Professional Documents

Culture Documents

Drum Brakes SL: According To DIN 15435

Uploaded by

LukaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Drum Brakes SL: According To DIN 15435

Uploaded by

LukaCopyright:

Available Formats

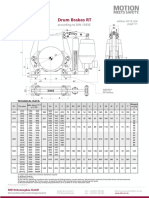

Drum Brakes SL edition 10/19 | EN

page 1/1

according to DIN 15435

Compensaring sheets

do not form a part of the delivery

TECHNICAL DATAS:

MBr [Nm]1) 4) 5) Weight

D1 Thrustersize A1max A2max Bmax Cmax B1 B2 B3 D3 H I K M N P Q T

µ = 0,3 µ = 0,4 ca. kg 2)

23/5 75 - 230 100- 300 235 190

200 162 730 75 70 80 14 155 55 145 90 85 5 10 155 24

30/5 75 - 300 100- 400 260 230

23/5 75 - 230 100- 300 260 210 162 810

250 95 90 100 18 185 65 180 100 105 5 13 172 33

30/5 75 - 310 100- 410 260 245 160 785

23/5 90 - 280 120- 370 315 265 162 880 45

30/5 90 - 395 120- 520 315 265 160 880 45

315 118 110 110 18 225 80 220 110 135 5 13 208

50/6 260 - 700 350- 900 320 285 195 925 47

80/6 260 - 1200 350- 1600 320 285 205 925 47

30/5 115 - 400 150- 520 325 325 190 970 60

50/6 260 - 700 350- 920 325 325 195 1005 62

400 150 140 140 22 270 100 270 120 180 10 18 252

80/6 260 - 1200 350- 1600 325 325 205 1005 62

121/6 380 - 1930 500- 2550 445 390 240 1105 90

50/6 380 - 930 500- 1230 405 395

80/6 380 - 1550 500- 2050 405 395

500 250 1245 190 180 180 22 330 130 325 140 220 10 18 315 125

121/6 570 - 2400 750- 3180 425 400

201/6 760 - 3750 1000- 4950 425 400

121/6 745 - 2350 1000- 3100 185

630 201/6 745 - 3700 1000- 4900 470 470 300 1400 236 225 220 27 410 170 400 160 285 10 22 390 185

301/6 1100 - 5700 1500- 7500 190

121/6 1100 - 2700 1500- 3550 235

1500- 5500 235

710 201/6 1100 - 4200 530 530 325 1485 265 255 240 27 460 190 450 180 320 10 22 430

301/6 1500 - 6450 2000- 8500 240

1) Value lower than the minimum stated on request

2) Without thrustor

3) Dimensions in mm

4) The various operating conditions like cirumferencial (sliding) speed, contact pressure, thermal load, material of the brake drum and enviromental

influences can change the friction value. It should be taken into consideration when calculating the brake

5) Recommandation: necessary braking torque between 30 % and 80 % of the maximum value

You might also like

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- Fib Lucas StaDocument5 pagesFib Lucas StafabriziomaccalliniNo ratings yet

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic Seriess 1 2 3 4 5 6 7 8 9 10 11 12Document3 pagesFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriess 1 2 3 4 5 6 7 8 9 10 11 12Jorge FerrerNo ratings yet

- Creating Attachments To Work Items or To User Decisions in WorkflowsDocument20 pagesCreating Attachments To Work Items or To User Decisions in Workflowselampe100% (1)

- Pressure Temperature Charts ASTMDocument4 pagesPressure Temperature Charts ASTMAnonymous rdv9nb1No ratings yet

- Dielectric Properties of SolidsDocument15 pagesDielectric Properties of SolidsMahesh Lohith K.S100% (11)

- Grade-9 (3rd)Document57 pagesGrade-9 (3rd)Jen Ina Lora-Velasco GacutanNo ratings yet

- Unit 07 Self-Test Chemistry Self TestDocument2 pagesUnit 07 Self-Test Chemistry Self TestOluwatusin Ayo OluwatobiNo ratings yet

- Tractor Traction Wheels TyresDocument14 pagesTractor Traction Wheels Tyresmehmed şahinNo ratings yet

- Optimization of Decarbonization On Steel IndustryDocument28 pagesOptimization of Decarbonization On Steel Industrymsantosu000No ratings yet

