Professional Documents

Culture Documents

Chapter 1. Timber Frame Construction

Chapter 1. Timber Frame Construction

Uploaded by

Matt MacDonagh0 ratings0% found this document useful (0 votes)

6 views15 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views15 pagesChapter 1. Timber Frame Construction

Chapter 1. Timber Frame Construction

Uploaded by

Matt MacDonaghCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 15

1 Timber frame construction: An overview

4 Timber frame construction:

An overview

‘Timber frame is method of construction. It is not a system of building

although there are a number of well researched systems which use timber

frame as & basis, Timber frame construction uses timber studs and rails,

together with a wood-based sheathing, to form a structural frame which

‘transmits all vertical and horizontal loads to the foundations (Figure 1.1

‘The exterior cladding is non-losdbearing, although it may contribute to wind

resistance; it is used te weatherproof the building and to provide the desired

external appearance.

Figure 1.4 Pia

TRADA Technology Timber frame construction,

In the UK, timber freme construction generally uses factory-manufactured

vrall frames and roof trusses, of, in some cases, roof panels, with only a few

specialist companies making and erecting framas on site. The extent of

factory prefabricetion can and does vary considerably; from the prevalent so

called ‘open panels’ consisting of simple sheathed stud panels with

breather membrane, to the Jess common ‘closed panels’ which include insu-

lation and internal Linings and may also include components such as joiner

and eometimes also cladding. Floor and roof panels may also be factory.

piefabricated as open panels with simple joists or rafters and sheathing

panels, or as closed panels with insulation, linings eto fitted in the factory.

Economic and functionel issues typically dictate the choice between open

‘and closed construction, The selection of an appropriate arrangement is an

erly decision in the design process.

‘Timber frame primarily developed in the UK for house building, although it

is also widely used for buildings such as hotels, hostels, clinics, nursing

hhomes, schools, student accommodation, offices and similar structures.

1.1 Methods of construction

Platform frame is the most commonly used method in the UK. Bach storey is

framed with floor-to-ceiling height panels and the floor deck of one floor

becomes the erection platform of the next (Fgure 1.1}, This book conoen-

trates on design and construction principles of the platform frame method.

‘The prefabricated wall panels can be either small units (up to approximately

3.6 m in length), designed to be manhandled into place within health and

safety guidelines (Figure 1.2a) or up to full elovation-width panels with or

‘without ancillary components for placing with a crane (Figure 1.3). On-site

stick build smatl pane} construction is also utilised in the UK (Figure #.2b),

on: a Small panels; b On-site stick bulld

Figure 1.3 Platform frame construction: Large panels.

1 Timber frame construction: An overview

ES EEE

Other types which may be used include:

Floor-!o-floor panel frame: this is an erection method whereby the wall

panels (except for the topmost storey) are floor-to-flooy, or storey height,

rather than floor-to-ceiling and the intermediate floors aze hung inside the

wall panel (Figure 1.4), This method is not common in the UK but does

reduoe orces-sectional shrinkage of timber in the external wall and enables

the insulation and vapour control layer to be continuous up the wall face,

Volumettic: involves the factory fabrication of box units which can form indi

vidual rooms, or larger spaces, complete with finishes and services and

which requize crane erection (gure 1.6). This is best suited to repetitive

units, such as hotels, hostels or nursing homes. Bathroom pods are the only

widespread use of volumetric construction in the UK timber frame industry

Pods thet form complete dwellings are not widespread, due to the high front-

end cost and the requizement for a large number of repetitive units

Figure 1.4 Storey height panels (may be

large or small)

Post and beam: comprises a loadbearing system of posts and beams with

lightweight timber or glazed infil panels (Rgure 1.6). In the UK, this tends to

i be used in the specialist ‘traditional appearance’ market, but there are

modern timber frame eyetems using post and beam in the UK and elsewhere

in Burope.

