EEM 3 Troubleshooting

Uploaded by

Alejandro MayrEEM 3 Troubleshooting

Uploaded by

Alejandro Mayr- Introduction: Introduces the EEM3 troubleshooting information, covering the document's purpose, scope, and the definitions of key terms.

- EEM3 General Instructions: Outlines general safety and operational guidelines for handling EEM3 systems safely.

- Initial System Check: Provides step-by-step instructions for conducting an initial check on the EEM3 system, ensuring all parts are functioning correctly.

- Engine Monitoring: Covers procedures and reactions concerning engine monitoring, emphasizing fault codes and interpretation for diagnostics.

- Engine Sensor Diagnostics: Describes various engine sensor diagnostic procedures focusing on temperature and pressure sensor functionalities.

- Fuel Injection System Monitoring: Details the monitoring procedures for the fuel injection system, including common issues and diagnostic techniques.

- ECU Diagnostics: Explores various diagnostic procedures for the ECU, handling voltage outputs and configurations for system monitoring.

- ID-Module Diagnostics: Provides a rundown on diagnosing ID-module issues, covering specification mismatches and memory errors.

- ECU Replacement Procedure: Lists the essential steps for safely replacing the ECU, ensuring no electrical damage during the process.

- IDM Bypass Activation Procedure: Describes procedures for IDM bypass activation, useful for maintaining operations during system faults or updates.

- Component Descriptions: Gives detailed descriptions of EEM3 components, including diagrams and connector details for understanding system layouts.

- ECU Terminal Diagrams: Includes diagrams of ECU terminals to assist in troubleshooting and connection identification for repair work.

EEM3 Troubleshoot information 1

Research & Development 838014000.C2

838014000.C2

EEM3 TROUBLESHOOT INFORMATION

(SW V1.2.0.0)

8.3.2006

EEM3 Troubleshoot information

EEM3 Troubleshoot information 2

Research & Development 838014000.C2

Copyright 2010 Sisu Diesel Inc.. All rights are reserved.

This document and its contents are the property of Sisu Diesel Inc. and may not be

reproduced or redistributed any way without their written consent.

This document is subject to change without notice. Information contained in these

materials are confidential trade secrets of Sisu Diesel Inc., and may not be used or

disclosed to any person without the express written consent of Sisu Diesel Inc..

EEM3 Troubleshoot information

EEM3 Troubleshoot information 3

Research & Development 838014000.C2

CHANGE HISTORY

Version Change Note Date

.C2 Updated 4 cyl. Engine solenoid valve information 8.3.2006

.C1 Update for sw v1.2.0.0 3.3.2006

.B2 Updated missing information on various faults 29.1.2006

.B1 Initial draft for sw v1.1.0.0 8.12.2005

EEM3 Troubleshoot information

EEM3 Troubleshoot information 4

Research & Development 838014000.C2

1 INTRODUCTION ....................................................................................................................................... 9

1.1 Purpose............................................................................................................................................. 9

1.2 Scope ................................................................................................................................................ 9

1.3 Definitions, Terms, Acronyms and Abbreviations ....................................................................... 9

1.4 References ....................................................................................................................................... 9

2 EEM3 GENERAL INSTRUCTIONS ........................................................................................................ 10

3 INITIAL SYSTEM CHECK....................................................................................................................... 11

4 ENGINE MONITORING........................................................................................................................... 12

4.1 98, SPN 100, FMI 18, Oil pressure LOW, warning....................................................................... 12

4.2 99, SPN 100, FMI 1, Oil pressure LOW, alarm ............................................................................. 13

4.3 102, SPN 102, FMI 18, Boost pressure LOW ............................................................................... 14

4.4 103, SPN 102, FMI 16, Boost pressure ABOVE NORMAL.......................................................... 14

4.5 112, SPN 110, FMI 16, Coolant temperature HIGH, warning...................................................... 15

4.6 113, SPN 110, FMI 0, Coolant temperature HIGH, alarm ........................................................... 16

4.7 116, SPN 105, FMI 16, Intake manifold temperature ABOVE NORMAL.................................... 17

4.8 94, SPN 190, FMI 16, Engine Overspeed (over 3000 rpm) ........................................................ 18

4.9 92, SPN 100, FMI 16, Oil pressure ABOVE NORMAL (9,5bar/30°C) .......................................... 18

4.10 276, SPN 102, FMI 31, Intake manifold pressure drop too HIGH at cranking .......................... 19

5 ENGINE SENSOR DIAGNOSTICS......................................................................................................... 20

5.1 COOLANT TEMPERATURE SENSOR .......................................................................................... 20

5.1.1 110, SPN 110, FMI 4, Coolant temperature sensor defect LOW ............................................ 20

5.1.2 111, SPN 110, FMI 3, Coolant temperature sensor defect HIGH ........................................... 20

5.2 FUEL TEMPERATURE SENSOR................................................................................................... 21

5.2.1 251, SPN 174, FMI 4, Fuel temperature sensor defect LOW.................................................. 21

5.2.2 252, SPN 174, FMI 3, Fuel temperature sensor defect HIGH................................................. 22

5.3 INTAKE AIR TEMPERATURE SENSOR ....................................................................................... 22

5.3.1 114, SPN 105, FMI 4, intake manifold temperature sensor defect LOW ................................ 22

5.3.2 115, SPN 105, FMI 3, intake manifold temperature sensor defect HIGH ............................... 23

5.4 OIL PRESSURE SENSOR.............................................................................................................. 23

5.4.1 96, SPN 100, FMI 4, Oil pressure sensor defect LOW............................................................ 23

5.4.2 97, SPN 100, FMI 3, Oil pressure sensor defect HIGH........................................................... 24

5.4.3 95, SPN 100, FMI 31, Oil pressure sensor defect ................................................................... 25

5.5 BOOST PRESSURE SENSOR ....................................................................................................... 26

5.5.1 100, SPN 102, FMI 4, Boost pressure sensor defect LOW..................................................... 26

5.5.2 101, SPN 102, FMI 3, Boost pressure sensor defect HIGH .................................................... 26

EEM3 Troubleshoot information

EEM3 Troubleshoot information 5

Research & Development 838014000.C2

5.6 RAIL PRESSURE SENSOR ........................................................................................................... 27

5.6.1 263, SPN 157, FMI 4, Rail pressure sensor defect LOW........................................................ 27

5.6.2 264, SPN 157, FMI 3, Rail pressure sensor defect HIGH ....................................................... 28

5.7 FUEL FILTER PRESSURE SENSOR............................................................................................. 29

5.7.1 291, SPN 94, FMI 4, Fuel filter pressure sensor defect LOW ................................................. 29

5.7.2 292, SPN 94, FMI 3, Fuel filter pressure sensor defect HIGH ................................................ 29

5.7.3 442, SPN 9153, FMI 31, Fuel Filter pressure sensor, loose of contact................................... 30

