Professional Documents

Culture Documents

M-18 Stern Tube L.O. Piping Diagram

M-18 Stern Tube L.O. Piping Diagram

Uploaded by

Vivek LakhwaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M-18 Stern Tube L.O. Piping Diagram

M-18 Stern Tube L.O. Piping Diagram

Uploaded by

Vivek LakhwaniCopyright:

Available Formats

05130015

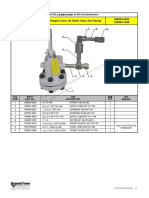

STERN TUBE L.O. PIPING DIAGRAM PAGE

广船国际 K4640435

艉管滑油系统 3 /7

W.PRESS. N.DIA. WEIGHT STANDARD NO. COMPUTER

CODE ITEM MATERIAL Q'TY. DESCRIPTION ON NAMEPLATE REMARKS

(MPa) (mm) (kg) OF ACCESSORY CODE

代号 名称 工作压力 通径 材料 数量 重量 标准号或图号 上机代号 铭牌刻字内容 备注

BELL MOUTH STEEL

US01 32 1 1.8 AS32Y CB/T495-1995

吸入口 钢

STOP CHECK VALVE BRONZE S/T L.O.DUPLEX FILTER INLET

US02 0.6 32 1 6.4 BS6032 GB/T588-93

截止止回阀 青铜 艉管滑油滤器进口

DUPLEX FILTER ASSEMBLY

US03 0.6 32 1 594.711.SLY323 600µ

双联滤器 组合件

FROM TRANSF.PUMP TO

STOP VALVE BRONZE

US04 0.6 32 1 6.6 AS6032 GB/T587-93 GRAVITY TK.

截止阀 青铜

从滑油输送泵至重力油柜

STOP VALVE BRONZE S/T L.O. GRAVITY TK.DRAIN

US05 0.6 32 1 6.6 AS6032 GB/T587-93

截止阀 青铜 艉管滑油重力油柜泄放

STOP VALVE BRONZE L.O.FROM GRAVITY TK.TO TUBE

US06 0.6 32 1 6.6 AS6032 GB/T587-93

截止阀 青铜 重力油柜滑油至艉管

PRESSURE GAUGE & VALVE ASSEMBLY

US07 0~0.5 1 YT-100CII

压力表及三通考克阀 组合件

STOP VALVE BRONZE VENT OF STERN TUBE

US08 0.6 32 1 6.6 AS6032 GB/T587-93

截止阀 青铜 艉管透气

STOP VALVE BRONZE VENT OF STERN TUBE

US09 0.6 32 1 6.6 AS6032 GB/T587-93

截止阀 青铜 艉管透气

STOP CHECK VALVE BRONZE STERN TUBE L.O.INLET

US10 0.6 32 1 6.7 AS6032 GB/T588-93

截止止回阀 青铜 艉管滑油进口

STOP VALVE BRONZE TO S/T L.O.DRAIN TK.