Figure 1.5 Volumetric construction Figure 1.6 Post and beam construction

Timber frame panels and other components are usually obtained fiom a

Specialist manufacturer/fabricator although they can, loss commonly, be

Tsnulactured by the contractor, either offsite or m @ temporary fectory on

the site. Most fabricstors have developed their own method of fitting

‘ogether the timber frame components and are able to offer a full building kit

\o their own designs, or to designs produced by theit cients. Same produos

components to detaile supplied to them and leave responsibility for the

Sttuctorel or constructional detailing of the final building ta the designer

Whatever the procurement method used, itis important thet the client and

‘supplies egies exactly what the timber fame package will comprise, even

own to supply andor fixing of oose items such as noggings and strutting,

This chapter provides a broad introduction to timher frame construction;

biote detailed consideration is given to particular espects in si nt

one is given to particular aspects in subsequent

TRADA Technology Timber frame construction

1.2 Modern timber frame

Platform frame external wall panels axe constructed from vertical studs,

normally at 400 mm or 600 rama contes, nailed with simple butt joints to top

and bottom rails, Strength graded timber must always be used: 89 x 98 mm

and 140 x 38 min are the most common sizes but 97 x 47 mm sections are

flso used, With the increasing neod for eneicy efficiency, even deeper studs

{are boing specified. The size of panels dictates the method of construction,

eg whether to use a crane for erection. Wind bracing is usually provided by

@ wood-based board material, normally nailed to the external face of the

frame (Figure 1.7) of in certain cases, by ctoss-racing combined with

intemal plasterboard, Alvemative wall designs, using either wood-based

oars, mineral fibre boards or fibre reinforced gypsum boards, fixed on the

intemal face of the studs t0 provide the wind bracing, have also been

developed (Figure 1.7b) and are discussed in more detail in Section 44.

Inter ning if

required

internal

sheathing to

0d framework

Internal ring

Vapour control

layer

Insulation

Ineuation

Sheathing to

‘8d framework

— High

performance

breatier

membrane

Breather

membrane

lading cladding

Ventiaes — Ventilated caviy

canty

Figure 1.7 Typical wall construction: a (left) sheathing on external face of frame b (ight) sheathing on internal face of frame

External claddings can be chosen from a wide range of materials, including

brickwork, cement rendered blockwork, tiling, slating, timber boarding,

coment render on battens or proprietary claddings.

Internal loedbearing and non-loadbeering walls may be constructed simply

by using a stud frame lined on both sides with plasterboard or other sheet

material, Petty walls are generally constructed from two separate stud

frames (twin leaf), with fore inculation between the studs, end room inings

of at Jeast 20 mm of plasterboard applied in two or more layers with

staggered joints. It is also possible to construct party wells with a brick or

concrete block core between the two timber frames; this provides @ method

for supporting masonry cladding to walls at steps (changes of level) between

buildings.

Floor and roof framing are similar to other forms of construction, although

the junction detailing is different, The intermediate ‘loors and the roof

provide structural diaphragras which, by means of structurally efficient

20

sancti

1 Timber frame construction: An overview

connections to the walls, contribute to the overall stability of the building,

Fioor framing, particulasly for modium-rise buildings, is taking advantage of

superdry timber and new materiols with increasing use of engineered

timber components, such as Hoists and metal web joists, and structural

timber composites, uch as laminated veneer lumber (LVL) or parallel strand

umber (PSL) for header joists and rim beams

‘The structural design of all timber frame buildings needs to be approved by

fa etructural engineer. The timber frame manufactusers will produce their

‘own drawings priot to panel manufacture, These will have a high degree of

accuracy and are often used directly via CAD/CAM systems in the manufac-

turing process.

‘The platform frame method of building timber frame favoured in the UK is

suited to both low-rise and medium-rise buildings. Medium-tise timber

frame (normally up to a maximum of seven storeys) has seen significant

growth in the UX over recent years

‘The need for a significant increase in house-building in the UK is generating

{interest in modern methods of construction to deliver the numbers of units

required, Timber frame is a tried and tested method able to deliver the speed

‘and quality associated with off-site construction. The sustainability and

Glimste change agenda is encouraging clients, developers, builders and.

