Professional Documents

Culture Documents

Actuator For Modulating Control: Data Sheet

Uploaded by

Gabriel LukodaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Actuator For Modulating Control: Data Sheet

Uploaded by

Gabriel LukodaCopyright:

Available Formats

Data sheet

Actuator for modulating control

AME 435

Description • energy saving, cost reducing and energy

efficiency improving anti-oscillation function

• the advanced design incorporates load

related ‘switch-off’ to ensure that actuators

and valves are not exposed to overload

Combinations with other valves could be seen

under Accessories.

Main data:

• Nominal voltage (AC or DC):

- 24 V, 50 Hz/60 Hz

• Control input signal:

- 0(4)-20 mA

- 0(2)-10 V

• Force: 400 N

• Stroke: 20 mm

• Speed (selectable):

- 7,5 s/mm

- 15 s/mm

AMV 435 actuator is used with two and three-way • Max. medium temperature: 130 °C

valves type VRB, VRG, VF and VL up to DN 80 • Self stroking

diameter and for AHQM DN 40-100. • LED signalling

• External RESET button

The actuator has some special features: • Output signal

• it automatically adapts its stroke to the valve • Manual operation

end positions which reduces commissioning

time (self stroking)

• valve flow adjustment feature; flow can be

variably-adjusted from linear to logarithmic or

opposite.

Ordering Actuator Accessories-Adapter

Power supply max. Δp

Type Code No. Valves DN Code No.

(V) (bar)

AME 435 24 AC/DC 082H0161 15 9

20 4

Accessories-Stem heater 25 2

For old valves

065Z0313

VRB, VRG, VF, VL 32 1

Type DN Code No.

40 0,8

Stem heater 15-80 065Z0315 50 0,5

DEN-SMT/SI VD.LE.K5.02 © Danfoss 11/2014 1

Data sheet Actuator for modulating control AME 435

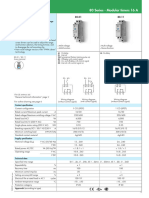

Technical data Power supply V 24 AC/DC; ±10%

Power consumption VA 4,5

Frequency Hz 50/60

V 0-10 (2-10); Ri = 95 kΩ

Control input Y

mA 0-20 (4-20); Ri = 500 Ω

Output signal X V 0-10 (2-10); RL = 650 Ω (maximal load)

Closing force N 400

Max. stroke mm 20

Speed s/mm 7,5 or 15

Max. medium temperature 130

Ambient temperature °C 0 … 55

Storage and transport temperature –40 … 70

Protection class II

Grade of enclosure IP 54

Weight kg 0,45

Low Voltage Directive (LVD) 2006/95/EC: EN 60730-1, EN 60730-2-14

- marking in accordance with standards EMC Directive 2004/108/EC: EN 61000-6-2, EN 61000-6-3

Installation Mechanical

No tool is required to mount actuator on the

valve. Installation of the valve with the actuator

is allowed in horizontal position or upwards.

Installation downwards is not allowed.

①

The actuator must not be installed in an

explosive atmosphere, at ambient temperature

lower than 0 °C or at ambient temperature higher ③

②

than 55 °C. It must not be subject to steam jets, ⑤

water jets or dripping liquid as well.

④

Note:

The actuator may be rotated up to 360° with respect

to the valve stem by loosening the retaining fixture.

Once the actuator is placed, retighten the fixture.

Electrical

Electrical connections can be accessed by

removing the actuator cover. Two cable gland

entries without thread (Ø16 and combined

Ø16/Ø20) are prepared for cable glands. From

factory one entry is provided by rubber cable

gland and the other entry is prepared for

opening.

Note:

Cable and cable gland used must not compromise

the actuator’s IP rating, and must ensure the

connectors are fully strain relieved.

Rubber cable gland delivered from factory does not

compromise IP rating but it does not provide fully

strain relieve according to LVD directive.

Please observe local rules and regulations as well.

