Professional Documents

Culture Documents

E1061, E1063 - Installation Manual MA00815-A (04.06)

Uploaded by

gOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

E1061, E1063 - Installation Manual MA00815-A (04.06)

Uploaded by

gCopyright:

Available Formats

MITSUBISHI ELECTRIC

E1061 and E1063

Installation manual

MA00815 2006-04

English

Foreword

Installation manual for the E1000 series operator terminals

Foreword

The E1000 operator terminal is developed to satisfy the demands of human-

machine communication. Built-in functions such as displaying and controlling text,

dynamic indication, time channels, alarm and recipe handling are included.

The operator terminal work, for the most part, in an object-oriented way, making it

easy to understand and use. The configuration operation of the terminal is made in

a personal computer, using the configuration tool E-Designer. The project is then

transferred and stored in the operator terminal.

The operator terminal can be connected to many types of automation equipment,

such as PLCs, servos or drives. In this manual the expression “the controller“ is used

as a general term for the connected equipment.

This manual explains how to install the operator terminal. Please refer to the refer-

ence manual for further information.

© Mitsubishi Electric, MA00815, 2006-04

The information in this document is subject to change without notice and is provided as available at the time

of printing. The manufacturer reserves the right to change any information without updating this publication.

The manufacturer assumes no responsibility for any errors that may appear in this document.

Read the entire installation manual prior to installing and using this equipment.

Only qualified personnel may install, operate or repair this equipment. The manufacturer is not responsible

for modified, altered or renovated equipment.

Because the equipment has a wide range of applications, users must acquire the appropriate knowledge to use

the equipment properly in their specific applications.

Persons responsible for the application and the equipment must themselves ensure that each application is in

compliance with all relevant requirements, standards and legislation in respect to configuration and safety.

Only parts and accessories manufactured according to specifications set by The manufacturer may be used.

THE MANUFACTURER SHALL NOT BE LIABLE TO ANYONE FOR ANY DIRECT, INDIRECT,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING FROM THE

INSTALLATION, USE OR REPAIR OF THIS EQUIPMENT, WHETHER ARISING IN TORT,

CONTRACT, OR OTHERWISE. BUYER'S SOLE REMEDY SHALL BE THE REPAIR,

REPLACEMENT, OR REFUND OF PURCHASE PRICE, AND THE CHOICE OF THE APPLICABLE

REMEDY SHALL BE AT THE SOLE DISCRETION OF THE MANUFACTURER.

Mitsubishi Electric, MA00815

Table of Contents

Table of Contents

1 Safety Precautions................................................................................. 5

1.1 UL Installation.................................................................................. 5

1.2 General ............................................................................................. 5

1.3 During Use ....................................................................................... 5

1.4 Service and Maintenance................................................................... 6

1.5 Dismantling and Scrapping............................................................... 6

2 Installation ........................................................................................... 7

2.1 Space Requirements .......................................................................... 7

2.2 Installation Process............................................................................ 7

2.2.1 Mode Switches .................................................................................................. 9

2.2.2 Connections to the Controller ........................................................................... 9

2.2.3 Other Connections and Peripherals ................................................................... 9

3 Technical Data ................................................................................... 11

4 Chemical Resistance ........................................................................... 13

4.1 Metal Casing................................................................................... 13

4.2 Touch Screen and Overlay .............................................................. 13

4.2.1 Touch Screen Surface ...................................................................................... 13

4.2.2 Autoflex EB ..................................................................................................... 14

4.2.3 Autotex F250................................................................................................... 16

5 Operator Terminal Drawings ............................................................. 19

5.1 Communication Ports..................................................................... 19

5.2 E1061/E1063 Outline .................................................................... 20

Mitsubishi Electric, MA00815

Table of Contents

Mitsubishi Electric, MA00815

Safety Precautions

1 Safety Precautions

Both the installer and the owner and/or operator of the operator terminal must read

and understand this installation manual.

1.1 UL Installation

Power, input and output (I/O) wiring must be in accordance with Class 1, Division

2 wiring methods (Article 501-4 (b) of the National Electric Code, NFPA 70) and

in accordance with the authority having jurisdiction.