5.8 ENGINE SPEED SENSORS, GENERAL MONITORING............................................................... 31

5.8.1 269, SPN 9090, FMI 31, Engine speed signal, evaluation error ............................................. 31

5.9 CRANK SPEED SENSOR .............................................................................................................. 32

5.9.1 271, SPN 9070, FMI 31, Crank speed signal TPU .................................................................. 32

5.9.2 272, SPN 9071, FMI 31, Crank speed signal, too much noise pulses .................................... 33

5.9.3 273, SPN 9072, FMI 31, Crank speed sensor, reverse connected ......................................... 34

5.10 CAM SPEED SENSOR ................................................................................................................... 35

5.10.1 281, SPN 9080, FMI 31, Cam speed signal APS .................................................................... 35

5.10.2 282, SPN 9081, FMI 31, Cam speed signal TPS .................................................................... 36

5.10.3 283, SPN 9082, FMI 31, Cam speed sensor, reverse connected ........................................... 37

5.10.4 284, SPN 9083, FMI 31, No cam speed signal found ............................................................. 38

5.11 AUXILIARY SENSOR DIAGNOSTICS ........................................................................................... 39

5.11.1 80, SPN 91, FMI 4, Throttle 1 sensor defect LOW .................................................................. 39

5.11.2 81, SPN 91, FMI 3, Throttle 1 sensor defect HIGH ................................................................. 40

5.11.3 82, SPN 9140, FMI 4, Throttle 2 sensor defect LOW.............................................................. 40

5.11.4 83, SPN 9140, FMI 3, Throttle 2 sensor defect HIGH ............................................................. 41

5.11.5 84, SPN 9141, FMI 4, Throttle 3 sensor defect LOW.............................................................. 42

5.11.6 85, SPN 9141, FMI 3, Throttle 3 sensor defect HIGH ............................................................. 43

6 FUEL INJECTION SYSTEM MONITORING........................................................................................... 45

6.1 Fuel supply..................................................................................................................................... 45

6.1.1 441, SPN 9152, FMI 31, Fuel Filter pressure, fluctuating ....................................................... 45

6.1.2 445, SPN 94, FMI 16, Fuel Filter pressure ABOVE NORMAL ................................................ 46

6.1.3 446, SPN 94, FMI 18, Fuel Filter pressure BELOW NORMAL ............................................... 46

6.1.4 253, SPN 174, FMI 16, Fuel temperature ABOVE NORMAL (> + 90 °C)............................... 47

6.1.5 121, SPN 97, FMI 31, Water in fuel (optional sensor)............................................................. 48

6.2 RAIL PRESSURE MONITORING ................................................................................................... 49

6.2.1 265, SPN 157, FMI 16, Rail pressure ABOVE NORMAL........................................................ 49

6.2.2 381, SPN 157, FMI 1, Rail pressure LOW............................................................................... 50

6.2.3 382, SPN 157, FMI 0, Rail pressure HIGH.............................................................................. 51

6.2.4 383, SPN 9150, FMI 16, Rail pressure, Negative deviation .................................................... 52

6.2.5 384, SPN 9150, FMI 18, Rail pressure, Positive deviation...................................................... 53

6.2.6 385, SPN 9150, FMI 5, Rail pressure, Leakage detected during low idle............................... 54

6.2.7 386, SPN 9150, FMI 8, Rail pressure, Leakage detected by quantity balance....................... 55

6.2.8 387, SPN 9150, FMI 31, Rail pressure, Leakage detected during overrun............................. 56

6.2.9 391, SPN 9151, FMI 31, PRV recognised as open ................................................................. 56

6.2.10 392, SPN 9151, FMI 7, PRV is sticking ................................................................................... 58

6.3 INJECTOR DIAGNOSTICS............................................................................................................. 58

6.3.1 311, SPN 9131, FMI 6, Solenoid valve 1, Short circuit to GROUND (Bank off)...................... 58

6.3.2 312 SPN 9131, FMI 3, Solenoid valve 1, Short circuit between cables (Bank off).................. 60

6.3.3 313 SPN 9131, FMI 5, Solenoid valve 1, OPEN CIRCUIT...................................................... 61

6.3.4 314 SPN 9131, FMI 31, Solenoid valve 1, Fast decay error (Bank off)................................... 62

6.3.5 315 SPN 9131, FMI 12, Solenoid valve 1, Current level error (Bank off)................................ 62

EEM3 Troubleshoot information

EEM3 Troubleshoot information 6

Research & Development 838014000.C2

6.3.6 321, SPN 9132, FMI 6, Solenoid valve 2, Short circuit to GROUND (Bank off)...................... 63

6.3.7 322 SPN 9132, FMI 3, Solenoid valve 2, Short circuit between cables (Bank off).................. 65

6.3.8 323 SPN 9132, FMI 5, Solenoid valve 2, OPEN CIRCUIT...................................................... 65

6.3.9 324 SPN 9132, FMI 31, Solenoid valve 2, Fast decay error (Bank off)................................... 66

6.3.10 325 SPN 9132, FMI 12, Solenoid valve 2, Current level error (Bank off)................................ 67

6.3.11 331, SPN 9133, FMI 6, Solenoid valve 3, Short circuit to GROUND (Bank off)...................... 67

6.3.12 332 SPN 9133, FMI 3, Solenoid valve 3, Short circuit between cables (Bank off).................. 69

6.3.13 333 SPN 9133, FMI 5, Solenoid valve 3, OPEN CIRCUIT...................................................... 70

6.3.14 334 SPN 9133, FMI 31, Solenoid valve 3, Fast decay error (Bank off)................................... 71

6.3.15 335 SPN 9133, FMI 12, Solenoid valve 3, Current level error (Bank off)................................ 71

6.3.16 341, SPN 9134, FMI 6, Solenoid valve 4, Short circuit to GROUND (Bank off)...................... 72

6.3.17 342 SPN 9134, FMI 3, Solenoid valve 4, Short circuit between cables (Bank off).................. 74

6.3.18 343 SPN 9134, FMI 5, Solenoid valve 4, OPEN CIRCUIT...................................................... 74

6.3.19 344 SPN 9134, FMI 31, Solenoid valve 4, Fast decay error (Bank off)................................... 75

6.3.20 345 SPN 9134, FMI 12, Solenoid valve 4, Current level error (Bank off)................................ 76

6.3.21 351, SPN 9135, FMI 6, Solenoid valve 5, Short circuit to GROUND (Bank off)...................... 76

6.3.22 352 SPN 9135, FMI 3, Solenoid valve 5, Short circuit between cables (Bank off).................. 78

6.3.23 353 SPN 9135, FMI 5, Solenoid valve 5, OPEN CIRCUIT...................................................... 79

6.3.24 354 SPN 9135, FMI 31, Solenoid valve 5, Fast decay error (Bank off)................................... 79