2 VD.LE.K5.02 © Danfoss 11/2014 DEN-SMT/SI

Data sheet Actuator for modulating control AME 435

Jumper/DIP switch setting Jumper

2 … 10 V

• U/I - Input signal type selector

SMART

SLOW

LOG

- U position; voltage input is selected

INV

- I position; current input is selected

DIP switches

• SW 1: Not used

0 … 10 V

DIR

FAST

LIN

ACT

• SW 2: Input signal range selector

- OFF position; the input signal is in the range

from 0-10 V (voltage input) or from 0-20 mA

(current input)

- ON position; the input signal is in the range • SW 7: Linear or equal-percentage flow

from 2-10 V (voltage input) or from 4-20 mA through valve selector

(current input) - OFF position; the valve position is linear acc.

to the control signal

• SW 3: Direct or inverse acting selector - ON position; the valve position is equal-

- OFF position; the actuator is in direct acting percentage acc. to the control signal. This

mode (stem extracts as voltage increases) relation is adjustable - see Equal-percentage

- ON position; the actuator is in inverse acting valve-flow adjustment section

mode (stem retracts as voltage increases)

• SW 8: Smart function selector

• SW 4: Fast/Slow - Speed selector - OFF position; the actuator does not try to

- OFF position; the actuating speed is 7,5 s/mm detect oscillations in the system

- ON position; the actuating speed is 15 s/mm - ON position; actuator enables special anti

oscillations algorithm – see Anti oscillations

• SW 5: Not used algorithm section

• SW 6: Not used

Equal-percentage valve-flow adjustment

(SW 7 in position ON)

The actuator has a special valve-flow

adjustment feature. Flow can be, by turning

the potentiometer clock wise (CW) or counter

clockwise (CCW), variably adjusted from linear

to logarithmic or opposite. For details see

Instructions.

DEN-SMT/SI VD.LE.K5.02 © Danfoss 11/2014 3

Data sheet Actuator for modulating control AME 435

Jumper/DIP switch setting Anti oscillations algorithm

(continued) (SW 8 in position ON)

The actuator has special anti oscillations After control signal does not oscillate anymore

algorithm. In case control signal Y on certain output to the valve slowly returns back to static

point oscillates (Fig. 1) - looking from time characteristics.

perspective, algorithm starts to lower the

amplification of the ouput to the valve. Instead of

having static characteristics actuator changes to

dynamic characteristics (Fig. 2) - certain output

stroke area changes to new slope (decrease

amplification).

Valve position X signal (V)

tic

r is

s te

a ra

ch

a tic

st

Point A

dynamic

charasteristic

linear area

Fig. 1 Fig. 2

iMCV 2nd generation Smoothening function

Harmonic oscillations are high frequency Smoothening function implemented in New 2nd

oscillations with low amplitude that vary around generation of anti-oscillation function reduces

its own equilibrium value and not around harmonic oscillations; consequently room

set‑point temperature. They can appear in up to temperature is closer to the set-point (desired)

70 % of control time, even though the system is temperature. Smoother operation of the MCV

properly commissioned. Harmonic oscillations increases lifetime of the valve and actuator and

have negative influence on control stability, and saves energy and reduces costs in general.

lifetime of the valve and actuator.

4 VD.LE.K5.02 © Danfoss 11/2014 DEN-SMT/SI

Data sheet Actuator for modulating control AME 435

Commissioning Complete the mechanical and electrical Automatic self stroking feature

installation, set jumper and DIP-switches, then The actuator automatically adapts its stroke to

perform the necessary checks and tests: the valve end positions:

- when power is applied for the first time or

• Apply power - afterwards by pressing the STAND-BY/RESET

Note that the actuator will now perform button for 5 seconds

automatic self stroking function

Testing entire valve stroke length

• Apply the appropriate control signal and The actuator can be driven to the fully-open or

check: closed positions (depending on valve type) by

- if the valve stem direction is correct for the connecting SN to terminals 1 or 3.

application and

- the actuator drives the valve over the entire

stroke length

The unit is now fully commissioned.