1.2 General

– Only qualified personnel may install or operate the operator terminal.

– The operator terminal must be installed according to the installation instructions.

– The operator terminal is designed for stationary installation on a plane surface,

where the following conditions are fulfilled:

• no high explosive risks

• no strong magnetic fields

• no direct sunlight

• no large, sudden temperature changes

– Never allow fluids, metal filings or wiring debris to enter any openings in the

operator terminal. This may cause fire or electrical shock.

– The operator terminal fulfills the requirements of article 4 of EMC directive

89/336/EEC.

– Storing the operator terminal where the temperature is lower/higher than

recommended in this manual can cause the LCD display liquid to congeal/become

isotopic.

– The LCD display liquid contains a powerful irritant. In case of skin contact, wash

immediately with plenty of water. In case of eye contact, hold the eye open, flush

with plenty of water and get medical attention.

– The supplier is not responsible for modified, altered or reconstructed equipment.

– Use only parts and accessories manufactured according to specifications of the

supplier.

– Peripheral equipment must be appropriate for the application and location.

– The figures in this manual serves an illustrative purpose. Because of the many

variables associated with any particular installation, the supplier cannot assume

responsibility for actual use based on the figures.

– The supplier neither guarantees that the operator terminal is suitable for your

particular application, nor assumes responsibility for your product design,

installation or operation.

1.3 During Use

– Keep the operator terminal clean.

– Emergency stop and other safety functions may not be controlled from the

operator terminal.

– Do not use too much force or sharp objects when touching the keys, display etc.

Mitsubishi Electric, MA00815 5

Safety Precautions

1.4 Service and Maintenance

– Only qualified personnel should carry out repairs.

– The agreed warranty applies.

– Before carrying out any cleaning or maintenance operations, disconnect the

equipment from the electrical supply.

– Clean the display and surrounding front cover with a soft cloth and mild

detergent.

– Replacing the battery incorrectly may result in explosion. Only use batteries

recommended by the supplier.

1.5 Dismantling and Scrapping

– The operator terminal or parts thereof shall be recycled according to local

regulations.

– The following components contain substances that might be hazardous to health

and the environment: lithium battery, electrolytic capacitor and display.

6 Mitsubishi Electric, MA00815

Installation

2 Installation

2.1 Space Requirements

– Installation plate thickness: 1.5 - 7.5 mm (0.06 - 0.3 inch)

– Space requirements when installing the operator terminal:

100 mm

(4.0 inch)

152 mm

(5.98 inch) 100 mm

50 mm 50 mm (4.0 inch)

(2.0 inch) (2.0 inch)

100 mm

(4.0 inch)

56.8 mm

(2.24 inch)

201 mm

(7.91 inch)

Caution

The openings on the enclosure are for air convection. Do not cover these

openings.

2.2 Installation Process

1. Unpack and check the delivery. If damage is found, notify the supplier.

Panel cut out 180 x 130 mm

(7.09 x 5.12 inch)

x4

Note:

Place the operator terminal on a stable surface during installation.

Dropping it or letting it fall may cause damage.

2. Place the panel cut out where the operator terminal is to be situated, draw along

the outer sides of the holes and cut according to the markings.

Mitsubishi Electric, MA00815 7

Installation

3. Secure the operator terminal in position, using all the fastening holes and the

provided brackets and screws:

x4

0.5 - 1.0 Nm

4. Connect the cables in the specified order.

A Caution

Ensure that the operator terminal and the controller system have the

same electrical grounding (reference voltage level), otherwise errors

in communication may occur.

B Use an M5 screw and a grounding conductor (as short as possible)

with a cross-section of minimum 2.5 mm2.

C

Caution

- Use only shielded communication cables.

- Separate high voltage cables from signal and supply cables.

D Caution

- The operator terminal must be brought to ambient temperature

before it is started up. If condensation forms, ensure that the

operator terminal is dry before connecting it to the power outlet.

- Ensure that the voltage and polarity of the power source is correct.

B Power

Controller

RS422/

RS485

RS232

24V DC 24V DC

C

Ethernet

5. Carefully remove the laminated film over the operator terminal display, to avoid

static electricity that could damage the terminal.

