Professional Documents

Culture Documents

Control Valves Datasheet 10inch

Uploaded by

Anas KadriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Valves Datasheet 10inch

Uploaded by

Anas KadriCopyright:

Available Formats

1 Tag No.

S040-FCV-2542

2 Service PUMP MIN FLOW

3 Line Class P & ID No. 1CC1B01 D-NS040-1225-202

GENERAL

4 Area Classification Class I Zone 2

5 Tightness Requirements IV (HOLD)

6 Line No. 10"-P-S040-9006-1CC1B01-NI

7 Line Size Inlet Outlet 10" 10"

PIPE LINE 8 Pipe Schedule Inlet Outlet STD STD

9 Pipe Material Pipe Insulation ASTM A106 Gr. B NI

10 Process Fluid P-HYDROCARBON

11 Upstream Condition LIQUID

12 Design Pressure Design Temperature 0 Kg/cm²-g 95 °C

13 Units @ Min @ Norm @ Max

14 Flow Rate Kg/hr TBA

15 Inlet Pressure Kg/cm2-g 0.00

16 Pressure Drop Kg/cm2-g TBA

o

PROCESS 17 Inlet Temperature C 61.0

CONDITIONS 18 Inlet Density / Specific Gravity / Molecular Mass -

19 Inlet Compressibility Factor -

20 Inlet Viscosity cP

21 Inlet Specific Heats Ratio -

22 Inlet Vapour Pressure Kg/cm2-a

23 Inlet Critical Pressure Kg/cm2-g

24 Shut-Off Pressure Kg/cm2-g 0 (HOLD) 0 (HOLD) 0 (HOLD)

25 Travel % or Degree VTA VTA VTA

26 Flow Coefficient Cv VTA

CALCULATED

27 Sound Pressure Level <85 dB

RESULTS

28

29 MFR | Model TBA VTA 61 MFR | Model VTA VTA

30 Body Type Globe 62 Signal 4-20mA (24V) HART

31 Body Size / Characteristic 10" NOTE 4 EQ% (VTA) 63 Increase Signal Valve OPEN (HOLD)

32 Inlet flange Sizing / Rating 10" NOTE 4 150# RF 64 Cam Characteristics VTA

33 Outlet flange Sizing / Rating 10" NOTE 4 150# RF 65 Bypass | Gauges NIL YES

34 Rated Cv VTA 66 Electric Conn. Size 1/2" NPT(F)

35 CV AT MIN FLOW / % Rating CV VTA VTA POSITIONER 67 IP Degree IP66 (min)

36 CV AT NORM FLOW / % Rating CV VTA VTA 68 Electrical Class Exd

37 CV AT MAX FLOW / % Rating CV VTA VTA 69

38 Stages VTA 70

39 Body Material ASTM A216-WCB 71

BODY AND 40 Bonnet Type | Material STD* VTA 72

TRIM 41 Flow Direction VTA 73

42 Gland Packing Type | Material STD* GRAPHITE 74 MFR | Model - -

43 Lubricator Isolat. Valve - - 75 Type | Quantity - -

44 Guiding No. of Ports VTA VTA 76 De-Enegr.Valve -

45 Trim Type 8 SOLENOID 77 Tag No. -

46 Rated Travel VTA VALVE 78 Reset | Voltage - -

47 Plug/ Ball/ Disk Material 13 CR 79 Speed Controller -

48 Seat Material Co-Cr HARDFACING 80 IP Degree -

49 Cage/Guide Bushing Mat VTA 81 Electrical Class -

50 Stem Material 13 CR 82 MFR | Model - -

51 NACE Compliance NO 83 Type -

52 Leakage Class IV (HOLD) 84 Contacts -

53 MFR | Model VTA VTA SWITCHES 85 Switching Position -

54 Type DIAPHRAGM 86 Tag No. -

55 Size | Area VTA VTA 87 IP Degree -

56 Air Failure Valve CLOSE 88 Electrical Class -

ACTUATOR

57 Handwheel NOT REQUIRED 89 MFR | Model VTA VTA

58 Bench Range VTA 90 Set Pressure(kg/cm2G) 4

AIR SET

59 Color MFR STD 91 Filter | Gauge YES YES

60 92 Pneumatic Connection 1/4" TUBING

Notes:

1. VTA = VENDOR TO ADVISE, MFR STD = MANUFACTURER STANDARD

2. VALVE SIZING CALCULATION SHALL COMPLY ISA S75.01

3. VENDOR TO VERIFY/ RECONFIRM THE INFORMATION/CACULATION PROVIDED IN ASTERIK

4.THE SIZE SHALL BE DETERMINE BY CALCULATION &SHALL BE UPDATED ACCORDINGLY AFTER VENDOR CALCULATION.

