Professional Documents

Culture Documents

The Widest Range of Orbital Welding Equipment in The World

Uploaded by

Vladimir KarpovOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Widest Range of Orbital Welding Equipment in The World

Uploaded by

Vladimir KarpovCopyright:

Available Formats

The widest range of orbital welding equipment in the world

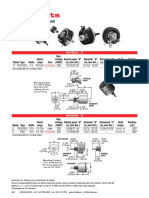

The Model 9 series of orbital weld heads are

designed for fusion (TIG) welding of tube,

pipe, fittings or other cylindrical components.

Available in eight sizes and three versions, they

accommodate diameters from 3/32” (2,3 mm) to

7.5” (190,5 mm) OD, and wall thicknesses from

0.01” (0,25 mm) to 0.16” (4 mm). Each weld head

fits a wide range of tube sizes via easily replaced,

size-specific clamps. These weld heads are

compatible with all AMI Power Supplies.

The standard Model 9 incorporates a two-sided

clamping mechanism to hold components being

welded in line and concentric - eliminating the

need for tack welding. Several of these heads

incorporate a flip-up viewing window, for easy

verification of fit-up. Most Model 9 weld heads

are plumbed for water cooling of both the cables

and internal weld head components - allowing

increased duty-cycles.

Conversion Kits

To enhance versatility, many Model 9 series weld heads may be converted to an alternate configuration by

installing a conversion kit. The conversion takes 5 to 10 minutes, using only a screwdriver and a hex wrench.

Model 9E Model 9CT

Model 9-500/C X

Model 9-750 X X

Model 9-1500 X X

Model 9-2500 X

Model 9-3500 X

Model 9-4500 X

Model 9-7500 X

MODEL 9-250, MINI WELD HEAD

The Model 9-250 is a precision, orbital GTAW (TIG) weld

head designed for fusion butt welding up to 1/4” (6,35 mm)

OD tubing, mini-fittings, and valve bodies with extremely

tight radial clearance limitations.

The tooling for the 9-250 is provided with a visual sight

window to verify fit-up and it incorporates two sets of hard-

ened clamp plates. The unique latch design provides a firm

grip while maintaining concentric alignment of the parts to

be welded.

MODEL 9-500 & 9-500C MINI WELD HEADS

The Model 9-500 & Model 9-500C weld heads are designed mainly for welding of components with

stick-out as short as 0.25” (6,35 mm) in diameters from 3/32” (2,3 mm) through 1/2” (12,2 mm). The

Model 9-500C is water-cooled so it is capable of higher duty cycle applications. It is provided with a

Quick Release Kit, which allows for remote loading of the clamp assemblies. The Quick Release Kit

(optional for the Model 9-500) provides a 360 view of the weld joint, and facilitates the use of multiple

clamp assemblies to further increase the duty-cycle. A wide variety of tooling is available for both

models, such as clamp assemblies, tube clamp and fitting clamp inserts, and adjustable mini cubes.

Model 9-500C Model 9-500 Quick Release Kit

TOOLING

Clamp assemblies Clamp inserts Adjustable mini cubes

MODEL 9E SERIES

The Model 9E series weld heads are designed for

fusion (TIG) welding of tube or thin-wall pipe through

the range of 0.25” (6,3 mm) to 6.625” (168,3 mm)

OD. It’s available in five sizes to weld components

that do not provide enough stick-out for a double-

clamp set up. An off-set electrode, single-sided

clamp and gas seal make the Model 9E series weld

heads adaptable to a wide variety of applications,

e.g. pipe fitting and short sanitary ferrules.

Clamp inserts and gas seals are available for all

standard sizes as well as for custom applications.

MODEL 9CT SERIES

Available in three sizes, the Model 9CT (Cassette

Type) series weld heads are designed for fusion

(TIG) welding of tube or thin-wall pipe through the

range of 0.093” (2,3 mm) to 1.50” (38,1 mm) OD.

The clamps on this type of head are mounted into a

removable cassette module which acts as a fixturing

device to align and hold the tubing or fittings prior to

welding. It also allows 360 visibility of the weld joint.

The use of multiple cassettes facilitates significantly

higher production rates.

All Model 9CT weld heads have built-in water cooling

capability for high-duty cycle applications.

ACCESSORIES

Fitting Support Mandrel Additional Accessories

Designed to facilitate the orbital weld-

ing of fitting-to-fitting assemblies which Tungsten electrodes

do not have sufficient straight length to

be held in an orbital weld head. It also Off-set electrode holders

serves as an ID purge device. The tool

is adaptable to a wide range of fitting Bench mount bracket

sizes and assembly configurations.