US11 0.6 40 1 8.7 AS6040 GB/T587-93

截止阀 青铜 至艉管滑油泄放柜

STOP VALVE BRONZE STERN TUBE L.O.CHECK VALVE normally closed

US12 0.6 32 1 6.6 AS6032 GB/T587-93

截止阀 青铜 艉管滑油检查阀 常闭

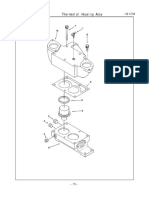

STERN TUBE L.O. PIPING DIAGRAM PAGE

广船国际 K4640435

艉管滑油系统 4 /7

W.PRESS. N.DIA. WEIGHT STANDARD NO. COMPUTER

CODE ITEM MATERIAL Q'TY. DESCRIPTION ON NAMEPLATE REMARKS

(MPa) (mm) (kg) OF ACCESSORY CODE

代号 名称 工作压力 通径 材料 数量 重量 标准号或图号 上机代号 铭牌刻字内容 备注

STOP CHECK VALVE BRONZE STERN TUBE L.O.DRAIN normally closed

US13 0.6 32 1 6.7 AS6032 GB/T588-93

截止止回阀 青铜 艉管滑油泄放 常闭

STOP CHECK VALVE BRONZE STERN TUBE L.O.DRAIN normally closed

US14 0.6 32 1 6.7 AS6032 GB/T588-93

截止止回阀 青铜 艉管滑油泄放 常闭

FROM STORAGE TK.TO GRAVITY

STOP VALVE BRONZE

US15 0.6 32 1 6.6 BS6032 GB/T587-93 TK. 从储

截止阀 青铜

存柜至重力油柜

FROM TRANSF.PUMP TO

STOP VALVE BRONZE

US16 0.6 32 1 6.6 AS6032 GB/T587-93 STORAGE TK.

截止阀 青铜

从输送泵至艉管滑油储存柜

STOP CHECK VALVE BRONZE TO S/T L.O.DRAIN TK.

US17 0.6 40 1 8.7 AS6040 GB/T588-93

截止止回阀 青铜 至艉管滑油泄放柜

STOP VALVE BRONZE L.O.STORAGE TK.DRAIN

US18 0.6 32 1 6.6 BS6032 GB/T587-93

截止阀 青铜 艉管滑油储存柜泄放

STOP VALVE BRONZE S/T L.O. GRAVITY TK.INLET

US19 0.6 32 1 6.6 AS6032 GB/T587-93

截止阀 青铜 艉管重力油柜进口

SIGHT GLASS ASSEMBLY

US20 0.1 40 2 TS1040 CB/T42293

视察镜 组合件

STOP VALVE BRONZE S/T L.O. TRANS.P/P INLET

US21 0.6 32 1 6.6 AS6032 GB/T587-93

截止阀 青铜 艉管滑油输送泵进口

STOP CHECK VALVE BRONZE S/T L.O. TRANS.P/P OUTLET

US22 0.6 32 1 AS6032 GB/T588-93

截止止回阀 青铜 艉管滑油输送泵出口

NAMEPLATE FITTED NEAR

US23 ※DETAILED PAGE 7

铭牌 US12

STOP VALVE BRONZE

US24 0.6 25 1 6.6 AS6025 GB/T587-93

截止阀 青铜

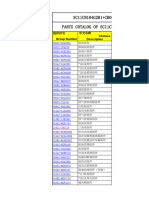

STERN TUBE L.O. PIPING DIAGRAM PAGE

广船国际 K4640435

艉管滑油系统 5 /7

W.PRESS. N.DIA. WEIGHT STANDARD NO. COMPUTER

CODE ITEM MATERIAL Q'TY. DESCRIPTION ON NAMEPLATE REMARKS

(MPa) (mm) (kg) OF ACCESSORY CODE

代号 名称 工作压力 通径 材料 数量 重量 标准号或图号 上机代号 铭牌刻字内容 备注

SPECTACLE FANGE STEEL

US25 0.6 25 1 BS6025 GB/T4450-1995

眼镜法兰 钢

PAGE

广船国际 K4640435

6 /7

LENGT

SPEC.

N.DIA. H MATERIAL CONNECTION PIECE

NO. APPLICATION OF PIPES OF PIPE REMARKS

(mm) (ABOU 材料 连接件

(mm)

T) (m)

NAME MARK Q'TY.

序号 管子用途 通径 管子规格 估算长 STD.NO. 标准号 备注

名称 牌号 数量

S/T L.O. PIPES Seamless Steel CLASS 3

1 40 48x4 25

艉管滑油管 无缝钢管

S/T L.O. PIPES Seamless Steel CLASS 3

2 32 42x4 50

艉管滑油管 无缝钢管

VENT PIPE Seamless Steel CLASS 3

3 50 60X4 2

透气管 无缝钢管

COPPER PIPE FOR PRESS. G. copper

4 8x1.5 1.0

压力表接管 紫铜管

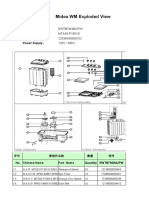

According the manufacturer’s information: HULL NO. 05130013/15 K4640435 STERN TUBE L.O.SYSTEM 第7页 NO.

