Professional Documents

Culture Documents

And Industries Limited

Uploaded by

Rajnish ShuklaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

And Industries Limited

Uploaded by

Rajnish ShuklaCopyright:

Available Formats

SUTLEJ TEXTILES AND

INDUSTRIES LIMITED

suta and industries limited

Lotus Corporate Park, 'E' Wing, 5th/6th Floor,

185/A, Graham Firth Compound, Near Jay Coach,

Goregaon (East), Mumbai - 400 063, INDIA.

Phone : (022) 4219 8800/6122 8989 Fax : (022) 4219 8830

E-mail : info@sutlejtextiles.com Website : www.sutlejtextiles.com

CIN No. : L17124RJ2005PLCO20927

09th May, 2022

BSE Ltd. National Stock Exchange of India Ltd.

Phiroze Jeejeebhoy Towers, Exchange Plaza, 5th Floor, Plot No. C/1,

Dalai Street, Fort, G-Block, Bandra - Kuria Complex,

Mumbai 400 001. Bandra (E), Mumbai 400 051.

Scrip Code: 532782 Scrip Code: SUTLEJTEX

Ref.: Disclosure under Regulation 30 of SEBI (Listing Obligations and Disclosure

Requirements) Regulations, 2015

Dear Sirs,

Sub: Greenfield expansion project - 89,184 spindles

The Board of Directors at its meeting held today i.e. 09th May, 2022, have inter alia, considered

and approved setting up of a green field project for 89,184 spindles comprising of Cotton Mélange

Yarn and PC Grey Yarn along with Dye House in Jammu & Kashmir at an estimated project

cost of Rs. 914 crore which will be implemented around Q4 FY 2025. The project will be funded

through internal accruals and debt.

The existing capacity of the Company in yarn production is around 4.21 lakh spindles. The

Company operates at around 94 - 95% capacity utilization.

The rationale for the expansion project is given in Annexure A.

You are requested to kindly take note of the above.

Thanking you

Yours faithfully

For Sutlej Textiles and Industries Limited

Manoj Contractor

CIS

Company Secretary and Compliance Officer

Encl.: a/a

(Govt. Recognised Three Star Export House)

Regd. Office : Pachpahar Road, Bhawanimandi - 326 502 (Rajasthan)• Mills : Bhawanimandi (Raj.), Kathua (J&K), Baddi (H.P.), Bhilad (Guj.)

sutie

and industries limited

Annexure A

Rationale for Expansion

The entire Indian Textile & Apparel Industry after witnessing a strong recovery from the

pandemic is now embarked upon a new trajectory of growth. Textile & Apparel (T&A) being

one of the largest in world trade and exports is effectively in the midst of a gradual shift away

from single source country and the efforts targeted at diversifying the supply chain. Since

India's T&A value chain has underlying strengths in the form of country being a huge source

of raw materials (India is one of the world's largest producers of raw cotton), with presence

across the value chain and quality of the products, the aforesaid phenomenon is being

considered as a huge opportunity for the Indian Textile Industry. Indian spinners and home

textile players are being considered as the key beneficiary of this favourable trend.

The textile sector continues to witness robust demand. This positive outlook is further getting

supported by a favourable policy in the form of Government's initiatives to enhance the ease

of doing business, generate employment, create market access, correct sector's weaknesses

like the lack of scale, boost textile exports, ambitious schemes like PLI scheme for MMF

Segment, Mega Investment Textile Parks (MITRA) Scheme and Extension of RoSCT,

RoDTEP and different FTAs already done or planned to benefit the entire textile value chain.

Besides strong improvement in capacity utilization, this has also spurred a series of aggressive

capex plans across spinning, processing, made ups and garment manufacturing by major

textile players.

With the 2nd largest spindle capacity in the world, the Indian spinners are seeing full utilization

of their capacities and superior margins as the yarn business remains strong. The

unprecedented growth and improvement in profitability over the last few quarters has been on

account of China+1 policy and US ban on Chinese textile products made from Xinjiang cotton.

