Professional Documents

Culture Documents

Hydrocarbons, Halogenated 1003: Table 1 MW: Table 2 Cas: Table 1 Rtecs: Table 1

Hydrocarbons, Halogenated 1003: Table 1 MW: Table 2 Cas: Table 1 Rtecs: Table 1

Uploaded by

MICROLABORATORIO S.A de C.VOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrocarbons, Halogenated 1003: Table 1 MW: Table 2 Cas: Table 1 Rtecs: Table 1

Hydrocarbons, Halogenated 1003: Table 1 MW: Table 2 Cas: Table 1 Rtecs: Table 1

Uploaded by

MICROLABORATORIO S.A de C.VCopyright:

Available Formats

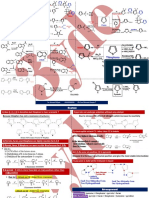

HYDROCARBONS, HALOGENATED 1003

Table 1 MW: Table 2 CAS: Table 1 RTECS: Table 1

METHOD: 1003, Issue 3 EVALUATION: PARTIAL Issue 1: 15 February 1984

Issue 3: 15 March 2003

OSHA : See TABLE 1 PROPERTIES: See TABLE 2

NIOSH: See TABLE 1

ACGIH: See TABLE 1

COMPOUNDS: See TABLE 1

(synonyms)

SAMPLING MEASUREMENT

SAMPLER: SOLID SORBENT TUBE TECHNIQUE: GAS CHROMATOGRAPHY, FID

(coconut shell charcoal, 100 mg/50 mg)

(Lot # 2000) ANALYTE: compounds listed above

FLOW RATE: 0.01 to 0.2 L/min DESORPTION: 1 mL CS2 , stand 30 min

VOL-MIN: Table 3 INJECTION

-MAX: Table 3 VOLUME: 1 µL

SHIPMENT: Routine TEMPERATURE: Group A: Inj = 200°C, Det = 250°C ;

35°C (3 min) to 150°C

SAMPLE (8°C/min).

STABILITY: 30 days for all analytes Group B: Inj = 225°C, Det = 250°C ;

35°C (3 min) to 190°C

BLANKS: 2 to 10 field blanks per set (8°C/min).

CARRIER GAS: He, (Group A: 2.6 mL/min)

(Group B: 4.7 mL/min)

ACCURACY

COLUMN: Group A: capillary, fused silica, 30 m x 0.32-mm

RANGE STUDIED: see EVALUATION OF METHOD [1] ID; 1.80-µm film diphenyl/ dimethyl

polysiloxane, Rtx® -502.2 or equivalent.

Group B: capillary, fused silica, 30 m x 0.53 - mm

BIAS: see EVALUATION OF METHOD [1]

ID; 3-µm film 35% diphenyl- 65%

dimethyl polysiloxane, Rtx® -35 or

OVERALL

equivalent.

PRECISION ( Ö r T ): see EVALUATION OF METHOD [1]

CALIBRATION: standard solutions of analytes in CS2

ACCURACY: see EVALUATION OF METHOD [1]

RANGE: see Evaluation of Method

ESTIMATED LOD: Table 4

PRECISION (þ r ): Table 4

APPLICABILITY: See Table 3 for working ranges. This method can be used for simultaneous determination of two or more of

the analytes of interest either by use of both of the capillary columns listed above or by modifying the analytical parameters (i.e.,

temperature program) of the method. High humidity during sampling will decrease total breakthrough volume.

INTERFERENCES: None identified but as the number of different analytes sampled increases so does the chance for

interferences. The choice of capillary column or analytical parameters may be modified to circumvent such interferences.

OTHER METHODS: This method is an update for NMAM Method 1003 (Issue 1, 2/15/84) [2]. Trichloroethylene, NIOSH

Method 1022, was included in this method update [3]. Method improvements include higher recoveries at lower sample recovery

levels, lower LOD and LOQ values, incorporation of capillary column chromatography, and acceptable recoveries in a 30 day

storage stability study.

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

HYD RO CAR BO NS, H ALO GE NAT ED: M ETH OD 1003, Issue 3, dated 1 5 Ma rch 2003 Page 2 o f 7

REAGENTS: EQUIPMENT:

1. Ca rbon disulfide, chrom atog raph ic qua lity.* 1. Sampler: glass tube, 7 cm long, 6-mm OD,

2. An alyte s, reagent grade quality. 4-mm ID, flame-sealed ends with plastic caps,

3. Nitrogen or helium, purified. containing two sections of 20/40 mesh

4. Hydrogen, prepurified. activated (600 °C) coconut shell charcoal

5. Air, filtered. (front = 100 mg; back = 50 mg) separated by

a 2-mm urethane foam plug. A silylated glass

wool plug precedes the front section and a

3-mm urethane foam plug follows the back

sec tion. Pre ssu re drop a cross th e tube at 1

* See SPECIAL PRECAUTIONS. L/m in airflow m ust be less than 3.4 k Pa.

Tubes are comm ercially available (e.g., SKC

#226-01 , Lot# 2000 or equ ivalent).

2. Personal sampling pump, 0.01 to 0.2 L/min,

with flexible connecting tubing.

3. Gas chromatograph, FID, integrator and

colum ns (see pa ge1003 -1).

4. Via ls, 2-m L, glass, P TFE -line d septum crim p

caps.