Placement of the gravity tank is adapted for a pressure gradient of 0.1 船号: /16/17/20/21 艉管滑油系统 共7页 TOTAL

to 0.3 Bar at maximum draft of the vessel.

(I) First calculate maximum depth to propeller shaft:

Hw= Dmax. - X1 = 13.5 - 3.5 = 10 (m)

Dmax.: water level at maxmum draught US-013(40)

X1 : distance between propeller and base line

S/T L.O.STOR.TK.

(II) Distance between the propeller and gravity tank:

US-008(32)

艉管滑油储存柜

Calculation use a typical density of the oil with 900Kg/m (900L)

X2 = Hw×1.14 + 1.20 = 10×1.14 + 1.2=12.6(m)

US20

根据厂家资料:

艉管重力油柜的安装高度应能满足在最大重载条件下, 其产生的压力梯度为0.1

~ 0.3Bar.

1.螺旋桨的最大深度:

Hw= Dmax. - X1 = 13.5 - 3.5 = 10 (m) US16

US15 US18

Dmax.: 重载水线

X1 : 螺旋桨中心线与基线的垂直距离

US19 US04 US24 US25

2.螺旋桨中心线与重力油柜的垂直距离: US-009(32) (25)

US-051(??)

计算采用典型的油的密度, 为900Kg/m

X2 = Hw×1.14 + 1.20 = 10×1.14 + 1.2=12.6(m) S/T L.O.GRAV. TK.

艉管重力油柜(80L)

US-012(32)

US-001(32)

US-006(40)

LAL

1903 US20

US-011(40)

US07

US-014(32) US08

US06

US05

US-015(32) US09

12.6 0 m

US-004(40) US17

+2

US-019(32)

850

US22

US-002(32)

US-010(40)

S/T.OIL.TRANSF.PUMP

艉管滑油输送泵

US10

0.5m3/h 0.35MPa

US21

US03

STERN TUBE

US-005(32)

US13 US-016(32)

常闭

NORMAL CLOSED

US14

US-017(32) US-003(40) US11

Sampling

Procedure US02

US-018(32)

常闭

US23 NORMAL CLOSED US12

常闭N.C. FS LAH

1905

The sampling procedure for stern tube L.O. system:

1. The sampling procedure to be based on the stern tube L.O. system diagram (K4640435). S/T L.O.SLUMP TK.

2. First of all, closing the stop valve US11 which control the L.O. flowing from stern tube to 艉管滑油循环柜

stern tube L.O. drain tank. 1000L

3. Open the stop check valve US13/US14, then open the stop valve US12 and take oil US01 FS LAL

1904

samples from the outlet of stop valve US12.

After the sampling, recover the system.

You might also like

- Loncin 250 ManualDocument19 pagesLoncin 250 Manualdvdpt100% (1)

- Liugong CLG835H Parts ManualDocument499 pagesLiugong CLG835H Parts ManualVontext92% (13)

- SC4503-462-04 Lo Stern TubeDocument7 pagesSC4503-462-04 Lo Stern TubeLam Phuc TuNo ratings yet

- M-14 Incinerator Piping DiagramDocument8 pagesM-14 Incinerator Piping DiagramVivek LakhwaniNo ratings yet

- M-16 L.O. Service Piping DiagramDocument8 pagesM-16 L.O. Service Piping DiagramVivek LakhwaniNo ratings yet

- ZHSC4674-510-03 Er Oily Water Separating SystemDocument6 pagesZHSC4674-510-03 Er Oily Water Separating SystemSergey shapovalovNo ratings yet

- Bilge Ballast and Fire SystemDocument16 pagesBilge Ballast and Fire Systemh.kazemNo ratings yet

- M-17 L.O. Drain Piping DiagramDocument6 pagesM-17 L.O. Drain Piping DiagramVivek LakhwaniNo ratings yet

- JH512-054-14 Fuel Oil Transfer SysDocument9 pagesJH512-054-14 Fuel Oil Transfer SysGMlexuz NamikazeNo ratings yet

