Professional Documents

Culture Documents

TB Vol1 No4

TB Vol1 No4

Uploaded by

Aqidi Mohammad0 ratings0% found this document useful (0 votes)

7 views3 pagesOriginal Title

TB-VOL1-NO4

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views3 pagesTB Vol1 No4

TB Vol1 No4

Uploaded by

Aqidi MohammadCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

REGULATING LINE PRESSUHE.

Most transmissions use a_boost

valve to help adjust the position of

the main pressure regulator valve to

regulate line pressure. If the

hydraulic integrity of the boost

valve assembly is compromised due

to wear, proper line pressure regula

tlon will be affected, which could

result in: soft or harsh shifts, slide

shifts, slips, flares, burned clutches

and bands, broken parts, and/or

delayed reverse. Since line pressure

is critical to the overall health and

proper functioning of the transmis-

sion, the boost valve assembly

should be inspected for wear during

any rebuild. When applicable,

Sonnax provides details on how to

WAT (Wet Air Test) or perform a

captive hydraulic test using ATF

and low air pressure on these

assemblies while still in the pump

or valve body casting. This is a

oor line 1

Sot shits

Scar)

5

quick and simple method_ for

checking excessive wear that affects | jog :

function Tee aor 2 Semte

When inspecting boost valve | p@tam aazaw 7

assemblies, tere seem to be as | Premature chiteh/

many different designs as there are band failure

transmissions. Some assemblies are gg ‘

made from steel, while others are Sirs cuteh faiture

manufactured. from aluminum

Some assemblies have only one a@uD »

valve spool, while others have two Saftshift, tow fine

or three spools, and a few transmis- Pres

sions (like the 41.60) even have two

A904 rz, camuma, 10

boost valve assemblies in the pres- “mums

sure regulator bore. Some boost — Siippagein reverse

valves have different size ratios

available for the same transmission. G4Ab rans, "

Why the differences?

The choice of base material for

boost valve assemblies is very

important, but is best left for its

(Continued on Page 2)

be NC

pore

Seca

Pearcy

Pl ne eens eae

aed

Cry

Brae

Cost

eur

ou

Seay

1-2 or 3-4 shift

ie

ees

SE acoy

Low line rise

oe MeomCo me

STS

youl

installs in just

pyre ates

Rone ee

A

acc

own technical article. In examining why boost

valve assemblies have varying numbers of aitical

spool valves, it can be generalized that the number

of spools coincides with the number of different

circuits playing a role in regulating line pressure.

‘These circuits vary by transmission, and whether

the unit Is hydraulic oF electronic also makes a dif-

ference,

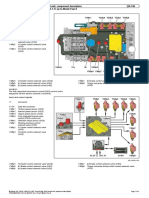

For example, the C6 (Figure 1) and AALD transmis-

sions each have a 3-spooled boost valve, The valve

body bore cross-section of the C6 shows the pres-

sure regulator valve in the maximum line pressure

position, as no excess line pressure is beng,

exhausted back to the sump. In this hydraulic

unit, modulated line or throttle valve (TV) pres-

sure is always at the small diameter of the boost

valve during vehicle operation. The heavier the

throttle, the higher the TV pressure, and the high-

er the line pressure. During reverse line, pressure is

applied to the middle boost diameter. The reacting

area of the reverse to TV spools is less than the TV

area alone. Reverse pressure will be greater than TV

because the incoming pressure is the same as line.

‘TV pressure is limited to an average of 80 psi max-

imum. Pressure is applied at the largest boost valve

spool only during increased torque demands, such

as heavy throttle, by balancing govesnat and TV

pressures at the cufback and line pressure coast

valves.

Another similarity between the A4LD (Figure 2)

and the C6 is that they each have different size

ratios available for the boost valve assembly.

Generally speaking, the larger ratio or larger spool

diameters are used in Vehicles used for heavy duty

or high performance applications, This is because

the boost pressures react on a greater surface area,

resulting in more line pressure and faster line rise.

