Professional Documents

Culture Documents

ROCKSTAR

Uploaded by

Jodi GandawaliCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ROCKSTAR

Uploaded by

Jodi GandawaliCopyright:

Available Formats

INTRODUCTION

Background of the study

The heating and cooling of buildings uses a lot of energy, so engineers

continually look for creative ways to reduce the heating and cooling demands, and thus

the total amount of energy required, one way to do this is by making fiberboard.

Engineers have developed many types of insulation such as fiberglass, rock wool,

mineral wool, natural wool, cotton, straw, cellulose, paper, polyurethane foam,

polystyrene foam, polyester and soy foam (Robert McKinney and Marissa H. Forbes,

2013).

Due to their low thermal conductivity and low cost production cellulose fibers has

been widely adopted in many countries. More importantly, these materials are non-toxic,

harmless and eco-friendly making them more appealing to use. Cellulose fibers like

Johnson grass has also advantages like minor health issues if any, easy to install,

inhibits airflow, environmentally friendly, and helps minimize fire damage.

Studies shows that thermal characteristics of grass-made fiber materials are

strong enough to be used in particular kind of insulation, and equivalent to mineral

wools. The researcher come up with the idea of making an fiberboard made of Johson

grass aiming to produce economical, non- toxic and acceptable fiberboard.

The study of Johnson grass fiber as fiberboard requires less production cost,

which will be affordable and therefore helps people improve their quality of life. This

study is also useful for building owners since this requires less energy to maintain. More

importantly, this study does not harm the environment instead helps to minimize waste

and utilize a materials’ potential to be used as a construction material.

The main goal of this study is to make an fiberboardmade up of Johnson grass

fiber. Furthermore, the study specifically aims to determine the thermal conductivity,

bending strength and moisture content of the fiberboard

The coverage of this study is to determine the potential of Johnson grass fiber as

fiberboard. The tests to be conducted are thermal conductivity test, bending test and

moisture content of the board.

This study proposes the use of Johson grass fiber and adhesive as a binder for

the production of fiberboard. For the adhesive, the polyester resin, epoxy resin and

urea-formaldehyde will be use as an alternate resin for binding. The development of this

study will be used by builders, construction firms, and engineers especially in the wall,

safety barrier, alternative materials, ceiling and room partition in the house, and other

structural uses.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Blow Mould DesignDocument78 pagesBlow Mould Designabhi858100% (13)

- Entrance Examination SlipDocument1 pageEntrance Examination Slipgyle gallogoNo ratings yet

- Giant Reed (Arundo Donax) As ParticleboardDocument60 pagesGiant Reed (Arundo Donax) As ParticleboardJodi GandawaliNo ratings yet

- Research Conceptualization: AytacDocument3 pagesResearch Conceptualization: AytacJodi GandawaliNo ratings yet

- Es 322 Module 3Document64 pagesEs 322 Module 3Jodi GandawaliNo ratings yet

- Group 6 Exercise 2Document24 pagesGroup 6 Exercise 2Jodi GandawaliNo ratings yet

- Investigation of The Mechanical Properties of Napier-Grass-Reinforced Composites For The Aerospace Industry: A ReviewDocument14 pagesInvestigation of The Mechanical Properties of Napier-Grass-Reinforced Composites For The Aerospace Industry: A ReviewJodi GandawaliNo ratings yet

- I Love UniverseDocument1 pageI Love UniverseJodi GandawaliNo ratings yet

- Es 322 Module 2Document37 pagesEs 322 Module 2Jodi GandawaliNo ratings yet

- Engr. Eliseo L. Otoc: (Nylon) Net As Fibrous Ferrocement"Document1 pageEngr. Eliseo L. Otoc: (Nylon) Net As Fibrous Ferrocement"Jodi GandawaliNo ratings yet

- I Love UniverseDocument2 pagesI Love UniverseJodi GandawaliNo ratings yet

- Elements of Media LiteracyDocument2 pagesElements of Media LiteracyJodi GandawaliNo ratings yet

- TDS - Xypex Concentrate&Xypex Megamix IIDocument3 pagesTDS - Xypex Concentrate&Xypex Megamix IIengsam777No ratings yet

- Timber DesignDocument36 pagesTimber DesignKristine May Maturan100% (1)

- Project Proposal On Design and Modelling and Development Of: Submission DateDocument24 pagesProject Proposal On Design and Modelling and Development Of: Submission DatemuseNo ratings yet

