Professional Documents

Culture Documents

TEAM - SmartHeat Wireless Heat Treating System - LTR-WEB

TEAM - SmartHeat Wireless Heat Treating System - LTR-WEB

Uploaded by

ram0629Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TEAM - SmartHeat Wireless Heat Treating System - LTR-WEB

TEAM - SmartHeat Wireless Heat Treating System - LTR-WEB

Uploaded by

ram0629Copyright:

Available Formats

SmartHeat ®

Wireless Heat-Treating System

Advanced Technology Lowers Labor Costs while Increasing Heat-Treating Accuracy

TEAM’s long history of building the most powerful, precise and durable heat-treating equipment in the world continues with

the development of our advanced SmartHeat® Wireless Heat-Treating System.

Programmable Logic Controllers (PLC) and SCADA (Supervisory Control and Data Acquisition) Software provide the brains of

TEAM’s SmartHeat® system ensuring that piping and vessel systems are heat-treated accurately and precisely every time.

The system is driven by interchangeable computers that store time and temperature information in encrypted form. Heat

cycle information for up to 48 inputs is continuously saved to log files as well as redundantly to the on-board memory during

the cycle and is controlled wirelessly from a single computer.

Time and temperature data can be exhibited with each machine’s thermocouples per chart or separated out and displayed as

a single thermocouple per chart, which provide for better oversight and quality control on small-bore piping or single-circuit

heat treatments. Job information is entered prior to heat cycle startup and the final trend chart can be delivered in printed

form as well as in digital format including email, CD or USB device.

TeamInc.com

VERSION 1.0 04/01/2019

SmartHeat ®

Wireless Heat-Treating System

Benefits of TEAM’s SmartHeat ® Wireless Heat-Treating System

• Reduced Costs – Only one operator is needed to control and monitor multiple

heat cycles from the complex controllers with inputs for thermo-couples and

heater current. Multiple units can be managed using any TEAMScadaTM

Software-equipped computer.

• Enhanced Quality – Customers and TEAM support personnel can view real-

time data from laptops, desktop computers and mobile devices on the same

network. Reduced errors result when temperature requirements are verified from

SmartHeat® by TEAM’s operation support personnel before and during heat Main View screen

cycles.

• Better Record Keeping – TEAM’s SmartHeat® Wireless Heat-Treating System

delivers clear, concise documentation for customers while guaran-teeing chart

accuracy. Each console includes a Programmable Logic Controller (PLC) with

TEAM’s unique SCADA Software and is equipped with backup on-board

memory to store heat cycle data for easy retrieval should there be any

communication interruptions to the computer. Documentation is saved

electronically and stored locally on TEAM servers making it readily available for

fast retrieval for auditing purposes and/or duplication.

• Reduced Space Requirements – TEAM’s SmartHeat® System’s

Profile View screen

footprint is 40% smaller than traditional equipment. Consoles can be stacked in

tight plant locations when limited space is available. The mobile generators

minimize the area needed and the noise generated as compared to the larger

rigs.

• Minimized Risk – TEAM’s SmartHeat® Wireless Heat-Treating System further

exemplifies TEAM’s long-standing commitment to safe and injury-free worksites.

The system streamlines the heat-treating processes, reduces equipment and

labor requirements and ultimately reduces risk. The remote access control and

monitoring helps to remove personnel from sensitive, congested and/or risky

facility areas. Trend View screen

To learn how TEAM’s SmartHeat® System can lower labor

costs while increasing heat-treating and record keeping

accuracy, call 1-800-662-8326.