8 Mitsubishi Electric, MA00815

Installation

2.2.1 Mode Switches

All mode switches must be in OFF position during operator terminal use.

The mode switches should not be touched unless by qualified personell.

1 2 3 4

ON DIP

1 2 3 4

ON DIP

2.2.2 Connections to the Controller

For information about the cables to be used when connecting the operator terminal

to the controller, please refer to the help file for the driver in question.

2.2.3 Other Connections and Peripherals

Cables, peripheral equipment and accessories must be suitable for the application

and its environment. For further details or recommendations, please refer to the

supplier.

Mitsubishi Electric, MA00815 9

Installation

10 Mitsubishi Electric, MA00815

Technical Data

3 Technical Data

Parameter E1061 E1063

Front panel, W x H x D 201 x 152 x 6 mm

Mounting depth 56.8 mm (156.8 mm including clearance)

Front panel seal IP 66

Rear panel seal IP 20

Touch screen material Touch screen: Polyester on glass, 1 million finger touch

operations.

Overlay: Autotex F250 *.

Reverse side material Powder-coated aluminum

Weight 0.87 kg

Serial port RS422/ 25-pin D-sub contact, chassis-mounted female with standard

RS485 locking screws 4-40 UNC.

Serial port RS232C 9-pin D-sub contact, male with standard locking screws 4-40

UNC.

Ethernet Shielded RJ 45

USB Host type A (USB 1.1), max output current 500 mA

Flash memory for 12 MB (incl. fonts)

application

Real time clock ±20 PPM + error because of ambient temperature and supply

voltage.

Total max error: 1 min/month at 25 °C

Minimum life of the real time clock battery: 3 years

Temperature coefficient: 0.004 ppm/°C2

Power consumption at Normal: 0.25 A

rated voltage Maximum: 0.45 A

Display CSTN-LCD. FSTN-LCD.

320 x 240 pixels, 64K colors. 320 x 240 pixels, monocrome.

CCFL backlight lifetime at CCFL backlight lifetime at

the ambient temperature of the ambient temperature of

+25 °C: >60,000 h. +25 °C: >45,000 h.

Active area of display, 115.2 x 86.4 mm

WxH

Fuse Internal DC fuse, 2.0 AT, 5 x 20 mm

Power supply +24V DC (20 - 30V DC). 3-pin jack connection block.

CE: The power supply must conform with the requirements

for SELV or PELV according to IEC 950 or IEC 742.

UL: The power supply must conform with the requirements

for class II power supplies.

Ambient temperature Vertical installation: 0 ° to +50 °C

Horizontal installation: 0 ° to +40 °C

Storage temperature -20 ° to +70 °C

Relative humidity 5 - 85 % non-condensed

EMC tests on the The operator terminal conforms with the essential protection

operator terminal requirements in article 4 of the directive 89/336/EEC. Noise

tested according to EN61000-6-3 emission and EN61000-6-2

immunity.

UL, cUL approvals UL 1604 Class I, Div 2 / UL 508 / UL 50 4x indoor use only

(when product or

packing is marked)

DNV Certification in progress

NEMA 4x indoor use only

* See section Chemical Resistance for more information.

Mitsubishi Electric, MA00815 11

Technical Data

12 Mitsubishi Electric, MA00815

Chemical Resistance

4 Chemical Resistance

4.1 Metal Casing

The frame and casing material is powder-coated aluminum. This powder paint

withstands exposure of up to 24 hours duration to the following chemicals without

visible change:

Ammonia 25% Isopropyl alcohol Nitric acid 3%

De-ionized water Tap water Chlorhydric acid 10%

Butanol Cooling liquid 50% Washer fluid 33%

Citric acid 10% Ligroin Sulphuric acid 20%

Diesel Cooking oil Turpentine

Ethanol 99.5% denaturated Lactic acid 10% Urea saturated

FAM-Normal petrol Sodium di-chromate Hydroperoxide 3%

saturated

Alcohol 95% Caustic soda 5% Acetic acid 10%

Phosphoric acid 43% Sodium hypochlorite Alu-cleaner

solution

Glycol Sodium carbonate 10% -

Industrial petrol Sodium chloride 20% -

4.2 Touch Screen and Overlay

4.2.1 Touch Screen Surface

The touch screen surface on the operator terminal withstands exposure to the

following solvents without visible change:

Solvents Time

Acetone 10 minutes

Isopropanol 10 minutes

Toulene 5 hours

Mitsubishi Electric, MA00815 13

Chemical Resistance

4.2.2 Autoflex EB

It is recommended to use the Autoflex EB touch display protection film, that can be

ordered from the supplier.