6.3.25 355 SPN 9135, FMI 12, Solenoid valve 5, Current level error (Bank off)................................ 80

6.3.26 361, SPN 9136, FMI 6, Solenoid valve 6, Short circuit to GROUND (Bank off)...................... 80

6.3.27 362 SPN 9136, FMI 3, Solenoid valve 6, Short circuit between cables (Bank off).................. 82

6.3.28 363 SPN 9136, FMI 5, Solenoid valve6, OPEN CIRCUIT....................................................... 83

6.3.29 364 SPN 9136, FMI 31, Solenoid valve 6, Fast decay error (Bank off)................................... 83

6.3.30 365 SPN 9136, FMI 12, Solenoid valve 6, Current level error (Bank off)................................ 84

6.4 HIGH PRESSURE PUMP CONTROL (MPRPOP control) ............................................................ 85

6.4.1 421, SPN 9174, FMI 6, MPROP control, Short circuit to ground............................................. 85

6.4.2 422, SPN 9174, FMI 3, MPROP control, Short circuit to BAT+............................................... 85

6.4.3 423, SPN 9174, FMI 5, MPROP control, Open circuit............................................................. 86

6.4.4 424, SPN 9174, FMI 31, MPROP control, Excess temperature.............................................. 86

7 ECU DIAGNOSTICS ............................................................................................................................... 88

7.1 ECU supply voltage ....................................................................................................................... 88

7.1.1 18, SPN 168, FMI 0, Battery voltage VERY HIGH (> 36 V) .................................................... 88

7.1.2 17, SPN 168, FMI 1, Battery voltage VERY LOW (< 6,5 V) .................................................... 88

7.1.3 371, SPN 168, FMI 18, Battery voltage BELOW NORMAL (< 7,8 V) ..................................... 88

7.1.4 372, SPN 168, FMI 16, Battery voltage ABOVE NORMAL ..................................................... 89

7.2 Power management....................................................................................................................... 89

7.2.1 221, SPN 9025, FMI 31, Self test shutoff paths, watchdog..................................................... 89

7.2.2 222, SPN 9026, FMI 3, Self test shutoff paths, processor voltage check HIGH ..................... 90

7.2.3 223, SPN 9027, FMI 4, Self test shutoff paths, processor voltage check LOW ...................... 90

7.2.4 231, SPN 9033, FMI 31, ECU Shut-off does not work ............................................................ 91

7.2.5 233, SPN 9034, FMI 31, ECU Shut-off did not work at last time............................................. 92

7.2.6 235, SPN 9030, FMI 6, Short circuit to ground, ECU main relay 1 ......................................... 92

7.2.7 236, SPN 9031, FMI 6, Short circuit to ground, ECU main relay 2 ......................................... 93

7.2.8 237, SPN 9032, FMI 6, Short circuit to ground, ECU main relay 3 ......................................... 94

7.2.9 241, SPN 9030, FMI 3, Short circuit to BAT+, ECU main relay 1 ........................................... 94

7.2.10 242, SPN 9031, FMI 3, Short circuit to BAT+, ECU main relay 2 ........................................... 95

7.2.11 243, SPN 9031, FMI 3, Short circuit to BAT+, ECU main relay 3 ........................................... 96

7.3 Voltage output................................................................................................................................ 97

7.3.1 211, SPN 9021, FMI 4, 5 Vdc supply 1 defect LOW ( <4.6V) ................................................. 97

7.3.2 212, SPN 9021, FMI 3, 5 Vdc Supply 1 defect HIGH (>5.2V)................................................. 97

7.3.3 213, SPN 9022, FMI 4, 5 Vdc supply 2 defect LOW ( <4.6V) ................................................. 98

7.3.4 214, SPN 9022, FMI 3, 5 Vdc Supply 2 defect HIGH (>5.2V)................................................. 98

EEM3 Troubleshoot information

EEM3 Troubleshoot information 7

Research & Development 838014000.C2

7.3.5 214, SPN 9023, FMI 4, 5 Vdc supply 3 defect LOW ( <4.6V) ................................................. 99

7.3.6 214, SPN 9023, FMI 3, 5 Vdc Supply 3 defect HIGH (>5.2V)................................................. 99

7.3.7 248, SPN 9024, FMI 18, Water in fuel sensor supply voltage BELOW NORMAL ................ 100

7.3.8 249, SPN 9024, FMI 16, Water in fuel sensor supply voltage ABOVE NORMAL................. 101

7.4 ECU internal sensor diagnostics ............................................................................................... 101

7.4.1 22, SPN 1136, FMI 3, ECU temperature sensor defect HIGH .............................................. 101

7.4.2 21, SPN 1136, FMI 4, ECU temperature sensor defect LOW ............................................... 101

7.4.3 20, SPN 1136, FMI 16, ECU temperature ABOVE NORMAL (> 115 °C) ............................. 102

7.4.4 471, SPN 9010, FMI 4, Ambient pressure sensor defect LOW............................................. 102

7.4.5 472, SPN 9010, FMI 3, Ambient pressure sensor defect HIGH ............................................ 103

7.4.6 473, SPN 9010, FMI 16, Ambient pressure ABOVE NORMAL............................................. 103

7.5 Measurement system .................................................................................................................. 104

7.5.1 109, SPN 110, FMI 2, Coolant temperature NO SIGNAL ..................................................... 104

7.5.2 261, SPN 174, FMI 2, Fuel temperature NO SIGNAL........................................................... 104

7.5.3 117, SPN 105, FMI 2, Intake manifold temperature sensor NO SIGNAL ............................. 104

7.5.4 93, SPN 100, FMI 2, Oil pressure NO SIGNAL ..................................................................... 105

7.5.5 104, SPN 102, FMI 2, Boost pressure NO SIGNAL .............................................................. 105

7.5.6 266, SPN 157, FMI 2, Rail pressure NO SIGNAL ................................................................. 106

7.5.7 293, SPN 94, FMI 2, Fuel filter pressure NO SIGNAL .......................................................... 106

7.5.8 19, SPN 168, FMI 2, Battery voltage NO SIGNAL ................................................................ 106

7.5.9 23, SPN 1136, FMI 2, ECU temperature NO SIGNAL .......................................................... 107

7.5.10 474, SPN 9010, FMI 2, Ambient pressure NO SIGNAL ........................................................ 107

7.6 CAN bus monitoring.................................................................................................................... 108

7.6.1 141, SPN 9006, FMI 31, Vehicle CAN off.............................................................................. 108

7.6.2 143, SPN 9008, FMI 31, ID module CAN off(ECU to IDM) ................................................... 108

7.6.3 146, SPN 898, FMI 4, Requested speed by the CAN out of range, LOW (<500rpm).......... 109

7.6.4 147, SPN 898, FMI 3, Requested speed by the CAN out of range, HIGH (>3000 rpm) ...... 109

