Professional Documents

Culture Documents

Butterfly Flange: SAE 1 " To SAE 5"

Uploaded by

Hydro PierivOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Butterfly Flange: SAE 1 " To SAE 5"

Uploaded by

Hydro PierivCopyright:

Available Formats

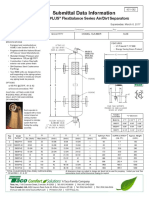

Butterfly Flange

SAE 1 ½” to SAE 5”

The asa butterfly flange with SAE and DIN connections allows the combination with an elastic element (rubber compensator) to make a short

compensating and economical connection with the pump port. The lever position can be changed through our new mechanism. The handle

direction (clockwise or counter clockwise) can be changed by turning the switch bracket. Please note that the butterfly flange may only be opened

in mounted state and with greased or lubricated sealing. The adapter flange may only be welded with demounted butterfly flange.

possible valve positions and

actuating directions*)

*)

…the shown valve is attached with the optional

available inductive limit switch. Please contact us to

discover all functions and options.

Technical Data

description order number size A B C D E F G ØH J M Ø N NW TK weight

SAE DIN [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [kg]

AF 40 SDA0040 1 ½“ 40 70 35,7 102 120 162 25 43 60 23,5 M12 13,5 40 110 2,17

AF 50 SDA0050 2“ 50 77,8 42,9 111 112 155 20 43 73 35,8 M12 13,5 48 125 2,2

AF 63 SDA0063 2 ½“ 65 89 50,8 111 119 161 20 40 83 55,3 M12 13,5 63 125 2,15

AF 80 SDA0080 3“ 80 106,4 62 144 145 187 20 41 95 73,9 M16 18 80 160 2,98

AF 100 SDA0100 4“ 100 130,2 77,8 163 162 205 20 43 123 98,2 M16 18 100 180 4,01

AF 125 SDA0125 5“ 125 152,4 92 185 185 227 20 43 148 124,0 M16 18 125 210 4,8

Working Ranges

max. working pressure 7 bar (absolute)

max. differential pressure 6 bar

temperature range -20°C to +80°C

Materials

housing GGG 40, cast iron

lever steel

valve disc aluminium

seals NBR

Options

limit switch mechanical or inductive type

This data sheet shows a technical overview of our products. Please contact us if more exact information is needed. As we are constantly improving our products, their characteristics, dimensions and weights may also change, although

we do our best to incorporate these changes continually. The information in this data sheet is intended to be used as a first general guideline only. asa assumes no liability for any information therein, any errors, omissions, misprints,

nor any direct or indirect damages, losses or costs resulting therefrom. The cooling performance and the general technical values indicated in this catalogue are measured at a test bench according to asa testing procedures Because

there is no standardized testing procedure, tests used by other manufacturers could have different results. Due to different conditions in testing and application environments the cooling performance may also vary by +/- 15%.

Therefore we recommend all coolers to be checked under the system operating conditions. This is also true of vibrations and mechanical stress as well as for pressure peaks and thermal stress and any other relevant factors.

© asa hydraulik, January 2015

You might also like

- Parts Book Pc2000-8 - Lepbp2m800Document1,898 pagesParts Book Pc2000-8 - Lepbp2m800Nugroho Prasetyo100% (1)

- Yamaha Exciter 440 EX440 1980Document18 pagesYamaha Exciter 440 EX440 1980mkaukolaNo ratings yet

- Redutor GFTDocument4 pagesRedutor GFTIkaro MatosNo ratings yet

- CASE 580N EP Backhoe Loader Tier 4BDocument2,268 pagesCASE 580N EP Backhoe Loader Tier 4BCristian Fernando Tarifa Martinez67% (3)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- CRD Devices Ltd Industrial Actuator SpecificationsDocument4 pagesCRD Devices Ltd Industrial Actuator SpecificationsFlorent YIBOKOUNo ratings yet

- Autoclave Parker Needle ValvesDocument12 pagesAutoclave Parker Needle ValvesCarlig Radu MihaiNo ratings yet