Led signalling/

Actuator operating modes RESET/STAND-BY Flashing green LED:

Self stroking mode

(period is every second)

≈

Constant green LED:

POSITIONING MODE

Flashing green LED:

NORMAL MODE

(period is every 6

seconds)

Flashing red LED:

STAND-BY MODE

(period is every two

seconds)

LED function indicator • POSITIONING MODE

The bi-colour LED is green and stays on during

The bi-colour (green/red) LED function indicator positioning of the actuator according to the

is located on the actuator cover. It indicates the control signal

operating modes.

• NORMAL MODE

External button When the positioning of the actuator is

finished the LED flashes green every 6

Actuator has external STAND-BY/RESET-button seconds.

which is located next to LED indicator. By

pressing on this button in different ways different • STAND BY MODE

operating modes are initiated: Pressing the STAND-BY/RESET-button

switches the actuator to STAND-BY MODE.

• Self stroking mode The actuator keeps its last position in this

Pressing the STAND-BY/RESET-button for mode and does not react to any control

5 sec. causes the actuator to start self stroking signal. This mode can be used for manual

procedure: operation during the commissioning of other

The bi-colour LED flashes green at 1 sec. equipment, or for service purposes.

intervals during calibration procedure, which The bi-colour LED flashes red at 2 sec. intervals.

begins by extracting the stem. When the After pressing the STAND-BY/RESET-button

maximum force is detected (at the end valve again actuator switches to normal mode.

position), the actuator then retracts the

stem, until the maximum force is once again

detected (on the other valve end position).

The actuator will then enter to normal mode

and respond to the control signal.

DEN-SMT/SI VD.LE.K5.02 © Danfoss 11/2014 5

Data sheet Actuator for modulating control AME 435

Manual override Manual override is done by means of control

knob on actuator housing:

• Disconnect power supply or press STAND-BY/

RESET button

• Adjust valve position using the control knob

(observe the rotation direction)

After manual override is not needed:

• Restore power supply or press STAND-BY/

RESET button again

Remark:

When the manual override has been used, the

output signal (X) is not correct until the actuator

reaches its end position.

Wiring SP 24 V AC/DC ............. Power supply

SN 0 V .............................. Common

24 V AC/DC only Y 0(2)-10 V.................... Input signal

0(4)-20 mA

X 0(2)-10 V.................... Output signal

1, 3 Override input signal

(can not be used for 3-point control)

Recommended cross-sectional

Wiring length

power area of the wiring

supply

0-50 m 0,75 mm2

> 50 m 1,5 mm2

down up

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

6 VD.LE.K5.02 © Danfoss 11/2014 DEN-SMT/SI

Data sheet Actuator for modulating control AME 435

Dimensions

147 82,5

min. 180

159,5

Actuator - valve combinations

AME 435 + AME 435 + AME 435 + AME 435 + AME 435 +

VRB 2, VRG 2 VRB 3, VRG 3 VF 2, VL 2 VF 3, VL 3 AHQM (DN 40-100)

DEN-SMT/SI VD.LE.K5.02 © Danfoss 11/2014 7

Data sheet Actuator for modulating control AME 435

8 VD.LE.K5.02 Produced by Danfoss A/S © 11/2014

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Actuador Proporcional Ame435Document8 pagesActuador Proporcional Ame435nelson contrerasNo ratings yet

- Amv (E) 55,56Document4 pagesAmv (E) 55,56AleksandarSashaStankovichNo ratings yet

- Actuators For Modulating Control AME 55, AME 56: Data SheetDocument8 pagesActuators For Modulating Control AME 55, AME 56: Data SheetimtiazNo ratings yet

- Ame55-56 Ed96r702Document8 pagesAme55-56 Ed96r702Florian_AngererNo ratings yet

- Finder 80 91 0 240 0000 16a Monofunction Modular Timer SPDT Co 400vac Ip20 80 91 0 240 0000 Hoja de DatosDocument8 pagesFinder 80 91 0 240 0000 16a Monofunction Modular Timer SPDT Co 400vac Ip20 80 91 0 240 0000 Hoja de DatosMario LopezNo ratings yet

- Actuator CN7505 - 7510Document8 pagesActuator CN7505 - 7510Vivace SystmNo ratings yet