- Dover Artificial Lift - Hydraulic Lift Jet Pump BrochureDocument8 pagesDover Artificial Lift - Hydraulic Lift Jet Pump BrochurePedro Antonio Mejia Suarez100% (1)

- Belt and Bucket Elevator - LBEB - Data Sheet - ENDocument2 pagesBelt and Bucket Elevator - LBEB - Data Sheet - ENsalih khattabNo ratings yet

- Flange Bolt-Up Bolting Torque Table 4 PDFDocument4 pagesFlange Bolt-Up Bolting Torque Table 4 PDFddarioxavier80No ratings yet

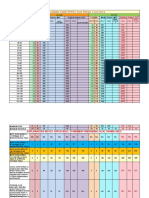

- Drum Brakes RT: According To DIN 15435Document1 pageDrum Brakes RT: According To DIN 15435LukaNo ratings yet

- LIST-PRICE-w e F 22 06 2021Document2 pagesLIST-PRICE-w e F 22 06 2021roy oyeNo ratings yet

- Large Axial Fans: Dimensions (MM)Document1 pageLarge Axial Fans: Dimensions (MM)Pradeep JhaNo ratings yet

- Bea Rings: Price-ListDocument1 pageBea Rings: Price-ListGautam YᗩᗪᑌᐯᗩᑎᔕᕼINo ratings yet

- Chapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopDocument8 pagesChapter 5. Control Valve Selection: Cast Carbon Steel (ASTM A216 Grade WCC) - WCC Is The Most PopRedzaNo ratings yet

- Common Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsDocument1 pageCommon Bolt Markings Torques Tech Bulletin AERA Melling Engine PartsNazar AlrodainyNo ratings yet

- Asme B16.5 2003 Table F2-3 PDFDocument14 pagesAsme B16.5 2003 Table F2-3 PDFSantos RandazzoNo ratings yet

- Face-To-Face Valve Dimensions - EN-558-1: DN Basic SeriessDocument3 pagesFace-To-Face Valve Dimensions - EN-558-1: DN Basic Seriessdona_001No ratings yet

- Agnee Helical Bevel Gear Box - Dimensional Details PDFDocument41 pagesAgnee Helical Bevel Gear Box - Dimensional Details PDFgabisaNo ratings yet

- Arrowline Sae 100 R 1Document1 pageArrowline Sae 100 R 1mohammed sulaimanNo ratings yet

- Wire Ampacity and Ocpd Rating StandardsDocument3 pagesWire Ampacity and Ocpd Rating StandardsJule LobresNo ratings yet

- DX Spec SheetDocument2 pagesDX Spec SheetAllanNo ratings yet

- VODCDocument2 pagesVODCVineet Maheshwari100% (1)

- Nec TablesDocument21 pagesNec TablesDelmar FerrerNo ratings yet

- Hole Saw Speed Chart Bulletin 194Document2 pagesHole Saw Speed Chart Bulletin 194Muhammad IshaqNo ratings yet

- Geartec Turbogetriebe PrintDocument24 pagesGeartec Turbogetriebe PrintZacEffortNo ratings yet

- Flange Sizing ProgramDocument15 pagesFlange Sizing Program심판자0% (1)

- Flange Sizing ProgramDocument15 pagesFlange Sizing Program심판자No ratings yet

- Padeye Design: Allseas LogoDocument12 pagesPadeye Design: Allseas LogoHemam PrasantaNo ratings yet

- Dynamic - Ampacity 2020Document2 pagesDynamic - Ampacity 2020Jar son PascuaNo ratings yet

- Anchor Chain Eqpt NoDocument2 pagesAnchor Chain Eqpt NoSusmita SahaNo ratings yet

- IR Fare SuburbanDocument4 pagesIR Fare SuburbanSoumabho ParuiNo ratings yet

- IR Fare SuburbanDocument4 pagesIR Fare SuburbanPandiyanNo ratings yet

- IR Fare SuburbanDocument4 pagesIR Fare SuburbanbharathbuddyNo ratings yet

- PB Cast Iron HubsDocument2 pagesPB Cast Iron Hubsabhijit287No ratings yet

- 1 Actuator AssemblyDocument1 page1 Actuator AssemblyYuriPasenkoNo ratings yet

- ZSY ZDY ZFY ZLY Series Industrial GearboxDocument13 pagesZSY ZDY ZFY ZLY Series Industrial GearboxGarry Yan DiazNo ratings yet