Solvent Resistance

Autoflex is based upon biaxial orientated polyester film and therefore has much

enhanced solvent resistance, strength, durability and toughness sustrates such as

polycarbonate and vinyl.

Autoflex EB withstands exposure of more than 24 hours duration under DIN 42 115

Part 2 to the following chemicals without visible change:

Potassium ferrocyanide/ Sodium hypchlorite <20% 1.1.1. Trichloroethane

ferricyanide (bleach) (Genklene)

Cyclohexanol Acetaldehyde Ethylacetate

Diacetone alcohol Aliphatic hydrocarbons Diethyl ether

Glycol Toluene N-Butyl acetate

Isopropanol Xylene Amylacetate

Glycerine White spirit Butycellosolve

Methanol Fromic acid <50% Ether

Triacetin Acetic acid <50% MIBK

Dowanol DRM/PM Phosphoric acid <30% Cutting oil

Acetone Hydrochloric acid <36% Potassium carbonate

Metyl ethyl ketone Nitric acid <10% Washing powders

Dioxan Trichloracetic acid <50% Fabric conditioner

Cyclohexanone Sulphuric acid <10% Ferric chloride

Ethanol Formaldehyde 37% - 42% Ferrous chlorid

Isophorone Potassium hydroxide <30% Dibutyl Phthalate

Ammonia <40% Linseed oil Dioctyl Phthalate

Caustic soda <40% Paraffin oil Sodium carbonate

Hydrogen peroxide <25% Blown castor oil Petrol

Alkalicarbonate Silicone oil Teepol

Bichromate Turpentine substitute Water

Diesel oil Univeral brake fluid Sea water

Acetonitrile Decon -

Sodium bisulphate Aviation fuel -

Autoflex withstands DIN 42 115 Part 2 exposure of up to 1 hour duration to glacial

acetic acid without visible change.

Autoflex is not resistant to high pressure steam at over 100 °C or the following

chemicals:

Concentrated mineral acids Benzyl alcohol

Concentrated caustic solution Mehylene chloride

14 Mitsubishi Electric, MA00815

Chemical Resistance

Autoflex withstands 24 hours exposure to the following reagents at 50 °C without

visible staining:

Top Job Grape Juice Ariel Ajax

Jet Dry Milk Persil Vim

Gumption Coffee Wisk Domestos

Fantastic - Lenor Vortex

Formula 409 - Downey Windex

Very slight discoloration was noted under critical viewing conditions with the

following materials:

Tomato juice Tomato ketchup Lemon juice Mustard

Outdoor Use

In common with all polyester based films, Autoflex EB is not suitable for use in

conditions of long term exposure to direct sunlight.

Mitsubishi Electric, MA00815 15

Chemical Resistance

4.2.3 Autotex F250

Autotex F250 covers the overlay surrounding the touch screen.

Solvent Resistance

Autotex F250 withstands exposure of more than 24 hours duration under DIN 42

115 Part 2 to the following chemicals without visible change:

Potassium ferrocyanide/ Sodium hypchlorite <20% 1.1.1. Trichloroethane

ferricyanide (bleach) (Genklene)

