Professional Documents

Culture Documents

Condition Monitoring Conmon

Condition Monitoring Conmon

Uploaded by

fahrian050 ratings0% found this document useful (0 votes)

23 views12 pagesOriginal Title

Condition-Monitoring-Conmon(2)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views12 pagesCondition Monitoring Conmon

Condition Monitoring Conmon

Uploaded by

fahrian05Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 12

COMPANY PROFILE

Condition Monitoring Products & Services

www.cistech.co.id

PT. CISTECH ALPHA INDONESIA is an Engineering Company focuses in providing high

quality products and services in the area of preventive and predictive maintenance.

Established in 2005 and at first represent Bruel & Kjaer Vibro as an exclusive distributor in

Indonesia and through over years, Cistech has gained acceptance and recognition for the

provision of technologically advance Vibration Monitoring products coupled with supreme

professionalism to support the activities of installing, commissioning and after sales supports.

Over the years, as the company has grown and scope pf products sales have expanded to

Laser Alignment system, Infrared Camera, Quality Measurement Tools and Workshop

Balancing Machine while our Condition Monitoring Services includes : Vibration Analysis

Survey, Insitu Balancing, Onsite Laser Alignment, Infrared Thermography and IR Gas Leak

Services.

Vision

To become an Indonesian leading company providing integrated Condition Monitoring

‘System and Solution

Mission

‘To offer the best Condition Monitoring products and services, targeted at helping plants in

achieving optimized machines availability, productivity and quality while continuing

reducing overall cost

To offer highly competence engineering skills by on going development of our people

Culture

Integrity — Commitment - Team Work — Education - Gratitude

Romas Djailani - Director

BOC eet Rn Eee

a spectris company

You can view, save and open your data

anytime, anywhere, and with anyone

SETPOINT CMS does not care where you .

store the data. Bssoor meet

Better technology, better reli Removable 32GB

and better value. SD card in rack

256G8 embedded

solid-statehard

dive in rack

@.& Ce B&:

VIBROCONTROL 8000 (VC-8000)

See Seat aay

en eee reuc Rm Reels)

Pee ena Cue)

noma ica cena chs

Up to 60 vibration/position/speed channels

ea eres h reesei

can be monitored and displayed in a single

ceaeres

SETPOINT® CMS Condition Monitoring Software

Advanced analytics the way you want it

CMS data, whether stored in your PI System or in our .cms format files, is “open” allowing you to export

it to spread-sheets and use it with other software.

Sharing and storage flexibility the way you want

SETPOINT™ CMS software is designed to be just like Adobe® Reader® so that you can view, save

and open your data anytime, anywhere, and with anyone

Online Condition Monito:

VCM-3 adds a new dimension of healthcare awareness to your assets, whether it be balance-of-plant,

non-critical machines and even isolated critical machines.

Accessories/Spars

GYRO Nn kon coed GSE do nee

reac Prana rocco Preedateal

2x DIN clip including serews, for mounting anno

A2039 2 DDAUSIVCM-S to a DIN-all (2x DIN clips P2136 Se eee rea ‘

required fer one VCM-3) “J

Machine Protection System

Machine protection is mandatory if you want to avoid catastrophic machine damage and expensive

production losses. An effective protection solution will evaluate several machine parameters to shut

the machine down only when necessary to protect the machine and its environment.

Accessories

SAMto Display _SystemPower__-ExtemalPower Power Connection Weathesproot

cama cate ‘Supplies, Modul Housing

The portable VIBROPORT 8000 (VP-8000) hardware platform is based on our rack-based VC-8000 machine

protection system. Using the VIBROPORT 8000 you can connect to your existing machinery protection systems

to immediately view, log, and share all data needed to understand machinery behaviors.

Leave the VIBROPORT 8000 connected to your machines for hours, days, or months. It collects all valuable

data ~ even without a computer connected to the rack. The VIBROPORT 8000 is ideal for monitoring during

turnarounds or following maintenance. Collect startup and shutdown data and keep an eye on machine

resonances. Connect the VIBROPORT 8000 to your machines during process changes to monitor any degrading

mechanical conditions.