5. Volumetric flasks, 10-mL.

6. Syringes, 10-µL to 1-mL, readable to 0.1 µL.

7. Pipet, 1-mL, with pipet bulb.

SPECIAL PRECAUTIONS: Carbon disulfide is toxic and a serious fire and explosion hazard (flash

point = !30 °C). W ork with it only in a hood. Several of the analytes are suspect carcinogens

(Table 1). W ear appropriate protection clothing and work with these compounds in a well ventilated

hoo d.

SAMPLING:

1. Calibrate each personal sampling pump with a representative sampler in line.

2. Break the ends of the sampler imm ediately before sampling. Attach sampler to personal sampling

pump with flexible tubing.

3. Sam ple at an accurately known flow rate between 0.01 and 0.2 L/min for a total sample size between

the limits shown in Table 2.

4. Ca p the sam plers. Pac k secu rely for shipm ent.

SAMPLE PREPARATION:

5. Place the front and back sorbent sections of the sampler tube in separate vials. The glass wool plug

should be included in the vial containing the front sorbent section. Discard the glass wool and foam

plugs.

6. Add 1.0 mL CS 2 to each vial. C ap each vial.

7. Allow to stand 30 min with occasional agitation.

CALIBRATION AND QUALITY CONTRO L:

8. Ca librate daily with at leas t six wo rking standa rds over the appro priate rang e from below the LOD to

10x the LO Q or grea ter if required (see T able 3).

a. Add known amounts of neat analyte or calibration stock solution to CS 2 in 10-mL volumetric flasks

and dilute to the mark.

b. Analyze with samp les and blanks (steps 11 and 12).

c. Prepare calibra tion gra ph (p eak area vs. :g analyte).

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

HYD RO CAR BO NS, H ALO GE NAT ED: M ETH OD 1003, Issue 3, dated 1 5 Ma rch 2003 Page 3 o f 7

9. Determine desorption efficiency (DE) at least once for each lot of charcoal used for sampling in the

range of interest. Prepare three tubes at each of five concentrations plus three media blanks.

a. Rem ove and disca rd back sorbent sec tion of a blank sam pler.

b. Inject a known amount (2 to 20 µL) of pure analyte, or calibration stock solution, directly onto front

sorbent section with a microliter syringe.

c. Ca p the tube. Allow to stand overnight.

d. Deso rb (steps 5 through 7 ) and analyze together with working standards (steps 11 and 12).

e. Prepare a graph of DE vs. µg analyte recovered.

10. Analyze three quality control blind spikes and three analyst spikes to insure that the calibration graph

and D E graph are in control.

MEASUREMENT:

11. Set gas chromatograph according to manufacturer's recomm endations and to conditions given on

pag e 10 03-1 . Inject s am ple aliqu ot either m anu ally using solve nt flush technique o r with

autosam pler.

NOTE: If peak area is above the linear range of the working standards, dilute with CS 2, rean alyze

and apply the appropriate dilution factor in calculations.

12. Measure peak area.

CALCULATIONS:

13. Determ ine the ma ss, µg (correc ted for DE), of analyte found in the sam ple front (W f) and back (W b)

sorbent sec tions and in the average m edia blank front (B f) and back (B b) sorbent sections.

NOTE: If W b > W f/10, report breakthrough and possible sample loss.

14. Calculate conce ntration, C, of analyte in the air volume sam pled, V (L):

EVALUATION OF METHOD:

The current laboratory evaluation of the analytes listed in this method included the incorporation of

capillary column chrom atography, the improvem ent of LOD/LOQ values, a desorption efficiency study

rang ing fro m app roximately 3-5X LOQ to 0.1x the R EL/PEL, and the inclusion of a 30 day sto rage stability

study. Most of the analytes evaluated over this range exhibited acceptable recoveries [4]. However four

analyte s had unaccepta ble rec overies at th e lowe st level evaluate d [4]. These analyte s included benzyl

chloride, chloroform, carbon tetrachloride and chlorobenzene. For these compounds the LOQ was

adju sted acc ordingly. All of the a nalytes evaluated during the stora ge s tability study were d eterm ined to

be s table a fter 7, 1 4, and 30 days stora ge [4]. Brom oform was m arginally stable a t 30 days [4].

The initial laboratory evaluation was conducted using spiked samples and generated atmospheres and

using SKC Lot 105 coconut shell charcoal as the collection media [1]. Results were:

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

HYD RO CAR BO NS, H ALO GE NAT ED: M ETH OD 1003, Issue 3, dated 1 5 Ma rch 2003 Page 4 o f 7

Range Sample Bias Precision Accuracy Desorption

Compound mg/m3 Size % Overall Measurement ±% Efficiency Ref.