Cyclohexanol Acetaldehyde Ethylacetate

Diacetone alcohol Aliphatic hydrocarbons Diethyl ether

Glycol Toluene N-Butyl acetate

Isopropanol Xylene Amylacetate

Glycerine White spirit Butycellosolve

Methanol Fromic acid <50% Ether

Triacetin Acetic acid <50% MIBK

Dowanol DRM/PM Phosphoric acid <30% Cutting oil

Acetone Hydrochloric acid <36% Potassium carbonate

Metyl ethyl ketone Nitric acid <10% Washing powders

Dioxan Trichloracetic acid <50% Fabric conditioner

Cyclohexanone Sulphuric acid <10% Ferric chloride

Ethanol Formaldehyde 37% - 42% Ferrous chlorid

Isophorone Potassium hydroxide <30% Dibutyl Phthalate

Ammonia <40% Linseed oil Dioctyl Phthalate

Caustic soda <40% Paraffin oil Sodium carbonate

Hydrogen peroxide <25% Blown castor oil Petrol

Alkalicarbonate Silicone oil Teepol

Bichromate Turpentine substitute Water

Diesel oil Univeral brake fluid Sea water

Acetonitrile Decon -

Sodium bisulphate Aviation fuel -

Autotex withstands DIN 42 115 Part 2 exposure of up to 1 hour duration to glacial

acetic acid without visible change.

Autotex is not resistant to high pressure steam at over 100 °C or the following

chemicals:

Concentrated mineral acids Benzyl alcohol

Concentrated caustic solution Mehylene chloride

Autotex withstands 24 hours exposure to the following reagents at 50 °C without

visible staining:

Top Job Grape Juice Ariel Ajax

Jet Dry Milk Persil Vim

Gumption Coffee Wisk Domestos

Fantastic - Lenor Vortex

Formula 409 - Downey Windex

16 Mitsubishi Electric, MA00815

Chemical Resistance

Very slight discoloration was noted under critical viewing conditions with the

following materials:

Tomato juice Tomato ketchup Lemon juice Mustard

Outdoor Use

In common with all polyester based films, Autotex F250 is not suitable for use in

conditions of long term exposure to direct sunlight.

Mitsubishi Electric, MA00815 17

Chemical Resistance

18 Mitsubishi Electric, MA00815

Operator Terminal Drawings

5 Operator Terminal Drawings

5.1 Communication Ports

RS-232

RS-422 RS-485

RS-422/485

USB

Ethernet

Drawing No. S-05005, Date 2004-10-27

Mitsubishi Electric, MA00815 19

Operator Terminal Drawings

5.2 E1061/E1063 Outline

Drawing No. P-06545, Date 2005-09-21

20 Mitsubishi Electric, MA00815

MITSUBISHI ELECTRIC

Mitsubishi Electric Automation, Inc.

500 Corporate Woods Parkway

Vernon Hills, IL 60061, USA

Mitsubishi Electric Europe B.V.

Gothaer Strasse 8

D-40880 Ratingen, Germany

You might also like

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Misubishi E110Document26 pagesMisubishi E110mohamed abdelhayNo ratings yet

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- Installation Manual: EnglishDocument20 pagesInstallation Manual: EnglishCarlosNo ratings yet

- Abc of Power Modules: Functionality, Structure and Handling of a Power ModuleFrom EverandAbc of Power Modules: Functionality, Structure and Handling of a Power ModuleNo ratings yet

- E1061 E1063 HW Installation EnglishDocument26 pagesE1061 E1063 HW Installation EnglishAxicelNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- E1022 HW Installation EnglishDocument28 pagesE1022 HW Installation EnglishAxicelNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- E1060 E1062 HW Installation EnglishDocument28 pagesE1060 E1062 HW Installation EnglishAxicelNo ratings yet

- Electrician's Troubleshooting and Testing Pocket Guide, Third EditionFrom EverandElectrician's Troubleshooting and Testing Pocket Guide, Third EditionRating: 5 out of 5 stars5/5 (1)

- Mitsubishi E1100 ManualDocument24 pagesMitsubishi E1100 ManualAmri ChakerNo ratings yet

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- Installation Manual: EnglishDocument20 pagesInstallation Manual: EnglishPrameet BisoiNo ratings yet

- Electrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceFrom EverandElectrician''s Guide to Control and Monitoring Systems: Installation, Troubleshooting, and MaintenanceNo ratings yet

- E1070 HW Installation EnglishDocument28 pagesE1070 HW Installation EnglishAxicelNo ratings yet

- EXTER T150-st: Installation ManualDocument24 pagesEXTER T150-st: Installation ManualdwdawadNo ratings yet