SETPOINT® CMS Software powered by OSIsoft PI VIBROSUITE — Standalone Wind Turbine

SETPOINT® to PI Adapter Monitoring

VC-8000 Setup Software Compact Monitor Setup Software for Configuration

of VIBROCONTROL 9xx & VIBROCONTROL 18xx

FSS rE carTanied Software fee cemuurn Compact Analyzer Software for Configuration of

Report & Route Manager Software VIBROCONTROL Ox & VIBROCONTROL 18x

MT RCT Ey

ab

Se ally

AGM

4) aa al

ala

seating DSS i Transmitt lonemsen cor

Eo

| 3

PS OU eel Wen Ole) ete Ae Sees Uo) (@ @ OSIsoft.

is now part of AVEVA

OSlsoft’s market-leading P| System is the proven system of record for operational data in essential

sectors such as power generation and utilities, water, oil and gas, mining, metals, manufacturing,

pharmaceutical, facilities, transportation, food and beverage, and more. Every day, industrial

professionals in 146 countries rely on the PI System to improve performance, protect health and safety,

keep the lights on, and make the world run more smoothly.

PI System is a cost-effective choice for companies deciding

whether to buy or build an operational data store to support

analysts and data scientists.

The PI System’s integrated

product portfolios :

PLEDGE

BENEFITS FOR OPERATIONS | BENEFITS FOR BUSINESS

Pervasive, real-time data collection

for remote assets and lloT devices

PI CORE

On-premises for 24/7critical

operations

PI CLOUD

Scalable, integrated data

services for advanced analytics

Tie itera Tc

‘Customize fe) ‘Custom Applications

Bussiness System

Notifications

Event Frames =

= —_— & PI Cloud Connect

Bussiness Intelligence Tools

Pl interfaces integrate. HiMcrosot EI%.. @esri

& eet,

PI Connectors

Visualize PI Vision

Geile atatink

PI System delivers cleansed and formatted data to analysis tools, data science and AI/ML platforms,

and applications. The seamless integration of Pl System products across the operations core, edge,

and in the cloud ensures data integrity and allows data to be shared securely outside the industrial

control network.

PI System empowers employees across and beyond the organization with ready access to a rich set

of operations data to visualize trends, reveal relationships, and support new business opportunities.

SENSORS FOR CONDITION MONITORING

PYMISENSORS

A PCB PIEZOTRONICS DIV.

PCB offers a full line of

eae cue ess ace

velocity sensors, dual output

vibration sensors, 4-20 mA

See en ene ea cee

relays, cables, displays and

Prececeicd

NTU Reta eric)

Cerne tere ed

Peet ees ences

IMI® Sensors is used to spot imbalance, bearing faults and misalignment by measuring machine

vibration, providing early fault diagnosis thus reducing downtime with the product line interfaces directly

with data acquisition equipment including online systems and handheld data collectors.

Typical vibration monitoring instrumentation

involves accelerometers, switches, 4-20 mA

transmitters, cables, junction boxes and other

accessories.

But the main components to a vibration

monitoring system are:

+ Sensors, including cables and junction

boxes

+ Data collection device

+ Monitoring/analysis software

This condition monitoring is driven by turbine

operator's biggest challenge — to monitor

combustion instability to ensure trouble-free

operation, worker safety, and to prevent

catastrophic failures. IMI high-temperature

accelerometers and pressure sensors are

manufactured to meet the specific power

generation and petrochemical design

requirements, including intrinsic safety

certification in accordance with ATEX and CSA.

Applications :

- Motor Vibration

- Paper Machines and Conveyors

- Gearboxes

- Steel Rolling and Annealing

- Vibratory Screens and Feeders

~ Mining Equipment

- Pumps and Submersible Pumps

- Shock in Shipping Containers

- Machine Tool Spindles

- Rotary Screw Compressors

- Food and Beverage Manufacturing

Applications :

- Combustion Instability in Gas Turbines

- Cooling Towers and HVAC Systems

- Reciprocating Machinery

- Nuclear Power Plants

- Wind Turbines

- Oil & Gas

- Hydroelectric Power Plants

- Industrial Cryogenic Facilities

> Agate. OPE CLM Ue Ole

AT-2040 provides a positive 24-volt supply for 4-20 mA input sensors

and negative 24 volts for proximity probe drivers. AT-2040 can also

simulate a wide variety of accelerometers, proximity probes and other

transducers that can be feed back into drivers, cabling, connectors,

and meters to quickly conduct system checkouts and new system

install

Application: — - Cabling and wiring troubleshooting

- Vibration signal simulation - accelerometers

and velocity probes

- Machinery speed signal simulation

- Calibration of

+ Accelerometers

+ Proximity probes and drives.