Benzyl chloride 2-8 10 L ! 8.4 0.096 0.031 25.6 94% @ 96-303 µg 4

Bromoform 3-10 10 L ! 1.3 0.071 0.043 14.0 94% @ 35-111 µg 4

Carbon tetrachloride 65-299 15 L ! 1.6 0.092 0.037 18.0 93% @ 32-4800 µg 4,5

Chlorobenzene 183-736 10 L 0.3 0.056 0.025 11.0 92% @ 111-7100µg 4,6

Chlorobromomethane 640-2655 5L 3.4 0.061 0.051 14.0 98% @39-13,000µg 4,7

Chloroform 100-416 15 L 1.3 0.057 0.047 11.6 97% @ 24-7400 µg 4,8

o-Dichlorobenzene 150-629 3L ! 1.9 0.068 0.013 13.7 94% @ 19-1900 µg 4,9

p-Dichlorobenzene 183-777 3L ! 4.3 0.052 0.022 12.5 98% @ 25-2700 µg 4,10

1,1-Dichloroethane 212-838 10 L 2.6 0.057 0.011 12.4 101% @20-8000 µg 4,11

1,2-Dichloroethylene* 475-1915 3L ! 2.9 0.052 0.017 11.3 101% @19-9500 µg 4,12

Ethylene dichloride 195-819 3L ! 2.0 0.079 0.012 15.7 94% @ 2.5-2500 µg 4,13

Hexachloroethane 5-25 10 L ! 6.6 0.121 0.014 25.4 98% @ 34-756.8 µg 4

1,1,1-Trichloroethane 904-3790 3L ! 0.6 0.054 0.018 10.6 100%@23-11000µg 4,14

Tetrachloroethylene 655-2749 3L ! 7.2 0.052 0.013 15.1 95% @ 8-8000 µg 4,15

1,1,2-Trichloroethane 26-111 10 L ! 9.0 0.057 0.010 17.5 100% @18-1200 µg 4,16

1,2,3-Trichloropropane 163-629 10 L 2.1 0.068 0.027 14.2 99% @ 21-6000 µg 4,17

*mixed isomers used (i.e., cis- and trans-).

REFERENCES:

[1] NIOSH [1977]. Docum entation of the NIOSH Validation Tests, S101, S110, S113, S114, S115,

S122, S123, S126, S133, S134, S135, S281, S314, S328, S335, S351, U.S. Department of Health,

Education, and W elfare, Publ. (NIOSH) 77-185, available as Stock No. PB 274-248 from NT IS,

Springfield, VA 22161.

[2] NIOSH [1994]. Hydrocarbons, Halogenated: Method 1003. In: Eller PM, Cassinelli ME, eds. NIOSH

m anu al of analytical m etho ds. 4 th ed. Cincinnati, OH: U.S. Department of Health and Human

Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for

Occupational Safety and Health, DHHS (NIOSH) Publication No. 94-113.

[3] NIOSH [1994]. Trichloroethylene: Method 1022. In: Eller, PM, Cassinelli, ME, eds. NIOSH m anual of

ana lytical metho ds. 4 th rev. ed. Cincinnati, OH: U.S. Department of Health and Human Services,

Public Health Service, Centers for Disease Control and Prevention, National Institute for

Occupational Safety and Health, DHHS (NIOSH) Publication No. 94-113.

[4] Pende rgrass S M [1 998 ]. Bac kup Data R epo rt for N MA M 1003 , Issue 3 M etho d Developm ent.

Cincinnati, OH: National Institute for Oc cupational Safety and Hea lth, (unpublished, Dec em ber).

[5] NIO SH [1977]. Ca rbon tetrac hloride : Me thod S31 4, NIOS H m anu al of analytical m etho ds, 2 nd ed.,

Vol. 1, Cincinnati, OH: U.S. Department of Health, Education, and W elfare, (NIOSH) Publication 77-

157-A.

[6] Ibid., S133.

[7] Ibid., S113.

[8] Ibid., Vol 3., S351, (NIOSH) Publication 77-157-C.

[9] Ibid., S135.

[10] Ibid., S281.

[11] Ibid., Vol. 2, S123, (NIOSH) Publication 77-157-A.

[12] Ibid., S110.

[13] Ibid., S122.

[14] Ibid., Vol 3, S328, (NIOSH) Publication 77-157-C.

[15] Ibid., S335.

[16] Ibid., Vol. 2, S134, (NIOSH) Publication 77-157-A.

[17] Ibid., S126.

METHOD REVISED BY:

Stephanie M. Pendergrass, NIOSH/ DART.

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

HYD RO CAR BO NS, H ALO GE NAT ED: M ETH OD 1003, Issue 3, dated 1 5 Ma rch 2003 Page 5 o f 7

TABLE 1. GENERAL INFORMATION.

Compound

RTECS Synonyms OSHA/NIOSH/ACGIH (ppm)

Group A

Bromoform tribromomethane; 0.5 (skin)/0.5 (skin)/0.5 (skin)

(CHBr3 ); PB5600000 CAS #75-25-2

Carbon tetrachlorideab tetrachloromethane; 10, C 25/STEL 2 (1 h)/5 (skin)

(CCl4 ); FG4900000 CAS #56-23-5

Chlorobenzene monochlorobenzene; phenyl 75/--/10

(C6 H5 Cl); CZ0175000 chloride; CAS #108-90-7

Chloroform ab trichloromethane; C 50/STEL 2/10

(CHCl3 ); FS9100000 CAS #67-66-3

1,1-Dichloroethane ethylidene chloride; 100/100/100

(CH3 CHCl2 ); KI0175000 CAS #75-34-3

Ethylene dichlorideab 1,2-dichloroethane; 50, C 100/1, STEL 2/10

(ClCH2 CH2 Cl); KI0525000 CAS #107-06-2

Tetrachloroethyleneab perchloroethylene; 100, C 200, P 300/0.4 (LOQ)/

(Cl2 C=CCl2 ); KX3850000 CAS #127-18-4 25, STEL 100

Trichloroethylenea ethylene trichloride; trichloroethene; 100 ppm (Ca 200 ppm)/Ca 50 ppm