- Hamgam-System - Ir S Mp3500 4500 2Document488 pagesHamgam-System - Ir S Mp3500 4500 2Adnan RaufNo ratings yet

- Ricoh MP 2510 Service ManualDocument433 pagesRicoh MP 2510 Service Manualconnectingeurope8479100% (2)

- EXTER™ T100: Installation ManualDocument26 pagesEXTER™ T100: Installation ManualQuazi Mosaddequl HaqueNo ratings yet

- 3-Rosemount Oxymitter 4000-OXT4CDocument198 pages3-Rosemount Oxymitter 4000-OXT4Cgudapati9No ratings yet

- Wired Remote Controller: Installation and Operation ManualDocument36 pagesWired Remote Controller: Installation and Operation ManualewothjogNo ratings yet

- Service 500Document488 pagesService 500FReaderNo ratings yet

- Ricoh Mp3500 Service ManualDocument488 pagesRicoh Mp3500 Service ManualBlack GoldNo ratings yet

- LCD Television Kalley Service Manual: ProductDocument42 pagesLCD Television Kalley Service Manual: Productgilberto gutierrezNo ratings yet

- User Manual: - Installation - OperationDocument49 pagesUser Manual: - Installation - OperationkutzooiNo ratings yet

- Yaskawa V7 InstructionsDocument42 pagesYaskawa V7 InstructionssunhuynhNo ratings yet

- LCD Television Kalley Service Manual: ChassisDocument42 pagesLCD Television Kalley Service Manual: ChassisMarcelo MoreiraNo ratings yet

- LHD32D77US 32D77 MT5305 Service Manual 20121213Document45 pagesLHD32D77US 32D77 MT5305 Service Manual 20121213Vicky MoralesNo ratings yet

- Operator Terminal Guide ''EXTER''Document54 pagesOperator Terminal Guide ''EXTER''AlexDorNo ratings yet

- Maintenance Guide FEH329Document21 pagesMaintenance Guide FEH329PrasetyaNo ratings yet

- Hisense 40h5Document40 pagesHisense 40h5The Rod Of CorrectionNo ratings yet

- Installation and Operation Manual: Cover - MAEN824E.fm Page 1 Monday, March 9, 2009 2:17 PMDocument30 pagesInstallation and Operation Manual: Cover - MAEN824E.fm Page 1 Monday, March 9, 2009 2:17 PMАлександр ПоповNo ratings yet

- Steca PR Night Instruction enDocument18 pagesSteca PR Night Instruction enShane BaileyNo ratings yet

- Model S-C3 F/SPF Models Machine Code: B284/B288 Service ManualDocument317 pagesModel S-C3 F/SPF Models Machine Code: B284/B288 Service ManualG OrgNo ratings yet

- A-C3 Service Manual SEODocument247 pagesA-C3 Service Manual SEOdieubimatNo ratings yet

- S Af2035Document254 pagesS Af2035liviumaraNo ratings yet

- 4P543053-1B - DBP - BRC2E61 - Controle Com Fio SimplificadoDocument36 pages4P543053-1B - DBP - BRC2E61 - Controle Com Fio SimplificadoIocas SoluçõesNo ratings yet

- Ricoh 3035 - 3045 SMDocument497 pagesRicoh 3035 - 3045 SMJoseph AlbertNo ratings yet

- UserManual OMNIK 1k-1.5k-2k EN 20131009 V4.2Document45 pagesUserManual OMNIK 1k-1.5k-2k EN 20131009 V4.2Sabina CristianNo ratings yet

- Model A-C3: (Machine Code: B079/B082) Service ManualDocument254 pagesModel A-C3: (Machine Code: B079/B082) Service ManualDen ZaytsevNo ratings yet

- Hisense Lcd32v88am Chassis Mst6e16js Noblex 32lc833h Tlc3202a Tls1232aDocument67 pagesHisense Lcd32v88am Chassis Mst6e16js Noblex 32lc833h Tlc3202a Tls1232aFabian Ortuzar100% (1)

- MELSEC iQ-F FX5 User's Manual Serial Communication OverviewDocument240 pagesMELSEC iQ-F FX5 User's Manual Serial Communication OverviewMinh Trieu NguyenNo ratings yet