7.7 System monitoring ...................................................................................................................... 110

7.7.1 10, SPN 629, FMI 10, Power On self test.............................................................................. 110

7.7.2 245, SPN 9035, FMI 31, Normal recovery............................................................................. 110

7.7.3 246, SPN 9036, FMI 31, Full restart after three recoveries within 2 seconds ....................... 111

7.8 Special functions ......................................................................................................................... 111

7.8.1 185, SPN 9305, FMI 31. Bad digital input configuration....................................................... 111

7.8.2 186, SPN 9306, FMI 31. PTO input error ............................................................................. 112

8 ID-MODULE DIAGNOSTICS ................................................................................................................ 113

8.1.1 451, SPN 9230, FMI 31 Engine specification mismatch ....................................................... 113

8.1.2 452, SPN 9231, FMI 31 Engine serial number mismatch ..................................................... 113

8.1.3 453, SPN 9233, FMI 31 ID module not present..................................................................... 113

8.1.4 454, SPN 9234, FMI 31 ID module not compatible with current ECU................................... 115

8.1.5 455, SPN 9235, FMI 31 ID module memory defect............................................................... 115

8.1.6 456, SPN 9235, FMI 3. ID module, Supply voltage HIGH.................................................... 115

8.1.7 457, SPN 9235, FMI 4. ID module, Supply voltage LOW..................................................... 116

8.1.8 458, SPN 9235, FMI 16. ID module, temperature HIGH ...................................................... 116

8.1.9 459, SPN 9236, FMI 31. ID module additional memory defect ............................................ 117

8.1.10 461, SPN 9237, FMI 31. ID module watchdog reset ............................................................ 117

8.1.11 462, SPN 9238, FMI 31. ID module, brownout reset............................................................ 117

8.1.12 463, SPN 9239, FMI 31. Engine specification missing......................................................... 118

8.1.13 464, SPN 9240, FMI 31. Engine serial number missing....................................................... 118

8.1.14 465, SPN 9241, FMI 31. ID module not present, BY PASS ACTIVE ................................... 119

8.1.15 466, SPN 9242, FMI 31. Generated by pass time expired................................................... 119

8.1.16 467, SPN 9243, FMI 31. Maximum ECU by pass time expired............................................ 119

EEM3 Troubleshoot information

EEM3 Troubleshoot information 8

Research & Development 838014000.C2

9 ECU REPLACEMENT PROCEDURE................................................................................................... 120

10 IDM BYPASS ACTIVATION PROCEDURE ..................................................................................... 121

10.1 IDM bypass ................................................................................................................................... 121

10.2 Bypass operation......................................................................................................................... 121

10.3 Bypass time activation................................................................................................................ 121

11 COMPONENT DESCRIPTIONS ....................................................................................................... 123

11.1 EEM3 ECU..................................................................................................................................... 123

11.1.1 ECU and connectors.............................................................................................................. 123

11.1.2 ECU power supply connection............................................................................................... 125

11.2 High pressure pump and MPROP valve .................................................................................... 125

11.3 Rail, rail pressure sensor and PRV............................................................................................ 126

11.4 Injector and MPROP wiring......................................................................................................... 127

11.4.1 6-cyl. 2-valve engine.............................................................................................................. 127

11.4.2 6-cyl. 4-valve engine.............................................................................................................. 128

11.4.3 4-cyl. 2-valve engine.............................................................................................................. 129

11.4.4 4-cyl. 4-valve engine.............................................................................................................. 130

11.5 Sensor details .............................................................................................................................. 131

11.5.1 Coolant temperature sensor .................................................................................................. 131

11.5.2 Fuel temperature sensor........................................................................................................ 132

11.5.3 Boost pressure and intake manifold temperature sensor...................................................... 133

11.5.4 Oil pressure sensor................................................................................................................ 135

11.5.5 Fuel pressure sensor ............................................................................................................. 136

11.5.6 Rail pressure sensor.............................................................................................................. 137

11.5.7 Crankshaft speed sensor....................................................................................................... 138

11.5.8 Camshaft speed sensor......................................................................................................... 139

11.5.9 Water-in-fuel sensor .............................................................................................................. 140

11.6 ID-module ..................................................................................................................................... 141

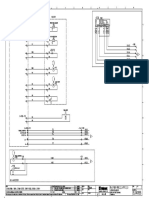

12 EM3 ECU TERMINAL DIAGRAM PART1/2 ..................................................................................... 142

13 EEM3 ECU TERMINAL DIAGRAM PART 2/2.................................................................................. 143

EEM3 Troubleshoot information

EEM3 Troubleshoot information 9

Research & Development 838014000.C2

1 INTRODUCTION

1.1 Purpose

This document is the troubleshoot information for Sisu Diesel EEM3 Electronic Engine

Management system. The provided fault descriptions include information on the possible causes

for the fault, influence on the engine operation and instructions to resolve the problem.

1.2 Scope

The system reports detected faults by fault codes. These fault codes can be read over CAN bus

from the EEM3 controller using a Service Tool. The fault codes may also be transmitted over CAN

bus to a vehicle instrument for display. Alternatively, the fault codes can be shown using blink

codes on a diagnostic lamp.

When a fault code is known, the enclosed documentation can be used to analyse the reason to the

fault and to find a solution for the problem. Additional equipment may be needed to inspect the

system components and their operation (e.g. voltmeter, resistance meter).

1.3 Definitions, Terms, Acronyms and Abbreviations

CAN Controller Area Network

ECU Electronic Control Unit

EEM3 Sisu Diesel Stage 3 Electronic Engine Management

IDM Engine Identification module (ID-module)

FC Fault Code

Service Tool Special software for system diagnostics running in personal

computer

FLn Fuel limitation level n (power limitation)

SLn Speed limitation level n

MPROP Magnetic Proportional valve, the control valve of the high

pressure pump

PRV Pressure relief valve, the mechanical safety valve on the

common rail unit

System Reset Turn ignition off for 3 seconds (minimum), then back on

1.4 References

[1] Engine operating manual

[2] Engine workshop manual

EEM3 Troubleshoot information

EEM3 Troubleshoot information 10

Research & Development 838014000.C2

2 EEM3 GENERAL INSTRUCTIONS

WARNING The fuel pressure in the EEM3 system is continuously at hazardous level during

operation.

This applies to the high pressure pump, the fuel line from the high pressure pump to

the common rail, the rail itself, the fuel lines from the rail to the injectors, the injectors

and all components attached to any of the above mentioned parts, including sensors,

valves, etc.

DO NOT TRY TO OPEN OR REMOVE ANY OF THE FUEL SYSTEM

COMPONENTS DURING CRANKING OR ENGINE RUNNING.

DO NOT TRY TO START THE ENGINE WITH ANY OF THE FUEL SYSTEM

COMPONENTS REMOVED.