cccuplers to recognise the environmental benefits of using @ renewable

structural material, This agenda is slso driving requizements for beter

‘thermal performance, in terihs of both insulation and air tightness. On all

these counts timber frame scores highly, providing good insulation values

‘and alr tightness in quality construction, using a structural material with

proven environmental credentials

1.3 Performance of timber frame construction

1.3.1 Thermal performance

‘The overall thermal resistance of the building envelope is the main factor in

Astermining its energy requirement, although other fectors such as ventila-

tion contiol, the building form, orientation and efficiency of the heating

system, all influence the cost of achieving comfortable conditions,

‘Timber frame conser

3 incorporates high levels of insulation within the

structural elements (Figure 1.7) and can achieve U values significantly

Detter than the minimum requirements of national building regulations, In

der to reduce the amount of water vapour entering the wall, which may

Condense as ¢ result of the temperature differential actoss the structure iis

‘Rormal practice to ensure that the internal face (lining) ofthe wall has more

Tesistance to water vapour than tho extemal faco of the fame. This is

usually achieved by placing a vapour contro layer on the inside face of the

stud frame, behind the wall lining but on the warm side of the insulation

‘There ate no differences between timber frame and other forms of construc-

tion so far as roof or ground floor insulation is concerned

In comme

" ‘with all forms of construction, windows and doors should be

Giaught-sealed and lobbies should be provided where possible to reduce

niilation heat loss. Small cracks and gaps at junctions, eg between

2

TRADA Technology Timber frame construction

windows and walls should be sealed. Alt permeability requirements end

accredited details differ nationelly and local recuirsments should always be

checked. Timber frame can achieve low air permeability values with correct,

detailing. The lower the air permeability value the more important it is to

have a inechanical ventilation end heat recovery system which enables

controlled movement of fresh and stale, warm and cool ait into and from the

building, A minimum requirement for winter ventilation should be the

provision in all rooms of trickle ventilators, usually fitted in the window

ame, together with provision for higher ventilation rates in bathrooms,

Jotchens and utility rooms, eg ay installing extract fans or passive ventile-

ton systems.

Insulated timber frame construction has relatively low thermal capacity and

therefore a fast response to heat input. In housing where heating is intermit

tent, this fast response can result in increased comfort and energy savings

However, the most important factor in energy saving, in ell construction

types, is to ensure that the heating system is compatible with the building

fabric response and the predicted occupancy pattern. Consideration should

always be given to using the sun as a supplementary heat source using

‘passive solar design techniques,

In the UK it is questionable if thermal mass for energy savings can be

realised with any form of construction when considering typical dwelling

esign and size. This is due in part to the area of glazing that would be

requized and the lack of sun-generated heat during the cold season. There

ate timber srame buildings designed that do utilise thermal mass but. a well

insulated timber frame dwelling will achieve the desired ambient air

temperature, cool or warm, efliciently without the use of thermal mass

Since occupants can have a significant effect on the energy efficiency of

uildings, designers should provide an operation manual to enable them to

‘obtain maximum benetit from the energy efficiency measures included

1.3.2 Fire performance

1.3.2.1 Fire resistance

‘The fie resistance of a timber frame structure is achieved by e combination

of the internal lining material, the timber structure and the insulation, Fixe

resistance requirements fos elements of construction aie defined in national

building regulations

Fite resistance performance is determined by tests carried out to the require-

‘ments of either British or European Standards by a UKAS (United Kingdom

‘Acoreditation Service) approved fire test laboratory. The relevent standards

BS 476 Mie tasts on building materials and structures Parts 20 10 24 (or

Part 8 for tests carried out prior to the dates specified in building

regulations)

S EN 1365 Fire resistance tests for loadbearing elements Parts 1 and 2

BS EN 1364 Fre resistance tests for non-loadbearing elements Parts 3

and 2

BS BN 1634-1 Fre resistance tests for door and shutter assemblies

22

|

|

BS BN 1966 Pre resistance tests for service installations (various parts)

may also be relevant

European classification Is undertaken in accordance with:

|Rg EN 13501-2 ire classiiostion of construction products and building

tion of data som fire resistance tests, excluding

clements. Classi

ventilation services.

‘There are other ways of demonstrating fire resistance performance:

+ caloulations in accordance with BS 6208-4 Section 42

‘Recomimendations for calculating Sor resistance of timber stud walle and

joisted oor constructions

4 design in accordance with Burocode 1-1-2 and Eurocode &:

4 constructions included in the BRE Report BR 128 Guidelines for the

construction of fire resisting structural elements

‘+ an assessment of the construction which is acceptable to the building

control authority,

‘Thirty and sixty minutes fire resistance are the current normal requirements

for low and medium rise buildings, The greater resistance is usually

obtained by the use of a double layer of plasterboard, each layer fixed inde:

pendently, with the joints staggered. Plasterboard is the most commonly

‘used lining material due to its economy, ease of working, and good fire

performance, Other materials can be used, provided an appropriate fire test

‘or assessment has been caztied out,

In many timber frame constructions, cavity barriers are required between

the timber frome and the cladding to restrict the passage of flames and hot

gases if a fie wore to occur in this outer cavity. Internal cavities, eg party

‘wall cavities, also require cavity barriers in prescribed locations. The

requirements for cavity barriers are different in Scotland compared with

‘other parts of the UK.