- Zsy Gearbox SogearsDocument12 pagesZsy Gearbox SogearsGear motorsNo ratings yet

- Below 30k Incentive Analysis AprilDocument20 pagesBelow 30k Incentive Analysis Aprilanand mishraNo ratings yet

- MONTABERTDocument6 pagesMONTABERTMiguelNo ratings yet

- 05.fabricated HDPE Tee R07Document7 pages05.fabricated HDPE Tee R07kuntasee.duckNo ratings yet

- SUNITRAC OTR Tyre CatalogDocument12 pagesSUNITRAC OTR Tyre CatalogCarlos Alberto Reque BardalesNo ratings yet

- 10% Torispherical Dished Ends: Di/Do MM Ri MM Ri MM THK Min Max Hi MM Vol LitresDocument1 page10% Torispherical Dished Ends: Di/Do MM Ri MM Ri MM THK Min Max Hi MM Vol LitresAJAY1381No ratings yet

- Anilox Lpi LPCM - Platescreencalculator - LRDocument1 pageAnilox Lpi LPCM - Platescreencalculator - LRJavier RealNo ratings yet

- ZSY ZDY ZFY ZLY Series Industrial GearboxDocument13 pagesZSY ZDY ZFY ZLY Series Industrial GearboxCemil KabakNo ratings yet

- Group Radius Angle Tangent Length (MM) Front L (MM)Document2 pagesGroup Radius Angle Tangent Length (MM) Front L (MM)rahatNo ratings yet

- Reliable. Economical. Total Solution.: Greaves Cotton LimitedDocument2 pagesReliable. Economical. Total Solution.: Greaves Cotton LimitedarunNo ratings yet

- Bus Bar Selection Chart AluminiumDocument1 pageBus Bar Selection Chart AluminiumJit0% (1)

- Funeec Solid Carbide - Price ListDocument12 pagesFuneec Solid Carbide - Price ListdpshradhaNo ratings yet

- Pressed 10% Torispherical Dished Ends - Stainless Steel: Ri SF Di Ri HiDocument2 pagesPressed 10% Torispherical Dished Ends - Stainless Steel: Ri SF Di Ri HiSunil KolheNo ratings yet

- Product 2Document2 pagesProduct 2AbinNo ratings yet

- Copper To Aluminum Conversion ChartDocument1 pageCopper To Aluminum Conversion Chartlester lorredoNo ratings yet

- Bucket Elevator - Lachenmeier MonsunDocument2 pagesBucket Elevator - Lachenmeier MonsunAnonymous lu0Bn8WXNo ratings yet

- Isfm HW 1Document7 pagesIsfm HW 1vedanthskumar0No ratings yet

- Top-Mech TX Serie Eot Cranes Pricelist-15tsg-Fem2mDocument1 pageTop-Mech TX Serie Eot Cranes Pricelist-15tsg-Fem2mfaisal3arainNo ratings yet

- Steel Bolt TorqueDocument1 pageSteel Bolt TorqueMohamed el attarNo ratings yet

- Broiler Feed Chart EXDocument2 pagesBroiler Feed Chart EXAaron JenksNo ratings yet

- Broiler Feed ChartDocument2 pagesBroiler Feed ChartAaron JenksNo ratings yet

- Broiler Feed ChartDocument2 pagesBroiler Feed ChartAaron JenksNo ratings yet

- DOUBLE INLET CENTRIFUGAL BLOWER - Rotech Inc.Document2 pagesDOUBLE INLET CENTRIFUGAL BLOWER - Rotech Inc.ABCDNo ratings yet

- Bolt Torque Chart, Team Buick PDFDocument1 pageBolt Torque Chart, Team Buick PDFnate anantathatNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument38 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Application - Three-Phase MotorsDocument4 pagesApplication - Three-Phase MotorsrinthusNo ratings yet

- United States Census Figures Back to 1630From EverandUnited States Census Figures Back to 1630No ratings yet

- CRANES & HOISTING - Form - 10074EDocument2 pagesCRANES & HOISTING - Form - 10074ELukaNo ratings yet

- N 0442 FEM Positionpaper Lifting Person - Guideline 2012-02-24 en FinDocument3 pagesN 0442 FEM Positionpaper Lifting Person - Guideline 2012-02-24 en FinegyinspectoryahooNo ratings yet