- ML7430E/ML7435E: Electric Linear Actuators For Modulating ControlDocument4 pagesML7430E/ML7435E: Electric Linear Actuators For Modulating ControlMarco ReNo ratings yet

- Finder Relays Series 80Document7 pagesFinder Relays Series 80rg cpeccNo ratings yet

- 1SBH143001R8140 Nl40e 24v DCDocument4 pages1SBH143001R8140 Nl40e 24v DCDivakar Pullam ChettiNo ratings yet

- Eaton 171890 Emt62 DB en GBDocument3 pagesEaton 171890 Emt62 DB en GBAriel TorresNo ratings yet

- HDF 2415 DDocument2 pagesHDF 2415 Dศักดิ์อิเล็กทรอนิกส์ ทุกชนิดNo ratings yet

- NL1150D 24Document1 pageNL1150D 24carolinammiyashiroNo ratings yet

- Data Sheet: HCPL-3120/J312 HCNW3120Document26 pagesData Sheet: HCPL-3120/J312 HCNW3120Nae CarNo ratings yet

- 80W Linear LED Driver User's ManualDocument6 pages80W Linear LED Driver User's Manualfhfgh gjgfhNo ratings yet

- Dual or Triple Output 75W Low Profile Power Supplies: Features BenefitsDocument5 pagesDual or Triple Output 75W Low Profile Power Supplies: Features Benefitsbmr_guruNo ratings yet

- DDR 240 SpecDocument9 pagesDDR 240 Specb8f4fk5nqtNo ratings yet

- ML7421A/ML7421B: Electric Linear Valve ActuatorDocument4 pagesML7421A/ML7421B: Electric Linear Valve ActuatorS M NaveedNo ratings yet

- MANUAL SENSOR DE NIVEL sv115230Document2 pagesMANUAL SENSOR DE NIVEL sv115230Juan GuzmanNo ratings yet

- S80ENDocument12 pagesS80ENshamim ahmedNo ratings yet

- Ame 55QMDocument4 pagesAme 55QMJaison MacorimNo ratings yet

- CC-E Series: Feature BenefitDocument2 pagesCC-E Series: Feature BenefitchiquicikNo ratings yet

- NS2 80Document14 pagesNS2 80Luis ROMERONo ratings yet

- SV115230Document2 pagesSV115230Jose BuferNo ratings yet

- LM2588 Simple Switcher 5A Flyback Regulator With Shutdown: General Description FeaturesDocument29 pagesLM2588 Simple Switcher 5A Flyback Regulator With Shutdown: General Description FeaturescsclzNo ratings yet

- HCF4060B 14-Stage Ripple Carry Binary Counter/divider and OscillatorDocument9 pagesHCF4060B 14-Stage Ripple Carry Binary Counter/divider and OscillatorSherif EltoukhiNo ratings yet

- 350W Single Output DC-DC Converter: SeriesDocument3 pages350W Single Output DC-DC Converter: Seriesninjai_thelittleninjaNo ratings yet

- SlimrelayonronDocument14 pagesSlimrelayonronMantención FastpackNo ratings yet

- MSR125H/HP: DescriptionDocument3 pagesMSR125H/HP: DescriptionI SNo ratings yet

- Electric Actuators for Ball Valves, Butterfly Valves & DampersDocument16 pagesElectric Actuators for Ball Valves, Butterfly Valves & DampersTraian Daniel IvanoviciNo ratings yet

- Eaton Afdd Catalog Tech en UsDocument4 pagesEaton Afdd Catalog Tech en UsjenelbNo ratings yet

- Panel Mount: GN3 SeriesDocument6 pagesPanel Mount: GN3 SeriesRAJNo ratings yet

- Eng 135831Document11 pagesEng 135831Mohan MohaNo ratings yet

- Product Data Sheet 4AM3242-8DD40-0FA0: General Technical DetailsDocument3 pagesProduct Data Sheet 4AM3242-8DD40-0FA0: General Technical DetailsMARIAMNo ratings yet