1.3.2.2 Reaction to fire

In aduition to fire resistance, it is necessary to control the potential for the

Jinings of walls and ceilings to contribute to @ developing fire. This potential

{8 assessed through a series of ‘reaction to fire! tests which can be carried

ut in accordance with the British or European Standards listed below:

BS 476-6 Method of test for fire propagation for products,

BS 476-7 Method of test to determine the classification

spread of flame of products

the surface

Note: In some sivaations, Building Regulations call for @ performance

Supetior to those defined in BS 476-7. This is designated Class O and can be

‘met by combining results from BS 476.6 and BS 476-7.

1 Timber frame construction: An overview

TRADA Technology Timber frame construction

BS EN ISO 1182 Reaction to dire tests for building products. Non

combustibility test

BS EN ISO 1716 Reaction to fire tests for building products.

Determination of the gross calorific value

BS EN 12822 Reaction to fire tests for building products. Building

products excluding foorings exposed to the thermal attack by a single

burning item

BS ENV ISO 11925 Reaction to fire tests for building products. Ignitabibty

when subject to direct impingement of flame.

European classification is undertaken in accordance with

BS EN 13501-2 Fre classification of construction products and building

‘elements. Classification of data from lire resistance tests.

‘The requirements are Jaid down in national regulations for different levels of

risk which are based on the size and purpose group of the relevant part of

the building, The national clasolfications de not equate with the European

ones and products cannot typically assume a European class unless thay

have been tested accordingly.

Table 1.1 shows typical flame spread ratings for cladding and lining

‘materials to national standards

Table 1.4 Typical national surface spread of flame ratings for commonly used timber

frame cladding and lining materials

(Clasatication to BS 476-7 [and ES 4765) [Material

ea aero

|Coment render

Te and slate hanging

|Comert-bonded paricleboard

Flore coment boards

Plasterboara

Treated” wood-based materia og softwood,

harcwood, plywood, OSB, chipbosr,

Imesiumbcard, mdf, hardboard, ofboard

[cass 7 irate ict materi 09 sotv00d

Jnarcwood, plywood, OSB, chipboard,

Imectumboard, maf harcboard, sotboard

cast [Tiber or waod-based boards with a densiy|

lgreater than 400 kg/m (painted or

unpainted)

IF “Treatad Tay consist af sana Tiber Iripragnated with fame relardant chenfeals

Jcoated wit aflame retardant frish or wood-based pane! products to which treatments ae]

lapped during or afer manufacture, by impregnation ofthe bres othe finshed board, by

Ite incorporation of ery chemicals ito particle coatings and adhesives or by the

[application of surface coatings tothe board

24

‘Tne European system allows gonoric groups of products with known and

predictable fire performance to be ‘Classified Without Further Testing’

(CWET). This approach has been applied to vatious types of wood products,

including untreated wood-based panels as shown in Table 12. Further infor

mation ie available ftom FireRetard.Com wurw fireretard.com

‘Table 1.2 European reaction to fire CWET ratings for wood-based panels (from BS.

EN 13986)

1 Timber frame construction: An overview

[iicad-baced panel mounted without an air gap [BS EN reference [Minimum denaliy [Minimum [Reaction to fire class

against class At oF A2st, dO products with minimum aim? thickness (excluding floorings)

density 10 kgim?, or atleast class D-s2, d0 products mm

lt: minimum density 400 kg/m’

[ose IBSEN 300 [B00 a Be oo

[Parideboaras BSENSTZ [600 ie Daz ao

[Fiveboads [hardboard jBSENeae —_[o00 fe ibe ao

fnedumboard IBSEN as [600 Fe Bee oo

joo P IE pane

jotboare IBS ENea+ [250 ie IE pase

oF JBSENexs [600 ie [D200

Piwoos IBS ENves5 [400 g [D2 00

[Cement bonded parteebowad™ IBSEN 6ae2 [7000 he lest

[Said wood pandie IBSEN Tas [400 Hz [p20

[ Gamant content ational 75% by mass

[Products can bo treated to upgrade ther performance to European class C or B. There is continual development of suitable product,

[The WPA Manual Industral fame retardant eatment of solid timber and panel products gives details