With expansion in capacities, consolidation and export demand for Indian yarn still at

reasonably good levels, the Indian spinning business is witnessing strong growth.

The Company is not present in the greige (grey) product segment. In order to compliment the

dyed/melange product offering, the Company needs to have grey product in its product basket.

In view of increasing demand of cotton/polyester blends across multiple categories of end use,

there is market potential for grey blended yarns both in domestic and exports.

You might also like

- A Project Report On Working Capital Management at Gadag Textile Project Report by Babasab Patil (Karisatte)Document75 pagesA Project Report On Working Capital Management at Gadag Textile Project Report by Babasab Patil (Karisatte)Harsh TrivediNo ratings yet

- Chairmans Statement 2019Document5 pagesChairmans Statement 2019Narendra MauryaNo ratings yet

- SWOT Analysis For ACC CementDocument5 pagesSWOT Analysis For ACC CementAliantus ArchNo ratings yet

- Kiri Q4FY20 EarmingsDocument28 pagesKiri Q4FY20 EarmingsSwamiNo ratings yet

- Industry OutlookDocument9 pagesIndustry OutlookMohammed Saleem KhaderNo ratings yet

- CottonDocument17 pagesCottonSakhamuri Ram's100% (1)

- Managerial Aptitude Assignment 3Document5 pagesManagerial Aptitude Assignment 3najla fedawiNo ratings yet

- Krutika Pradip Gada: Manufactures Of: Spunbond Nonwoven FabricsDocument4 pagesKrutika Pradip Gada: Manufactures Of: Spunbond Nonwoven FabricsspipsmailNo ratings yet

- Chenab Textile MillsDocument18 pagesChenab Textile MillsRockyNo ratings yet

- Finance Project - TextileDocument72 pagesFinance Project - TextilePooja Bindal100% (1)

- SM PDFDocument10 pagesSM PDFabhishek tyagiNo ratings yet

- Aditya Vision Limited: Puonrals SeDocument44 pagesAditya Vision Limited: Puonrals SeContra Value BetsNo ratings yet

- Gujarat Textile Policy 2012Document15 pagesGujarat Textile Policy 2012Michael KingNo ratings yet

- TEXPROCIL Member Profiles - VTG 2017 - ENGDocument10 pagesTEXPROCIL Member Profiles - VTG 2017 - ENGAnkit KaushikNo ratings yet

- Working Capital Management at Gadag Textile Project ReportDocument75 pagesWorking Capital Management at Gadag Textile Project ReportBabasab Patil (Karrisatte)100% (1)

- Investor Presentation - Q2FY2018-19 KiriDocument25 pagesInvestor Presentation - Q2FY2018-19 Kiriravi.youNo ratings yet

- BSE Limited. National Stock Exchange of India Ltd. Metropolitan Stock Exchange of India LTDDocument4 pagesBSE Limited. National Stock Exchange of India Ltd. Metropolitan Stock Exchange of India LTDdipyaman patgiriNo ratings yet

- CGPOWER 13032024073419 Press Release 13032024Document3 pagesCGPOWER 13032024073419 Press Release 13032024Sashil ReddyNo ratings yet

- Industrial Analysis: Textiles, Electronics and AutomobilesDocument26 pagesIndustrial Analysis: Textiles, Electronics and AutomobilesKhoai TâyNo ratings yet

- Goodluck IndiaDocument15 pagesGoodluck Indialong-shortNo ratings yet

- A Study On Financial Analysis of Ultratech Cement Industry: Dr. C. Vadivel, K. Satya BhamaDocument3 pagesA Study On Financial Analysis of Ultratech Cement Industry: Dr. C. Vadivel, K. Satya BhamaSIVARANJANI PNo ratings yet

- Ambuja Cements: Report by V Niraj AdityaDocument5 pagesAmbuja Cements: Report by V Niraj AdityaBell BottleNo ratings yet

