Professional Documents

Culture Documents

Rice Mill

Rice Mill

Uploaded by

omkar maharana0 ratings0% found this document useful (0 votes)

12 views14 pagesOriginal Title

rice mill79bbb68d-d63c-4b30-985e-0766e60f9b31(1)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views14 pagesRice Mill

Rice Mill

Uploaded by

omkar maharanaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 14

ale

PROJECT PROFILE

Name of Unit : M/s. PRADEEP GURUNATH AROLKAR

Promoter : Mr. Pradeep Gurunath Arolker

Product : Rice Mill (Polish & Steam Boiled Rice)

Factory Location : Plot No.B-25-26/13, Kundaim Industrial Estate,

(Proposed) Kundaim, Ponda, Goa

Office : C-02, Poonam Apts, Kaziwada, Ponda,Goa —

Production Capacity : 4000 M.T.

Mob: : 9423812249

Email : arolkarp@yahoo.co.in

PAN No. : AFKPA6713R. .

Project Cost : Rs. 152.25 lakhs “

1,0 INTRODUCTION

Paddy or rice grain consists of husk and brown rice, Brown rice, in tum, contains bran Which

comprises the outer layer and the edible portion. Rice milling is removal or separation of husk

(de-husking) and bran to obtain the edible portion for consumption. The process has to be

accomplished with care to prevent excessive breakage of the kernel and improve recovery of

paddy or rice. The extent of recovery during milling depends on many factors like variety of

paddy, degree of milling required, the quality of equipment used, the operators, etc. Rice mill

is a common activity and can be started in many parts of the country and considering the

leverage of production of paddy in Goa and neighboring states, and increasing demand for

consumption rice in Goa due to influx of people for better prospects and livelihood, this

project report considers Goa as the prospective location.

ae

1.1 OVERVIEW

The production of rice in India has grown substantially with coverage of area of 43 million

hectares with an output of 110 million tones. The export of non-basamati rice by India is

highest in 2015-16 amounting to with export of 6.37 million tones in 2016-17 In recent times

Goa, is witnessing increase in production of paddy due to Govt. support for farming activities.

The consumption of rice is also increasing on account of floating as well as regular influx of

people from neighboring states who are mainly consumer of rice. Thus the farmers are likely

to get attracted towards growing rice in the fields and thus a big leap is expected in production

of rice in Goa. A bright future awaits to food processing industry and the rice mill is one of

the major area of growth.

L.MISSION

/ © To purchase the produce of paddy growing farmers of Goa at the best price.

©, To facilitate hardship of Goan farmers in curtailing the cumbersome process of boiled

rice ie. boiling, drying, processing in huller thereby subjecting the farmers to

hardships, time and low quality processed boiled rice.

LP. To give best quality rice by using state of art modem machinery for processing.

© To restore the confidence of Goan farmers in paddy farming lost due to lack of quality

processing facility in Goa.

© To curtail import of polished rice in Goa from neighboring states vis-d-

joa economy.

a make Goa hub for quality polished and boiled rice with brand Goa.

_©. To engage locals and provide gainful employment.

© To increase production with timely adoption of new technology in the processing area

and provide best price for the produce of the farmers thereby increasing area under

farming.

ve

2.0 PROMOTER’S PROFILE:

‘The promoter is a 45 yrs. youth highly educated with degree in Commerce (B.Com) and Post

Graduate degree in Personnel and Labor Management . He is presently employed in an

renowned company having multiple responsibility in personnel and labor management as

well as marketing. He is an upcoming entrepreneur having vision to be a successful business

man to become self reliant and be an employer and provide employment to locals. His long

experience in marketing and management will be quite useful in successful management of

the enterprise. The product selection is based on the market survey , availability of raw

material, marketing and good infrastructure.

3.0 PRODUCTS

3.1 Applications

What comes out during milling operation are husk, milled rice or edible portion, bran and the

broken rice. Depending upon the type of rice mill, the by-products come out in mixed or

separated form. Milling is usually done when paddy is dry (around 14% moisture content).

Wet soft grains are powered and very dry brittle grains would break.

3.2. Availability of technical know-how and Compliances.

CFTRI (Central Food Technological Research Institute), Mysore, has successfully developed

the technical know-how. Compliance under the PFA Act (Prevention of Food Adulteration) is

compulsory.