- Installation and Maintenance Instructions For Three Phase Induction MotorsDocument9 pagesInstallation and Maintenance Instructions For Three Phase Induction MotorsAnibal QuezadaNo ratings yet

- Adapter Flange enDocument1 pageAdapter Flange enD.CORNEILLENo ratings yet

- Dust Collector Main Pulse Valves: FeaturesDocument4 pagesDust Collector Main Pulse Valves: FeaturesQuân TrịnhNo ratings yet

- Gemue 655 GBDocument4 pagesGemue 655 GBLucio J. Rojas R.No ratings yet

- Sr220 Case - PartesDocument882 pagesSr220 Case - PartesJorge Diaz Nestor MonsalveNo ratings yet

- GFT8140 A6veDocument4 pagesGFT8140 A6veHercules StyliarasNo ratings yet

- Parker-VOAC Motor PilyDocument16 pagesParker-VOAC Motor PilyHarwesterNo ratings yet

- mpfiltripentruAGC 20180131064751.556 XDocument19 pagesmpfiltripentruAGC 20180131064751.556 XBoghian ElenaNo ratings yet

- Style W489Document4 pagesStyle W489Ummes AhmedNo ratings yet

- GIW Technical Series: Pipe Flange BoltsDocument4 pagesGIW Technical Series: Pipe Flange BoltsTravis SkinnerNo ratings yet

- Dresser 3 Way ValveDocument24 pagesDresser 3 Way ValveAmjath Pallas100% (1)

- 6.75in Hemidril MotorDocument2 pages6.75in Hemidril Motorerdal aydinNo ratings yet

- Implementing DuraSquirt DTIs in accordance with AISC/RCSC 2.12Document6 pagesImplementing DuraSquirt DTIs in accordance with AISC/RCSC 2.12rob westoverNo ratings yet

- World Wide Fittings Catalog - BodyDocument230 pagesWorld Wide Fittings Catalog - BodywarrentimeNo ratings yet

- HIGH FLOW PULSE VALVESDocument4 pagesHIGH FLOW PULSE VALVESFelipe SalvatierraNo ratings yet

- World Wide Fittings Catalog - BodyDocument230 pagesWorld Wide Fittings Catalog - BodyasdfdfNo ratings yet

- Spidex OperatingDocument10 pagesSpidex Operatingwalk001No ratings yet

- NOCCHI A2L - A4L "IN LINEDocument10 pagesNOCCHI A2L - A4L "IN LINEzibbex555No ratings yet

- 3020-Plataforma 3020Document557 pages3020-Plataforma 3020Genival FaustinoNo ratings yet

- اینورتر اسانسورDocument40 pagesاینورتر اسانسور208020No ratings yet

- Screenshot 2022-07-14 at 12.30.24Document44 pagesScreenshot 2022-07-14 at 12.30.24zakkNo ratings yet

- TLB840R Hydraulic Testing GuideDocument13 pagesTLB840R Hydraulic Testing GuideLuisAntonioVegaParangueo100% (1)

- Electricmotor: Product DatasheetDocument5 pagesElectricmotor: Product Datasheetmichael gutierrezNo ratings yet

- Directional Control Valve: Service and Parts ManualDocument22 pagesDirectional Control Valve: Service and Parts ManualRichard SchmidtNo ratings yet

- PT 27 - Torch - F 15 203 C PDFDocument16 pagesPT 27 - Torch - F 15 203 C PDFAnonymous jOwMSp5lrkNo ratings yet

- Sanitary FittingsDocument29 pagesSanitary FittingsBudy GedhaBlackNo ratings yet

- Gate Valves Closing TorqueDocument6 pagesGate Valves Closing TorqueWaltico SaljareNo ratings yet

- Kailing ActuatorsDocument8 pagesKailing Actuatorsmanh hung leNo ratings yet

- TESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveDocument132 pagesTESTO ITC KORINNA 28mm Allargato: Monoblock Directional Control ValveHIDRAULICA MANSE SERVICIO TECNICONo ratings yet

- Planetary GearboxDocument4 pagesPlanetary Gearboxeaglego00No ratings yet

- Manual Pala Case 580NDocument1,820 pagesManual Pala Case 580Nmabertovallejo04No ratings yet

