Professional Documents

Culture Documents

Appendix 2

Appendix 2

Uploaded by

Matt MacDonagh0 ratings0% found this document useful (0 votes)

9 views3 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views3 pagesAppendix 2

Appendix 2

Uploaded by

Matt MacDonaghCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

Sennen

Appendix 2 Materials deta

Appendix 2 Materials dat

A2.1 Densities and weights of materials

‘The weight of materials can be obtained by sample seate, information from

manufacturers and reference to BS 648 Schedule of weights of building

materials,

‘Typical densities of commonly used materials are included below for

reference. The weight (in kg/m) of a specific thickness of material is

obtained by multiplying the density by the thickness in metres.

For example: the weight of 22 mm chipboard flooring would be

"750 (o/mn? ) x 0.022 (rn) = 16.6 ko/m?

Nove: Values shown are typical, though the density of individual products

can vary considerably and these values should only be taken as a general

guide, For detailed calculation the manufacturers’ figures should be used,

‘Table A2.1 Typical doncity of common materials

Material “Typical density kale

Timber Softwood 350 = 550

Structural harcwood 5350 - 1000

Structural compost timber, ag LVL 5350 - 600

‘Sheet materials ‘Sheathing! fooring grade plywood 530

Wood chipboard PS. 750

Oriented strand board 720

(Cement bonded particleboard 1250

Hardboard 50

‘Tempered heraboare 1000

Impregnated sofboars 400

MOF 900

Plasterboard Type 4 950

Gypsum fibreboard 1200

: Mineral fereboard up to 1500

Glass 2800

Insulation Minor woo, glass 2

Mineral woo), rock 20

Mineral wool, as resent layer 60 - 100

Celkiose fibre 38

Expanded polystyrene 28

Extruded polystyrene 35

Phenolic 35

Poyisoeysruraie 22

Polyurotane 2

‘Gypsum plactor 1200

Cement render 00

ggg gg

TRADA Technology Timber frame construction.

eR

‘There are some composite constructions which are more easily quoted as

weights per square metze for guidance purposes including:

Table A2.2 Typical weights of composite constructions

iMsteriat Typical weight kai?

Roofing fot ‘Sayers fet and chiopiras sr

Tia battens 2 100 mm gauge a4

Concrete paving slabs 50 mm thick ur

Ballast ‘50 mn thick 80

Roafing ‘concrete interocking tes 42-58

conereto plain tes 80

flay - machine-made tes 64

‘lay - hand-made tee n

states 25-78

ote coment sates 25

Insulated metal deck roofing 20-39

A 2.2 Vapour resistivity and vapour

resistance values

"The values quoted are typical mean velues for materials commonly used in

timber frame construction. Manufacturers may quote different figures for

their produois, When a tango of values if shown, the lower value should be

uused when the board is used on the warm side of the construction and the

higher value used when the board is located on the cold side, Values for

materials not ineluded in Table 2.2 should be obtained from the manufac

turer

"The values for thin materlais, such as metal folls and membranes ere shown

a5 @ vapour resistance for the materiel. Other materials are shown as a

‘vapour resistivity value,

Vapour resistance is calculated by multiplying the thickness in metres by the

vapour resistivity.

All values are from BS BN 12524 Building materials and products.

Hygrothermal properties. Tabulated values, except as noted,

238

A 2.3 Thermal conductivity of materials

‘The values shown in Table A2.4 ace typical design values. Manufacturers

‘may providle more precise figures if require.