(CICH = CCl2 ); KX4550000 CAS # 79-01-6

1,1,1-trichloroethane methyl chloroform; 350/C 350/350, STEL 450

(CH3 CCl3 ); KJ297500 CAS #71-55-6

Group B

1/C 1.0/1

Benzyl chloridea (chloromethyl) benzene;

(C6 H5 CH2 Cl); XS8925000 "-chlorotoluene; CAS #100-44-7

200/200/200

Chlorobromomethane bromochloromethane;

(CH2 BrCl); PA5250000 Halon 1011; CAS #74-97-5

50/C 50/25 (skin); STEL 50

o-Dichlorobenzenec 1,2-dichlorobenzene;

(1,2-C6 H4 Cl2 ); CZ4500000 CAS #95-50-1

75/1.7 (LOQ)/75, STEL 110

p-Dichlorobenzeneac 1,4-dichlorobenzene;

(1,4-C6 H4 Cl2 ); CZ45500000 CAS #106-46-7

200/200/200

1,2-Dichloroethylene acetylene dichloride;

(ClCH=CHCl); KV9360000 1,2-dichloroethene;

CAS #540-59-0

1 (skin)/1/1 (skin)

Hexachloroethaneac perchloroethane;

(CCl3 CCl3 ); KI4025000 CAS #67-72-1

10 (skin)/10 (skin)/10 (skin)

1,1,2-Trichloroethanead vinyl trichloride;

(Cl2 CHCH2 Cl); KJ3150000 CAS #79-00-5

50/10 (skin)/10 (skin)

1,2,3-Trichloropropanea allyl trichloride;

(CH2 ClCHClCH2 Cl); TZ9275000 glycerol trichlorohydrin;

CAS #96-18-4

a

Suspect carcinogen [20,21,22]; b Group I Pesticide; c Group II Pesticide; d Group III Pesticide

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

HYD RO CAR BO NS, H ALO GE NAT ED: M ETH OD 1003, Issue 3, dated 1 5 Ma rch 2003 Page 6 o f 7

TABLE 2. PHYSICAL PROPERTIES

Compound M.W. mg/m3

RTECS = 1 ppm Synonyms Properties

@ NTP

Group A

Bromoform 252.75 10.33 tribromomethane liquid, d 2.887; BP 148 °C; nonflammable

(CHBr3 )

Carbon tetrachloride 153.84 6.29 tetrachloromethane liquid; d 1.585; BP 76.7 °C; FP ! 23.0 °C; VP

(CCl4 ) 91.3 mm @ 20 °C; vapor density (air = 1) 5.3

Chlorobenzene 112.56 4.60 monochlorobenzene; liquid; d 1.105 @ 25 °C; BP 131.6 °C; MP ! 45

(C6 H5 Cl) phenyl chloride °C; flash pt. 29.4 °C (CC)

Chloroform 119.39 4.88 trichloromethane liquid, d 1.485 @ 20 °C; BP 61.2 °C;

(CHCl3 ) FP -63.5 °C

1,1-Dichloroethane 98.95 4.05 ethylidene chloride liquid, d 1.174 @ 20 °C; BP 57 to 59 °C; FP ! 98

(CH3 CHCl2 ) °C

Ethylene dichloride 98.96 4.05 1,2-dichloroethane liquid; d 1.2554 @ 20 °C; BP 83.5 °C; FP ! 35.5

(ClCH2 CH2 Cl) °C; flash pt. 13 °C; explosive limits in air 6

to 16%

Tetrachloroethylene 165.83 6.78 perchloroethylene liquid; d 1.625 @ 20 °C; BP 121 °C;

(Cl2 C=CCl2 ) FP ! 22.4 °C

1,1,1-trichloroethane 133.42 5.45 methyl chloroform liquid; d 1.325; BP 75 °C; FP ! 30.4 °C;

(CH3 CCl3 ) nonflammable

Trichloroethylene 131.40 5.37 ethylene trichloride; liquid; d 1.459 @ 20°C; BP 87.2°C; FP- 72.8°C;

(CICH=CCl2 ) trichloroethene VP 58 mm Hg @ 20°C (9.9 kPa); explosive

range 11 to 41% v/v in air

Group B

Benzyl chloride 126.58 5.17 (chloromethyl) benzene; liquid; BP 179 °C; MP ! 48 to ! 43 °C; d 1.100 @

(C6 H5 CH2 Cl) "-chlorotoluene 20 °C; flash pt. 67 °C

Chlorobromomethane 129.39 5.29 bromochloromethane; liquid; d 1.93 @ 20 °C; BP 68 °C; MP ! 88 °C;

(CH2 BrCl) Halon 1011 nonflammable

o-Dichlorobenzene 147.00 6.01 1,2-dichlorobenzene liquid; d 1.284; BP 172 to 179 °C; FP ! 17 °C;

(1,2-C6 H4 Cl2 ) flash pt. 65.5 °C

p-Dichlorobenzene 147.00 6.01 1,4-dichlorobenzene solid crystals; d 1.458; BP 173.7 °C; MP 53 °C;