TeamInc.com

VERSION 1.0 04/01/2019

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- How To Remove Omron PLC Password - Automation-Talk PDFDocument3 pagesHow To Remove Omron PLC Password - Automation-Talk PDFJafarShojaNo ratings yet

- 1st Lecture PPT On Intro of Cyber CrimeDocument29 pages1st Lecture PPT On Intro of Cyber Crimeapi-327908336100% (1)

- Discuss The Three Approaches of MIS DevelopmentDocument2 pagesDiscuss The Three Approaches of MIS Developmentndgharat100% (6)

- LEGO Mindstorm RCX LectureDocument18 pagesLEGO Mindstorm RCX LecturegarneliNo ratings yet

- Gforth 2018 11 23Document305 pagesGforth 2018 11 23Vitalij IljuchinNo ratings yet

- MECanalyst ManualDocument33 pagesMECanalyst ManualOja Yaman100% (2)

- 2.aiticss-Advance Excel MCQ QuestionsDocument8 pages2.aiticss-Advance Excel MCQ QuestionsRajeswarirameshkumarVenkataramanNo ratings yet

- CPU Scheduling: Source: Operating System Concepts by by Silberschatz, Galvin and GagneDocument50 pagesCPU Scheduling: Source: Operating System Concepts by by Silberschatz, Galvin and GagneRavi SoniNo ratings yet

- Introducere in AIDocument2 pagesIntroducere in AIIosif BelciugNo ratings yet

- CG Project ReportDocument26 pagesCG Project ReportVinutha Reddy100% (1)

- 7.1 7th - PID-Inverter Compressor - (FreeCourseWeb - Com)Document16 pages7.1 7th - PID-Inverter Compressor - (FreeCourseWeb - Com)lamine fayNo ratings yet

- HP 1910 Fast Ethernet Switch Series Getting Started GuideDocument28 pagesHP 1910 Fast Ethernet Switch Series Getting Started GuidejunediiiNo ratings yet

- ACI Short NoteDocument26 pagesACI Short NoteAmit PandeyNo ratings yet

- Final Professional-Cloud-Architect-CertificationCoursera PDF US-Letter RGB June-2020Document2 pagesFinal Professional-Cloud-Architect-CertificationCoursera PDF US-Letter RGB June-2020davidNo ratings yet

- Module 1Document7 pagesModule 1SonamAgarwalNo ratings yet

- Dspic Control Board: For Industrial ApplicationsDocument5 pagesDspic Control Board: For Industrial Applicationstakaca40No ratings yet

- Icf Grade 7Document7 pagesIcf Grade 7Manliguis AisaNo ratings yet

- SnipDocument580 pagesSnipShanker MylsamyNo ratings yet

- Weblogic Stdout Rotaion ProblemsDocument5 pagesWeblogic Stdout Rotaion Problemsvali07No ratings yet

- EtechDocument5 pagesEtechKent Joshua PatayNo ratings yet

- Project Report On Shopping MallDocument36 pagesProject Report On Shopping MallGurlagan Sher GillNo ratings yet

- Chapter 15 Transaction MGMT Edited#1Document55 pagesChapter 15 Transaction MGMT Edited#1YASMIN KAMILIANo ratings yet

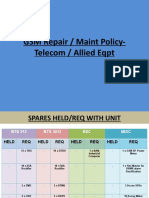

- GSM Repair / Maint Policy-Telecom / Allied EqptDocument9 pagesGSM Repair / Maint Policy-Telecom / Allied EqptImran AzizNo ratings yet

- Cs3451 Ios Unit 5 NotesDocument21 pagesCs3451 Ios Unit 5 NotesspartansheikNo ratings yet

- RecordPoint Records Management With SharePointDocument17 pagesRecordPoint Records Management With SharePointoptical420No ratings yet

- Control and Instrumentation Final Exam QuestionDocument4 pagesControl and Instrumentation Final Exam QuestionMuhammad KhalilNo ratings yet

- PDAM Spec Web Service 1.0.4Document22 pagesPDAM Spec Web Service 1.0.4luwiceNo ratings yet

- 695 2021 KtuDocument1 page695 2021 KtuFAYIZ FEROSHNo ratings yet

- The Different Types of Network TopologyDocument2 pagesThe Different Types of Network TopologyAlthea Faye OlarteNo ratings yet

- 8-2 Understanding WebMethods Product SuiteDocument84 pages8-2 Understanding WebMethods Product SuiteJose Angel Huerta ZamilpaNo ratings yet