INSTRUMENT SPECIFICATION

CONTROL VALVE

A1 HA 20-Dec-17 For Design JOB CODE : G-K070-12-0001 SHEET NO. : 5 OF : 9

No. By Date Revision Code: - DOC. No: 1660-8550-DS-S040-0016 Rev. A1

JGULF DOC. NO.: S-NS040-1374-103

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Microstrip Square AntennaDocument5 pagesMicrostrip Square AntennaAnas KadriNo ratings yet

- Digital Electronics LMDocument75 pagesDigital Electronics LMAnas KadriNo ratings yet

- 62CH3208Document3 pages62CH3208Anas KadriNo ratings yet

- SOLAR POWER SATELLITE SystemDocument13 pagesSOLAR POWER SATELLITE SystemmycatalystsNo ratings yet

- Wireless infrared communications overviewDocument10 pagesWireless infrared communications overviewjet_mediaNo ratings yet

- Heliodisplays 2010Document6 pagesHeliodisplays 2010Anas KadriNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Fluid Mechanics ch.2.2Document7 pagesFluid Mechanics ch.2.2A ALBALOSHINo ratings yet

- NSTP Exam 2Document3 pagesNSTP Exam 2Franky Magdadaro100% (1)

- Earthandlife11 q1 Mod1 EarthandEarthSystem Forprint-ApprovedDocument13 pagesEarthandlife11 q1 Mod1 EarthandEarthSystem Forprint-ApprovedAngel DelgallegoNo ratings yet

- 03 Proklima Code of Practices For RAC System Servicingt-WebDocument1 page03 Proklima Code of Practices For RAC System Servicingt-WebFranz CorasNo ratings yet

- Chemistry: Higher Tier Paper 2Document32 pagesChemistry: Higher Tier Paper 2karuneshnNo ratings yet

- Grade 3-6 Weather, Water, AirDocument8 pagesGrade 3-6 Weather, Water, AirMis GloriaNo ratings yet

- P&ID Pabrik Amoniak 100.000 Ton TahunDocument1 pageP&ID Pabrik Amoniak 100.000 Ton TahunAndriano Suryawan UtamaNo ratings yet

- The Inner Planets of our Solar SystemDocument5 pagesThe Inner Planets of our Solar SystemLyckseleRodulfaNo ratings yet

- Causes of Global WarmingDocument2 pagesCauses of Global WarmingTuan Hoang TrinhNo ratings yet

- Cambridge IGCSE: Combined Science 0653/43Document24 pagesCambridge IGCSE: Combined Science 0653/43Dhruva VengalaNo ratings yet

- Science 10 NotesDocument17 pagesScience 10 NotesDerik ResultayNo ratings yet

- Gas Laws Worksheetsand SolutionsDocument9 pagesGas Laws Worksheetsand SolutionskjgfsogkpsNo ratings yet

- Task #9 - Climate Change and Energy CrisisDocument8 pagesTask #9 - Climate Change and Energy CrisisKristoff Dela CruzNo ratings yet

- Fronts FGDocument23 pagesFronts FGTrang tin FacebookNo ratings yet

- Effects of Climate ChangeDocument3 pagesEffects of Climate Changejiofjij100% (1)

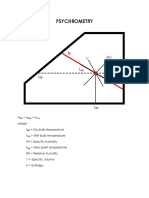

- Psychrometry: V RH T T SHDocument13 pagesPsychrometry: V RH T T SHKAL ELNo ratings yet

- Weather VocabularyDocument8 pagesWeather VocabularyasdNo ratings yet

- Planet Earth: Find Out AboutDocument16 pagesPlanet Earth: Find Out AboutosunahabaNo ratings yet

- 2019 Yokdil Ilkbahar Fen PDFDocument20 pages2019 Yokdil Ilkbahar Fen PDFgizemcetinNo ratings yet

- API 500 505 PresentationDocument51 pagesAPI 500 505 Presentationtharun venkatNo ratings yet

- 1.edible Coating Limitation - PossibilitiesDocument9 pages1.edible Coating Limitation - PossibilitiessukmiyatiagustinNo ratings yet

- Weights and Measures: Unit Abbr Equivalent MetricDocument6 pagesWeights and Measures: Unit Abbr Equivalent MetricAnilbishtNo ratings yet

- Environmental Science and Engineering: Definitions, Types, Components and ImportanceDocument14 pagesEnvironmental Science and Engineering: Definitions, Types, Components and ImportanceSivakumar KNo ratings yet

- Solar System Planets Diagram and Comprehension QuestionsDocument5 pagesSolar System Planets Diagram and Comprehension QuestionsLili MoralesNo ratings yet

- Legend of Legaia ArtsDocument5 pagesLegend of Legaia ArtsFlorian Marteein YambaliaNo ratings yet

- Vapor-Liquid EquilibriumDocument8 pagesVapor-Liquid EquilibriumMagesh kumarNo ratings yet

- Gaussian Plume Dispersion Model PrinciplesDocument24 pagesGaussian Plume Dispersion Model PrinciplesPanca NababanNo ratings yet

- Geoinformatics: What Is Remote Sensing?Document152 pagesGeoinformatics: What Is Remote Sensing?Bupe MaphosaNo ratings yet

- FilipinoDocument7 pagesFilipinoKrissa N.No ratings yet

- Chemistry ProjectDocument17 pagesChemistry ProjectNitish kumar MelliNo ratings yet