(1,4-C6 H4 Cl2 ) sublimes; flash pt. 65.5 °C

1,2-Dichloroethylene 96.94 3.96 acetylene dichloride; liquid; transisomer; d 1.257; BP 47 to 49 °C; MP

(ClCH=CHCl) 1,2-dichloroethene ! 57°C; cis-isomer; d 1.282; BP 58 to 60 °C;

flash pt. 3.9 °C; FP ! 80 °C

Hexachloroethane 236.74 9.66 perchloroethane solid; d 2.091; MP 185 °C; BP sublimes at

(CCl3 CCl3 ) 187 °C

1,1,2-Trichloroethane 133.41 5.45 vinyl trichloride liquid; d 1.4432 @ 20 °C; BP 113.7 °C;

(Cl2 CHCH2 Cl) FP ! 36.4 °C; VP 19 mm Hg @ 20 °C

1,2,3-Trichloropropane 147.43 6.03 allyl trichloride; liquid; d 1.3888 @ 20 °C; BP 156.2 °C;

(CH2 ClCHClCH2 Cl) glycerol trichlorohydrin FP ! 15 °C; flash pt. 82.2 °C (OC)

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

HYD RO CAR BO NS, H ALO GE NAT ED: M ETH OD 1003, Issue 3, dated 1 5 Ma rch 2003 Page 7 o f 7

TABLE 3. SAMPLING LIMITS.

Compound Air Sample Volume (L) Working Range, ppm,

Min Max Target at Max Sample Volume

Bromoform 4 @ 0.5 ppm 70 10 0.2 to 4

Carbon tetrachloride 3 @ 10 ppm 150 15 2 to 105

Chlorobenzene 1.5 @ 75 ppm 40 10 10 to 430

Chloroform 1 @ 50 ppm 50 15 2 to 190

1,1-Dichloroethane 0.5 @ 100 ppm 15 10 4 to 250

Ethylene dichloride 1 @ 50 ppm 50 3 16 to 1320

1,1,1-Trichloroethane 0.1 @ 350 ppm 8 3 18 to 1450

Tetrachloroethylene 1.0 @ 100 ppm 40 3 9 to 1900

Trichloroethylene 0.2 @ 100 ppm 30 10 0.3 to 62.1

Benzyl chloride 6 @ 1 ppm 50 10 0.6 to 5.8

Chlorobromomethane 0.5 @ 200 ppm 60 5 18 to 450

o-Dichlorobenzene 1 @ 50 ppm 10 3 16 to 1100

p-Dichlorobenzene 1 @ 75 ppm 8 3 27 to 330

1,2-Dichloroethylene 0.2 @ 200 ppm 5 3 16 to 560

Hexachloroethane 3 @ 1 ppm 70 10 0.3 to 8.3

1,1,2-Trichloroethane 2 @ 10 ppm 60 10 1.8 to 64

1,2,3-Trichloropropane 0.6 @ 50 ppm 60 10 3 to 310

TABLE 4. MEASUREMENT PARAMETERS.

Compound Limit of Detection (LOD) Limit of Quantitation (LOQ) Precision (S r )

Bromoform 6.0 19.3 0.051

Carbon tetrachloride 4.0 20.0 0.046

Chlorobenzene 0.6 110.0 0.025

Chloroform 0.8 15.0 0.035

1,1-Dichloroethane 2.0 5.1 0.030

Ethylene dichloride 0.7 2.3 0.026

Tetrachloroethylene 2.0 7.1 0.032

1,1,1-Trichloroethane 1.0 3.0 0.009

Trichlorethylene 0.6 1.9 0.018

Benzyl chloride 1.0 4.5 0.076

Chlorobromomethane 1.5 41.0 0.053

o-Dichlorobenzene 0.8 2.7 0.022

p-Dichlorobenzene 2.0 7.5 0.041

1,2-Dichloroethylene 2.0 5.1 0.041

Hexachloroethane 2.0 6.6 0.021

1,1,2-Trichloroethane 1.0 3.0 0.036

1,2,3-Trichloropropane 1.0 2.7 0.020

Units = µg analyte per sample

Note: For a few of the compounds in this method the LOQ values, when compared to the preceding method development

results, may appear higher. This can be explained by the fact that in the initial method development no recovery study

was conducted at a level near or above the instrumentally determined LOQ recoveries for each analyte.

NIOSH Manual of Analytical Methods (NMAM), Fourth Edition

You might also like

- NIOSH 0500-1994 (Total Dust As Inhalable Dust)Document4 pagesNIOSH 0500-1994 (Total Dust As Inhalable Dust)apriliandiniNo ratings yet

- Dr. Susumu Ohno (Auth.) - Evolution by Gene Duplication-Springer-Verlag Berlin Heidelberg (1970)Document171 pagesDr. Susumu Ohno (Auth.) - Evolution by Gene Duplication-Springer-Verlag Berlin Heidelberg (1970)Ehab Kardouh100% (1)

- NIOSH Manual of Analytical Methods - 1501Document7 pagesNIOSH Manual of Analytical Methods - 1501Eng Wanders MillerNo ratings yet