- ML7420A-7425AB SD ENDocument4 pagesML7420A-7425AB SD ENSameer JainNo ratings yet

- ML7421A, B Electric Linear Valve Actuator: FeaturesDocument8 pagesML7421A, B Electric Linear Valve Actuator: FeatureshadNo ratings yet

- SG 1524 - 2524 - 3524 - (LinFinity) PDFDocument7 pagesSG 1524 - 2524 - 3524 - (LinFinity) PDFJosé AdelinoNo ratings yet

- Cn20, Cn34 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating / 2-Position ControlDocument8 pagesCn20, Cn34 Series: Non-Spring Return Direct-Coupled Damper Actuators For Modulating and Floating / 2-Position ControlDeepjyoti GogoiNo ratings yet

- TemporizadorDocument12 pagesTemporizadorsouzaguimaraisericNo ratings yet

- Actuators For Three Point Control Amv 85K, Amv 86K: Data SheetDocument4 pagesActuators For Three Point Control Amv 85K, Amv 86K: Data SheetandreiterenteNo ratings yet

- AXIOMATIC DSDA-SMB-SC-MT-1A Solenoid DriverDocument10 pagesAXIOMATIC DSDA-SMB-SC-MT-1A Solenoid Driverdylan_dearing@hotmail.comNo ratings yet

- 1SFA896106R7000 psr12 600 70Document5 pages1SFA896106R7000 psr12 600 70degaizaorellanaNo ratings yet

- 1SBH143001R8753 Nl53e 125 V DCDocument4 pages1SBH143001R8753 Nl53e 125 V DCTurnerNo ratings yet

- FDPA Programing1231Document10 pagesFDPA Programing1231Engr. Syed Ghulam Mustafa ShahNo ratings yet

- 3RV20111DA15_SIEMENSDocument6 pages3RV20111DA15_SIEMENSItzayana ChinNo ratings yet

- SPE-075 Brushless DC ThrusterDocument1 pageSPE-075 Brushless DC ThrusterPranesh SbNo ratings yet

- Features: 83 Series - Modular Timers 10 - 16 ADocument8 pagesFeatures: 83 Series - Modular Timers 10 - 16 AJustBeltránNo ratings yet

- 06 Lp1500dmaDocument1 page06 Lp1500dmalsNo ratings yet

- GT 5478 HJDocument6 pagesGT 5478 HJAlex MojkoNo ratings yet

- Finder Relays Series 4CDocument5 pagesFinder Relays Series 4CJavid SalamovNo ratings yet

- Ml7420a8088 e Honeywell Valve ActuatorDocument4 pagesMl7420a8088 e Honeywell Valve ActuatorstranfirNo ratings yet

- CWD2425P SSR CrydomeDocument8 pagesCWD2425P SSR Crydome100regNo ratings yet

- TR24-SR-T US Technical Data Sheet: Modulating, Non-Spring Return, 24 V, For DC 2... 10 V or 4... 20 MaDocument2 pagesTR24-SR-T US Technical Data Sheet: Modulating, Non-Spring Return, 24 V, For DC 2... 10 V or 4... 20 Manicolas sNo ratings yet

- 2022042913383312-String DisconnectDocument16 pages2022042913383312-String DisconnectChrisNo ratings yet

- Simex SPS-24 1.5 FUENTEDocument1 pageSimex SPS-24 1.5 FUENTENeyser Vigo SaldañaNo ratings yet

- DDR 30 Spec PDFDocument4 pagesDDR 30 Spec PDFencus170785No ratings yet

- Features: 56 Series - Miniature Power Relays 12 ADocument10 pagesFeatures: 56 Series - Miniature Power Relays 12 ADepZai DatNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- PXF5 PXF9 ManualDocument24 pagesPXF5 PXF9 ManualGabriel LukodaNo ratings yet

- MA8692 Standard EU enDocument252 pagesMA8692 Standard EU enAlvaro PantojaNo ratings yet

- Ba01393den 0317 PDFDocument192 pagesBa01393den 0317 PDFjaime anibal navarrete aburtoNo ratings yet