- Farymann Technical Data Engines After 1981Document1 pageFarymann Technical Data Engines After 1981emreorakNo ratings yet

- Motor and Application Data: ApplicationsDocument2 pagesMotor and Application Data: ApplicationsZineddine ALICHENo ratings yet

- MM T Frame Maintenance ManualDocument9 pagesMM T Frame Maintenance Manualneomar BaptistaNo ratings yet

- Everything You Need to Know About Norval Pressure RegulatorsDocument8 pagesEverything You Need to Know About Norval Pressure RegulatorsMohsen ParpinchiNo ratings yet

- Variable Speed AC Motor Drives Installation ManualDocument47 pagesVariable Speed AC Motor Drives Installation ManualWalther Ernesto Molina DominguezNo ratings yet

- Modular Lube Lubrication Systems: Divider ValvesDocument6 pagesModular Lube Lubrication Systems: Divider ValvesIbrahimAmroNo ratings yet

- L223 T3 PartsDocument908 pagesL223 T3 Partskevin100% (3)

- 5900 FlexBalance Plus Series Separators Submittal 401-082 102319Document1 page5900 FlexBalance Plus Series Separators Submittal 401-082 102319Rafael SalazarNo ratings yet

- Model GP-1000 Series Pressure Reducing Valve Installation & Operation ManualDocument14 pagesModel GP-1000 Series Pressure Reducing Valve Installation & Operation ManualJefanthony StevanoyaNo ratings yet

- Service Manual MS-GF20VA MS-GF25VA MS-GF35VA MS-GF50VA MS-GF60VA MS-GF80VADocument42 pagesService Manual MS-GF20VA MS-GF25VA MS-GF35VA MS-GF50VA MS-GF60VA MS-GF80VAjerrytzNo ratings yet

- Httplequoc vnuploadsuserfiles38AE PDFDocument6 pagesHttplequoc vnuploadsuserfiles38AE PDFnam nguyenNo ratings yet

- 1 Manual PDFDocument27 pages1 Manual PDFMehdi SoltaniNo ratings yet

- Auma 1Document2 pagesAuma 1hamidkatebiNo ratings yet

- RPM Limits - TIR068Document5 pagesRPM Limits - TIR068Sanjenbam SumitNo ratings yet

- FITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDocument9 pagesFITTING OPERATION and MAINTENANCE - Flexible Unit PWM SeriesDênis DáyolNo ratings yet

- Gfps-Dk-Technical Data Metal Butterfly Valve Type 039Document7 pagesGfps-Dk-Technical Data Metal Butterfly Valve Type 039Omar GuillenNo ratings yet

- SAW D ManualDocument16 pagesSAW D ManualjlmansillaNo ratings yet

- Liquid Level Switches: LS200 SeriesDocument3 pagesLiquid Level Switches: LS200 SeriesAdvenser GroupNo ratings yet

- Alfagomma - Oil & GasDocument115 pagesAlfagomma - Oil & GasIgor Bastos100% (1)

- HanbellRC2 TM ManualDocument109 pagesHanbellRC2 TM Manualdcallahanmasonbarry100% (3)

- Din en 853 2 SN: Wire Braid Hydraulic Hose Meets EN 853 2 SN, SAE 100R2 and ISO 1436 2SNR2Document1 pageDin en 853 2 SN: Wire Braid Hydraulic Hose Meets EN 853 2 SN, SAE 100R2 and ISO 1436 2SNR2Zoran JankovNo ratings yet

- Weil Mclain Parts Catalog CD Version 2010Document298 pagesWeil Mclain Parts Catalog CD Version 2010123anthonyNo ratings yet

- CHYHBH-AV32 - 4PEN471761-1C - 2019 - 09 - Installer Reference Guide - EnglishDocument108 pagesCHYHBH-AV32 - 4PEN471761-1C - 2019 - 09 - Installer Reference Guide - EnglishChris BrauchliNo ratings yet

- Effective Strengthening of Reinforced Concrete Corbels Using Post-TensioningDocument17 pagesEffective Strengthening of Reinforced Concrete Corbels Using Post-TensioningAlaa tahaNo ratings yet