We

4.0 MARKET POTENTIAL

Rice is considered to be staple food diet in most parts of India including the Western, East and

North-East states. Paddy is the most important agricultural commodity in these zone and the

total area under cultivation is estimated to be around 80% of the total cultiv:

growing area. Apart from every household, there are many bulk buyers like hospitals,

caterers, restaurants, hostels, etc. The establishment of single window shopping at malls,

in rice

departmental stores, wholesalers, etc will be explored for marketing of the products. With

proper efforts, it is possible to enter into a long term contract with big traders or contractors.

Besides, the support price for paddy from the Govt. make the price competitive compared to

other staple commodity. Thus, there is more market due to its prices and easy and regular

availability.

Marketing will also be undertaken through modem methods of e-marketing. For the purpose

acceptance and delivery of goods at door steps to the customers as value added service will be

introduce to manage the business in line with modern trend.

5.0 MANUFACTURING PROCESS

The process is very well standardized. First of all, paddy is cleaned to remove unwanted

matters like mud, stones, chaff etc. This cleaned lot is then fed to de-husker where with the

help of rubber roller, husk is separated. The brown rice is then taken to huller where polishing

is done by mild friction created within the polishing chamber. The resulting polished rice and

bran are separated and collected. Recovery of edible rice is around 80%. By-products consti-

tute about 15% whereas balance 5% is waste and process loss. The process flow chart is as

under:

5

1

POLISHED RICE

Cleaning of Paddy

‘Screening for removal foreign particles, mud, weeds, etc

De-husking

Polishing

‘Screening for quality rice separation

Final product fine rice / broken rice

Packing & dispatch

BOILED RICE

Cleaning of Paddy

Screening for removal foreign particles, mud, weeds, etc

Steam Boiling

I

Mechanized Drying

|

De-husking

Polishing

Screening for quality rice separation

eee L

Final product - fine boiled rice / Broken rice

t

Packing & dispatch of boiled rice & broken rice.

%

6.0 CAPITAL INPUTS

6.1 Land and Building

An open plot of around 1000 sq.mtrs. is sufficient to meet the working requirement. The

promoter has acquired a plot of 900 m2 from Goa IDC at Kudaim Industgrial estate for an

estimated cost of Rs.15.00 lakhs on which the built-up area of 450 sq.mtrs. costing around Rs.

65.00 lacs would be developed.

~/6.2 Plant And Machinery

The minimum viable capacity has to be processing of 4000 tons per year on | shift

working and around 250 working days. It is proposed to install latest version of modem

milling machinery and equipment which yields enough production with quality products and

whole rice with minimum wastage. The following equipment is need to be installed:

(Rs. in lacs)

Item

1.De-husking Machine with rubber

Rollers of 10 inches

2-Polishing Machine

3.Huller 58.00

4.Boiler

5.Parra boiled rice de-husking m/c.

6.Others is

7.Erection & Installation 2.00

Total 60.00

6.3 Miscellaneous Assets

A provision of Rs.2.00,000/- would be required towards furniture and fixtures, storage

facilities, electrification, ete.

6.4 Utilities

Total power requirement will be 35 HP whereas water requirements are minimal upto 2 m3.

Annual expenditure under this head at 100% activity level could be Rs.150,000/-.

6.5 Raw Material

Paddy is the only raw material required. The input-output ratio is 10:0.80 and to that extent,

the quantum of paddy would go up. Thus even at 100% utilisation, the requirement will not be

more than 4000 tonnes per year. Looking to the production of paddy in Goa, Karnataka,

‘Andhra Pradesh, Telengana, the Rice paddy farming states, supplies should not be a problem.

But it is advisable to have long term supply arrangements in place and sufficient stock.

6.6 Production of Paddy in Goa.

Goa’s average kharif and rabbi production is around 182945 m.tons and is on an upward trend

due to overwhelming support of Govt. and availability of mechanized farming equipment to

farmers from Agriculture Dept. at a subsidized rate. The total production of paddy in Goa is

processed locally using traditional method i.e. rice huller. In the absence of rice mill with

modem machinery for polished and para boiled rice, the farmers are compelled to process

boiled rice which has a limited market compared to polished rice. Thus establishment of

modem rice mill for polished as well as boiled rice would attract attention of farmers and they

will be able to grow and market polished rice and fetch good price which is otherwise

imported in Goa from neighboring states..

al&

8

7.0 Manpower Requirement

P .)_ Total Monthly Salary (Rs)

Factory Supervisor 1 12,000 12,000

Skilled Worker 2 9,000 18,000

Unskilled workers 6 6,000 36,000

Total 9 66,000

Service benefits @10% 6,600

72,600

8.0 TENTATIVE IMPLEMENTATION SCHEDULE

i Period (in m

Application and sanction of loan

Commencement of civil work 05

Completion of civil work and placement of

orders for machinery 10

Erection, installation and trial runs 15

Total peri 14.0 months

9.0 DETAILS OF THE PROPOSED PROJECT

9.1 Land and Building

Land admeasuring about 900 sq.mtrs. with built-up area of 450 sq mtrs. will be adequate. The

Tespective cost would be Rs. 16.50 lac and Rs. 60.00 lacs. Respectively.