- Disc Brake SST 10: Dimensions and Technical DataDocument1 pageDisc Brake SST 10: Dimensions and Technical DataLukaNo ratings yet

- Program Number 0170/0180: Maintenance Instructions Maintenance of End Stop BuffersDocument9 pagesProgram Number 0170/0180: Maintenance Instructions Maintenance of End Stop BuffersLukaNo ratings yet

- Kolana WG DIN 2605-1 Kolana WG DIN 2605-1 Kolana WG DIN 2605-1Document1 pageKolana WG DIN 2605-1 Kolana WG DIN 2605-1 Kolana WG DIN 2605-1LukaNo ratings yet

- Ampla's Technology ArchitectureDocument4 pagesAmpla's Technology ArchitecturesyeadtalhaaliNo ratings yet

- Hindu Temples Models of A Fractal Universe by Prof - Kriti TrivediDocument7 pagesHindu Temples Models of A Fractal Universe by Prof - Kriti TrivediAr ReshmaNo ratings yet

- Chapter VI DP and NetworkDocument66 pagesChapter VI DP and NetworkSirgut TesfayeNo ratings yet

- Chapter 1 IntroductionDocument49 pagesChapter 1 IntroductionGemex4fshNo ratings yet

- Mbs PartitionwallDocument91 pagesMbs PartitionwallRamsey RasmeyNo ratings yet

- Acuvim II Profibus Modules Users Manual v1.10Document36 pagesAcuvim II Profibus Modules Users Manual v1.10kamran719No ratings yet

- Design and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSDocument17 pagesDesign and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSKashif FurkanNo ratings yet

- Teaching Tactics and Teaching Strategy: Arthur W. Foshay'Document4 pagesTeaching Tactics and Teaching Strategy: Arthur W. Foshay'Ahmed DaibecheNo ratings yet

- General Pathology Lecture Group 1 HandoutDocument6 pagesGeneral Pathology Lecture Group 1 HandoutCecille AnnNo ratings yet

- Nuclear Fusion EnergyDocument3 pagesNuclear Fusion EnergyAner Labaka UgarteNo ratings yet

- CSIE Fisa Disciplina - Baze de DateDocument4 pagesCSIE Fisa Disciplina - Baze de DateCostin CheluNo ratings yet

- Experiment No. 2 Rockwell Hardness Test IntroductionDocument3 pagesExperiment No. 2 Rockwell Hardness Test IntroductionAhmad Abd100% (1)

- Varargout Tugas - GUI (Varargin) : FunctionDocument7 pagesVarargout Tugas - GUI (Varargin) : FunctionDwi Lestari dwi375ft.2019No ratings yet

- PRD Doc Pro 3201-00001 Sen Ain V31Document10 pagesPRD Doc Pro 3201-00001 Sen Ain V31rudybestyjNo ratings yet

- Q2. Give An Example of Each A. Stochastic Model B. Continuous Model C. Discrete Model D. Static Model E. Dynamic ModelDocument2 pagesQ2. Give An Example of Each A. Stochastic Model B. Continuous Model C. Discrete Model D. Static Model E. Dynamic Modelsheena RomNo ratings yet

- TOEC8431120DDocument522 pagesTOEC8431120Dvuitinhnhd9817No ratings yet

- CHM170L Exp3 Surface TensionDocument5 pagesCHM170L Exp3 Surface TensionKaiser SaltoNo ratings yet

- PHYSICSDocument24 pagesPHYSICS21SO204 AnvithaNo ratings yet

- Orthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Document30 pagesOrthographic Views in Multiview Drawings: Autocad 2015 Tutorial: 2D Fundamentals 5-1Uma MageshwariNo ratings yet

- M. Fatur - H1C018040 - PETROLOGIDocument15 pagesM. Fatur - H1C018040 - PETROLOGIFaturrachmanNo ratings yet

- New Features in IbaPDA v7.1.0Document39 pagesNew Features in IbaPDA v7.1.0Miguel Ángel Álvarez VázquezNo ratings yet

- Fiber SyllabusDocument1 pageFiber SyllabusPaurav NayakNo ratings yet

- Solved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Document4 pagesSolved - Which $1,000 Bond Has The Higher Yield To Maturity, A T...Sanjna ChimnaniNo ratings yet