- M-29 Steam Tracing Piping Diagram in Engine Room PDFDocument5 pagesM-29 Steam Tracing Piping Diagram in Engine Room PDFАндрей ХмелярчукNo ratings yet

- Bể tách khí nước 汽水分離桶Document1 pageBể tách khí nước 汽水分離桶Hoàn DươngNo ratings yet

- Cruisym 300é Ä Æ ÅDocument62 pagesCruisym 300é Ä Æ Å张连杉No ratings yet

- MPDocument5 pagesMPsf wNo ratings yet

- 1 1PG3111348Document41 pages1 1PG3111348AndreyIvanov100% (1)

- JTDocument2 pagesJTsf wNo ratings yet

- M C 25 Và 26 (NSX Diamond Power)Document1 pageM C 25 Và 26 (NSX Diamond Power)Erick100% (1)

- WL-530 Series Parts List (2020V)Document5 pagesWL-530 Series Parts List (2020V)Diego ChamorroNo ratings yet

- S1183M402103E ER Local Press Water Mist SystemDocument7 pagesS1183M402103E ER Local Press Water Mist SystemPhan Cao An TruongNo ratings yet

- Cummins KTA19 PartsDocument75 pagesCummins KTA19 PartsAnky Ismas0% (1)

- 刀闸阀 WB11Document7 pages刀闸阀 WB11sf wNo ratings yet

- 刀闸阀 WB12Document5 pages刀闸阀 WB12sf wNo ratings yet

- XTD-2500ID 说明书Document6 pagesXTD-2500ID 说明书Edward FernandezNo ratings yet

- SO10831 Parts Catalogue (08!1!25第1版) Model6BTAA5.9-G2Document95 pagesSO10831 Parts Catalogue (08!1!25第1版) Model6BTAA5.9-G2ValeriyNo ratings yet

- LDLC R01 2018KW CNDocument86 pagesLDLC R01 2018KW CN王StevenNo ratings yet

- BOP Part - Remain PDFDocument12 pagesBOP Part - Remain PDFGusti Prasetyo Rendy AnggaraNo ratings yet

- DHB06G0094 SL30WDocument104 pagesDHB06G0094 SL30Wheri setyonoNo ratings yet

- Liugong CLG855NDocument745 pagesLiugong CLG855NAfry Andi100% (1)

- Data Sheets High Pressure Stop Valves Model Va500 Asme Sempell ZH ZH CN 5445894Document8 pagesData Sheets High Pressure Stop Valves Model Va500 Asme Sempell ZH ZH CN 5445894david.smithNo ratings yet

- MRC40Document3 pagesMRC40mariguanixNo ratings yet

- 刀闸阀 WB14EDocument9 pages刀闸阀 WB14Esf wNo ratings yet

- Despiece EWIE10F3MMW EWIE10F3MMWDocument7 pagesDespiece EWIE10F3MMW EWIE10F3MMWCarmen Adriana Garcia MendozaNo ratings yet

- 6 Cylinder Spare Parts Catalogue YTO 120 140HPDocument93 pages6 Cylinder Spare Parts Catalogue YTO 120 140HPFlip SasbrinkNo ratings yet

- SC11CB220G2B1+CB0264发动机配件目录清单 (XCMG)Document205 pagesSC11CB220G2B1+CB0264发动机配件目录清单 (XCMG)Khee SoonNo ratings yet

- 刀闸阀 HXDocument8 pages刀闸阀 HXsf wNo ratings yet

- Dongfeng Cummins Engine Parts CatalogDocument84 pagesDongfeng Cummins Engine Parts CatalogZelalem100% (1)

- Despiece Ewie09f3mmw Ewie09f3mmgDocument7 pagesDespiece Ewie09f3mmw Ewie09f3mmgCarmen Adriana Garcia MendozaNo ratings yet

- 4bta3.9-G2 So12016Document72 pages4bta3.9-G2 So12016Isaac Perez Salas100% (2)

- 阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。 阀门完全开启后, HPT阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。Document5 pages阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。 阀门完全开启后, HPT阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。sf wNo ratings yet

- 4BT3.9-G2 PartsDocument73 pages4BT3.9-G2 PartsAlex barker0% (1)