‘Table A 2.3 Vapour resistivity and vapour resistance values

Tatoriat ‘Vapour resistivity Vapour resistance

Nsom NSIS

Prasterioard Type 1 20,

Gypoum fibre reinforced board 1308

Softwood 100

Hardivood 250

Expanded polystyrene 300

Extruded polystyrene 750

Caluiose fire 10

Mineral wool (ass or rock) 5

Cement bonded particlsboard 150

Impregnated sotboard (no fim face) 25

Mediumboard (high density) 1501

MOF 100

rented strand board (OSB) 150

Plywood 450

‘Tempered hardboard 150

\Wood chipboard 100

Brickwork 50

Blockwork 50

Gemant render 50

Glass ath

Vapour contol plastorboard soi")

‘Auesiniur fi 7500

0.12 mm polythene shest—~ 250

10.25 ram polythene sheet 500

Breather membrane - a0! greater than ose

Metal daddings wi)

Breather roof underiey 0.6 max

Roofing fet aid in bitumen 0000

Rooting felt underay 500)

‘GiValus from manufacturer Value fom BS 5250

(© For calculation assume arbitaty lage value 69 100,000

Table A2.4 Thermal conductivity of materials

iteriat “Thermal eondvetivity (Wie)

Fiasierboard Type 1 0.16

[Gypsum fbre reinforced board 938,

Softwood oa

Hardood D4

CCaluiose bee 0.43

Expanded palystyrone 0.038

Exiruded polystyrene 0.027

Mineral woo! (alse or rock) 0037

Phenol 3.020

Poylscyanurale 9.028

Polyurethane 0.025

Cement bonded particleboare 2.35

Iimpregnated softvosrd 0.056

Mediumboard 0.08

Medium density fibreboard (MOF) ong

Oriented strand board (OSB) ona

Piyaood (sheathing grade) 04

‘Tempered hardboard 02

eed chipboard 04

Brickaere oad

Blockwork 096

Cement render 11.00

lass 1.05

Appendix 2 Materials data

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

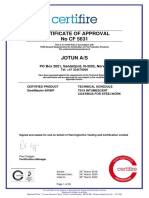

- Certificate of Approval No CF 5631: PO Box 2021, Sandefjord, N-3202, NorwayDocument20 pagesCertificate of Approval No CF 5631: PO Box 2021, Sandefjord, N-3202, NorwayMatt MacDonaghNo ratings yet

- Unistrut CatalogDocument172 pagesUnistrut CatalogMatt MacDonaghNo ratings yet

- S.I. No. 497:1997 - Building Regulations, 1997.Document18 pagesS.I. No. 497:1997 - Building Regulations, 1997.Matt MacDonaghNo ratings yet

- Civil Liability Act, 1961Document21 pagesCivil Liability Act, 1961Matt MacDonaghNo ratings yet

- Copy RIAI Contract ScanDocument26 pagesCopy RIAI Contract ScanMatt MacDonaghNo ratings yet

- Consolidated BRegs 2020 AnnotatedDocument88 pagesConsolidated BRegs 2020 AnnotatedMatt MacDonaghNo ratings yet

- Lafarge Drywall ManualDocument6 pagesLafarge Drywall ManualMatt MacDonaghNo ratings yet

- ETAG 007: Guideline For European Technical Approval ofDocument46 pagesETAG 007: Guideline For European Technical Approval ofMatt MacDonaghNo ratings yet

- Staifix Wall Ties & Restraint FixingsDocument36 pagesStaifix Wall Ties & Restraint FixingsMatt MacDonaghNo ratings yet

- Made Simple: Natural StoneDocument20 pagesMade Simple: Natural StoneMatt MacDonaghNo ratings yet

- Gypwall™: Staggered Stud Acoustic Partition SystemDocument14 pagesGypwall™: Staggered Stud Acoustic Partition SystemMatt MacDonaghNo ratings yet

- British Gypsum Internal Wall Insulation Systems Gyplyner Iwl Insulated Dry Lining SystemDocument14 pagesBritish Gypsum Internal Wall Insulation Systems Gyplyner Iwl Insulated Dry Lining SystemMatt MacDonaghNo ratings yet

- Gypframe Metal Products: Safety Data SheetDocument11 pagesGypframe Metal Products: Safety Data SheetMatt MacDonaghNo ratings yet

- Gypwall™ and Gypwall™: The Definitive Metal Stud and Partition SystemDocument24 pagesGypwall™ and Gypwall™: The Definitive Metal Stud and Partition SystemMatt MacDonaghNo ratings yet