+ Monitoring systems

+ Charges amplifiers

AT-2040 + Avionics equipment

eRe eRe Advanced Features :

fella lel Mele me Iie ols

Ce ere mue ST)

Pee mcet ens

voltage, IEPE, charge

Seen

- Built-in sensor signal conditioner

let cece ieeteMts Net ected

Sse Ra etn cee

Ser cs eee cir

- Automatic mass load correction

Eee te Cee ni

USMC Mure cclar|

ern tees ol BONUS stn

BS Bue Reo Cur el te Ome ECR ong

Other Agate’s Products You May Need

AT-2035

AT-2035 is here as an alternative to a portable calibrator as an affordable alternative. This version is

designed by combining the features of AT-2030 standard portable calibrator and AT-2040 executive-class

portable vibration calibrator.

AT-2030

AT-2030 shaker table and vibration calibrator is a variable frequency, variable amplitude, battery operated

portable shaker capable of calibrating accelerometers, transducers, and proximity probes. It is designed

for simple accelerometer and vibration transducer calibration without the need for advanced features.

AT-2050

AT-2035 is here as an alternative to a portable calibrator as an affordable alternative. This version is

designed by combining the features of AT-2030 standard portable calibrator and AT-2040 executive-class

portable vibration calibrator.

EEXERTHERM” permanent infrared Hotspot Detection

24x? Thermal Monitoring

Continuous Thermal Monitoring will predict 70% more failures

PE ar ee ot Renta

APPLICATIONS :

LV Switchgear

MV Switchgear

Dry Transformers LV Transformers

Motor Control Centre

The key benefits of the ARM XI

+ Monitoring 24x7 up to 80 Exertherm Sensors

and / or up to 60 MCC Drawers for potentially

compromised joints and terminations;

+ Using industry standard Modbus TCP/IP allows

the pass through of the ‘raw temperature data’ to

a host system — this enables data to be integrated,

+ Protecting circuits operating at a low load with

the Patented Exertherm LoadMap solution

This can adjust the warning alarm level to suit

the maximum load that will be applied to a circuit

Sensors)

trended and stored according to client

requirements;

Inspection Frequency

% Chance of Problem Detection

Positioning

View

Reliability

Availabilty

Safety

Self-diagnostics

Low Load

es

Thermal Imaging/Windows

Typically 1 day out of 365 = <1% of

time

0.27%

External

Limited

Dependent on luck/correllation

Data is not integrated or real-time

Places operator at risk

Operator dependent

Extremely difficult to detect faults

being thermally monitored. (This is only applicable

to the circuits using the 8ch Datacard / IR EM

eed

ern aC)

24x7/365 = 100% of time

100%

Internal

Unlimited - direct line of sight

Continuous reliable data

Real-time data - integrated to

BMS/EMS/SCADA

Increases facility/operator safety

Automatic.

Load related alarm thresholds

The most common cause of electrical failures and arc flash incidents is poor busbar:busbar joints and

cable terminations. A compromised joint can only be identified by the excess heat it generates. Not to

confuse ‘excess heat' with ‘heat rise’, Exertherm sensors measure the Delta T (AT).

| a

PRE-CUT SHIMS

BO CuO mur eR ret ae ’

Pre-cut Shims make alignment and other machine levelling tasks easier and more cost effective

It made from high-grade stainless steel material to prevent corrosion from exposure to acid or alkalis

in sizes to suit almost any type of machine.

a Itis available in several machine foot sizes, each with different

thickness options and pre-packed in refillable aluminium framed

i ~ case fitted with clearly marked slots to hold individual sets of

© shims to give exactly the right alignment correction facility for

almost any machines,

The pre-cut shims are completely flat, ensuring stability,

consistent machine support over the full surface of shim and

also burr-free with specially rounded corner to avoid injury to

operatives during alignment positioning,

Ge

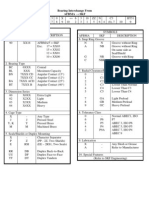

Designation Quantity A B C Thickness Bolt size

R-50-0025Ak 10pcs SOmm 50mm 13mm 0.025mm = M12.

R-50-005An 10pcs_ 50mm 50mm 13mm —0.05mm m2

R-50-010Ap 10pcs_ = 50mm = 50mm = 13mm_—_0.10mm m2

R-50-020Ar 10pcs_ 50mm = 50mm 13mm —0.20mm m2

R-50-0025Bk 10pcs 50mm 50mm 13mm 0.025mm = M18.

