pagesSection 8.3 - Design and Developmentturkih_1988No ratings yet

- ISO 13485:2012 Certification Documents by Global Manager GroupDocument6 pagesISO 13485:2012 Certification Documents by Global Manager GroupManagement ConsultantNo ratings yet

- Required Documents and RecordsDocument4 pagesRequired Documents and RecordsEr Pajapati YashNo ratings yet

- Lawsuit!: Reducing the Risk of Product Liability for ManufacturersFrom EverandLawsuit!: Reducing the Risk of Product Liability for ManufacturersNo ratings yet

- 4.3 Design (Amendment) Rules, 2008Document26 pages4.3 Design (Amendment) Rules, 2008dhir.ankurNo ratings yet

- Ipr NotesDocument179 pagesIpr NotesRajan MeenaNo ratings yet

- 3.2 Copyrights (Amendment) Act, 2012Document14 pages3.2 Copyrights (Amendment) Act, 2012Ankur DhirNo ratings yet

- 3.3 Copyright Rules, 2013Document41 pages3.3 Copyright Rules, 2013dhir.ankurNo ratings yet

- Trade Mark RulesDocument282 pagesTrade Mark Ruleslovingboy22No ratings yet

- Manual of Trade Marks: Practice & ProcedureDocument143 pagesManual of Trade Marks: Practice & ProcedureSaurabh KumarNo ratings yet

- Process FlowDocument1 pageProcess Flowdhir.ankurNo ratings yet

- QMR Q F PR03 001 Job Description MatrixDocument1 pageQMR Q F PR03 001 Job Description Matrixdhir.ankurNo ratings yet

- DNV Brochure FOOD Tcm163-344274Document12 pagesDNV Brochure FOOD Tcm163-344274dhir.ankurNo ratings yet

- Application Form HALALDocument4 pagesApplication Form HALALdhir.ankurNo ratings yet

- Pharma News 27 June 2022 PDF-1Document13 pagesPharma News 27 June 2022 PDF-1dhir.ankurNo ratings yet

- Establishing An Integrated Management SyDocument65 pagesEstablishing An Integrated Management Sydhir.ankurNo ratings yet

- Halalindia EcodesDocument5 pagesHalalindia Ecodesdhir.ankurNo ratings yet

- Ananya Consultants Application FormDocument2 pagesAnanya Consultants Application Formdhir.ankurNo ratings yet

- EthicsPolicy SampleTemplateDocument4 pagesEthicsPolicy SampleTemplatedhir.ankurNo ratings yet

- Chapter 1Document10 pagesChapter 1dhir.ankurNo ratings yet

- Key Ethical PrinciplesDocument2 pagesKey Ethical Principlesdhir.ankurNo ratings yet

- Chapter2975 PDFDocument25 pagesChapter2975 PDFDivya ChauhanNo ratings yet

- Business Ethics in IndiaDocument7 pagesBusiness Ethics in IndianiviNo ratings yet

- Flowchart For Reporting Ethics IssuesDocument1 pageFlowchart For Reporting Ethics Issuesdhir.ankurNo ratings yet

- Declaration of Conformity MDD Class IDocument2 pagesDeclaration of Conformity MDD Class Idhir.ankurNo ratings yet

- QCI AIMED Certification ProcessDocument14 pagesQCI AIMED Certification ProcessAnkurNo ratings yet

- MDD Classification Document: Mapping of RequirementsDocument12 pagesMDD Classification Document: Mapping of Requirementsdhir.ankurNo ratings yet

- Ic E90Document100 pagesIc E90manikopaNo ratings yet

- Class DiagramDocument7 pagesClass Diagrammanognamanu802_10982No ratings yet

- Building A Flutter Project An Understanding The TermsDocument7 pagesBuilding A Flutter Project An Understanding The TermsSujal ShresthaNo ratings yet

- SyllabusDocument1 pageSyllabussandeepjaglan22No ratings yet

- Process Industry Practices Vessels: PIP VEFV6100 Vessels/S&T Heat Exchangers Internals DetailsDocument4 pagesProcess Industry Practices Vessels: PIP VEFV6100 Vessels/S&T Heat Exchangers Internals Detailsmsaldivar177No ratings yet

- AIRCANVAS (Final REport) (1) 8Document39 pagesAIRCANVAS (Final REport) (1) 8Vidiyala srujanaNo ratings yet

- NSN GLN0 Interrogating IPDocument20 pagesNSN GLN0 Interrogating IPNgweno MzitoNo ratings yet

- Science Subject For Pre-K - Activities To Celebrate World Habitat DayDocument56 pagesScience Subject For Pre-K - Activities To Celebrate World Habitat DaythibautintinNo ratings yet

- YD19008 Medical Wearables 2019 Yole Flyer 3Document5 pagesYD19008 Medical Wearables 2019 Yole Flyer 3francistsyNo ratings yet

- Salah Ud Din Lab 2Document4 pagesSalah Ud Din Lab 2Nouman HamzaNo ratings yet

- BPO Whitepaper Business Process Transformation 0512-1Document8 pagesBPO Whitepaper Business Process Transformation 0512-1Ganesh BabuNo ratings yet

- SA2008-000355 en Universal Testing Method For Power Transformer DifferentiaDocument15 pagesSA2008-000355 en Universal Testing Method For Power Transformer DifferentiaRatheesh KumarNo ratings yet

- Lutron / Tridium Bacnet Integration: QuantumDocument7 pagesLutron / Tridium Bacnet Integration: Quantumfairguy80No ratings yet

- Modeling and Simulation of Frequency Reconfigurable Microstrip Patch Antenna For Wimax ApplicationsDocument54 pagesModeling and Simulation of Frequency Reconfigurable Microstrip Patch Antenna For Wimax Applicationskasi sirishaNo ratings yet

- Yusra Hanif: Lecturer Computer Science Concordia College SahiwalDocument21 pagesYusra Hanif: Lecturer Computer Science Concordia College SahiwalYusraNo ratings yet

- Unit 4Document3 pagesUnit 4Saloni ChaudharyNo ratings yet

- DRDO - Improvements in Aircraft Gas Turbine EnginesDocument4 pagesDRDO - Improvements in Aircraft Gas Turbine EnginesSouravkavinannanNo ratings yet

- Characteristics of A ProductDocument8 pagesCharacteristics of A ProductCamilo OrtegonNo ratings yet

- Ami Aptio Afu User Guide NdaDocument32 pagesAmi Aptio Afu User Guide NdaMarcoNo ratings yet

- EE154 Electrical Machine DesignDocument1 pageEE154 Electrical Machine DesignHimanshu AgarwalNo ratings yet

- EPABA Brochure B-3Document4 pagesEPABA Brochure B-3Aashish PanchalNo ratings yet

- TWG 5B DraftDocument87 pagesTWG 5B DraftMoe ThidarNo ratings yet

- WP Oas Installation Config Enterprise Manager 5.5Document154 pagesWP Oas Installation Config Enterprise Manager 5.5quintas omondiNo ratings yet