‘There may also he requirements to control external surface spread of flamne

in certain buildings. This is, to some extent, affected by building height and

use, but is primarily governed by the distance of the building from the

boundary,

‘As with any type of construction, it is important thet a fire risk assessment

is cartied out before construction begins on site, No smoking, provision of

fire extinguishers, training of operatives using blowtorches or other hot

‘trades, as well as the appropriate site security are some of the precautions

thot can be taken on a timber frame site. Me performance of timber frame

dwellings, TRADA Wood Information Sheet produced in association wits

the UK Timber Frame Association contains information on fire safety in

lumber frame construction sites and guidelines to assessing risk

1.3.3 Sound insulation

‘Timber frame structures rely to a large degree upon structural separation to

Achieve sound techuction, rather than incorporating mass into the structure

National building regulations require walls and floors separating dwellings

from another building, another part of the building, or another dwelling, to

resist aitborne sound. Floors above a dwelling, which separate it from

another dwelling or from another part of the same building, not used

25

exclusively as part of the dwelling, are required to resist impact sound. The

use of approved design detalls or acoustic testing in the completed building

is tequited for floors separating dwellings.

Sound insulation of walls between two adjoining occupancies Is achieved

mainly by the use of two separate stud walls with an air space between

them; the studs are plasterboard faced, with a sound absorbent material in

one or both of the stud cavities (see Chapter 6).

Reduction of aitborne sound through floors separating dwellings is also

achieved by the use of an absorbent blanket in the structural floor, a heavy

plasterboard ceiling that may be separated from the structure by resilient

bare, plus @ floating upper layer. This floating layer also serves to reduce the

taansmission of impact sound as do the resilient bars (see Chapter 7)

‘The requirements for airborne sound reduction within a dwelling differ

nationally and local requirements should always be checked

aizborne sound insulation requirements ate required within a dwelling, labo

ratory test reculte will suffice, Internal airborne sound transmission between

rooms can be reduced by the use of multiple Linings and/or sound absorbing

‘materials, such as mineral wool, in the stud cavity. Limiting sound transmis.

sion through floors within @ dwelling, or other floors, is achieved by the

snoorporation of an absorbent blanket in the structaral floor and a prescribed

mass in the floor deck. If better results are desired they can be easily

achioved by tho use of additional plasterboard end the inclusion of resilient,

bars to support the ceiling,

Sound transmission levels through extemal walls are normally governed by

the presence and relative size of window and door openings, the effective:

ness of weatherstripping and the form of multi-glazing, An imperforate

timber frame external wall can achieve 45 to 60 decibels sound reduction,

depending upon the cladding used.

4.3.4 Durability

‘The long-term durability of any construction must always be considered ae

part of the design process, For timber, the potential for decay, arising from

high moisture content levels, is usually the major consideration, Timber

which remeine et @ moisture content of 20%, or less, is below the decay

threshold. Preservative treatment may he specified as an insurance, and

may be required by warranty bodies, where timber c

sible or difficult to replace. Timber ascecsed as being ot risk of remaining

above this moisture content level for protonged periods, eg cladding, should

either be a naturally durable species or be treated with preservative

‘The vast majority of low tise timber frame buildings in the UK uses

softwoods rated as non-durable (see Appendix 1) for the structural compo-

nents. However, properly designed and constructed timber frame buildings

do not rely upon preservative treatments for durability. The wall framework

{is designed so that st will maintain an equilibrium moisture content. comfort-

ably lower than that which could allow fungal growth. It is, however,

common practice for the structural components in the external wall to be

preservetive-treated as an insurance against any future failure of the

weather resistant cladding which might allow water to penetrate to the

umber structure, The Building Regulations require softwood roofs in certain

26

1 Timber frame construction: An overview

areas of England to be weated with a ‘suitable’ preservative against the

house longhorn beetle.

‘There is no specific requirement to preservative-treat suspended timber

ground floor components although these are also sometimes treated to

reduce the risk of deterioration if, for example, ventilation aix paths are inad-

vertently blocked during the life of the building.

‘Timber cladding and any supporting battens are normally treated with

suitable preservatives unless the timber used is sufficiently durable and

contains no sapwood. External joinery should be manufactured from

Durability Class 3 (moderately durable) timber epecies o: better, or from

other suitable joinery species treated with preservative.

For further information on preservative treatments see Appendix 1, Section

ALS.