- CP500 UserDocument338 pagesCP500 UserFlorin NeacsuNo ratings yet

- Manual de Servicio para MP 6500 SM - 5500 - 6500 - 7500Document870 pagesManual de Servicio para MP 6500 SM - 5500 - 6500 - 7500Jose PadillaNo ratings yet

- Instalación Ventilador Motor CDDocument12 pagesInstalación Ventilador Motor CDcarcruparkNo ratings yet

- Operating-Instructions Compact-Inverters S2u-Ip66 Eng r01 0Document166 pagesOperating-Instructions Compact-Inverters S2u-Ip66 Eng r01 0r.andremartins8No ratings yet

- M8300 M8400 Series PDFDocument25 pagesM8300 M8400 Series PDFAnonymous 51h2oV93100% (1)

- Ix Txa: Service & Maintenance ManualDocument19 pagesIx Txa: Service & Maintenance ManualCristhian BolivarNo ratings yet

- A-C3e/f Service ManualDocument273 pagesA-C3e/f Service ManualCristian BobaruNo ratings yet

- Hisense Ledn32k360 Service Manual 46Document46 pagesHisense Ledn32k360 Service Manual 46Niraaj Chandran NairNo ratings yet

- LCD Television Service Manual: Chassis MTK5652Document59 pagesLCD Television Service Manual: Chassis MTK5652Silvina CappelloNo ratings yet

- Bizhub 250 - 350 SM Theory PDFDocument284 pagesBizhub 250 - 350 SM Theory PDFParaschiv RaresNo ratings yet

- Combivert: Installation Guide & Operation Manual D-Housing 1-5 HP 230V 1 - 10 HP 480V B Control C Control G ControlDocument52 pagesCombivert: Installation Guide & Operation Manual D-Housing 1-5 HP 230V 1 - 10 HP 480V B Control C Control G ControlAhmet KayurNo ratings yet

- (نسخة) TAL Installation and maintenanace manual-TAL044Document32 pages(نسخة) TAL Installation and maintenanace manual-TAL044Mahmood NabilNo ratings yet

- Series: 30 W / Operating ManualDocument44 pagesSeries: 30 W / Operating ManualMuhammad Adam Rustam PasaribuNo ratings yet

- LSA44.3 - Maintenance ManualDocument28 pagesLSA44.3 - Maintenance ManualMuhammad HaekalNo ratings yet

- MT5380Document48 pagesMT5380danielradu27No ratings yet

- LTDN39K310US 39K310 MT5320 Service Manual 20121212Document44 pagesLTDN39K310US 39K310 MT5320 Service Manual 20121212Vicky Morales0% (1)

- 3281p enDocument28 pages3281p enfirdNo ratings yet

- Vr-7030-Liveplayer Om Eng 44851eDocument97 pagesVr-7030-Liveplayer Om Eng 44851egNo ratings yet

- VR-5034 - Live - Player - OME44182 - B VR 3000-5000Document96 pagesVR-5034 - Live - Player - OME44182 - B VR 3000-5000gNo ratings yet

- E1000-Series ServiceMaintenance MA00758ADocument65 pagesE1000-Series ServiceMaintenance MA00758AoakyjoeNo ratings yet

- Tron 60S/GPS EPIRB: Float-Free and Manual BracketDocument48 pagesTron 60S/GPS EPIRB: Float-Free and Manual BracketgNo ratings yet

- Year 7 Energy Resources and Electrical Circuits-2Document11 pagesYear 7 Energy Resources and Electrical Circuits-2PhysicsF3No ratings yet

- Carbon and Its CompoundsDocument25 pagesCarbon and Its CompoundsdubstepoNo ratings yet

- Copper Ferrite ThesisDocument7 pagesCopper Ferrite ThesisCynthia King100% (2)

- Chemistry MCQs SSBCrack PDFDocument18 pagesChemistry MCQs SSBCrack PDFutkarsh chaturvediNo ratings yet

- Sessions Case Notes PDFDocument31 pagesSessions Case Notes PDFSini AdvNo ratings yet

- FSSA - Stainless Steel Volute Pump PDFDocument7 pagesFSSA - Stainless Steel Volute Pump PDFBOYALFREDONo ratings yet