During vehicle or engine service and repair, please observe the following recommendations:

• Electric welding (or other operation using high electrical current):

• Disconnect the EEM3 controller main connectors before working

• High pressure wash or application of strong cleaning solvent:

• Cover the EEM3 controller, sensors and connectors

• Avoid heavy wash and high pressure spray directly on the electrical components

The EEM3 system consists of several different types of components. For faultless system

operation all these components must be 100% functional. All EEM3 components are well

protected, but to avoid even the smallest risk to these components, it is recommend to follow the

instructions above.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 11

Research & Development 838014000.C2

3 INITIAL SYSTEM CHECK

When power is switched on, observe the correct operation of the engine oil pressure warning light

on the instrument panel. Engine oil pressure warning light should be on when engine is not

running. If the oil pressure warning light doesn’t go on, then the oil pressure sensor, the indicator

light, the vehicle CAN bus or the EEM3 controller may be defective.

If the light does not turn on within 4 seconds after switching the ignition on or the light is dim, then

first try to start the engine normally. If the engine starts normally, then:

• Check the wiring and operation of the oil pressure indicator light according to the

vehicle manufacturers instructions.

• When applicable, check the CAN bus wiring between the EEM3 controller and the

instrument panel

• Check the wiring and operation of the oil pressure sensor (see 11.5.4). If there is

problem with the sensor or the sensor wiring, there should also be a fault active in the

EEM3 ECU.

If the engine does not crank or cranks but fails to start, then check the following items:

• Check the battery voltage. If the battery voltage is below 11.5V, the battery and the

generator have to be inspected and replaced as necessary.

• Check the fuses for the EEM3 controller. If the fuse or fuses are blown, replace them

with new fuses and switch the power on. If fuse or fuses blow again, check the wiring

from the fuses to the EEM3 for short circuit to tractor ground. If no short circuit is found

and voltages are correct, the controller is defective.

• Check the +12V or +24V continuous power supply and ground paths to the EEM3

controller (see 11.1.2).

• Check the +12V or +24V ignition key operation and path (fuse 5A) to the EEM3

controller (see 11.1.2).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional with the replacement

ECU, then the original ECU is defective.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 12

Research & Development 838014000.C2

4 ENGINE MONITORING

4.1 98, SPN 100, FMI 18, Oil pressure LOW, warning

Description:

The measured oil pressure is below the warning limit. The low oil pressure signal may be caused

by the following reasons:

• The engine oil level is too low

• The oil quality is poor

• The oil filter is clogged

• The oil grade is not correct

• The oil is too hot

• The oil is diluted by fuel

• The bearings have excessive clearance

• The oil pressure control valve is not operating correctly

• The oil pump has excessive wearing

• The idling speed is too low

• The oil pressure sensor wiring is defective

• The oil pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and oil pressure warning lamp is activated. CAN message indicates active fault.

Solution:

Find the cause for the low oil pressure indication. Check and repair the possible mechanical

problems according to the service instructions:

• Check the oil level and condition of oil

• Check the oil filter

• Check mechanical condition of the engine

• Check the idling speed

To check the electrical defects, check the oil pressure sensor, the sensor wiring and the controller

input:

• Check the oil pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.4).

• Check the oil pressure sensor operation (see 11.5.4).

EEM3 Troubleshoot information

EEM3 Troubleshoot information 13

Research & Development 838014000.C2

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.2 99, SPN 100, FMI 1, Oil pressure LOW, alarm

Description:

The measured oil pressure is below the alarm limit. The low oil pressure signal may be caused by

the following reasons:

• The engine oil level is too low

• The oil quality is poor

• The oil filter is clogged

• The oil grade is not correct

• The oil is too hot

• The oil is diluted by fuel

• The bearings have excessive clearance

• The oil pressure control valve is not operating correctly

• The oil pump has excessive wearing

• The idling speed is too low

• The oil pressure sensor wiring is defective

• The oil pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and oil pressure warning lamp is activated. The engine will stop after 30 seconds.

CAN message indicates, that shutdown is pending.

Solution:

Find the cause for the low oil pressure indication. Check and repair the possible mechanical

problems according to the service instructions:

• Check the oil level and condition of oil

• Check the oil filter

• Check mechanical condition of the engine

• Check the idling speed

To check the electrical defects, check the oil pressure sensor, the sensor wiring and the controller

input:

• Check the oil pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.4).

EEM3 Troubleshoot information

EEM3 Troubleshoot information 14

Research & Development 838014000.C2

• Check the oil pressure sensor operation (see 11.5.4).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.3 102, SPN 102, FMI 18, Boost pressure LOW

Description:

The measured boost pressure drops below the alarm level during operation. Possible causes are:

• The boost air piping is leaking.

• The turbocharger is defective

• The engine is mechanically defective

• The boost pressure sensor wiring is defective

• The boost pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault.

Solution:

Find the cause for the low boost pressure indication:

• Check the boost air system tightness (piping, intercooler)

• Check the turbo charger condition

• Check the mechanical condition of the engine

• Check the boost pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.3).

• Check the boost pressure sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.4 103, SPN 102, FMI 16, Boost pressure ABOVE NORMAL

Description:

The measured boost pressure rises above the warning limit during operation. Possible causes are:

EEM3 Troubleshoot information

EEM3 Troubleshoot information 15

Research & Development 838014000.C2

• Too high fuel injection quantity (mg/str) for the engine type (tuning chip)

• Incorrect nozzles for the engine type

• Incorrect turbo charger for the engine type

• The boost pressure sensor wiring is defective

• The boost pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine speed is limited to 1500rpm(SL2) and engine

power will be reduced (FL1). CAN message indicates active fault. No recovery before system

reset.

Solution:

Find cause for the high boost pressure indication:

• Check, that the control system is configured according to the original specification and

no additional devices have been attached

• Check that the nozzles and the turbocharger meet the original specifications

• Check the boost pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.3).

• Check the boost pressure sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.5 112, SPN 110, FMI 16, Coolant temperature HIGH, warning

Description:

The measured coolant temperature exceeds the overheating warning limit. Possible causes are:

• The fan belt is slipping or the belt is broken

• Cooling system is not completely filled

• Water pump is defective

• Cooling system is clogged

• Thermostat is defective or removed (double acting thermostat)

• Thermostat is upside down

• The radiator filler cap is not pressure tight

• The engine is overloaded

• The coolant temperature sensor wiring is defective

• The coolant temperature sensor is defective

• The control unit is defective

EEM3 Troubleshoot information

EEM3 Troubleshoot information 16

Research & Development 838014000.C2

Reaction in EEM:

FC is stored and warning lamp is activated. The engine power will be reduced above the warning

limit to prevent overheating of the engine. CAN message indicates active fault.