- 500 1000 Imo Company Update 20230215Document74 pages500 1000 Imo Company Update 20230215Contra Value BetsNo ratings yet

- Gujarat Ambuja Exports Limited: Sub.:-Our Intimation Letter Dated September, Bearing Reference NoDocument1 pageGujarat Ambuja Exports Limited: Sub.:-Our Intimation Letter Dated September, Bearing Reference NoHimat KhimaniNo ratings yet

- 178 Research Report Sel Manufacturing Company LTDDocument8 pages178 Research Report Sel Manufacturing Company LTDPasupathy VkNo ratings yet

- Balkrishna IndustriesDocument11 pagesBalkrishna IndustriesRohit KhannaNo ratings yet

- BEML LTD Organization StudyDocument64 pagesBEML LTD Organization StudyArpitha Kagdas100% (2)

- GTN Project Sub by KrishnaDocument86 pagesGTN Project Sub by KrishnaYepuru ChaithanyaNo ratings yet

- INVESTOR GUIDE Technotex 2013 PDFDocument200 pagesINVESTOR GUIDE Technotex 2013 PDFmukesh0887No ratings yet

- Aditya Birla SummaryDocument10 pagesAditya Birla SummaryChris NgoNo ratings yet

- Siya RamDocument62 pagesSiya RamNeeraj SoniNo ratings yet

- Patidar CottonDocument57 pagesPatidar CottonFarhanNo ratings yet

- Company Production Installed Capacity Net Profit (2008-2009) (Rs Lakhs)Document7 pagesCompany Production Installed Capacity Net Profit (2008-2009) (Rs Lakhs)Ponnoju ShashankaNo ratings yet

- MBA - Final Year Project - Employee SatisfactionDocument76 pagesMBA - Final Year Project - Employee SatisfactionThabi christyNo ratings yet

- NAME: Vishant Krishnan ROLL NO: 714 Room No: 24: Ultratech Cement: A SWOT Analysis and Perception of The BrandDocument15 pagesNAME: Vishant Krishnan ROLL NO: 714 Room No: 24: Ultratech Cement: A SWOT Analysis and Perception of The BrandRitika MalhotraNo ratings yet

- Services,: The Manager The ManagerDocument2 pagesServices,: The Manager The Managervishal3152No ratings yet

- VikasDocument29 pagesVikasGaurav SharmaNo ratings yet

- Chapter - 1: Introduction of GrasimDocument66 pagesChapter - 1: Introduction of GrasimLovish SharmaNo ratings yet

- Cement: Indian Cement Industry AnalysisDocument4 pagesCement: Indian Cement Industry AnalysisDeepak KapoorNo ratings yet

- Introduction To Enterprise: Mini Project On Entrepreneur Development and ProgramDocument26 pagesIntroduction To Enterprise: Mini Project On Entrepreneur Development and Programhasnain57233% (3)

- 17-5 Poddar PigmentsDocument12 pages17-5 Poddar Pigmentsvra_p100% (1)

- Nithyakalyani - Main ChaptersDocument25 pagesNithyakalyani - Main Chaptersselva100% (1)

- A Project Report On Ratio Analysis at The Gadag Co-Operative Textile Mill LTD by Babasab Patil (Karisatte)Document68 pagesA Project Report On Ratio Analysis at The Gadag Co-Operative Textile Mill LTD by Babasab Patil (Karisatte)rajmalaleNo ratings yet

- N0822MAYURUNIQDocument30 pagesN0822MAYURUNIQPoonam AggarwalNo ratings yet

- Brief Profile AnchlikDocument10 pagesBrief Profile AnchlikDeepika GuptaNo ratings yet

- Con Call Trascript 17-01-2024Document19 pagesCon Call Trascript 17-01-2024mathnetindiaNo ratings yet

- The Apparel IndustryDocument8 pagesThe Apparel IndustryTharindu IlleperumaNo ratings yet