9.2 Plant and Machinery

A detailed list is furnished above. The total cost under this head is taken at Rs. 60.00 lacs.+

‘equipment.

9.3 Miscellaneous Assets

A provision of Rs.2,00,000/- is earmarked.

ie

9.4 Preliminary & Pre-operative Expenses

Expenses like registration and legal fees, administrative and other charges, interest during

implementation ec, are taken at Rs. 1,00,000/-,

9.5 Working Capital Requirement

Capacity utilization in the first year is assumed to be 60% of the total production capacity of

4000 M.Tons and at that level total working capital needs are likely to be Rs. 20.00 lacs for

purchase of raw material and stock of finish goods and rs.10.00 lakhs for other expenditure

aggregating to Rs.30.00 lakhs comprising of bank loan of Rs.18.25 lacs and margin of Rs.

11.75 lacs as worked out here under. Besides, the availability of paddy during the limited

period of harvesting for Rabi and Kharif crop involves bulk purchase and stocking. Thus the

need for working capital is assumed at an bulk estimate with sustained consumption

throughout the year.

(Rs. in lacs)

iculars Period Tot nk Promo

Stock of RMs 2Month 30% 10.00 7.00 3.00

Stock of Finished %Month 25% 10.00 7.50 2.50

Goods

Receivables I Month 25% 5.00 3.75 —1.25

Other Expenses 1 Month 100% 5.00 = 5.00.

Total 30.00 18.25 11.75

10

9.6 Cost of the Project and Means of Financing

(Rs. in lacs)

Item Amount

Land 16.50

Building 60.00%

Plant and Machinery 60.00

Miscellaneous Assets 2.00

Pre-op & Preliminary Expenses 2.00

Contingencies on Building

and Plant & Machinery

Working Capital Margin 11.756.

Total 152.25

Means of Finance

Promoters' Contribution - 15% 2.83

Loan from Bank/FI 129.42

Total 152.25

Promoters’ Contribution - W.C. 25-30% (Avg)

- TL 15%

10.0 PROFITABILITY CALCULATIONS

10.1 Production Capacity and Build-up.

The processing capacity is taken at 4000 tons per year on single shift working of 8 hrs/day for

250 days in a year. As explained earlier, processing of 4000 tons would on an average yield

3200 tons of edible rice with 80% recovery. The capacity utilization in the first year is taken

at 60% whereas second year onwards, it is assumed to be 70%. | how

Jenni)

a

HIG

uW

10.2 Sales Revenue at 70! (Rs. in lacs)

Produet Qty. Sales Value

(Tonnes)

Rice 2240 492.80

Husk/Bran, etc. 560 22.40.

Total 515.20

Selling price of rice would vary depending upon the quality of inputs. Product-mix may vary

and hence an average selling price of Rs. 22,000/- per ton is assumed. Similarly, price of husk

and bran is also taken at Rs. 5,000/- which would fluctuate in line with quality of inputs,

processing techniques etc. as explained earlier.

10.3 Raw Materials Required at 70%

Different qualities of paddy is grown in the state/neighbouring states and the mill would

Procure and process suitable good paddy from time to time. The annual requirement at 70%

capacity shall be 2800 tonnes. Considering average price of Rs. 12000/- per ton, the yearly

cost would be Rs. 336.00 lacs.

10.4 Utilities

‘The annual expenditure under this head at 70% activity level is estimated to be Rs. 1,00,000/-.

10.5 Interest

Interest on term loan/W.C of Rs. 129.42 lacs is calculated @ 13% assuming repayment in 11

years including a moratorium period of | year and computed during the period.

feet gle

10.6 Depreciation

It is computed on WDV basis and rates assumed are 5% on building and 10% on machinery

and miscellaneous assets.