1.4 Dimensional discipline

1.4.1 The structural grid

The regular spacing of studs, joists end roof members in a timber frame

construction leads naturally to the use of a simple planning grid at the

design stage. Since most sheathing, lining and flooring materials aie

supplied in sheets 2400 mm Jong and 1200 or 600 mm wide, the most

obvious structural grids are 400 mm or 800 min. T

for wall studs end floor jolsts is 600 mm.

‘most common spacing

‘The 600 mm modular grid is very effective when planning lige buildings

(gure 1.6), This can be advantageous in reducing cutzing and wastage of

sheet materials but may prove a difficult discipline, especially in buildings

that contain a number of party walle between dwellings, or smell buildings

where size is dictated by plot size. It is helpful to consult a timber frame

manufacturer at an early stage of the building design process and it is

essential that the manufacturer be instructed on the dimensioning position

Uused in the design of the building before panet design and fabrication

commences,

/-—Non-mosiuer

mo meme memo mo /omteupsnd

oa tH

> | | |

Overat

itera

wth of

m | Bulging

I

L i

1 | {

on |

Figure 1.8 Using a structural gia’ on a

hon-modular building

TRADA Technology Timber frame construction

When choosing the grid in planning there are advantages and disedvan-

tages in each of the three methods below, In practice, there is often a combi.

nation of all three methods used. Whichever method is being utilised, i is

recommended that the discipline is clearly noted and followed during

planning, setting out and the building process.

Placing the external face of the cladding, typically brickwork. on the grid

gives cleat overall building dimensions and placement for openings in

zelation to the externel cladding. The disadvantage is that the designer may

‘wish to determine room size and opening locations according to practical

‘and aesthetic considerations rather than being constrained by the module of

external brickwork (see Section 9.3},

Placing the finished wall face, typically plasterboard, on the grid gives clear

finished spaces of modular dimensions, which allows the simple fitting of |

standard components such as staircases, dootsets and kitchen units. The

disadvantage is that setting out dimensions are moze complex since

allowance should be made for the thickness of wall linings on all component

izes at junctions

Placing the face of the extemal structuzal timber frame wall and the timber

face of internal walls on the grid simplifies setting out dimensions but

produces finished spaces less than the full modular size. It is, however, the

method most commonly used by timber frame manufacturers. During this

planning phase the designer should be aware of the wall types, their meas-

urements and the cavity widths to be included in the building (Rigure 1.9).

‘Wall dimensions aze governed by

‘© Cladding (self-supporting brick or blockwork ox supported by the timber

frame)

¢ Extarnal wall cavities (typical cavity width 60 mm for brick and block)

4 Party wall cavitios typical cavity width 89 mm)

+ Sheathing thickness (typically 9 min)

+ Swad depth (typically 89 or 140 mm)

4+ Linings (single and/or double for acoustic and fire performance). Internal

and party wells may be sheathed and lined. Typically, spaniel party

‘walls are lined but not sheathed, whereas external gable end spanciel

panels typically are sheathed but not lined.

‘With the use of 140 mm external walls and 89 mm party/internal walls there

may be unwanted steps in the surface of adjoining walls if they are not

shifted or the 89 mm wall is not battened out. It may also be necessary to

batten out wall around WCs thet contain the services to achieve the

specified acoustic performance.

Except for the floor zone extending out to the external and party wall cavity,

Doth the floor layout and roof design are similar to other types of construc-

tion. When planning large open areas in the floor plan and/or unique roof

design it is advisable to contact a timber frame manufacturer early in the

rooess to discuss loed transfer issues.

28

|

1 Timber frame construction: An overview ‘

9

aera

— -

q 7 I 1 I

= = ee

u 4450 2830

~ External wall panels (140 mm timber)

Beal ober

ere

eee

: ieee

3 plasterboard qecral inher tas

een ganic i:

. sm os8 seating moll}

‘

q ic | CI

Stud layout stars at begining of wall with

Centre of fist stud at 600 msn, The rerraicing

wall studs are at 800 mm centres for xing

of standard sheathing

Figure 1.9 Example of timber frame wall panel layout

j

‘struct ae '