- Niosh 1403Document5 pagesNiosh 1403MICROLABORATORIO S.A de C.VNo ratings yet

- Acetona Niosh 1300 PDFDocument5 pagesAcetona Niosh 1300 PDFOscar Garcia GutierrezNo ratings yet

- Methyl AcetateDocument3 pagesMethyl AcetatetranhungNo ratings yet

- Formulas: Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 2553Document4 pagesFormulas: Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 2553Nicolas ZeballosNo ratings yet

- Table 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 1301Document5 pagesTable 1 MW: Table 1 Cas: Table 1 Rtecs: Table 1: Ketones Ii 1301Nicolas ZeballosNo ratings yet

- Niosh 1450Document6 pagesNiosh 1450MICROLABORATORIO S.A de C.VNo ratings yet

- Cloruro de MetilenoDocument4 pagesCloruro de MetilenoLuisa MinaNo ratings yet

- 1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEDocument4 pages1,1,1,2-TETRACHLORO-2,2-DIFLUOROETHANE and 1016 (2) 1,1,2,2-TETRACHLORO-1,2-DIFLUOROETHANEPatricia RoaNo ratings yet

- CH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615Document4 pagesCH Oc (CH) MW: 88.15 CAS: 1634-04-4 RTECS: KN5250000: Methyl Tert-Butyl Ether 1615MICROLABORATORIO S.A de C.VNo ratings yet

- Table 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400Document4 pagesTable 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Alcohols I 1400Cristian Gutiérrez PeñaNo ratings yet

- Niosh 2500 Metil Etil Cetona (Mek)Document4 pagesNiosh 2500 Metil Etil Cetona (Mek)EverChumpisucaAlvarezNo ratings yet

- NIOSH 1457-1994 Ethyl Acetate Udara Lingker GC FIDDocument4 pagesNIOSH 1457-1994 Ethyl Acetate Udara Lingker GC FIDFakhri MuflihNo ratings yet

- CCL F MW: 120.91 Cas: 75-71-8 Rtecs: Pa8200000: Dichlorodifluoromethane 1018Document4 pagesCCL F MW: 120.91 Cas: 75-71-8 Rtecs: Pa8200000: Dichlorodifluoromethane 1018Patricia RoaNo ratings yet

- (CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Document3 pages(CLCH CH) O MW: 143.01 Cas: 111-44-4 Rtecs: Kn0875000: Dichloroethyl Ether 1004Patricia RoaNo ratings yet

- CH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Document4 pagesCH CHO MW: 44.05 CAS: 75-07-0 RTECS: AB1925000: Acetaldehyde by GC 2538Haryo SaputroNo ratings yet

- (CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Document4 pages(CH O) SO MW: 126.13 CAS: 77-78-1 RTECS: WS8225000: Dimethyl Sulfate 2524Fauzan FebriyantoNo ratings yet

- Niosh 2555Document5 pagesNiosh 2555KayceePortsNo ratings yet

- Niosh 1501Document7 pagesNiosh 1501Lucas OliveiraNo ratings yet

- CH CHCN MW: 53.06 CAS: 107-13-1 RTECS: AT5250000: Acrylonitrile 1604Document4 pagesCH CHCN MW: 53.06 CAS: 107-13-1 RTECS: AT5250000: Acrylonitrile 1604Huy MinhNo ratings yet

- Plastificanti Come DOPDocument5 pagesPlastificanti Come DOPMarco CorrengiaNo ratings yet

- Descripcion MetodoDocument4 pagesDescripcion MetodoAaron HernandezNo ratings yet

- Niosh Naftas 1550Document6 pagesNiosh Naftas 1550Enrique Alejandro OvandoNo ratings yet

- Niosh 1610Document3 pagesNiosh 1610tio dameroNo ratings yet

- Niosh 1610Document4 pagesNiosh 1610MICROLABORATORIO S.A de C.VNo ratings yet

- CH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000: Allyl Chloride 1000Document3 pagesCH CHCH CL MW: 76.53 CAS: 107-05-1 RTECS: UC7350000: Allyl Chloride 1000Cristian Gutiérrez PeñaNo ratings yet

- Niosh Methanol 2000Document4 pagesNiosh Methanol 2000Endang MilahNo ratings yet

- NISOH 1401 ButanolDocument4 pagesNISOH 1401 Butanolluis norabuenaNo ratings yet

- Niosh Method 1501Document7 pagesNiosh Method 1501Memet ganashpatiNo ratings yet

- 1600 PDFDocument4 pages1600 PDFHarold Alonso CFNo ratings yet

- TOLUENE (Diffusive Sampler) 4000: C H CH MW: 92.14 CAS: 108-88-3 RTECS: XS5250000Document4 pagesTOLUENE (Diffusive Sampler) 4000: C H CH MW: 92.14 CAS: 108-88-3 RTECS: XS5250000VaninaNo ratings yet

- Niosh 2554 PDFDocument4 pagesNiosh 2554 PDFMICROLABORATORIO S.A de C.VNo ratings yet

- CBRF MW: 148.92 CAS: 75-63-8 RTECS: PA5425000: Trifluorobromomethane 1017Document4 pagesCBRF MW: 148.92 CAS: 75-63-8 RTECS: PA5425000: Trifluorobromomethane 1017Patricia RoaNo ratings yet

- 2542 Metil Merkaptan Metil SulideDocument4 pages2542 Metil Merkaptan Metil SulideEndang WahyulNo ratings yet