Solution:

Find cause for the overheating indication:

• Check the fan belt and the belt tension

• Check the coolant level

• Check condition of the radiator

• Check the mechanical condition of the engine

• Check the coolant temperature sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.1).

• Check the coolant temperature sensor operation (see 11.5.1).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.6 113, SPN 110, FMI 0, Coolant temperature HIGH, alarm

Description:

The measured coolant temperature exceeds the overheating alarm limit. Possible causes are:

• The fan belt is slipping or the belt is broken

• Cooling system is not completely filled

• Water pump is defective

• Cooling system is clogged

• Thermostat is defective or removed (double acting thermostat)

• Thermostat is upside down

• The radiator filler cap is not pressure tight

• The engine is overloaded

• The coolant temperature sensor wiring is defective

• The coolant temperature sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. The engine will stop after 30 seconds. CAN message

indicates, that shutdown is pending.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 17

Research & Development 838014000.C2

Solution:

Find cause for the overheating indication:

• Check the fan belt and the belt tension

• Check the coolant level

• Check condition of the radiator

• Check the mechanical condition of the engine

• Check the coolant temperature sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.1).

• Check the coolant temperature sensor operation (see 11.5.1).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.7 116, SPN 105, FMI 16, Intake manifold temperature ABOVE NORMAL

Description:

The measured intake manifold temperature rises above the warning limit (+90 °C). The

temperature sensor is integrated to the boost pressure sensor. Possible causes for the high

temperature indication are:

• The charge air cooling system is not working properly

• The intake manifold temperature sensor wiring is defective

• The intake manifold temperature sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault.

Solution:

Find cause for the high intake manifold temperature indication:

• Check condition of the air-cooling system. (Cleanliness, pressure tightness, fan

operation, etc.)

• Check the intake manifold temperature sensor wiring, connectors and contact surfaces

of the connector pins (possible oxidation) (see 11.5.3).

EEM3 Troubleshoot information

EEM3 Troubleshoot information 18

Research & Development 838014000.C2

• Check the intake manifold temperature sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.8 94, SPN 190, FMI 16, Engine Overspeed (over 3000 rpm)

Description:

The fault is activated if the engine speed exceeds 3000 rpm during operation. Possible cause is

engine braking at downhill with too low gear ratio.

Reaction in EEM:

FC is stored and warning lamp is activated. No fuel injection. CAN message indicates active fault.

NOTE: Running the engine at excessive speed may damage the engine.

Solution:

Engine will recover to normal operation, whenever the engine speed is reduced below 3000 rpm

(use vehicle brakes, use exhaust brake, select proper gear)

4.9 92, SPN 100, FMI 16, Oil pressure ABOVE NORMAL (9,5bar/30°C)

Description:

The measured oil pressure is above the warning limit (9,5 bar). Possible causes are:

• The oil pressure control valve is not operating correctly

• The oil pressure sensor wiring is defective

• The oil pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and oil pressure warning lamp is activated. Engine power and speed will be reduced

(FL1 and SL1). CAN message indicates active fault.

NOTE: Monitoring is active only when the engine is running and the coolant temperature is > 30

°C.

Solution:

• Check the oil pressure control valve according to service instructions [1], [2]

EEM3 Troubleshoot information

EEM3 Troubleshoot information 19

Research & Development 838014000.C2

• Check the oil pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.4).

• Check the oil pressure sensor operation (see 11.5.4).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

4.10 276, SPN 102, FMI 31, Intake manifold pressure drop too HIGH at cranking

Description:

The measured intake manifold pressure (signal from boost pressure sensor) is below the warning

limit during engine cranking. Possible causes are:

• The engine air supply is clogged

• The boost pressure sensor wiring is defective

• The boost pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. CAN message indicates active fault.

NOTE: The engine may not start or starts slowly and runs badly.

Solution:

• Check the engine air supply system completely, refer to service instructions as

necessary (see [1], [2]):

• Air filter

• Piping from air filter to turbocharger (look for obstacles in joints, bends)

• Turbocharger

• Piping from turbocharger to charge air cooler (look for obstacles in joints, bends)

• Charge air cooler

• Piping from charge air cooler to inlet manifold (look for obstacles in joints, bends)

• Check the boost pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.3).

• Check the boost pressure sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 20

Research & Development 838014000.C2

5 ENGINE SENSOR DIAGNOSTICS

5.1 COOLANT TEMPERATURE SENSOR

5.1.1 110, SPN 110, FMI 4, Coolant temperature sensor defect LOW

Description:

The measured coolant temperature signal is below the normal operating range. Possible causes

are:

• The coolant temperature sensor wiring is defective

• The coolant temperature sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine protection and other functions dependent on the coolant temperature

are not active.

NOTE: Engine overheating protection is not active. The engine may damage, if overheating

happens.

Solution:

• Check the coolant temperature sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.1).

• Check the coolant temperature sensor operation (see 11.5.1).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.1.2 111, SPN 110, FMI 3, Coolant temperature sensor defect HIGH

Description:

The measured coolant temperature signal is above the normal operating range. Possible causes

are:

• The coolant temperature sensor wiring is defective

• The coolant temperature sensor is defective

• The control unit is defective

EEM3 Troubleshoot information

EEM3 Troubleshoot information 21

Research & Development 838014000.C2

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine protection and other functions dependent on the coolant temperature

are not active.

NOTE: Engine overheating protection is not active. The engine may damage, if overheating

happens.

Solution:

• Check the coolant temperature sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.1).

• Check the coolant temperature sensor operation (see 11.5.1).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.2 FUEL TEMPERATURE SENSOR

5.2.1 251, SPN 174, FMI 4, Fuel temperature sensor defect LOW

Description:

The measured fuel temperature signal is below the normal operating range. Possible causes are:

• The fuel temperature sensor wiring is defective

• The fuel temperature sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the fuel temperature are not active.

Solution:

• Check the fuel temperature sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.2).

• Check the fuel temperature sensor operation (see 11.5.2).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 22

Research & Development 838014000.C2

5.2.2 252, SPN 174, FMI 3, Fuel temperature sensor defect HIGH

Description:

The measured fuel temperature signal is above the normal operating range. Possible causes are:

• The fuel temperature sensor wiring is defective

• The fuel temperature sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the fuel temperature are not active.

Solution:

• Check the fuel temperature sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.2).

• Check the fuel temperature sensor operation (see 11.5.2).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.3 INTAKE AIR TEMPERATURE SENSOR

5.3.1 114, SPN 105, FMI 4, intake manifold temperature sensor defect LOW

Description:

The measured intake manifold air temperature signal is below the normal operating range (the

sensor is integrated to the boost pressure sensor). Possible causes are:

• The intake manifold temperature sensor wiring is defective

• The intake manifold temperature sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the intake manifold temperature are not

active.

Solution:

EEM3 Troubleshoot information

EEM3 Troubleshoot information 23

Research & Development 838014000.C2

• Check the intake manifold temperature sensor wiring, connectors and contact surfaces

of the connector pins (possible oxidation) (see 11.5.3).