R-50-005Bn 10pcs 50mm 50mm 13mm 0.05mm M18

R-50-010Bp 10pces 50mm 50mm 13mm 0.10mm M18

-C R- 50-020Br 10pcs 50mm SOmm 13mm 0.20mm. MIs

Oe eee

3.00 mm then bolt size R-50-0025Ck 10pcs 50mm 50mm 13mm = 0.025mm M27

M36 & M52 that doesn't R- 50-005Cn 10pcs 50mm 50mm 13mm 0.05mm M27

shown tiie (abies! R-50-010Cp 10pcs_ 50mm 50mm 13mm_—_0.10mm M27

R- 50-020Cr 10pces 50mm 50mm 13mm 0.20mm M27

Vibration We invite you to explore how certification can create a competitive

@ Institute advantage in yourcareer and for your employees.

Basic Machinery Vibration (BMV) prepares attendees to perform basic vibration analysis on industrial machinery

sing single-channel measurements, with or without trigger signals, according to established and recognized

procedures. It covers basics of sensors, database and data collector setup, data collection, signal processing,

fault analysis, and basics of single plane balancing. It is partial preparation for the Vibration Analyst Category Il

Certification Exam. The workshops and demonstrations scheduled throughout the training course are used

to illustrate theory and applications.

NTN ue ae Rae ty

advantage in yourcareer and for your employees.

Introduction to Machinery Vibrations (IMV) prepares attendees to perform a range of simple machinery

vibration condition monitoring and diagnostic activities. It is recommended for individuals as an

introduction to machinery vibrations and is partial preparation for the Vibration Analyst Category |

Certification Exam. The workshops and demonstrations scheduled throughout the training course are

used to illustrate theory and applications.

Accreditation by ANSI ensures that the Institute's vibration analyst certification program and process

Ce Ue RR ee cM Rk RU Re ied Rog eco

Peete uA

For certified vibration analysts OIE

eee ee oe ee

eae eNotes one

Coto Tee lee ole ie (eM LEU

effective practices.

It ensures technical competence and a

measurement for advancing careers.

Vibration Analysis Service

There are 3 characteristics that consider in vibration analysis :

amplitude, frequency, and phase — where they have their own

role in this scope. The amplitude changes in vibration level are

used to evaluate the severity of the machine, the frequencies

are used to recognize the machine faults that cause the

vibration, and phases are used to understand well the machine

behavior when operation.

In-situ balancing service

Unbalance is the most common problem and it has found out

in all-over rotating equipment. It takes a dominant amplitude

at 1x rpm of machine speed to be indicated as an unbalance

problem, It may turn into excessive vibration then ruined out

the bearings or others machine components.

Precission Laser Alignment

The most cause of machine vibration that created energy loss

and less efficiency is misalignment. It occurs during the

machine operation where stator and rotor have no linear

position. It's still elusive to detect the misalignment problem,

because it has influenced by machine speed and stiffness of

the system.

Infrared Thermography

Thermographic analysis provides a high-resolution, non-contact

means of monitoring the condition of electrical and electrome-

chanical equipment, roofing and wall insulation, and refractories

with a detailed report is submitted including electrical anomalies

found with colour photo documentation, infrared images,

summaries of problems and corrective actions to be taken.

Infrared Gas Leak Finder

ThermaCAM GasFindIR camera easily locates Hydrocarbon

leaks and with exact leak source info, repairs are less time

consuming and less expensive. Itis also cost-effectively as

numerous components are scanned simultaneously, identifying

gas leak with pinpoint accuracy.

Machinery Performance Test

Production machine performance is one of the most important,

things that must be considered. For this reason, maintenance

needs to be carried out.

10

PT Cistech Alpha Indonesia

Green Sedayu Biz Park Blok DM-6 No.15,

Jl. Daan Mogot Raya Km.18,

Kalideres - 11840

West Jakarta, Indonesia

Phone : +62 (21) 22522445

Fax: +62 (21) 22522 448

Email : info@ptcai.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pulse Height Analysis PlotDocument1 pagePulse Height Analysis Plotfahrian05No ratings yet

- Mech7350 13 Rolling Element BearingsDocument19 pagesMech7350 13 Rolling Element Bearingsfahrian05No ratings yet

- Simple Relay Motorbike Flasher CircuitDocument1 pageSimple Relay Motorbike Flasher Circuitfahrian05No ratings yet

- Variasi BandungDocument5 pagesVariasi Bandungfahrian05No ratings yet

- LTC Diagnostics EpriDocument10 pagesLTC Diagnostics Eprifahrian05No ratings yet

- Behind Pump VibrationsDocument30 pagesBehind Pump Vibrationsfahrian05No ratings yet

- AFBMA To SKFDocument1 pageAFBMA To SKFfahrian05No ratings yet