- Falcon Tyres LTD BSE: 509527 - NSE: FALCONTYRE - ISIN: INE511B01024 Market Cap: (Rs - CR.) 82 - Face Value: (RS.) 5 Industry: TyresDocument21 pagesFalcon Tyres LTD BSE: 509527 - NSE: FALCONTYRE - ISIN: INE511B01024 Market Cap: (Rs - CR.) 82 - Face Value: (RS.) 5 Industry: TyreschethansoNo ratings yet

- STK ITD Cem Presentation June 2020 1Document35 pagesSTK ITD Cem Presentation June 2020 1krishna prasadNo ratings yet

- 1000 2000 Corp Action 20220510Document82 pages1000 2000 Corp Action 20220510Contra Value BetsNo ratings yet

- 1000 2000 Result 20220510Document207 pages1000 2000 Result 20220510Contra Value BetsNo ratings yet

- An Introduction: Fibers, Yarns & Threads Industry OverviewDocument41 pagesAn Introduction: Fibers, Yarns & Threads Industry OverviewDipak KashyapNo ratings yet

- Chapter-1: Organization Study at Aditya Birla Ultratech LTDDocument65 pagesChapter-1: Organization Study at Aditya Birla Ultratech LTDSarva ShivaNo ratings yet

- Prince PipesDocument46 pagesPrince Pipessherwinmitra0% (1)

- Sub: Submission of Analysts/Investors Presentation Ref: Letter Dated April 20, 2022 Informing About Analysts/Investors CallDocument26 pagesSub: Submission of Analysts/Investors Presentation Ref: Letter Dated April 20, 2022 Informing About Analysts/Investors CallAMRISH SATISH DOLASNo ratings yet

- Authorized Signatory: R Gi T Ed of I: 15 5, H D in T - 9 129 50 E-Mai Esco Tsgroup C S Co I S Om Ra I N I LDocument3 pagesAuthorized Signatory: R Gi T Ed of I: 15 5, H D in T - 9 129 50 E-Mai Esco Tsgroup C S Co I S Om Ra I N I LPãräs PhútélàNo ratings yet

- CottonDocument43 pagesCottonEkta JoshiNo ratings yet

- Overview of Indian Cement Industry 2010Document17 pagesOverview of Indian Cement Industry 2010shubhav1988100% (2)

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- CRISIL Research - Assessment of Textile Industry - 28122021 (1) .3918a049Document93 pagesCRISIL Research - Assessment of Textile Industry - 28122021 (1) .3918a049Rajnish ShuklaNo ratings yet

- Brandloyaltybehaviourpsv SabriDocument10 pagesBrandloyaltybehaviourpsv SabriRajnish ShuklaNo ratings yet

- Textile Excellence Aug1-7Document12 pagesTextile Excellence Aug1-7Rajnish ShuklaNo ratings yet

- Vca Jordan Apparel Final Report - Cbi4Document76 pagesVca Jordan Apparel Final Report - Cbi4Rajnish ShuklaNo ratings yet

- Texprocil GCCDocument2 pagesTexprocil GCCRajnish ShuklaNo ratings yet

- Final WelspunDocument76 pagesFinal WelspunAnkit Jain0% (1)

- 2025 Sustainable Cotton Challenge Report - 2018 1Document66 pages2025 Sustainable Cotton Challenge Report - 2018 1Rajnish ShuklaNo ratings yet

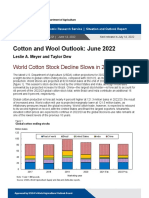

- CWS 22fDocument6 pagesCWS 22fRajnish ShuklaNo ratings yet

- Agrarian DisputesDocument15 pagesAgrarian DisputesBryle Keith TamposNo ratings yet

- Anouk - Hotel New YorkDocument46 pagesAnouk - Hotel New YorkRossi Tan100% (2)