- Roof Framing Plan: Al FrescoDocument1 pageRoof Framing Plan: Al FrescoBerlin Andrew SionNo ratings yet

- Installation and Maintenance Instructions: Resilient Seat Butterfly ValvesDocument12 pagesInstallation and Maintenance Instructions: Resilient Seat Butterfly ValvesBhargav PatelNo ratings yet

- s5-3-1 - Typical Composite and Steel Deck DetailsDocument1 pages5-3-1 - Typical Composite and Steel Deck Detailscewaleed2590No ratings yet

- CIPETDocument58 pagesCIPETsenthilvelanNo ratings yet

- Rencana Impor - Alas Kaki HS Code 6404 - PT Omega Fashindo AdiperkasaDocument21 pagesRencana Impor - Alas Kaki HS Code 6404 - PT Omega Fashindo AdiperkasaDede ariefNo ratings yet

- Pengaruh Temperatur Pemanasan Terhadap Kekerasan Dan Ketebalan Lapisan Pada Chromizing Baja Karbon RendahDocument12 pagesPengaruh Temperatur Pemanasan Terhadap Kekerasan Dan Ketebalan Lapisan Pada Chromizing Baja Karbon RendahFauzan ⎝⏠⏝⏠⎠ ZanklovkyNo ratings yet

- Garages Stubbie InstallDocument16 pagesGarages Stubbie InstallMattNo ratings yet

- Alloy 309Document3 pagesAlloy 309Branko FerenčakNo ratings yet

- JFE's Super Abrasion-Resistant Steel PlateDocument4 pagesJFE's Super Abrasion-Resistant Steel PlateKYAW SOENo ratings yet

- Fiber DiameterDocument8 pagesFiber DiameterkalvinamyNo ratings yet

- Tiny Shipping Container Home PDFDocument21 pagesTiny Shipping Container Home PDFDaniel GarzonNo ratings yet

- Induction BendingDocument23 pagesInduction BendingstevenNo ratings yet

- EHEDG Kerbs and Coving and Doorprotection Section 15 1 13Document8 pagesEHEDG Kerbs and Coving and Doorprotection Section 15 1 13AnnNo ratings yet

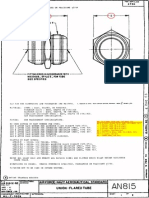

- Airforce-Navy Aeronautical Standard W-Au Union - Flared Tube .... !0.., 0,1! 0.,orr-L,, 0....Document4 pagesAirforce-Navy Aeronautical Standard W-Au Union - Flared Tube .... !0.., 0,1! 0.,orr-L,, 0....MAI_QualityNo ratings yet

- D Market Rate Analysis BuildingDocument74 pagesD Market Rate Analysis BuildingAjay ThakurNo ratings yet

- 464.10 821837931001 821837939999 Step Plate, Movable BF 800 BPDocument7 pages464.10 821837931001 821837939999 Step Plate, Movable BF 800 BPeshopmanual EnamNo ratings yet

- SG50 Curtain Walling System: Experts in AluminiumDocument2 pagesSG50 Curtain Walling System: Experts in Aluminiumtheking111111111No ratings yet

- Materials of Manav SadhnaDocument2 pagesMaterials of Manav SadhnaIshita JainNo ratings yet

- 2 Steel Used in BridgesDocument2 pages2 Steel Used in BridgesJay PatelNo ratings yet

- Bulk Deformation AssignmentDocument9 pagesBulk Deformation AssignmentMuhammad FasihNo ratings yet

- BOM (Roof-Deck Renovation)Document1 pageBOM (Roof-Deck Renovation)John Rhey Almojallas BenedictoNo ratings yet

- Material Reconciliation - PDF REVISEDDocument32 pagesMaterial Reconciliation - PDF REVISEDSrinivasan RanganathanNo ratings yet

- Omn Fac 406Document52 pagesOmn Fac 406vinodNo ratings yet

- KBR Inspection Test Plan For Shop Fabricated PipingDocument4 pagesKBR Inspection Test Plan For Shop Fabricated PipingSyafril AkbarNo ratings yet

- S.O.R. Bridge WorksDocument48 pagesS.O.R. Bridge WorksUmar KarimiNo ratings yet

- Acetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Document1 pageAcetal: Acetal Grades ACETAL COPOLYMER (Unfilled)Anonymous UcmNTu6rNo ratings yet