Tube alignment gauge

Purge Mandrel Tool

Provides a quick and easy method of Conversion kits

aligning sanitary ferrules and other simi-

lar types of fitting without pre-tacking. It

Extension cables

includes provisions for ID purging, and is Reusable, heavy-duty

adaptable for a wide range of ferrules

and fitting types and sizes.

shipping/storage case

OD RANGE/DIMENSIONS

Dimensions

Tube/Pipe

Model No. OD Range

A B C D E F

0.093” - 0.250”

2,3 - 6,3 mm 10.00” 0.83” 0.66” 1.31”

9-250 254 mm 21 mm 16,7 mm 33,3 mm 0.25” 0.48”

0.093” - 0.500” 6,3 mm 12,2 mm

2,3 - 12,7 mm 9.60” 0.96” 1.29” 2.58”

9-500/C 244 mm 24,4 mm 32,7 mm 65,5 mm

0.125” - 0750” 0.70” 1.40”

3,2 - 19 mm 11.30” 1.19” 1.38” 2.75” 17,8 mm 35,5 mm

9-750 287 mm 30,2 mm 35 mm 69,8 mm

0.250” - 1.500” 1.41” 2.81”

9-1500 6,3 - 38,1 mm 35,8 mm 71,4 mm

13.00” 1.88” 2.00” 4.00”

0.250” - 1.315” 330 mm 47,7 mm 50,8 mm 101,6 mm 0.37” 2.85”

9E-1500 6,3 - 33,4 mm 9,4 mm 72,4 mm

0.750” - 2.500” 1.72” 3.44”

9-2500 19 - 63,5 mm 43,7 mm 87,4 mm

15.75” 2.62” 2.88” 5.75”

0.750” - 2.375” 400 mm 66,5 mm 73,1 mm 146 mm 0.37” 3.53”

9E-2500 19 - 69,4 mm 9,4 mm 89,6 mm

1.000” - 3.500” 1.72” 3.44”

9-3500 25,4 - 88,9 mm 43,7 mm 87,4 mm

16.75” 3.12” 3.63” 7.25”

1.000” - 3.250” 425 mm 79,2 mm 92,2 mm 184,1 mm 0.37” 3.53”

9E-3500 25,4 - 82,5 mm 9,4 mm 89,6 mm

1.500” - 4.500” 2.00” 4.00”

9-4500 38,1 - 114,3 mm 50,8 mm 101,6 mm

1.500” - 4.000” 19.00” 4.25” 4.50” 9.00”

38,1 - 101,6 mm 483 mm 107,9 mm 114,3 mm 228,6 mm

9E-4500

0.37” 2.81”

1.500” - 4.500” 9,4 mm 71,4 mm

9ER-4500 38,1 - 114,3 mm

2.875” - 7.500” 2.16” 4.32”

9-7500 73 - 190,5 mm 54,8 mm 109,7 mm

22.00” 5.68” 6.12” 12.25”

2.875” - 6.626” 559 mm 144,3 mm 155,4 mm 311,1 mm 0.53” 3.97”

9E-7500 73 - 168,3 mm 13,4 mm 100,8 mm

Leaders & Innovators in

Automated Orbital Welding

MKT 9 SERIES WH/ April, 2011 / E

You might also like

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosFrom EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosNo ratings yet

- First Time Jewelry Making: The Absolute Beginner's GuideFrom EverandFirst Time Jewelry Making: The Absolute Beginner's GuideRating: 5 out of 5 stars5/5 (4)

- Orbital Welding Heads for Tube and Pipe FusionDocument4 pagesOrbital Welding Heads for Tube and Pipe FusionkyongngNo ratings yet

- Orbital welding equipment for pulled-tee jointsDocument2 pagesOrbital welding equipment for pulled-tee jointsmakmak9No ratings yet

- Kidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Document6 pagesKidde Mounting Straps and Wall Brackets For Clean Agent and Nitrogen Pilot and Driver Cylinders K-85-1230Isa KumNo ratings yet

- Conversion Table For Standard Test SievesDocument2 pagesConversion Table For Standard Test SievesAyo OshoNo ratings yet

- E 11 - 95 - RtexlvjfraDocument6 pagesE 11 - 95 - RtexlvjfraPrakash MakadiaNo ratings yet

- Mallas LaboratorioDocument2 pagesMallas Laboratoriorafa0714No ratings yet

- IMPCO CA200 CarburetorDocument5 pagesIMPCO CA200 Carburetorincore1976No ratings yet