- Lipid ExtractionDocument10 pagesLipid ExtractionZaman KhanNo ratings yet

- Design and Control of Ethyl Acetate Production Process: January 2015Document13 pagesDesign and Control of Ethyl Acetate Production Process: January 2015mahmoudmaamoun640No ratings yet

- Normas ASTMDocument64 pagesNormas ASTMDavidandyNo ratings yet

- ExperimentaltechniquesDocument52 pagesExperimentaltechniquesDivya Rao100% (1)

- Latent Print Procedures ManualDocument69 pagesLatent Print Procedures ManualFibri Hanggoro100% (1)

- Bar Manual Ircv1 - TraineeDocument59 pagesBar Manual Ircv1 - Traineeagdeshpande09100% (3)

- Try To Answer: IsopropylbenzeneDocument33 pagesTry To Answer: IsopropylbenzeneRoxanne Sioco100% (1)

- Craft Culture of Artisan SchnapsDocument75 pagesCraft Culture of Artisan SchnapsEmerik PišlNo ratings yet

- Research DesignDocument14 pagesResearch DesignNicoleNo ratings yet

- 4 6 Making Artificial Fragrances Lab Fy11Document3 pages4 6 Making Artificial Fragrances Lab Fy11markbronson2009No ratings yet

- Antidiabetic Activity of Gnidia Glauca and Dioscorea Bulbifera PDFDocument10 pagesAntidiabetic Activity of Gnidia Glauca and Dioscorea Bulbifera PDFvijaykavatalkarNo ratings yet

- Critical properties of elements and compoundsDocument2 pagesCritical properties of elements and compoundsWulfranoSánchezNo ratings yet

- Mosquito Repellent Candle FindingsDocument2 pagesMosquito Repellent Candle Findingschristine anchetaNo ratings yet

- Experiment Report 2Document12 pagesExperiment Report 2Lris Tan100% (1)

- Baker'S Yeast Production: Tanya Mehrotra M.Tech Biochemical Engineering 1 YearDocument10 pagesBaker'S Yeast Production: Tanya Mehrotra M.Tech Biochemical Engineering 1 Yeartanya mehrotraNo ratings yet

- Additive 117Document9 pagesAdditive 117Heru KristanokoNo ratings yet

- Organic - Reactions Practice Exercise 5 PDFDocument8 pagesOrganic - Reactions Practice Exercise 5 PDFgeronimo antNo ratings yet

- Davangere distillery industry profileDocument53 pagesDavangere distillery industry profilePrachi Rungta AnvekarNo ratings yet

- Organic Chemistry MasterDocument128 pagesOrganic Chemistry MasterLeigh DensingNo ratings yet

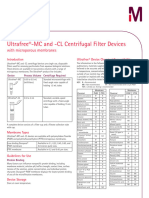

- Millipore Ultrafree-MC Centrifugal Filter Units 0,22 M Pr04184-Rev0618Document2 pagesMillipore Ultrafree-MC Centrifugal Filter Units 0,22 M Pr04184-Rev0618Ana SmolkoNo ratings yet

- Earth Resources in 40 CharactersDocument94 pagesEarth Resources in 40 CharactersLukeThompson100% (3)

- Qualitative Tests For Lipids: ExperimentDocument7 pagesQualitative Tests For Lipids: ExperimentAlthea Aubrey AgbayaniNo ratings yet

- Ethanol, AnhydrousDocument2 pagesEthanol, AnhydrousMiroslav IlicNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Waves and Beaches: The Powerful Dynamics of Sea and CoastFrom EverandWaves and Beaches: The Powerful Dynamics of Sea and CoastRating: 4 out of 5 stars4/5 (1)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Three Laws of Nature: A Little Book on ThermodynamicsFrom EverandThree Laws of Nature: A Little Book on ThermodynamicsRating: 4.5 out of 5 stars4.5/5 (10)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Basic Alarm Electronics: Toolbox Guides for Security TechniciansFrom EverandBasic Alarm Electronics: Toolbox Guides for Security TechniciansJohn SangerRating: 4 out of 5 stars4/5 (1)