Professional Documents

Culture Documents

Delta

Delta

Uploaded by

ay0 ratings0% found this document useful (0 votes)

11 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views8 pagesDelta

Delta

Uploaded by

ayCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

|

Series

DFC-60

.

mh

‘The company was incorporated in 1993

by experienced and professional

entroproncurs, who are committed to.

produce a quality range of products.

Y 1 Almost two decades of a strong,

Th i | customer-focused approach and the

pt e| continuous quest for world-class quality

have enabled tho company to attain and

sustain leadership in all its major lines of

business. The company comprises of

professionally qualified persons having passed through the

grass root level in sales, service and commitments.

As part of company's continuous improvement program, its

facility has been certified to ISO 9001 by an acoredited

certification body. The brand DELTA is also hacked by the All

India approval with The E-In-C, Military Engineering Services

(Ministry Of Defence).

DELTA COOLING TOWERS P LTD. has had an excellent tack

record, thanks to its focus on quality and customer care.

Company's commitment towards "TOTAL CUSTOMER

SATISFACTION’ has been the driving force behind its climb near

to tho cummit. Company constantly endoavors to fulfill this

commitment by emphasizing on quality, reliability and service,

With persistent dedication towards quality management Delta

has successfully become the leader in acquiring quality

certifications and approvals by various departments. No doubt

Delta's struggle to perfection has been acclaimed as a milestone

in the industry.

APPLICATIONS

Air Conditioning & Refgn. Systems

Compressors & Chillers

1H Injection & Blow Moulding Machines

§ Diesel Generator Sets

§ Induction Furnace

™ Process Cooling

Chemical Process

Pharmaceutical Industries

‘Oxygen Plants

Welding Machines

m Extruders

™ Dry Cleaning Machines

And many more,

DELTA'S DFC-60 sories cooling towers comes into

rectangular shape after erection at customer's site.

These cooling towers utilise the induced

draught counter flow principle of

operation. The fan creates vertical air

movement up the tower across the filling

in opposition to water flow. Thus the

coldest water contacts the driest air.

Heated circulated water enters via the

hot water inlet passing through fixed non

clogging spray splash distributed ovor

the heat exchange fills.

SPECIAL FEATURES |

High Efficiency

Fiberglass Reinforced Plastic (FRP)|

Construction

Induced draught fans with manually

adjustable pitch

Even water distribution with splash |

caps

Special drift eliminator to reduce

maximum drift loss

Part load operation may be provided!

Competitive cost

Fan Mctors: Special Cooling Tower motor

wih extended shaft -1P-55 protecion

Fan : Die Cast aluminium (LM).

Fan Ssreon & Hardware:

Manufactured fee hot-dp gatvanisad

Seal conf to DELTA Ngh design stancarda

Fan Gylnder: Designed io previe optimum

airflow and reduced ar turtulance whist

proving even airflow tough PVC Ts,

Roof Tray. Heavy duty

FRP roof ray - smooth gel coat tis.

\Water Distibution: Consits

PVC Dit Eliminatrs: Extruded"C’ Section

Designed to ater drection inert Speco

ee oraiise sit oss ‘omply wity DELTA standards

Casing : FRP

heavy duty casing wih

smocth gel coal frieh

‘ir ntake Mesh

a vor

ee High Effcency honey comb fill packs,

Configured te provide maximum alto

Water contact andlow sit preseu

Cold Water Basin / Botiom Tray’ drop, te ensure aficion heal transfor

FRP bottom vay works ae cold wait Ly ‘and minimise powar roqurements.

es =O 8 euleual

Note:

11. Illustration shown above has been made as per the design of cooling towers of

OTR or higher capacities,

2. Al models are avellable in grey colour normaly, other colours to match the

environment can be made available on request.

3. Cooling towers smaller than 15TR are not

supplied with ladder.

4. AEMS parts are hot dip galvanised.

5. Cooling Tower comes into existence after being

erected on concrete fourdation and MS base

frame provided by the customer at their site

DELTA COOLING TOWERS P LTD. specialises in cooling tower

technologies. For over 2 decades the pursuit of excellence and product

performance have established DELTA as the criterion of the industy.

‘More and more industrial, alsconditioning, steel, plastic, power

generation, chemicals and processing industries rely on DELTA

cooling technologies for uncompromising quality, guaranteed thermal

performance design and engineering excellence.

‘Whea it comes to cooling for high precision and agile machines,

‘owners, consultants and contractors look upon DELTA to provide

optimum cocling for their applicetions,

DELTA cooling technologies help HVAC eystems provide optimum

living, working and recreational environments in smell to large,

commercial and industrial facilities.

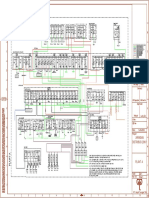

DIMENSIONS & TECHNICAL DATA

DESIGN | TR SIZE S(MM) FAN DIA(MM) | MOTOR HP | MOTOR (RPM) | OPERATING

Nos. | cap | L xX WXH WEIGHT (KG.)