- Mahboob Ms - t5 Flare Gas TransducerDocument8 pagesMahboob Ms - t5 Flare Gas TransducerVasilica BarbarasaNo ratings yet

- Service Specifications: Author: DateDocument1 pageService Specifications: Author: DateClodoaldo BiassioNo ratings yet

- WCT Cast Iron Bridge Plug Technical DatasheetDocument3 pagesWCT Cast Iron Bridge Plug Technical DatasheetEvolution Oil ToolsNo ratings yet

- Ansi-Bhma 156.7 HH 2019Document1 pageAnsi-Bhma 156.7 HH 2019Rey Eduard Q. UmelNo ratings yet

- Cat Fonte Segura Correias 2008 - 2009Document8 pagesCat Fonte Segura Correias 2008 - 2009Lyon Tratorpecas ITBNo ratings yet

- Manual RJ45 AmpDocument20 pagesManual RJ45 AmpMauroNo ratings yet

- Longitudinal Seam Welders Brochure PDFDocument8 pagesLongitudinal Seam Welders Brochure PDFVijo JoseNo ratings yet

- What to look for in precision test sievesDocument32 pagesWhat to look for in precision test sievesSlađa ObradovićNo ratings yet

- S111 EN 12 Aluminium Standard Inclinometric CasingDocument4 pagesS111 EN 12 Aluminium Standard Inclinometric CasingIrwan DarmawanNo ratings yet

- Nominal Pipe SizeDocument3 pagesNominal Pipe SizeNAYEEMNo ratings yet

- Standar Mallas ASTMDocument10 pagesStandar Mallas ASTMMichael RiveraNo ratings yet

- Kristeel CatalogueDocument52 pagesKristeel CatalogueRam TejaNo ratings yet

- Wheatland ASTM A 53 Schedule 40 Pipe SpecsDocument1 pageWheatland ASTM A 53 Schedule 40 Pipe SpecsKelvin RojasNo ratings yet

- Wire Ropes and DrillingDocument32 pagesWire Ropes and DrillingNed VasicNo ratings yet

- Sudhakar Marketing Agencies Pvt. LTD.,: E-9, Industrial Estate, Suryapet-508 214 Price List of Blue Threaded PVC PipesDocument1 pageSudhakar Marketing Agencies Pvt. LTD.,: E-9, Industrial Estate, Suryapet-508 214 Price List of Blue Threaded PVC Pipesab_s5036No ratings yet

- Astm Chart WstylerDocument1 pageAstm Chart WstylernghiNo ratings yet

- NPT ThreadsDocument4 pagesNPT ThreadssatphoenixNo ratings yet

- Din 7500 enDocument10 pagesDin 7500 enCălin Bălăiţă100% (1)

- Rheostats: (Potentiometers) WirewoundDocument3 pagesRheostats: (Potentiometers) WirewoundJumail SobaNo ratings yet

- ASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesDocument5 pagesASTM E 11-01 Standard Specification For Wire Cloth and Sieves For Testing PurposesPablo Antonio Valcárcel VargasNo ratings yet

- Bossard Taptite Self Tapping Screw CatalogueDocument10 pagesBossard Taptite Self Tapping Screw CataloguepmlmkpNo ratings yet

- Bore-Well Pipes PDFDocument6 pagesBore-Well Pipes PDFNikita KadamNo ratings yet

- TECON Scaffolding RinglockDocument9 pagesTECON Scaffolding RinglockSergio RebazaNo ratings yet

- Cable Solenoid: FeaturesDocument2 pagesCable Solenoid: FeaturesJohn GarnetNo ratings yet

- Astm A53Document2 pagesAstm A53joseocsilvaNo ratings yet

- Model Model: Belt Alignment Control Belt Alignment ControlDocument2 pagesModel Model: Belt Alignment Control Belt Alignment ControlJaime Valenzuela MarchantNo ratings yet

- Fastenr GradesDocument5 pagesFastenr GradesVipul ShereNo ratings yet

- Hazardous Area Cable Gland Dual Certified ATEX & IECExDocument1 pageHazardous Area Cable Gland Dual Certified ATEX & IECExhashmin karuvathilNo ratings yet

- Test Sieves, Sieve Shakers & Particle Analysis Equipment: AddressDocument64 pagesTest Sieves, Sieve Shakers & Particle Analysis Equipment: AddressSebastian Matias CruzNo ratings yet

- Digital Product Guide v80Document64 pagesDigital Product Guide v80Felipe Alfredo Martinez InterianoNo ratings yet