- BPHC HRSA-23-025 (H8H) FY 2023 Ending HIV Epidemic - FinalDocument44 pagesBPHC HRSA-23-025 (H8H) FY 2023 Ending HIV Epidemic - FinalTuhin DeyNo ratings yet

- Bplo Application FormDocument1 pageBplo Application Formraymond puaNo ratings yet

- Specpro 4Document12 pagesSpecpro 4Venice SantibañezNo ratings yet

- Ordnance Survey Business Portfolio Price ListDocument24 pagesOrdnance Survey Business Portfolio Price ListjoebrickleyNo ratings yet

- District Memo 2021 PPST PPSSHDocument2 pagesDistrict Memo 2021 PPST PPSSHRosalie MarquezNo ratings yet

- Khilafat Movement 1919-1924Document17 pagesKhilafat Movement 1919-1924Grane FrameNo ratings yet

- CCP Motivation Letter 2022Document3 pagesCCP Motivation Letter 2022mohammed ahmed0% (1)

- Elizabeth Stevens ResumeDocument3 pagesElizabeth Stevens Resumeapi-296217953No ratings yet

- Amazon Go ReportDocument3 pagesAmazon Go ReportkatyaNo ratings yet

- Salesforce - Service Cloud Consultant.v2021!11!08.q122Document35 pagesSalesforce - Service Cloud Consultant.v2021!11!08.q122Parveen KaurNo ratings yet

- Module - No. 7 CGP G12. - Name of AuthorsDocument77 pagesModule - No. 7 CGP G12. - Name of AuthorsJericson San Jose100% (1)

- Republic V Encelan GR No 170022 January 9, 2013Document20 pagesRepublic V Encelan GR No 170022 January 9, 2013ultra gayNo ratings yet

- Aac04 2017Document153 pagesAac04 2017Panneer SelvamNo ratings yet

- FDDocument17 pagesFDYash BhatnagarNo ratings yet

- Listening Test 2Document5 pagesListening Test 2teju patneediNo ratings yet

- Proposing A New InitiativeDocument8 pagesProposing A New InitiativeMike WonderNo ratings yet

- 08 - Case Law-Unknown Case Law ListDocument28 pages08 - Case Law-Unknown Case Law ListNausheen100% (1)

- Grupo NovEnergia, El Referente Internacional de Energía Renovable Dirigido Por Albert Mitjà Sarvisé - Dec2012Document23 pagesGrupo NovEnergia, El Referente Internacional de Energía Renovable Dirigido Por Albert Mitjà Sarvisé - Dec2012IsabelNo ratings yet

- Outgoing Global Volunteer: OG V BramantyaDocument12 pagesOutgoing Global Volunteer: OG V BramantyaPutri Nida FarihahNo ratings yet

- Auditing Unit - 5 by Anitha RDocument16 pagesAuditing Unit - 5 by Anitha RAnitha RNo ratings yet

- Levi Strass and Co v. Papikan Enterprises Trademark MSJDocument12 pagesLevi Strass and Co v. Papikan Enterprises Trademark MSJNorthern District of California BlogNo ratings yet

- Bang e Dara PDFDocument274 pagesBang e Dara PDFAtta ur Rehman100% (1)

- DMDocument12 pagesDMDelfin Mundala JrNo ratings yet

- Kanchipuram Silk SareesDocument12 pagesKanchipuram Silk SareesChandni Agarwal Dixit100% (2)

- IJN Minekaze, Kamikaze and Mutsuki Class DestroyersDocument11 pagesIJN Minekaze, Kamikaze and Mutsuki Class DestroyersPeterD'Rock WithJason D'Argonaut100% (2)

- Against Open Merit: Punjab Public Service CommissionDocument2 pagesAgainst Open Merit: Punjab Public Service CommissionSohailMaherNo ratings yet

- How To Survive Economic CollapseDocument4 pagesHow To Survive Economic CollapseZub AleandruNo ratings yet