Professional Documents

Culture Documents

DESCRIPTION

DESCRIPTION

Uploaded by

gobinath VP0 ratings0% found this document useful (0 votes)

5 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views8 pagesDESCRIPTION

DESCRIPTION

Uploaded by

gobinath VPCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

THE PATENTS ACT 1970

AL

A

ARIG

COMPLETE SPECIFICATION

A DEAD WEIGHT PRESSURE REGULATOR SYSTEM

FOR A PRESSURE COOKER

5

TTK PRESTIGE LIMITED,

11™ FLOOR, BRIGADE

TOWERS, 135 BRIGADE ROAD, BANGALORE 560 025,

uv KARNATAKA, AN INDIAN COMPANY

wo

~

THE FOLLOWING SPECIFICATION PARTICULARLY

DESCRIBES THE NATURE OF THIS INVENTION AND

THE MANNER IN WHICH IT IS TO BE PERFORMED.

This invention relates to a dead weight pressure regulator

system for a pressure cooker.

The term “pressure cooker” in this specification not only means

a pressure cooker commonly known as such, but also other

pressure vessels (autoclaves) wherein steam is generated and

retained under pressure.

The dead weight pressure regulator systom proposed herein is

self-contained so that it can be mounted on a pressure vessel,

such a8, a pressure cooker to maintain the internal pressure of

the said vessel at a value predetermined by the dead weight of

the said system.

Dead weight pressure regulator systems are known to the art.

In the known system, the upward movement of the dead weight,

when steam pressure acts on it, is limited by pins and a split

ring, the said pins restricting the upward movement of the dead

woight to a predetermined limit.

The above known arrangement has its drawbacks:

The pins get worn out soon as a result of the frequent

movement of the dead weight while letting out steam and the

equally frequent contact between the pina and the valve atem.

Variation in operation of the pins takes place resulting from

variation in the dimensions and strength of the pins.

Since the pins are metallic and thus not flexible, the manual

force required for withdrawing the dead weight from its seating

and inserting it back into place, ultimately causes damage to the

pins and the metallic valve stem, due to the frequent metal to

metal contact between the pins and the valve atem, leading to

the malfunctioning of the eystem.

Accordingly this invention proposes a dead weight pressure

regulator system by which the above mentioned drawbacks

associated with the known system are ovviated, resulting in an

efficient, durable and smooth funotioning device.

The various features and advantages of the dead weight

pressure regulator system, not hereinbefore explicitly set forth

will be apparent from the following further description.

The dead weight pressure regulator system for a pressure

cooker, according to this invention, comprises a dead weight

provided with a lifting knob and a valve pin; a valve stem with

an orifice normally closed by the valve pin, a portion of the

external periphery of the valve stem > tapering outwards,

characterised by a groove in the dead weight body surrounding

the valve stem below the tapered periphery; and an O-ring,

made out of an elastomer, appropriately seated in the groove

but protruding sidewards, out of the groove, to butt against

the tapered periphery, whenever the dead weight lifts under the

pressure of steam within the said cooker.

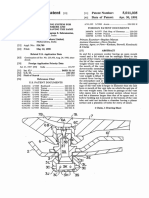

This invention will now be described with reference to the

accompanying drawings which illustrate, by way of example,

and not by way of limitation, one of various possible

embodiments of tho dead weight pressure regulator system

proposed herein,

Fig.1 illustrating the external view of the embodiment

And

Fig.2 illustrating a seotional view of the said embodiment.

The embodiment has a dead weight 14, the sleeve of which is

indicated by 4.

A lifting knob 7 enables the assembly to be manually lifted and

replaced in position.

A valve pin 6 of the dead weight normally closes an orifice 9 of

the valve stem 3 whenever the dead weight is in place. The

orifice 9 communicates with the interior of the pressure cookor,

go that as long as the steam pressure inside the cooker is at or

below a predetermined limit, the valve pin keops the orifice 9

closed, but when the pressure exceeds the limit, such pressure

forces the valve pin 6 to lift the dead weight 14, thus opening

the orifice 9 and allowing the steam to oscaps, until the

pressure reduces to allow the dead weight 14 to revert to its

normal position and thus cause the valve pin 6 to close the

orifice 9 once again.

‘The escape of steam takes place through the vents 10. A cowl

5 acts as a shield for preventing the escaping steam from

scalding the user.

As already explained in the known dead weight pressure

regulator system, the upward movement of the dead weight

under steam pressure above the predetermined limit is restricted

by pins against which the valve stem butts when the dead

weight is moved upwards by the steam Furthermore, whenever

the dead weight is to be manually removed and replaced from

time to time, it is only by a sliding friction contact between the

dead weight and the valve stem that this can be achieved. As

explained above this results in wear and tear of the pins, leading

to malfunctioning of the system.

‘This invention, however, is characterised by a groove 12 which

surrounds the valve stem 3 below the taper 13; and an O-ring 2

made out of an elastomer, snugly seated in the groove but

protruding sidewards, out of the groove.

Thus, whenever there is a pressure build-up inside the prossure

cooker, above a predetermined lim it, steam in the valve stem 3,

acting on the valve pin 6, lifts the dead weight 14. While doing

so the O-ring comes into contact with, thus butting against, the

tapered portion 13 and halts the further upward travel of the

dead weight 14. On the steam now escaping through the vents

10, the pressure reduces to @ value below the predetermined

limit, and the dead weight 14 reverts to its normal position.

It will thus be observed that the contact between the O-ring 2

and the tepered portion 13 eliminates the harsh metal to metal

contact of the known pressure regulator system, that the manual

removal of the dead weight 14 and replacement thereof in

position is smooth and effective by reason of the metal to elastomer contact (valve stem

to O-ring contact)

‘The O-ring is made of an elastomer capable of withstanding the continuous working,

temperature of steam, The O-ring is made of nitrile rubber, silicone rubber, fluoro

elastomer, chlorosulfonated. polyethylene

‘The terms and expressions in this specification are of description and not of timitation

{inasmuch as various other embodiments of this invention are possible without departing

from the scope and ambit thereof

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Winter Spiti - ALLDocument15 pagesWinter Spiti - ALLgobinath VPNo ratings yet

- J R. CatalogueDocument4 pagesJ R. Cataloguegobinath VPNo ratings yet

- ClaimsDocument2 pagesClaimsgobinath VPNo ratings yet

- Hawkins US5011035Document5 pagesHawkins US5011035gobinath VPNo ratings yet

- Hawkins 1 US4534485Document5 pagesHawkins 1 US4534485gobinath VPNo ratings yet