timber face

29

Tt rrr

cavly

TRADA Technology Timber frame construction

4.4.2 Vertical dimensions

In planning and in setting out

important considerations include

vertical dimensions (Figure 1.10) the

«External ground level

4 Foundation system

«Finished floor level

+ Floor to ceiling height

+ Opening size and sill type

+ Floor zone makeup

+ ‘Top floor ceiling lining

+» Roof overhang

+ Coursing of brick external cladding

It is common practice to standardise the panel height and the depth of floor

joists in order to maintain constant floor-to-floor dimensions. The ground

‘and top floor wall panels are often of different height from the storey panels

between, due to the foundation, ceiling lining, and floating floor where

(ied, The variation in joist span capacity is adjusted by altering the joist

spacing and/or by using joiste of a highsr strength class timber or structural

timber composites (see Appendix 1),

Vertical dimensions of wall panels can be arranged to make use of standard

sheet materials where possible, and various methods are available to the

designer to achieve this. If cutting is necessary, arguably itis proferable to

accept cutting the external sheathing to the required size if this enables the

internal lining to be in uncut sheets,

4.4.2.4 Brick cladding

With standard door and frame components 2.1 m high (other heights are

available) a 2100 mm dimension from datum (finished Moor level) to the

underside of the lintel fits an increment of 300 min or 4 brick courses. Careful

consideration of the brick coursing at the hase is therefore necessary for the

‘coursing to line through at door head level.

If the fitst floor levet datum is also a brick course, it enables the coursing to

run unchanged to the heads of upper floor openings. However, this is not

essential since it causes no difficulty for the coussing above 2.1m to be

‘gauged to suit non-standard brick dimensions up to the sill and head of the

upper floor windows

Changes in level at steps between adjoining buildings should correspond

‘with brick coursing dimensions to enable the coursing to continue across

adjoining buildings.

Most other claddings are not affected by vertical dimension rules (soe

Chapter 9),

30

4.980

7.800m

2,309

a.149m

§ 2 3

g yg

il

=h

a

af 8 8 &

me

zi 3 3

|

el

& ada

ig a} 8s

]

8

..000,m

34

1 Timber frame construction: An overview

Figure 1.10 Example of vertical heights

{or a three storey block of fais.

For iferenial movement sllowenoes see

Chapter 9 and Figure &1, and Chapter 10 i

{and Figure 10.8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

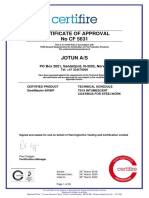

- Certificate of Approval No CF 5631: PO Box 2021, Sandefjord, N-3202, NorwayDocument20 pagesCertificate of Approval No CF 5631: PO Box 2021, Sandefjord, N-3202, NorwayMatt MacDonaghNo ratings yet

- Unistrut CatalogDocument172 pagesUnistrut CatalogMatt MacDonaghNo ratings yet

- S.I. No. 497:1997 - Building Regulations, 1997.Document18 pagesS.I. No. 497:1997 - Building Regulations, 1997.Matt MacDonaghNo ratings yet

- Civil Liability Act, 1961Document21 pagesCivil Liability Act, 1961Matt MacDonaghNo ratings yet

- Copy RIAI Contract ScanDocument26 pagesCopy RIAI Contract ScanMatt MacDonaghNo ratings yet

- Consolidated BRegs 2020 AnnotatedDocument88 pagesConsolidated BRegs 2020 AnnotatedMatt MacDonaghNo ratings yet

- Lafarge Drywall ManualDocument6 pagesLafarge Drywall ManualMatt MacDonaghNo ratings yet

- ETAG 007: Guideline For European Technical Approval ofDocument46 pagesETAG 007: Guideline For European Technical Approval ofMatt MacDonaghNo ratings yet

- Staifix Wall Ties & Restraint FixingsDocument36 pagesStaifix Wall Ties & Restraint FixingsMatt MacDonaghNo ratings yet

- Made Simple: Natural StoneDocument20 pagesMade Simple: Natural StoneMatt MacDonaghNo ratings yet

- Gypwall™: Staggered Stud Acoustic Partition SystemDocument14 pagesGypwall™: Staggered Stud Acoustic Partition SystemMatt MacDonaghNo ratings yet

- British Gypsum Internal Wall Insulation Systems Gyplyner Iwl Insulated Dry Lining SystemDocument14 pagesBritish Gypsum Internal Wall Insulation Systems Gyplyner Iwl Insulated Dry Lining SystemMatt MacDonaghNo ratings yet

- Gypframe Metal Products: Safety Data SheetDocument11 pagesGypframe Metal Products: Safety Data SheetMatt MacDonaghNo ratings yet

- Gypwall™ and Gypwall™: The Definitive Metal Stud and Partition SystemDocument24 pagesGypwall™ and Gypwall™: The Definitive Metal Stud and Partition SystemMatt MacDonaghNo ratings yet