- NIOSH 2549 - Compuestos Orgánicos Volátiles PDFDocument8 pagesNIOSH 2549 - Compuestos Orgánicos Volátiles PDFNoe Adrianzen MNo ratings yet

- NIOSH 6011 HalidaDocument6 pagesNIOSH 6011 HalidaAmalia NurbandiniNo ratings yet

- Niosh 1405Document6 pagesNiosh 1405MICROLABORATORIO S.A de C.VNo ratings yet

- Niosh 5040 PDFDocument5 pagesNiosh 5040 PDFPierinaPeredaNo ratings yet

- Yodo - NIOSH 6005Document4 pagesYodo - NIOSH 6005Mario LagosNo ratings yet

- Table 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Amines, Aromatic 2002Document6 pagesTable 1 MW: Table 1 CAS: Table 2 RTECS: Table 2: Amines, Aromatic 2002Huy MinhNo ratings yet

- CH CH BR MW: 108.97 CAS: 74-96-4 RTECS: KH6475000: Ethyl Bromide 1011Document4 pagesCH CH BR MW: 108.97 CAS: 74-96-4 RTECS: KH6475000: Ethyl Bromide 1011Patricia RoaNo ratings yet

- Volatile Organic Compounds, C1 To C10, Canister Method: Formula: Table 1 MW: Table 1 CAS: Table 1 RTECS: Table 1Document14 pagesVolatile Organic Compounds, C1 To C10, Canister Method: Formula: Table 1 MW: Table 1 CAS: Table 1 RTECS: Table 1Karly RodriguezNo ratings yet

- Niosh Method 1501-Hc GC B IndoDocument8 pagesNiosh Method 1501-Hc GC B IndoMemet ganashpatiNo ratings yet

- CH CHCLCH CL MW: 112.99 CAS: 78-87-5 RTECS: TX9625000: Propylene Dichloride 1013Document4 pagesCH CHCLCH CL MW: 112.99 CAS: 78-87-5 RTECS: TX9625000: Propylene Dichloride 1013Patricia RoaNo ratings yet

- CH CCL MW: 96.94 Cas: 75-35-4 Rtecs: Kv9275000: Vinylidene Chloride 1015Document4 pagesCH CCL MW: 96.94 Cas: 75-35-4 Rtecs: Kv9275000: Vinylidene Chloride 1015JM Safety Perú S.A.C. JM Safety Perú S.A.C.No ratings yet

- Niosh 6004 Dióxido de AzufreDocument4 pagesNiosh 6004 Dióxido de AzufreEverChumpisucaAlvarezNo ratings yet

- METHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionDocument30 pagesMETHAMPHETAMINE and Illicit Drugs, Precursors 9106 and Adulterants On Wipes by Liquid-Liquid ExtractionMatthew MulderNo ratings yet

- CH C H Oh MW: 108.14 Cas: 1319-77-3 Rtecs: Go5950000 C H Oh 94.11 108-95-2 SJ3325000Document4 pagesCH C H Oh MW: 108.14 Cas: 1319-77-3 Rtecs: Go5950000 C H Oh 94.11 108-95-2 SJ3325000HectorNo ratings yet

- O CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Document4 pagesO CH (CH) CH O MW: 100.12 CAS: 111-30-8 RTECS: MA2450000Vinoth BabuNo ratings yet

- Niosh 6010Document5 pagesNiosh 6010Mai Trung ToànNo ratings yet

- Al MW: 26.98 (Al) CAS: 7429-90-5 (Al) RTECS: BD0330000 101.96 (Al 0) 1344-28-1 (Al 0) BD1200000Document4 pagesAl MW: 26.98 (Al) CAS: 7429-90-5 (Al) RTECS: BD0330000 101.96 (Al 0) 1344-28-1 (Al 0) BD1200000Huu Thanh NguyenNo ratings yet

- Metodo NIOSH 0600 Polvo Respirable PDFDocument6 pagesMetodo NIOSH 0600 Polvo Respirable PDFVane OliveraNo ratings yet

- Aerobic Bacteria by Gc-Fame 0801Document4 pagesAerobic Bacteria by Gc-Fame 0801JM Safety Perú S.A.C. JM Safety Perú S.A.C.No ratings yet

- Simulated Distillation Analysis Middle Distillates PDFDocument8 pagesSimulated Distillation Analysis Middle Distillates PDFgraciela areinamoNo ratings yet

- 6231 1,2 Dibromoetano (Edb) y 1,2 Dibromo 3 ChloropropanoDocument4 pages6231 1,2 Dibromoetano (Edb) y 1,2 Dibromo 3 ChloropropanoCecilia AvilaNo ratings yet

- Niosh 6009 PDFDocument5 pagesNiosh 6009 PDFCaleb ConnerNo ratings yet

- Niosh 5522Document6 pagesNiosh 5522JAVIER MARTINEZNo ratings yet

- Calibration Data (Area Method)Document32 pagesCalibration Data (Area Method)api-3728640No ratings yet

- Olah - Beyond Oil and Gas The Methanol EconomyDocument4 pagesOlah - Beyond Oil and Gas The Methanol Economyapi-3728640100% (2)