- Manual de Partes Cummins 4BTA3.9-G11 SO13596Document77 pagesManual de Partes Cummins 4BTA3.9-G11 SO13596Cristian Riveros U100% (2)

- 6CTA8.3-G2 - Uni PilesDocument81 pages6CTA8.3-G2 - Uni PilesThomas Joseph VellanjilickalNo ratings yet

- Frenos Liugong Cargadora-856Document19 pagesFrenos Liugong Cargadora-856Nikolay Guerrero100% (1)

- Yto Series 6 Cylinders Diesel EngineDocument110 pagesYto Series 6 Cylinders Diesel EngineAngel jose100% (1)

- 109EPa043WQ45-WL - (R38M) cn-4Document16 pages109EPa043WQ45-WL - (R38M) cn-4JoséNo ratings yet

- Data Sheet VFB-002 VSP15205x 0108 ChineseDocument10 pagesData Sheet VFB-002 VSP15205x 0108 ChinesezhulibingNo ratings yet

- 02-02 - D1VW NG06标准型电磁方向阀Document8 pages02-02 - D1VW NG06标准型电磁方向阀ZHOUNo ratings yet

- SC11CB184G2B1+CB0035+20141205 (Engine Parts Book)Document198 pagesSC11CB184G2B1+CB0035+20141205 (Engine Parts Book)Khee SoonNo ratings yet

- 阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀门完全开启后, HL阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。Document9 pages阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀门完全开启后, HL阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。sf wNo ratings yet

- SR4 max-LX350T-5ADocument55 pagesSR4 max-LX350T-5AersinkavakliNo ratings yet

- Engines Lc190f、Lc190fd、Lc185f、Lc185fd Part ListDocument24 pagesEngines Lc190f、Lc190fd、Lc185f、Lc185fd Part ListRajendra MehtaNo ratings yet

- SC4490G1 463 01 - Er Sea Water Cooling SystemDocument8 pagesSC4490G1 463 01 - Er Sea Water Cooling SystemReynee Shaira Lamprea MatulacNo ratings yet

- Dongfeng Cummins Engine Parts CatalogDocument85 pagesDongfeng Cummins Engine Parts CatalogNouman SarwarNo ratings yet

- Water Pump 2″-3″ LC50ZB23-3.1Q (A) 、LC80ZB20-3.1Q (A) 、LC80WB30-4.5Q、LC50ZB60-4.5Q SPART LISTDocument35 pagesWater Pump 2″-3″ LC50ZB23-3.1Q (A) 、LC80ZB20-3.1Q (A) 、LC80WB30-4.5Q、LC50ZB60-4.5Q SPART LISTCarloss CastroNo ratings yet

- Despiece EWTB7M3MUPW FWTB7M3MUPWDocument7 pagesDespiece EWTB7M3MUPW FWTB7M3MUPWCarmen Adriana Garcia MendozaNo ratings yet

- 阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。 阀门完全开启后, HP阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。Document9 pages阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。 阀门完全开启后, HP阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。sf wNo ratings yet

- DLDAZ Full ZH Metric A4Document2 pagesDLDAZ Full ZH Metric A4caiNo ratings yet

- 阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。 阀门完全开启后, HG阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。Document10 pages阀板双侧具有压环系统,实现双向密 封。贯通阀板可保证高浓度和静态介 质的可靠关闭。 阀 板 从 打 开 到 关 闭 位 置 始 终 保 持 支 撑,并且顶部结构坚固稳定,确保可 靠密封。 阀门完全开启后, HG阀门的孔径几乎 没有腔室,可实现很好的流通性能。 在该位置,压环和阀板可以很好的保 护聚四氟乙烯( PTFE)阀座。sf wNo ratings yet

- 东康6CTA8.3-C190 II零件手册 - MOTOR GR180 PDFDocument88 pages东康6CTA8.3-C190 II零件手册 - MOTOR GR180 PDFJ Dany T. Delgado50% (2)

- F-Kart Engine Parts ListDocument13 pagesF-Kart Engine Parts ListkumaNo ratings yet