15) X 680 K 2300 450 05 2400 20

B00 X 800 x 2300 450 05 40 2

95) X 960 X 7300 600 10 4440 200

195) X 950 X 2300, 600 10 0 350

‘00 x 1100 x 2800 m0 10 60 400

‘00x 1100 x 2800 700 20 sao ‘450

4250 1260 x 2300, 00 20 960 00

4250 1250 x 2300, 00 20 440 0

41500 x 1500 x 2300, 1209 20 960 750

41800 x 1500 x 2300, 0) 20 960 0

4850 X 1850 X 3000, 1200 20 940 0

070 | 70 | 1850x1850 x 3000, 1200 30 0 1100

6080 | 30 | 2250x 1960 x 3000, 1200 30 960 1200

e007} 90 | 2250x2260 x 2900 200 30 960 200

ero | 110 | 2550x2260 x 2000, 200 50 960 600

125 | 425 | 2550x2560 x 2000, 1500 50 0 1000

150 | 15) | 250 x 2as0 x 3000, 1500 75 960 240)

ons | 175 | 3150x2850 3000 150 75 0 z00

6200}. 207 | 3450 x 3150 x 3000, 1800 15 ro 30)

6225 | 225 | 3450x3450x 3100, 1800 15 m9 3600

6250 |. 250__| 3750 x 4450 x 3000, 2x1200 2x15 2x 60 20)

ems | 275 | 4350x3160x 3000 2x1200 2x75 2X $60 200

6200 J. 300 | 4350 x 2450 x 3900, 2x1200 2x75 2x a0 4600

eas | 325 | 4350x2760 2000 2x 1500 2x75 2x 960 000

250350 | 4700x 3760 x 2000, 2x 1500 2x75 2x 60 40)

ears | 375 | 4350x4950 3100, 2x 1500 2x75 2x 720 200

6400s}. 400.5000 X 4050 x 3100, 2x 1500 2x15 2x 720 e200,

a5 | 425 | 5000x4350 3100 2x 1800 2x15 2x 720 roo

6450}. $50. | 5000 4700 x 3100, 2x2100 2x 109 2x 720 7200

500 | 500 | 6200%4050x 3100, 2x2100 2x 109 2x 720 7300

6550_}.550._.|.6200X 4360 x 3100, 2x2100 2x 109 2X 120 #300,

‘as00 | B00 | 6200xsoco x 3100, 2x2100 2x 100 2x 720 00

650 | 850 | 6200X 6300 x 2200, 2x2400 2x25 2x 720 +0000

700 | 700 | 6200x seco x 2200, 2x2400 2x 125 2x 720 10700

4750 | 75) | 6200x s9c0 x 3900, 2x2400 2x 125 2x 600 11900

jes000" 800 | 6500x200 x 3300, 2x2400 2x 125 2x e00 12500

5035 | 6500 x 8500 x 3300, 2xzm0 2x 180 2x0 13000,

800 | 900 | 6800x e500 x 3300, 2x2m00 2x 160 2x eo 13800

etKo_—| 1000 | 8000x 6200 x 3300, 2x2m00 2x 150 2x 600 15800,

‘8690 X 6200 X 2200 4x2100 4x 100 4x 720 16800

9250 x #500 x 2200, 4X 2100 4X 100 4X 720 16900,

Nominal TR capacty has teen computed on the basis of water circulation rate of 4 USGPMTR at 97 5-$0 83" F coniitons.

Performance is based uoon insallaton in an outdocr location and absence of nearby structures which might prevent free

Colina towers do not include base flame, motor starter, pumps. valves. controls,

foundation, ppe ftings etc

The jab exclues civ works, electical work, plumbing or piging work ete

All models are avaiable in grey colour normally other colours to maich

fenvironment can be made avalable on spacal request.

Cooling towers smaller than 15 TR ate not supglied with the ladder,

{AIMS parts are hot cip gavonised and hardwares are G.

‘The company operates a polcy on continues improvements and resorves the

right to make alterations in designs and specticaton wihout any noice.

DELTA'S ACTIVITIES INCLUDE

| Manufacturing of FRP counter flow cooling tower in

Round Bottle shape. Series — DFC-50.

™ Manufacturing of online Non Chemical Water

Treatment Device.

™ Manufacturing of Shell & Tube Type Heat Exchangers,

Chillers and Condensers.

Pipe line jobs on tun-key basis.

Manufacturing of FRP Air Washers.

Maintenance, repair, modification, upgradation,

overhauling of all type of cooling towers.

™ Custom made spare parts of all makes.

ISO 9001

DELTA WELCOMES YOUR ENQUIRY

To discuss and suggest best cooling tower suitable for your

specific needs, following are the date requirements:

Type of Application

Water Circulation Rate.

‘Temperature of water entering to the Cooling Tower.

‘Temperature of water leaving the Cooling Tower.

Ambient Wet Bulb Temperature.

‘Space! Power restrictions, if any.

PAREN

DELTA COOLING TOWERS P. LTD.

‘Ist FLOOR, BHAGWATI SADAN, PLOT NO8, COMMUNITY CENTRE,

BH-BLOCK, SHALIMAR BAGH, DELHI-110 088 (INDIA).

PHONES : +91-11- 27498801, 27495802, 27495803

FAX: +91-11-27495804

E-MAIL: delts@deltactowers.com WEBSITE : www.deltactowers com

Connect with us on Facebook

www.facebook.com/Deltacooling

eas EY

© Copyright registered anc owned by Delta Cooling Towers Put. Lid

Detar Potcal Sten Caneatats 9E175771

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Drawing Jmu.22414Document13 pagesDrawing Jmu.22414ayNo ratings yet

- Drawing Jmu.22414Document1 pageDrawing Jmu.22414ayNo ratings yet

- Drawing Jmu 22428 (Rev.0)Document5 pagesDrawing Jmu 22428 (Rev.0)ayNo ratings yet

- PT. Gajah Tunggal TBKDocument1 pagePT. Gajah Tunggal TBKayNo ratings yet

- Penggantian Breaker Capasitor Bank 20kV Berikut AksesoriesDocument1 pagePenggantian Breaker Capasitor Bank 20kV Berikut AksesoriesayNo ratings yet

- Jmu 1905 - Isometric Piping-Line 5-6Document1 pageJmu 1905 - Isometric Piping-Line 5-6ayNo ratings yet