Professional Documents

Culture Documents

MA - Auto Service Repair Manuals and Wiring Diagrams

MA - Auto Service Repair Manuals and Wiring Diagrams

Uploaded by

Tomy0 ratings0% found this document useful (0 votes)

160 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

160 views2 pagesMA - Auto Service Repair Manuals and Wiring Diagrams

MA - Auto Service Repair Manuals and Wiring Diagrams

Uploaded by

TomyCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

DAIHATSU

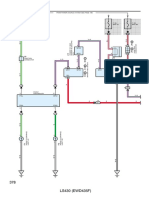

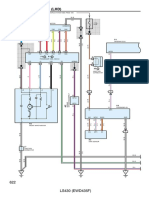

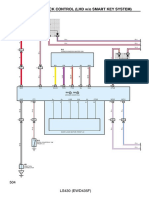

L200

EF-CL

MAINTENANCE

MAINTENANCE

ENGINE MAINTENANCE

EXHAUST EMISSION CONTROL SYSTEM

1. Secondary air suction system

(1) Start the engine.

(2) Disconnect the air hose between the air suction valve

and the air cleaner.

(3) At this time, ensure that the air is sucked into the air

hose.

(4) Connect the vacuum gauge to the air control valve,

using the 3 way.

(8) After the engine is warmed-up thoroughly, ensure that

no vacuum is applied to the vacuum gauge while idling.

(6) Race the engine up to about 4,000 rpm several times.

(7) Ensure that the vacuum is applied each time the engine

is raced,

2. EGR (Exhaust Gas Recirculating) system

(1) Connect the vacuum gauge between the Q port of EGR

valve and modulator valve.

(2). When the engine is cote

(Cooling water temperature is below 50°C)

Start the engine, check that the pointer of the

vacuum gauge registers around zero when the

‘engine is idling or even when the engine is raced

to about 4,000 rpm,

(2) When the engine is hot

(Cooling water temperature is above 80°C)

* If the pointer of the vacuum gauge registers

zero when the engine is started, it shows

satisfactory operation.

* Raise the engine revolution speed to ap-

proximately 4,000 rpm. If the pointer of the

vacuum gauge rises to around 100 mmHa, it

indicates that the EGR system is functioning

properly.

MA-2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- HRV RU5 Climate Control System Circuit DiagramDocument13 pagesHRV RU5 Climate Control System Circuit DiagramTomyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Toyota 2AR-FE Wiring DiagramDocument19 pagesToyota 2AR-FE Wiring DiagramTomyNo ratings yet

- Service Manual 3sz-VeDocument4 pagesService Manual 3sz-VeTomy100% (2)

- HRV RU5 Cooling Fan Controls Circuit Diagram With KeylessDocument1 pageHRV RU5 Cooling Fan Controls Circuit Diagram With KeylessTomy100% (1)

- Body ElectricalDocument14 pagesBody ElectricalTomyNo ratings yet

- Jazz GD3 Gauge Control ModuleDocument1 pageJazz GD3 Gauge Control ModuleTomyNo ratings yet

- Wiring DiagramDocument44 pagesWiring DiagramTomyNo ratings yet

- Jazz GK5 Starting System Circuit Diagram Separate Type MICU With KeylessDocument2 pagesJazz GK5 Starting System Circuit Diagram Separate Type MICU With KeylessTomyNo ratings yet

- Jazz GK5 Starting System Circuit Diagram Build-In Type MICUDocument1 pageJazz GK5 Starting System Circuit Diagram Build-In Type MICUTomyNo ratings yet

- Taillight (RHD)Document4 pagesTaillight (RHD)TomyNo ratings yet

- Jazz GK5 Starting System Circuit Diagram Separate Type MICU Without KeylessDocument2 pagesJazz GK5 Starting System Circuit Diagram Separate Type MICU Without KeylessTomyNo ratings yet

- BRV DG1 U0121, U0122, U0131, U0155, U129e 2789Document3 pagesBRV DG1 U0121, U0122, U0131, U0155, U129e 2789Tomy100% (1)

- Jazz GK5 Charging System Circuit Diagram Build-In Type MICUDocument1 pageJazz GK5 Charging System Circuit Diagram Build-In Type MICUTomyNo ratings yet

- City GM6 ABS Modulator Control Unit ConnectorDocument2 pagesCity GM6 ABS Modulator Control Unit ConnectorTomyNo ratings yet

- ForewordDocument170 pagesForewordTomyNo ratings yet

- BRV DG1 U0155, U1281 4187Document2 pagesBRV DG1 U0155, U1281 4187Tomy100% (1)

- Toyota 1NZ-FE Wiring DiagramDocument6 pagesToyota 1NZ-FE Wiring DiagramTomy100% (2)

- Driveline+ +axleDocument27 pagesDriveline+ +axleTomyNo ratings yet

- DTC Troubleshooting: P0137: DTC P0137: Secondary HO2S (Sensor 2) Circuit Low VoltageDocument5 pagesDTC Troubleshooting: P0137: DTC P0137: Secondary HO2S (Sensor 2) Circuit Low VoltageTomyNo ratings yet

- Troubleshooting Data: Plug Seen From The Cable SideDocument2 pagesTroubleshooting Data: Plug Seen From The Cable SideTomyNo ratings yet

- VSC and Pps (RHD) : S11, S12, S13, S14Document5 pagesVSC and Pps (RHD) : S11, S12, S13, S14TomyNo ratings yet

- Harness & Circuit DiagramDocument71 pagesHarness & Circuit DiagramTomy100% (1)

- VSC LDocument5 pagesVSC LTomyNo ratings yet

- Taillight (RHD) Taillight (RHD) : 378 LS430 (EWD435F) LS430 (EWD435F) 379 380 LS430 (EWD435F) LS430 (EWD435F) 381Document1 pageTaillight (RHD) Taillight (RHD) : 378 LS430 (EWD435F) LS430 (EWD435F) 379 380 LS430 (EWD435F) LS430 (EWD435F) 381TomyNo ratings yet

- Vibration Seat (LHD)Document2 pagesVibration Seat (LHD)TomyNo ratings yet

- Wiper and Washer (LHD)Document3 pagesWiper and Washer (LHD)TomyNo ratings yet

- Wiper and Washer (RHD)Document3 pagesWiper and Washer (RHD)TomyNo ratings yet

- Wireless Door Lock Control (LHD W/O Smart Key System)Document6 pagesWireless Door Lock Control (LHD W/O Smart Key System)TomyNo ratings yet

- LS430 (Ewd435f) 887Document3 pagesLS430 (Ewd435f) 887TomyNo ratings yet

- LS430 (Ewd435f) 899Document3 pagesLS430 (Ewd435f) 899TomyNo ratings yet