‘The E4OD and AXODE transmissions each have a

2-spooled boost valve.The valve body bore cross-

section of the E4OD (Figure 3) shows the pressure

regulator valve in low line pressure position, as

excess line pressure is routed back to the sump. In

this electronic unit, EPC (electronic pressure con-

ten Reet e eee)

Y Gaad opt

v

FO Mi

oe

trol) is applied at the small diameter of the boost

valve. This solenoid pressure Is controlled by the

‘computer within a preset range for precise line con-

tol. This causes the boost vaive to be more active

than in hydraulic units, which can lead to prema-

ture wear of the sleeve, During manual low or

reverse gear, when increased torque demands are

required, additional pressure is applied to the boost

valve at ‘the large spool, positioning the pressure

regulator valve into a higher line pressure position,

In the AXODE (Figure 4) unit, only reverse and EPC

pressures are used to modify Tine pressure.

In the AODE, the boost valve only has one reaction

diameter. The cross section of this pressure regula-

tor bore (Figure 5) shows that only reverse pressure

is used to adjust line pressure via the boost valve

assembly. EPC pressure applies directly on the pres-

sure regulator valve spool for positioning. So in this

instance, a worn boost sleeve will predominantly

result in reverse engagement/pressure complaints,

but can also allow some EPC pressure to exhaust

and create fine rise-related problems in forward

gears, Shift quality complaints, clutch/band failure

Ange

oe

;

2 i?

ewe

Pree

eg abe

het Tt

ee eee ee

and broken parts caused by uncontrollable line

pressure will result if excessive wear occurs between

the pressure regulator valve and its bore.

In Chrysler RWD units (Figure 6), do not use the

conventional "boost valve,” but rather a reducing

valve, as the function of the line pressure plug is

actually to reduce main line pressure. The forces

acting to keep the pressure regulator valve in the

higher tine pressure position are the two springs

and TV pressure acting on the throttle pressure

plug. Balance line pressure acting on the pressure

regulator valve, as well as line pressure on the

throttle pressure plug and line pressure plug, com-

bine to reduce line pressure,

Although there are many differences between

boost valve assemblies for specific transmissions,

they all function to adjust main line pressure,

Make a habit of checking these parts during any

rebuild, and if excessive wear is found, replace

them with a quality assembly. This will improve

the shift quality, the clutch and band life and keep

the transmission on the road.

wall Cea ate

be

nse

aiid

ein

rns

Tom fw

7]

J

inp

Va ae

Yo

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Of Your Slips, Bumps, & Shudders With These Unique TCC Control FixesDocument3 pagesOf Your Slips, Bumps, & Shudders With These Unique TCC Control FixesAqidi MohammadNo ratings yet

- Can Bus ManualDocument31 pagesCan Bus ManualAqidi MohammadNo ratings yet

- Mercedes-Benz - АКПП 722.3 - 722.4 - 722.5 - 722.6Document229 pagesMercedes-Benz - АКПП 722.3 - 722.4 - 722.5 - 722.6Aqidi MohammadNo ratings yet

- 722 - 9 VB Removal-Installation Guide EditedDocument7 pages722 - 9 VB Removal-Installation Guide EditedAqidi MohammadNo ratings yet

- CAN Part 2 of 3Document22 pagesCAN Part 2 of 3Aqidi MohammadNo ratings yet

- CAN Part 3 of 3Document22 pagesCAN Part 3 of 3Aqidi MohammadNo ratings yet

- VGS Control Unit, Component DescriptionDocument4 pagesVGS Control Unit, Component DescriptionAqidi MohammadNo ratings yet

- Aim Infotech: Bosch Motorsport Abs M4 Kit 500Kbs/1Mbs Abs M5 Kit 500Kbs/1MbsDocument7 pagesAim Infotech: Bosch Motorsport Abs M4 Kit 500Kbs/1Mbs Abs M5 Kit 500Kbs/1MbsAqidi MohammadNo ratings yet