11.0 PROJECTED PROFITABILITY

(Rs. in lacs)

No. Particulars Ist Year 2nd Year

A- Installed Capacity -— 3000 Tonnes(finish goods) —-

Capacity Utilization 60% 10%

% Sales Realization 446.40 515.20

B Cost of Production

Raw Materials 288.00 336.00

Utilities 0.90 1.00

Salaries 37 9.58

Stores & Spares 0.50 0.55

Repairs & Maintenance 0.60 0.66

Selling Expenses @ 5% 21.00 2.87

Administrative Expenses 2.00 2.20

Total 321.71 372.86

3 C Profit before Interest & Depreciation 124.69 142.34

Interest Loan 16.82 15.26

Depreciation 9.40 8.63

Net Profit 98.47 118.45

Income-tax @ 20% 19.69 23.69

Profit after Tax 78.18 94.76

Cash Accruals 88.18 103.39

Repayment of Term Loan 7 097

(132 months)

13

D__ Percentage of Profit 22%

1.1 ANALYSIS

(Rs. in lacs)

No Particulars Amount

1A] Sales 446.40

Bi Variable Costs

Raw Materials 288.00

Utilities (40%) 0.36

Salaries (40%) 3.48

Stores & Spares, 0.20

Selling Expenses (40%) 8.40

Admn Expenses (40%) 0.80

Interest on WC 237 304.41

Ic] Contribution [A] - [B] 141.99

12.0 SWOT ANAYLYSIS.

a. STRENGTHS

© Staple food of 80% people in India and world.

© Ideal location (GIDC) with good infrastructure

© Promoter is qualified in the field of management and marketing and well

experience of over 10 years.

© Easy accessibility to raw material in Goa & neighboring States.

o Easy availability of work force.

© Support from Govt. to farmers and food processing industry from State and

Central.

eh He

b. Weakness

‘© Competition from processors of neighboring states.

© Availability of good quality paddy.

© Long time storage of paddy and its exposure to pests & rodents.

© Constant change in price of paddy.

©. Opportunities

© Die hard habits of rice eating population in India vis-d-vis Goa.

© Growing Consumers for Rice in Goa.

g © Lack of polish rice milling facility in Goa and use of modem machinery for

processing will attract local farmers.

(© Parra boiled rice processing would saves energy and time of farmers who are

following traditional methods of steaming of paddy and natural drying.

© Health benefits of para boiled rice.

4. Threats

© Seasonal availability of paddy is subject to price fluctuations

© Improper storage facility and threat of attack from pests

© Non Availability of Standard quality paddy in Goa.

© Paddy rates are in wholesale market is controlled by few dealers in

neighboring states.

(Mr. Pradip Gurunath Arolkar)

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- JCI ID Card SriDocument2 pagesJCI ID Card Sriomkar maharanaNo ratings yet

- Egg Storage and Supply: Trupti EnterprisesDocument33 pagesEgg Storage and Supply: Trupti Enterprisesomkar maharana100% (1)

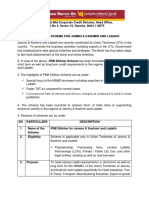

- Msme& Mid Corporate Credit Division, Head Office Plot No.4, Sector-10, Dwarka, New Delhi-110075Document2 pagesMsme& Mid Corporate Credit Division, Head Office Plot No.4, Sector-10, Dwarka, New Delhi-110075omkar maharanaNo ratings yet

- Building /site Permission /approval From Municipality/Nagar PanchayatDocument2 pagesBuilding /site Permission /approval From Municipality/Nagar Panchayatomkar maharanaNo ratings yet

- The Odisha Gazette: Extraordinary Published by AuthorityDocument174 pagesThe Odisha Gazette: Extraordinary Published by Authorityomkar maharanaNo ratings yet

- PNB Shikhar SchemeDocument3 pagesPNB Shikhar Schemeomkar maharanaNo ratings yet

- Category Margin Micro & Small Enterprises (As Per MSME Defined Ceiling) 10% Medium Enterprises (As Per MSME Defined Ceiling) 15% Others 25%Document3 pagesCategory Margin Micro & Small Enterprises (As Per MSME Defined Ceiling) 10% Medium Enterprises (As Per MSME Defined Ceiling) 15% Others 25%omkar maharanaNo ratings yet

- Msme Prime Plus: SN Parameters ParticularsDocument2 pagesMsme Prime Plus: SN Parameters Particularsomkar maharanaNo ratings yet

- Overdraft: Need BasedDocument2 pagesOverdraft: Need Basedomkar maharanaNo ratings yet

- Co - Lending by BanksDocument3 pagesCo - Lending by Banksomkar maharanaNo ratings yet