• Check the intake manifold temperature sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.3.2 115, SPN 105, FMI 3, intake manifold temperature sensor defect HIGH

Description:

The measured intake manifold air temperature signal is above the normal operating range (the

sensor is integrated to the boost pressure sensor). Possible causes are:

• The intake manifold temperature sensor wiring is defective

• The intake manifold temperature sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the intake manifold temperature are not

active.

Solution:

• Check the intake manifold temperature sensor wiring, connectors and contact surfaces

of the connector pins (possible oxidation) (see 11.5.3).

• Check the intake manifold temperature sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.4 OIL PRESSURE SENSOR

5.4.1 96, SPN 100, FMI 4, Oil pressure sensor defect LOW

Description:

The measured oil pressure signal is below the normal operating range (< 0,2 V). Possible causes

are:

• The oil pressure sensor wiring is defective

EEM3 Troubleshoot information

EEM3 Troubleshoot information 24

Research & Development 838014000.C2

• Oil pressure sensor power supply is not correct

• The oil pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and oil pressure warning lamp is activated. Engine power will be reduced (FL1). CAN

message indicates active fault. Engine protection functions on oil pressure are not active.

NOTE: Engine oil pressure protection is not active. The engine may damage, if oil pressure is too

low.

Solution:

• Check the oil pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.4).

• Check the 5 V power supply to the sensor (see 11.5.4).

• Check the oil pressure sensor operation (see 11.5.4).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.4.2 97, SPN 100, FMI 3, Oil pressure sensor defect HIGH

Description:

The measured oil pressure signal is above the normal operating range (> 4,7 V). Possible causes

are:

• The oil pressure sensor wiring is defective

• Oil pressure sensor power supply is not correct

• The oil pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and oil pressure warning lamp is activated. Engine power will be reduced (FL1). CAN

message indicates active fault. Engine protection functions on oil pressure are not active.

NOTE: Engine oil pressure protection is not active. The engine may damage, if oil pressure is too

low.

Solution:

EEM3 Troubleshoot information

EEM3 Troubleshoot information 25

Research & Development 838014000.C2

• Check the oil pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.4).

• Check the 5 V power supply to the sensor (see 11.5.4).

• Check the oil pressure sensor operation (see 11.5.4).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.4.3 95, SPN 100, FMI 31, Oil pressure sensor defect

Description:

The measured oil pressure sensor signal is too high (> 1,3V or > 200 kPa), when engine is not

running. Possible causes are:

• The oil pressure sensor wiring is defective

• Oil pressure sensor power supply is not correct

• The oil pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and oil pressure warning lamp is activated. Engine power will be reduced (FL1). CAN

message indicates active fault. Engine protection functions on oil pressure are not active. No

recovery before system reset.

NOTE: Engine oil pressure protection is not active. The engine may damage, if oil pressure is too

low.

Solution:

• Check the oil pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.4).

• Check the 5 V power supply to the sensor (see 11.5.4).

• Check the oil pressure sensor operation (see 11.5.4).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 26

Research & Development 838014000.C2

5.5 BOOST PRESSURE SENSOR

5.5.1 100, SPN 102, FMI 4, Boost pressure sensor defect LOW

Description:

The measured boost pressure signal is below the normal operating range (< 0,2 V). Possible

causes are:

• The boost pressure sensor wiring is defective

• Boost pressure sensor power supply is not correct

• The boost pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the boost pressure are not active. No

recovery before system reset.

Solution:

• Check the boost pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.3).

• Check the 5 V power supply to the sensor (see 11.5.3).

• Check the boost pressure sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.5.2 101, SPN 102, FMI 3, Boost pressure sensor defect HIGH

Description:

The measured boost pressure signal is above the normal operating range (> 4,7 V). Possible

causes are:

• The boost pressure sensor wiring is defective

• Boost pressure sensor power supply is not correct

• The boost pressure sensor is defective

• The control unit is defective

Reaction in EEM:

EEM3 Troubleshoot information

EEM3 Troubleshoot information 27

Research & Development 838014000.C2

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the boost pressure are not active.

Solution:

• Check the boost pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.3).

• Check the 5 V power supply to the sensor (see 11.5.3).

• Check the boost pressure sensor operation (see 11.5.3).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.6 RAIL PRESSURE SENSOR

5.6.1 263, SPN 157, FMI 4, Rail pressure sensor defect LOW

Description:

The measured rail pressure signal is below the normal operating range (< 0,4 V). Possible causes

are:

• The rail pressure sensor wiring is defective

• Rail pressure sensor power supply is not correct

• The rail pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power is heavily reduced (FL2) and speed is

reduced to 1500 rpm (SL2). CAN message indicates active fault. Engine functions dependent on

rail pressure are not active.

Normally the fault code 391, SPN 9151, FMI 31, ‘PRV recognised as OPEN’ is related to the rail

pressure sensor fault. Due to the sensor fault, the closed loop rail pressure control is not possible

any more. Full fuel supply is demanded from the high-pressure pump and the high pressure will

force the PRV (Pressure Relief Valve) to open.

Solution:

• Check the rail pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.6).

• Check the 5 V power supply to the sensor (see 11.5.6).

EEM3 Troubleshoot information

EEM3 Troubleshoot information 28

Research & Development 838014000.C2

• Check the rail pressure sensor operation (see 11.5.6).

NOTE: Rail pressure sensor removal, inspection and replacement should be

performed only by qualified injection system service personnel. Special instructions

may apply.

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.6.2 264, SPN 157, FMI 3, Rail pressure sensor defect HIGH

Description:

The measured rail pressure signal is above the normal operating range (> 4,8 V). Possible causes

are:

• The rail pressure sensor wiring is defective

• Rail pressure sensor power supply is not correct

• The rail pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power is heavily reduced (FL2) and speed is

reduced to 1500 rpm (SL2). CAN message indicates active fault. Engine functions dependent on

rail pressure are not active.

Normally the fault code 391, SPN 9151, FMI 31, ‘PRV recognised as OPEN’ is related to the rail

pressure sensor fault. Due to the sensor fault, the closed loop rail pressure control is not possible

any more. Full fuel supply is demanded from the high-pressure pump and the high pressure will

force the PRV (Pressure Relief Valve) to open.

Solution:

• Check the rail pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.6).

• Check the 5 V power supply to the sensor (see 11.5.6).

• Check the rail pressure sensor operation (see 11.5.6).

NOTE: Rail pressure sensor removal, inspection and replacement should be

performed only by qualified injection system service personnel. Special instructions

may apply.