- Jcice 64Document7 pagesJcice 64api-3728640No ratings yet

- QueryDocument1 pageQueryapi-3728640No ratings yet

- RevisionDocument22 pagesRevisionapi-3728640No ratings yet

- ManuscriptDocument20 pagesManuscriptapi-3728640No ratings yet

- FigureDocument7 pagesFigureapi-3728640No ratings yet

- ResponseDocument7 pagesResponseapi-3728640No ratings yet

- QueryDocument1 pageQueryapi-3728640No ratings yet

- For English Editing (Done)Document23 pagesFor English Editing (Done)api-3728640No ratings yet

- Revised ManuscriptDocument23 pagesRevised Manuscriptapi-3728640No ratings yet

- ManuscriptDocument20 pagesManuscriptapi-3728640No ratings yet

- Ala MatDocument1 pageAla Matapi-3728640No ratings yet

- Cover Letter1Document1 pageCover Letter1api-3728640100% (1)

- How To Determine Orders of ReactionDocument2 pagesHow To Determine Orders of Reactionapi-3728640100% (1)

- ResponseDocument2 pagesResponseapi-3728640No ratings yet

- Cover LetterDocument1 pageCover Letterapi-3728640No ratings yet

- Submission FormDocument2 pagesSubmission Formapi-3728640No ratings yet

- Pagecharges TPSDocument1 pagePagecharges TPSapi-3728640No ratings yet

- Style ManualDocument18 pagesStyle Manualapi-3728640No ratings yet

- FotosintesisDocument51 pagesFotosintesisDwi HardianiNo ratings yet

- Gate ValveDocument222 pagesGate ValveMetoo ChyNo ratings yet

- Clivaje FmocDocument12 pagesClivaje FmocAna Maria Barrera DiazNo ratings yet

- ScourDocument12 pagesScourzxy_cbeNo ratings yet

- Nutrition DietaryDocument35 pagesNutrition DietaryAbdul Quyyum100% (2)

- LAB REPORT Reactions of Aliphatic HydrocarbonsDocument6 pagesLAB REPORT Reactions of Aliphatic HydrocarbonsSafwan Jamil62% (13)

- .In Ypage: Name Reactions (Organic Chemistry)Document12 pages.In Ypage: Name Reactions (Organic Chemistry)vedangNo ratings yet

- 13 - CH-475 - Terpenes - CamphorDocument6 pages13 - CH-475 - Terpenes - CamphorUrva AmjadNo ratings yet

- Formulation and Evaluation of Alpha Arbutin Skin LDocument6 pagesFormulation and Evaluation of Alpha Arbutin Skin LShabbir SheikhNo ratings yet

- Recrystallization: ExperimentDocument9 pagesRecrystallization: ExperimentMaureen GabrielleNo ratings yet

- Mitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Document2 pagesMitsubishi Chemical Advanced Materials Nylatron ® GSM Nylon, Cast Mos2 Filled Type 6 (Astm Product Data Sheet)Irwan SaputraNo ratings yet

- Viva Questions For Odd SemestersDocument32 pagesViva Questions For Odd SemestersAstha SinghNo ratings yet

- Calculating ARIEL Lube RatesDocument2 pagesCalculating ARIEL Lube RateszhangjieNo ratings yet

- The Environmental Impacts of Fire-Fighting FoamsDocument11 pagesThe Environmental Impacts of Fire-Fighting FoamssilviamachadoNo ratings yet

- Buffer Exercises PDFDocument3 pagesBuffer Exercises PDFsdggNo ratings yet

- Standard Methods TOC (Wet Oxidation Method) .Document3 pagesStandard Methods TOC (Wet Oxidation Method) .FarazNo ratings yet

- Bebidas OrujosDocument16 pagesBebidas OrujosAndrea LeonNo ratings yet

- InVitroInvestigationofAntidiabeticPotential PDFDocument7 pagesInVitroInvestigationofAntidiabeticPotential PDFSamantha Vhiel VicenteNo ratings yet

- Geogemma MetabolismDocument2 pagesGeogemma MetabolismkkathrynannaNo ratings yet

- Isa GomezDocument6 pagesIsa Gomezapi-450482048No ratings yet

- CML103 Tutorial1 WithanswerDocument2 pagesCML103 Tutorial1 WithanswerYaswanth sai nukavarapuNo ratings yet

- Chapter 1 Natural Products IntroductionDocument21 pagesChapter 1 Natural Products IntroductionBakhita MaryamNo ratings yet

- HDJDKDocument2 pagesHDJDKWeda MaharaniNo ratings yet

- SIMONA Pvc-Caw PVC-HSV PVC-MZDocument21 pagesSIMONA Pvc-Caw PVC-HSV PVC-MZروشان فاطمة روشانNo ratings yet

- Hydrocarbon Alkynes 3Document13 pagesHydrocarbon Alkynes 3Raju SinghNo ratings yet

- BME (B) Project Report PDFDocument24 pagesBME (B) Project Report PDFMohul KatyalNo ratings yet

- Bs en 13130-2-2004 食品模拟物中对苯二酸的测定Document18 pagesBs en 13130-2-2004 食品模拟物中对苯二酸的测定catalinabar25100% (1)

- BP202TP PDFDocument1 pageBP202TP PDFDarshanNo ratings yet

- A3 ReactionsDocument3 pagesA3 ReactionshaNo ratings yet