- Generation Ii Series Condenser Tube Expanders: FeaturesDocument15 pagesGeneration Ii Series Condenser Tube Expanders: FeaturesSheikh ZakirNo ratings yet

- Medium Expansion Bridge Plug (ME) : Product DescriptionDocument2 pagesMedium Expansion Bridge Plug (ME) : Product DescriptionWan Abdullah Mahmood100% (1)

- PG 7Document1 pagePG 7kvramana006No ratings yet

- Clean Slot Brushes Residue Rotors StatorsDocument1 pageClean Slot Brushes Residue Rotors Statorsmansoor hussainNo ratings yet

- Armature Air Gap GaugeDocument1 pageArmature Air Gap GaugeArnold StevenNo ratings yet

- Thomas & Betts Cable Gland CatalogueDocument13 pagesThomas & Betts Cable Gland Cataloguekvp0107No ratings yet

- Pipe Dimensions: Nominal Pipe Size Pipe Schedule NoDocument2 pagesPipe Dimensions: Nominal Pipe Size Pipe Schedule NoBhavani PrasadNo ratings yet

- Catalog of Wire Nail Making MachinesDocument5 pagesCatalog of Wire Nail Making MachinesaselabollegalaNo ratings yet

- Pump Installation and Maintenance GuideDocument6 pagesPump Installation and Maintenance GuideMohammed Amin BenharkatNo ratings yet

- .750" To 16.250" (19.1 To 412.8 MM) O.D.: Flange FacingDocument4 pages.750" To 16.250" (19.1 To 412.8 MM) O.D.: Flange FacingTulioLopezJNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and BAngel PintoNo ratings yet

- Standard Pipe Schedule 40 ASTM A 53 Grades A and BDocument2 pagesStandard Pipe Schedule 40 ASTM A 53 Grades A and Btarek eidNo ratings yet

- Lugs and Connectors: Features - Advantages - BenefitsDocument14 pagesLugs and Connectors: Features - Advantages - BenefitsDELMAR QUIROGA CALDERONNo ratings yet

- F300 Valves For API 641 TestingDocument3 pagesF300 Valves For API 641 TestingSyed AhmedNo ratings yet

- Carbs Mixers PDFDocument105 pagesCarbs Mixers PDFAnkush SehgalNo ratings yet

- Longitudinal Seam Welders BrochureDocument8 pagesLongitudinal Seam Welders Brochuregrincheu70No ratings yet

- Impco Carburetors-MixersDocument100 pagesImpco Carburetors-MixersLuis Ramón Argüello RealNo ratings yet

- Week 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensityDocument27 pagesWeek 6 & 7-Specific Weight, Water-Absorption, Abrasion, DensitySamantha NamzugNo ratings yet

- 2 Drilling PipesDocument82 pages2 Drilling Pipesdf_campos3353No ratings yet

- Screwcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsFrom EverandScrewcutting in the Lathe for Home Machinists: Reference Handbook for Both Imperial and Metric ProjectsNo ratings yet

- Series "GGMU" Ultra-Pure Gauge Guard: Technological Breakthrough For Ultra-Pure Liquid and Deionized Water SystemsDocument2 pagesSeries "GGMU" Ultra-Pure Gauge Guard: Technological Breakthrough For Ultra-Pure Liquid and Deionized Water SystemsAlwin WanNo ratings yet

- SPC COR HSE 002 E - Rev03Document11 pagesSPC COR HSE 002 E - Rev03Vladimir KarpovNo ratings yet

- PDFDocument6 pagesPDFAmirul AsyrafNo ratings yet

- v8 - Ex. 1010, Martin Et Al., (Lyderson) Ed. Bioprocess Engineering Systems Equipment and Facilities (Chapter 9 in Full)Document56 pagesv8 - Ex. 1010, Martin Et Al., (Lyderson) Ed. Bioprocess Engineering Systems Equipment and Facilities (Chapter 9 in Full)Vladimir KarpovNo ratings yet

- Series 50F7 Seal Weld Ball ValveDocument2 pagesSeries 50F7 Seal Weld Ball ValveVladimir KarpovNo ratings yet

- PHARMA Systems: NewsletterDocument16 pagesPHARMA Systems: NewsletterVladimir KarpovNo ratings yet

- Homemade Plasma CutterDocument25 pagesHomemade Plasma Cutterisg8sevil100% (3)

- Challenge1 50Document7 pagesChallenge1 50qweertyNo ratings yet

- Nursing "Brains" Report Sheet 1Document1 pageNursing "Brains" Report Sheet 1girlywhirl100% (2)