- Breakwater: Are Structures ThatDocument5 pagesBreakwater: Are Structures ThatporkopyoNo ratings yet

- Kits Opcionais DoosanDocument75 pagesKits Opcionais DoosanChakroune100% (2)

- Range of Trim MaterialsDocument1 pageRange of Trim MaterialsAbu___AbdullahNo ratings yet

- Chem LiteDocument2 pagesChem LiteICPL-RWPNo ratings yet

- Structural EngineeringDocument12 pagesStructural EngineeringBTE100% (1)

- Five-Year Limited Warranty for BP CeilingsDocument4 pagesFive-Year Limited Warranty for BP CeilingsRosa OsbornNo ratings yet

- Building Services 1Document17 pagesBuilding Services 1SubhraJyotiBorahNo ratings yet

- Brosur Pipa Bertulang RBDocument1 pageBrosur Pipa Bertulang RBPP Kulon ProgoNo ratings yet

- P01511April2019 PDFDocument10 pagesP01511April2019 PDFswazsurvNo ratings yet

- Supreme Technology 2-Zinc Alloy&ZincDocument6 pagesSupreme Technology 2-Zinc Alloy&ZincTran Duong QuangNo ratings yet

- Basf Masterfiber 018 TdsDocument2 pagesBasf Masterfiber 018 TdsfffffffgggNo ratings yet

- Urban & Rural - Lecture 3Document16 pagesUrban & Rural - Lecture 3Anchal ShahNo ratings yet

- 09 Energy&Aeronautics&AuronauticsDocument211 pages09 Energy&Aeronautics&AuronauticsDorisman Feriandi SimorangkirNo ratings yet

- FRANKI Simplex SipoviDocument4 pagesFRANKI Simplex SipoviMiroslav NovakovicNo ratings yet

- Allen, D.E. - Building Vibrations From Human ActivitiesDocument12 pagesAllen, D.E. - Building Vibrations From Human ActivitiesHugo VerissimoNo ratings yet

- Esma Sultan Yalısı RaporDocument10 pagesEsma Sultan Yalısı RaporSümeyye Kevser UmarNo ratings yet

- Luxfer LCX SCBA Care and Maintenance Poster 2021Document1 pageLuxfer LCX SCBA Care and Maintenance Poster 2021sergio farfan medranoNo ratings yet

- Y-Pattern Check Valves FK 30.64 (7) GB: Primary CharacteristicsDocument2 pagesY-Pattern Check Valves FK 30.64 (7) GB: Primary CharacteristicsNguyen KhaNo ratings yet

- Use of Nanomaterials in Cementing ApplicationsDocument0 pagesUse of Nanomaterials in Cementing ApplicationsMobeen MurtazaNo ratings yet

- (Activity Sheets in Tle (Electronics) Grade 9 Quarter 1, Week 1)Document7 pages(Activity Sheets in Tle (Electronics) Grade 9 Quarter 1, Week 1)MaicaNo ratings yet

- Build cost centre codes and descriptionsDocument1 pageBuild cost centre codes and descriptionsKwen Codizal MendozaNo ratings yet

- Bye Laws For MirzapurDocument6 pagesBye Laws For MirzapurUtkarsh SharmaNo ratings yet

- Making Dolls' Houses in 1/12 Scale (1995)Document200 pagesMaking Dolls' Houses in 1/12 Scale (1995)Nickiedeposie100% (2)

- 7856.n1.40703.03-Ofgi 4070Document2 pages7856.n1.40703.03-Ofgi 4070Claudio Valencia MarínNo ratings yet

- HVAC EPCC PROJECT CHECKLISTDocument34 pagesHVAC EPCC PROJECT CHECKLISTTakrimi IsmailNo ratings yet

- Sintap BRITISH STEEL The Significance of Y-T RatioDocument33 pagesSintap BRITISH STEEL The Significance of Y-T RatioAshish TanejaNo ratings yet

- Material Approval & Specification Comparison SheetDocument3 pagesMaterial Approval & Specification Comparison Sheetfrancisbautista100% (1)