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 29

Research & Development 838014000.C2

5.7 FUEL FILTER PRESSURE SENSOR

5.7.1 291, SPN 94, FMI 4, Fuel filter pressure sensor defect LOW

Description:

The measured fuel filter pressure signal is below the normal operating range (< 0,2 V). Possible

causes are:

• The fuel filter pressure sensor wiring is defective

• Fuel filter pressure sensor power supply is not correct

• The fuel filter pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the fuel filter pressure are not active.

Solution:

• Check the fuel filter pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.5).

• Check the 5 V power supply to the sensor (see 11.5.5).

• Check the fuel filter pressure sensor operation (see 11.5.5).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.7.2 292, SPN 94, FMI 3, Fuel filter pressure sensor defect HIGH

Description:

The measured fuel filter pressure signal is above the normal operating range (> 4,7 V). Possible

causes are:

• The fuel filter pressure sensor wiring is defective

• Fuel filter pressure sensor power supply is not correct

• The fuel filter pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. Engine power will be reduced (FL1). CAN message

indicates active fault. Engine functions dependent on the fuel filter pressure are not active.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 30

Research & Development 838014000.C2

Solution:

• Check the fuel filter pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.5).

• Check the 5 V power supply to the sensor (see 11.5.5).

• Check the fuel filter pressure sensor operation (see 11.5.5).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.7.3 442, SPN 9153, FMI 31, Fuel Filter pressure sensor, loose of contact

Description:

The measured fuel filter pressure signal has large, quick and random variations indicating poor

contact between the sensor and the ECU. Possible causes are:

• The fuel filter pressure sensor wiring is defective

• Fuel filter pressure sensor power supply is not correct

• The fuel filter pressure sensor is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. CAN message indicates active fault. Engine functions

dependent on the fuel filter pressure are not active.

Solution:

• Check the fuel filter pressure sensor wiring, connectors and contact surfaces of the

connector pins (possible oxidation) (see 11.5.5).

• Check the 5 V power supply to the sensor (see 11.5.5).

• Check the fuel filter pressure sensor operation (see 11.5.5).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

EEM3 Troubleshoot information

EEM3 Troubleshoot information 31

Research & Development 838014000.C2

5.8 ENGINE SPEED SENSORS, GENERAL MONITORING

5.8.1 269, SPN 9090, FMI 31, Engine speed signal, evaluation error

Description:

Engine speed and angular position measurement is based on signals from crankshaft speed

sensor and camshaft speed sensor. The evaluation error is activated, if any of these two sensor

signals is found to be defective or if the signals are not in correct phase compared to each other.

One or more additional speed sensor faults may be active together with the evaluation error fault.

Possible causes are:

• Rapid engine speed changes due to rough engine running (problems with fuel

supply/quality, misfiring, mechanical defect), incorrect gear change, etc.

• No or invalid signal from crankshaft sensor. Possible causes:

- The sensor wiring is defective

- The sensor is defective

- Distance between the sensor and the trigger wheel is too high, possibly loose sensor

- The trigger wheel is defective

• No or invalid signal from camshaft sensor. Possible causes:

- The sensor wiring is defective

- The sensor is defective

- Distance between the sensor and the trigger wheel is too high, possibly loose sensor

- The trigger wheel is defective

• The measured signals from the crankshaft sensor and the camshaft sensor are not in

correct phase. Possible causes:

- Crankshaft or camshaft sensor wiring is defective, possibly reverse connection

- Camshaft trigger wheel is mounted wrong

- Crankshaft trigger wheel has drifted

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. CAN message indicates active fault. Engine power will

be reduced (FL1) and engine speed is limited to1800rpm (SL1). Engine starting may take longer

than normally and running may be bad due to missing/incorrect information for injection timing

control. The engine may be running with only one speed sensor signal.

Solution:

• If the engine is running roughly, check the condition of the fuel, the fuel system and

the mechanical condition of the engine according to the engine and vehicle service

manuals.

• If the fault is coming up only occasionally, check the possible conditions causing

abnormal engine speed changes, e.g. vehicle mishandling

• Check the crankshaft and camshaft sensor wiring, connectors and contact surfaces of

the connector pins (possible oxidation). Look also for possible reverse connection (see

EEM3 Troubleshoot information

EEM3 Troubleshoot information 32

Research & Development 838014000.C2

11.5.7 and 11.5.8).

• Check the coil resistance of the sensors (the engine must be stopped) (see 11.5.7 and

11.5.8). The normal resistance values at + 20 °C are:

- Crankshaft sensor coil: 1120 - 1530 Ohms

- Camshaft sensor coil: 774 - 946 Ohms

• Check the crankshaft and camshaft sensor mounting. The air gap between the sensor

tip and trigger wheel teeth should be 0,2 - 1,0 mm.

• Check the condition and mounting of the camshaft trigger wheel and the crankshaft

trigger wheel (damaged teeth, positioning of the trigger wheels) (see [2]).

• Check the ECU operation with another EEM3 controller (NOTE: See the instructions

for ECU replacement in section 9). If the system is functional and the fault is not active

with the replacement ECU, then the original ECU is defective.

5.9 CRANK SPEED SENSOR

5.9.1 271, SPN 9070, FMI 31, Crank speed signal TPU

Description:

The crankshaft speed and angular position evaluation module expects a defined sequence of

pulses from the crankshaft speed sensor (trigger wheel with 58 teeth and gap 2 teeth wide). If the

pulses are not received at correct time, the Time Processing Unit (TPU) reports a fault. Possible

causes are:

• Rapid engine speed changes due to rough engine running (problems with fuel

supply/quality, misfiring, mechanical defect), incorrect gear change, etc.

• Invalid signal from crankshaft sensor. Possible causes:

- The sensor wiring is defective

- The sensor is defective

- Distance between the sensor and the trigger wheel is too high, possibly loose sensor

- The trigger wheel is defective

• The control unit is defective

Reaction in EEM:

FC is stored and warning lamp is activated. CAN message indicates active fault. Engine power will

be reduced (FL1) and engine speed is limited to1800rpm (SL1). Engine starting may take longer

than normally and running may be bad due to missing/incorrect information for injection timing

control. The engine runs with camshaft speed sensor signal.

Solution:

EEM3 Troubleshoot information

EEM3 Troubleshoot information 33

Research & Development 838014000.C2

• If the engine is running roughly, check the condition of the fuel, the fuel system and

the mechanical condition of the engine according to the engine and vehicle service

manuals.

• If the fault is coming up only occasionally, check the possible conditions causing

abnormal engine speed changes, e.g. vehicle mishandling

• Check the crankshaft sensor wiring, connectors and contact surfaces of the connector

pins (possible oxidation). Look also for possible reverse connection (see 11.5.7).

• Check the coil resistance of the crankshaft sensor (the engine must be stopped) (see

11.5.7). The normal resistance values at + 20 °C is 1120 - 1530 Ohms.

• Check the crankshaft sensor mounting. The air gap between the sensor tip and trigger

wheel teeth should be 0,2 - 1,0 mm.