- Bill of Materials and Cost Estimates Description QTY Unit Unit Cost Total Cost Site Works PHP 17,854.77Document8 pagesBill of Materials and Cost Estimates Description QTY Unit Unit Cost Total Cost Site Works PHP 17,854.77RavNo ratings yet

- Data Calls Check Gena Reset Uplink DownlinkDocument14 pagesData Calls Check Gena Reset Uplink DownlinkPradheep Renganathan100% (1)

- Tanisha Minor Project FinalDocument49 pagesTanisha Minor Project FinalSharif ZayanNo ratings yet

- The Importance of Additive ManufacturingDocument9 pagesThe Importance of Additive ManufacturingraviNo ratings yet

- Humalyzer Primus: Semi-Automatic Microprocessor Controlled PhotometerDocument2 pagesHumalyzer Primus: Semi-Automatic Microprocessor Controlled Photometerali zeidNo ratings yet

- The Development of A Hardware in The Loop Simulation System For UAV Autopilot Design Using LabviewDocument24 pagesThe Development of A Hardware in The Loop Simulation System For UAV Autopilot Design Using LabviewAhmed Medhat YoussefNo ratings yet

- Marbella Inav 410 Sleek 4.3inch Navigator - Hardware Instruction ManualDocument43 pagesMarbella Inav 410 Sleek 4.3inch Navigator - Hardware Instruction ManualsurindersbainsNo ratings yet

- Remotely Operated Underwater Vehicle With 6DOF Robotic ArmDocument14 pagesRemotely Operated Underwater Vehicle With 6DOF Robotic ArmMethun RajNo ratings yet

- Red Alert ManualDocument17 pagesRed Alert ManualAlek KingNo ratings yet

- L&T Interview QuestionsDocument3 pagesL&T Interview QuestionsAnup BorseNo ratings yet

- Changjiang A969 A968 Quad-Band TV Dual Sim GSM Mobile PhoneDocument8 pagesChangjiang A969 A968 Quad-Band TV Dual Sim GSM Mobile Phoneabdul645No ratings yet

- Ultrasonido BKM Pro Focus 2202Document368 pagesUltrasonido BKM Pro Focus 2202Mariö OlveraNo ratings yet

- HFW1431S1 S4 PDFDocument3 pagesHFW1431S1 S4 PDFأبومحمدالزياتNo ratings yet

- RelNot Opis OPisDocument59 pagesRelNot Opis OPisxxxNo ratings yet

- Color Palette Blue and YellowDocument4 pagesColor Palette Blue and YellowdresscodebytereNo ratings yet

- Processing 1.4.1.JsDocument189 pagesProcessing 1.4.1.JsChristina PotterNo ratings yet

- Changeover Procedure in Asset Accounting (APC) to EurosDocument2 pagesChangeover Procedure in Asset Accounting (APC) to EurosSonianNareshNo ratings yet

- IOTDocument23 pagesIOTShendy Arief PrastyantoNo ratings yet

- Yealink SIP Phones Release Notes of Version V83Document27 pagesYealink SIP Phones Release Notes of Version V83William Jordache SaraivaNo ratings yet

- Panasonic+Ag-hvx200p An e Mc,+Ag-hvx202en+Parts,+Service+ManualDocument382 pagesPanasonic+Ag-hvx200p An e Mc,+Ag-hvx202en+Parts,+Service+ManualDJDogbone100% (1)

- M1-Assignment Solution-AlgorithmDocument2 pagesM1-Assignment Solution-AlgorithmRaman deepNo ratings yet

- A Review On Load Sharing of TransformerDocument5 pagesA Review On Load Sharing of TransformerIJSTENo ratings yet

- GMR3 Functionaldescription e DIT002Document70 pagesGMR3 Functionaldescription e DIT002Mauricio Schmidt MunizNo ratings yet

- Double Rail Parameter-1Document15 pagesDouble Rail Parameter-1cassanova jackNo ratings yet

- Chapter: 5 Design of Pneumatic Circuits: TopicsDocument3 pagesChapter: 5 Design of Pneumatic Circuits: Topicsparth bhardwajNo ratings yet

- Website Subpoena Instructions 11.1.2019Document2 pagesWebsite Subpoena Instructions 11.1.2019Mark RiveraNo ratings yet

- Preview - The Software-Defined Vehicle ReportDocument16 pagesPreview - The Software-Defined Vehicle Reportkothapallikartheek25No ratings yet