- Document 709Document1 pageDocument 709Gabriel LukodaNo ratings yet

- Chinese in The PHDocument15 pagesChinese in The PHMandalihan GepersonNo ratings yet

- Map Project Rubric 2018Document2 pagesMap Project Rubric 2018api-292774341No ratings yet

- Format of Synopsis - Project - 1Document5 pagesFormat of Synopsis - Project - 1euforia hubNo ratings yet

- Rolls-Royce M250 FIRST Network: 2015 Customer Support DirectoryDocument76 pagesRolls-Royce M250 FIRST Network: 2015 Customer Support Directoryale11vigarNo ratings yet

- Active and Passive Voice quizDocument2 pagesActive and Passive Voice quizM3xobNo ratings yet

- DSC analysis of hair denaturationDocument2 pagesDSC analysis of hair denaturationDiosel Rezia PrazaNo ratings yet

- 03 Authority To TravelDocument5 pages03 Authority To TravelDiana Marie Vidallon AmanNo ratings yet

- Q3 Curriculum Map - Mathematics 10Document3 pagesQ3 Curriculum Map - Mathematics 10Manilyn BaltazarNo ratings yet

- Pharmacology Ain Shams 123 - Compress 1Document552 pagesPharmacology Ain Shams 123 - Compress 1ahmed hoty100% (1)

- Definition and Scope of Public FinanceDocument2 pagesDefinition and Scope of Public FinanceArfiya MubeenNo ratings yet

- Atlas Ci30002Tier-PropanDocument3 pagesAtlas Ci30002Tier-PropanMarkus JeremiaNo ratings yet

- Introduction To Drug DiscoveryDocument45 pagesIntroduction To Drug Discoveryachsanuddin100% (5)

- Quantification Skills in The Construction IndustryDocument34 pagesQuantification Skills in The Construction IndustryBRGRNo ratings yet

- Inventario de Autoestima de Coopersmith PDFDocument10 pagesInventario de Autoestima de Coopersmith PDFNancy BerduzcoNo ratings yet

- 1.1 Enterprise AssessmentDocument1 page1.1 Enterprise AssessmentGermanRobertoFongNo ratings yet

- Board Question Paper: March 2018: Geography and EconomicsDocument2 pagesBoard Question Paper: March 2018: Geography and EconomicsVishvajit PatilNo ratings yet

- 21st Century Literary GenresDocument2 pages21st Century Literary GenresGO2. Aldovino Princess G.No ratings yet

- Annual Report 18Document363 pagesAnnual Report 18Safeer UllahNo ratings yet

- Patient Admission Note TemplateDocument4 pagesPatient Admission Note Templatejonnyahn100% (1)

- READMEDocument3 pagesREADMERadu TimisNo ratings yet

- Setup LogDocument77 pagesSetup Loganon-261766No ratings yet

- Adms OneAdms One ClassDocument9 pagesAdms OneAdms One ClasssafwatNo ratings yet

- Classification of AnimalsDocument6 pagesClassification of Animalsapi-282695651No ratings yet

- G7-UNIT - I. (Module - 1 (Week 1 - 3 (Microscopy & Levels of Org.)Document8 pagesG7-UNIT - I. (Module - 1 (Week 1 - 3 (Microscopy & Levels of Org.)Margie Gabo Janoras - DaitolNo ratings yet

- Bài Tập Phần Project ManagementDocument11 pagesBài Tập Phần Project ManagementhunfgNo ratings yet

- CARP Law NotesDocument5 pagesCARP Law NotesJustisia KaunlaranNo ratings yet

- 01 A Brief Introduction To Cloud ComputingDocument25 pages01 A Brief Introduction To Cloud ComputingfirasibraheemNo ratings yet

- Sand Compaction MethodDocument124 pagesSand Compaction Methodisaych33ze100% (1)

- Creating Literacy Instruction For All Students ResourceDocument25 pagesCreating Literacy Instruction For All Students ResourceNicole RickettsNo ratings yet

- Phy Worksheet IG 3 Phase 2Document6 pagesPhy Worksheet IG 3 Phase 2Umair RazaNo ratings yet