0% found this document useful (0 votes)

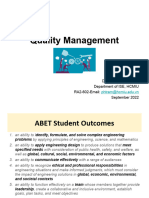

101 views75 pagesQuality Improvement and Control Basics

Faculty of Mechanical and Industrial Engineering

The document discusses quality control and statistical process control. It defines quality using various perspectives and outlines the evolution of quality management. It emphasizes that quality control is important to ensure products meet standards and expectations. There are two main sources of variation in processes - special causes due to specific factors like mistakes or breakdowns, and common causes which are inherent to the system. Quality control aims to reduce variation and improve consistency.

Uploaded by

geletaw mitawCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

101 views75 pagesQuality Improvement and Control Basics

Faculty of Mechanical and Industrial Engineering

The document discusses quality control and statistical process control. It defines quality using various perspectives and outlines the evolution of quality management. It emphasizes that quality control is important to ensure products meet standards and expectations. There are two main sources of variation in processes - special causes due to specific factors like mistakes or breakdowns, and common causes which are inherent to the system. Quality control aims to reduce variation and improve consistency.

Uploaded by

geletaw mitawCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd