Professional Documents

Culture Documents

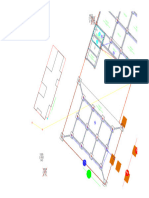

DWG 10052 1 - 6X

Uploaded by

Mohamed SamirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DWG 10052 1 - 6X

Uploaded by

Mohamed SamirCopyright:

Available Formats

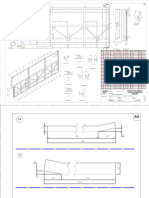

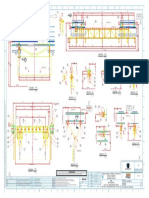

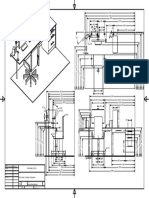

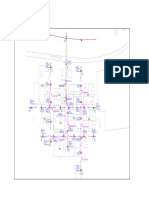

1400 6250 (T.L TO T.

L) 3600

50 107 3493

50 COURSE#3 = 1850 COURSE#2 = 2000 COURSE#1 = 2300 1463 2000

(+7600 FROM GROUND)

16 THK 16 THK 16 THK

M02

I01

04

(R.L. 0.00)

450 372

NAME PLATE

O03

ELLIPTICAL HEAD 2:1

TOP DAVIT SUPPORT

(+)6250

(+)5465

2400 ID, 16 THK A/F

(+) 1500

(+)750

20 310 30

INSULATION RING

NOM THK 20

TAILING

(-)1200

INLET WEIR

25 x 5 (TYP)

LUG

'A'

INSULATION

16 THK.

25 THK.

'B'

01

03

02

W.L.

W.L.

LS-4

T.L.

T.L.

LS-5

CS-3

CS-2

SLS-2

V01

CS-4

CS-1

300

LS-2

8 Nos. DIA. M24 ANCHOR BOLTS

730

00

Ø5

(+)1215

ELEVATION

B.C.D 2606

I.D 2400

I.D 2406

O01

2746

NLL

#1

#2

#3

LS-4

875

SA1-2

LS-3

SCS-1

C01

1250 LS-1 SLS-1

50

ELLIPTICAL HEAD 2:1

2400 ID, 16 THK A/F

'W1'

'W2'

90° LONG RADIUS ELBOW

'W1'

'W1'

SV1-4

'W1'

(INSIDE/OUTSIDE)

VORTEX BREAKER (FLUSH)

FIRE PROOFING

NOM. THK 20

CYLINDRICAL SKIRT

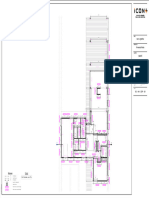

DWG 3- 115

10" NPS x SCH 60

HALF PIPE

(+)6100

40 THK.

(+)2810

(+)2610

(+)2460

'B'

EL. +4000 FROM GROUND

BOLT TORQUE N*m

(+)300

(+)150

2 NOS. LIFTING

DWG 3- 122

(+)4610

(+)3110

THK. 10

'A'

TRUNNION

(+)5150

FLANGE 50% 70% FINAL MAX.

Q02A

Q02D

Q02C

Q02B

L02A

L02B

S02

RS

C01 102 143 205 307

04

M02 525 735 1050 1574

1100 1640 1500 (2 SPACES @ 750) 3110 107 298 200

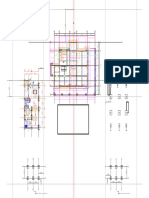

N 22.5°

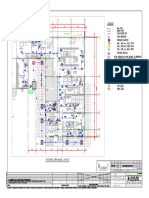

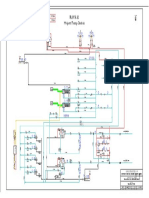

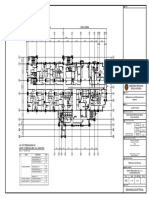

LIST OF GASKETS , STUD-BOLTS AND INT. BOLTING (INCLUDING SPARES) EN 10204 3.1 MATERIALS DESIGN DATA

FOR COMMISSIONING AND START-UP UNLESS OTHERWISE SPECIFIED DESIGN CODE: ASME VIII DIV.1 ED.2017 + PROJECT SPECIFICATIONS - UOP 3-11-9, 2544-00-SP-0511-102_0

GASKETS STUD-BOLTS SHELL ASME SA 516-70 N UOP STD DRAWING: 3-122

ITEM Q.TY Q.TY

(SEE MAT. LIST) (WITH 2 NUTS EACH ) ELL. HEADS (2:1) ASME SA 516-70 N DESIGN PRESSURE (INT./EXT.) 11.0 bar (g) (NOTE 19) / F.V.

0° C01 6 NPS x 150# (NOTE 17) 1+2 3/4" UNC x 110 LONG 8+2 FLANGES & FORGINGS ASME SA 105N DESIGN TEMPERATURE (INT./EXT.) 230 / 93 °C

ACCESS HOLE TO BE PROTECTED

WITH Ø2 WIRE MESH REMOVABLE M02 24 NPS x 150# (NOTE 17) 1+2 1"-1/4 UNC x 180 LONG 20+2 NOZZLES FROM PIPE ASME SA 333-6 M.A.W.P. 12.496 bar (g) LIMITED BY BOTTOM SHELL COURSE

45 P)

COVER, PITCH 25MM NOZZLES FROM PLATE

(T

ASME SA 516-70 N OPERATING TEMPERATURE 93 °C

°

O03

Y

REINFORCING PADS ASME SA 516-70 N JOINT EFFICIENCY 0.85

SA1 SV4 SS SPARE PARTS: 2 SET OF GASKETS AND 10% BOLTING (MIN. 2 PIECES) WITH 2 NUTS OF EACH SIZE)

VESSEL SUPPORT ASME SA 516-70 N CORROSION ALLOWANCE 3 mm + 1.6 mm FOR SUPPORT

SV1 M.D.M.T. @ DESIGN PRESSURE 4 °C

315° FITTINGS ASME SA 234 WPB

45° BILL OF MATERIAL HYDROSTATIC TEST PRESS. (SHOP HOR. / FIELD VERT.) 16.9 bar(g) FOR SHOP / 16.25 bar(g) FOR VERTICAL

TAILING LUG INT. ATTACHMENTS ASME SA 516-70 N

HEAD FORMING & QUALITY TRATMENT (IF ANY) COLD FORMED

ITEM NO. QTY. DESCRIPTION SIZE MATERIAL W.Kg. REMARK EXT. ATTACHMENTS ASME SA 516-70

JOINT EFFICIENCY / X-RAY EXAMINATION SPOT

LIFTING LUGS ASME SA 516-70

01 1 SHELL 16 THK.x 7590 CIR.x 2300 W SA 516 GR. 70 2192 P.W.H.T. NONE

NAME PLATE S.S. 304

IMPACT TEST EXEMPTION EQUIPMENT IMPACT TEST EXEMPTED UG-20(f), UCS-66 (b)(c)(g) etc...

02 1 SHELL 16 THK.x 7590 CIR.x 2000 W SA 516 GR. 70 1907 NAME PLATE SUPPORT ASME SA 516-70 WELD COUPON NONE

03 1 SHELL 16 THK.x 7590 CIR.x 1850 W SA 516 GR. 70 1764 INSULATION SUPPORT ASME SA 516-70 / S275 JR (*) SPECIAL SERVICE N.A.

04 2 DISHEND (2:1 ELLIPSOIDAL) 20 THK.x 3030 BLANK DIA. SA 516 GR. 70 2270 SHAPES S275 - JR (*) FLUID CONTAINED & DENSITY KEROSENE/HYDROCARBON GAS | 0.74 kg/dm3

8133 EXT. STUD-BOLTS & NUTS ASME SA 193 GR. B7/ A 194 GR. 2H CAPACITY VESSEL-V 31.893 m³

INT. STUD-BOLTS & NUTS S.S. 410 BY OTHERS FOR TRAYS INSPECTION AUTHORITY AUTHORIZED INSPECTOR

TRAYS S.S. 410 BY OTHERS ASME CERTIFICATION MARK YES "U" DESIGNATOR

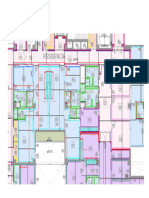

270° 90° SA2 LIST OF CONNECTIONS REMOVABLE INTERNALS S.S. 304 / S.S. 304L (DUAL CERTIFICATE) NATIONAL BOARD NUMBER NONE

ITEM Q.TY SIZE RATING TYPE BLIND SERVICE PROJ. TO CL REINF. PL. NECK THK. NOTE INSULATION / FIREPROOFING: INSULATION 25 mm / FIREPROOFING 40 mm (IN/OUT)

(NPS) INTERNAL GASKET ASBESTOS FREE

C01 6" 150 WN YES VENTILATION SEE DWG Ø270 x 16 THK SCH XS BLIND,GASKET,BOLTS ANCHOR BOLT A307 WIND: ASCE 7 - 2005 , BASIC WIND SPEED V=130 km/hr (36 m/s), EXPOSURE CAT "C". OCCUPANCY CAT III, IMPORTANCE FACTOR I=1.15

SLS-2 1

AT 260° EARTHQUAKE: UNIFORM BUILDING CODE - 1997, ZONE 2A, SOIL PROFILE : SC, IMPORTANCE FACTOR I=1.25.

I01 1 28" 150 WN INLET 1700 Ø1250 x 16 THK THK 13 ASME B16.47 SERIES B EXT. GASKETS : S.S. 304 SPIRAL WOUND GASKET NON ASBESTOS FILLER WITH S.S. 304

O01 1 34" 150 WN VAPOR OUTLET SEE DWG Ø1280 x 16 THK THK 13 ASME B16.47 SERIES B INNER/OUTER RING

V01 1 4" 150 WN VENT SEE DWG - SCH XXS (*) FOR PARTS NOT DIRECTLY WELDED ON MAIN BODY. GENERAL NOTES

O03 1 10" 150 WN OUTLET 1450 Ø540 x 16 THK SCH 60 WITH VORTEX BREAKER

L02A 1 2" 300 LWN LEVEL 1430 - 16.65 THK WITH BAFFLE WELDING SYMBOLS IN ACCORDANCE WITH AWS A 2.4 UNLESS OTHERWISE NOTED

a

L02B 1 2" 300 LWN LEVEL 1430 - 16.65 THK MT

Q02A 1 2" 300 LWN SHUTDOWN LT 1430 - 16.65 THK WITH BAFFLE MANUFACTURING UNDERTOLERANCES : PLATES (-0,25 mm.) ; FLANGES & FORGINGS (-0,5 mm.) ; PIPES & ELBOWS (-12,5% NOM. THK.)

Q02B 1 2" 300 LWN SHUTDOWN LT 1430 - 16.65 THK

No.2 EARTHING LUG

FA 1) QUANTITY No.1

Q02C 1 2" 300 LWN LEVEL 1430 - 16.65 THK WITH BAFFLE

OPP. @ 180° 135° 2) REFERENCE DOC. No. 2544-07-DW-0810-01_0

Q02D 1 2" 300 LWN LEVEL 1430 - 16.65 THK 0° 3) FABRICATION TOLERANCE AS PER SPEC. 2544-00-STC-0490-01, UOP 3-11-9, ASME VIII DIV 1, JSS-0570-01

225°

SV2 S02 1 2" 150 LWN STEAM OUT 1430 - 15.85 THK 90° ML Mc 4) NOZZLES ORIENTATION DEFINED IN PLAN

SV3 M02 1 24" 150 WN YES MANWAY 1550 Ø1180 x 16 THK 13 THK BLIND,GASKET,BOLTS,DAVIT

5) ALL FLANGE HOLES SHALL BE STAGGERED TO MAIN AXES OF VESSEL INDICATED ON DRAWING

RS 1 82 DIA - - INSERT PLATE - 16 THK

6) UNLESS OTHERWISE INDICATED ALL DIMENSIONS ARE IN mm.

SV1-4 4 4" - - SKIRT VENT SEE DWG - SCH 80

SLS-1

180° FL FC 7) ALL ELEVATIONS ARE RELATED TO THE REFER. LINE INDICATED ON THE DRAWING

ANCHOR CHAIR AT 190° SA1/SA2 2 500 I.D - - SKIRT ACCESS SEE DWG - 13 THK

8) NOZZLE PROJECTIONS ARE REFERRED FROM VESSEL CENTERLINE TO FLANGE CONTACT FACES

SS 1 427 I.D - - SKIRT SLEEVE SEE DWG - 6 10 THK

VIEW-"B-B" 180° 270° 9) TOTAL EXTERNAL SURFACE OF THE EQUIPMENT: 87.67 m2

ORIENTATION NOZZLE FLANGE FACINGS TO BE IN ACCORDANCE WITH ASME B16.5 AND B16.47B - SURFACE FINISH : 125÷250 AARH

10) INSIDE NOZZLE NECK SHALL BE ROUNDED TO 3mm RADIUS

11) ALL REMOVABLE INTERNALS SHALL PASS THROUGH A MANHOLE HAVING AN INTERNAL DIAMETER OF 584 mm

12) NOZZLES FABRICATED FROM PLATE TO HAVE LONGITUDINAL WELDS LOCATED AT 45° FROM NOZZLE PRINCIPAL AXES

L02B

0° 13) ALL INT. AND EXT. ATTACHMENTS WELDED DIRECTLY TO PRESSURE PARTS SHALL BE OF THE SAME QUALITY STEEL

LS-2 L02A 30° O03 45° 14) FOR WPS TO BE USED SEE ITEM RELEVANT WELDING MAP - WELDING BOOK N° WB - 2589-1

AT 320°

RS 15) FLANGES: ASME B16.5 ED.2013 / PIPES: ASME B36.10M ED.2015 / FITTING: ASME B16.9 ED.2012 / GASK.: ASME B16.20 ED.2017

N

IO

TOP DAVIT

N

THREAD BOLTS: ASME B1.1-2A ED. 2003 (R.2018) / THREAD NUTS: ASME B1.1-2B ED. 2003 (R.2018)

N

NOZZLE LOADS (NOTE 20)

U

SUPPORT 6 16) PAINTING IN ACC. WITH SPECIFICATION 2544-00-JSD-2300-01_LAST REVISION

TR

@315° N.D. FORCES - (N) MOMENTS- (Nm) 17) SPIRAL WOUND GASKETS CLASS 150 AND 300 SHALL BE OF "LOW SEATING STRESS" DESIGN: THE SEATING STRESS SHOULD BE 35 Mpa, m=2.5 .

NOZZLES

REFERENCE DRAWINGS AND DOCUMENTS (NPS) P Vl Vc Mt Ml Mc 18) ALLOWABLE STRESS FOR ANCHOR BOLTS ARE : 140 Mpa TENSION AND 70 Mpa SHEAR.

NUMBER TITLE S02 2" 3300 3300 2500 600 500 400 19) A TOTAL PRESSURE DROP OF 0.07 SHALL BE ADDED TO DESIGN PRESSURE IN CALCULATION.

V01 DWG-10052-02 NOZZLE DETAIL DRAWING 20) NOZZLE LOADS ARE IN ACCORDANCE WITH 2544-00-JSD-0400-02 OR, WHERE LOADS ARE DIFFERENT FROM THOSE SPECIFIED IN THIS DOCUMENT,

V01 4" 6300 6300 4700 2100 1800 1400

THEY ARE IN ACCORDANCE WITH LATEST REVISION OF ATTACHMENT C TO 2544-07-NM-1350-20

DWG-10052-03 DAVIT ASSEMBLY DRAWING C01 6" 9300 9300 7000 4600 4000 3100

DWG-10052-04 SKIRT ASSEMBLY DRAWING O03 10" 15100 15100 11300 12100 10500 8100

O01 DWG-10052-05 INTERNAL ATTACHMENTS I01 28" 39200 39200 29400 82300 71300 54900

O01 34" 47600 47600 35700 121400 105200 80900

DWG-10052-06 EXTERNAL ATTACHMENTS

DWG-10052-NP NAME PLATE DRAWING

RDC-10052 DESIGN CALCULATION

270° M02

CT 2589 PAINTING PROCEDURE WEIGHTS ORDER MIDOR REFINERY EXPANSION PROJECT

I01 90°

HT 2589 HYDROTEST PROCEDURE

ERECTED OPERATION TEST ITEM : 07-V-51

MPS-2589 MATERIAL PURCHASE SPECIFICATION SERVICE : VACUUM DRIER

C01

WEIGHT (KG) 12600 31700 57500

2544A0019 TITTLE : GENERAL ASSEMBLY DRAWING OF VACUUM DRIER

CENTER OF GRAVITY : 2391 FROM T.L. ( ERECTED CONDITION ) - -

JOB

6 22.02.2021 PROZEMEK R.B. TONIOLO AS BUILT

2589 5 16.12.2020 PROZEMEK R.B. TONIOLO ISSUE FOR REVIEW

4 22.09.2020 PROZEMEK R.B. TONIOLO ISSUE FOR REVIEW

3 22.07.2020 PROZEMEK R.B. ISSUE FOR REVIEW

235° SERIAL No. TONIOLO

LS-3 2 29.02.2020 PROZEMEK R.B. TONIOLO ISSUE FOR REVIEW

AT 135°

1 04.12.2019 PROZEMEK R.B. ISSUE FOR REVIEW

S02

10052 TONIOLO

16 THK.

10 THK.

11 THK

60°-70°±5° 60°-70°±5° 1 REVISE AND RESUBMIT

6 THK

NP (FPW) (FPW) 0 22.08.2019 PROZEMEK R.B. ISSUE FOR REVIEW

N

TONIOLO

IO

TO BE ISSUED AS FINAL PROVIDED

OUTSIDE OUTSIDE 2

N

COMMENTS ARE INCORPORATED

REV. DATE DRAWN VERIF. APPR. DESCRIPTION

N

155° REPRODUCTION OF THIS DRAWING WITHOUT

U

TR

3 NO COMMENT – FINAL ISSUE OUR WRITTEN APPROVAL IS FORBIDDEN

205° Q02A

LS-1

225° AT 220° Q02B INSIDE INSIDE

5 THK.

4 THK.

180° 4 FOR INFORMATION ONLY

Q02C 1.5-2.5 1.5-2.5 1.5-2.5 1.5-2.5

SCALE : 1:15 A1

Q02D

VIEW-"A-A"

ORIENTATION WELD DETAIL - 'W1' WELD DETAIL - 'W2'

Anna Maresca - Mar 02, 2021 GRANZIERO S.p.A. DWG. N°

LONG SEAM AND CIRC.SEAM SKIRT LONG SEAM AND CIRC.SEAM VIA GARIBALDI,1 - ALBIGNASEGO - PD (ITALY) DWG-10052-01

You might also like

- SOPORTE - MARCO-IZQUIERDO-8X5 - Rev 1Document1 pageSOPORTE - MARCO-IZQUIERDO-8X5 - Rev 1Fredy HumbertoNo ratings yet

- SampleDocument1 pageSampleJaime YubiNo ratings yet

- Zafra 2022 001Document1 pageZafra 2022 001Hernan CamachoNo ratings yet

- Mapa Zafra 001Document1 pageMapa Zafra 001Alexander ValdezNo ratings yet

- F11ES05934Document4 pagesF11ES05934Wuilian Ciromax Vargas PeñaNo ratings yet

- Master Plan Villa ComplexDocument1 pageMaster Plan Villa Complexnika daraNo ratings yet

- 586 Cementos Moctezuma, Planta Cerritos Ducto R-BDocument1 page586 Cementos Moctezuma, Planta Cerritos Ducto R-BSantiago MendozaNo ratings yet

- 26071-203-V61A-MWD0-00252-009 - Drainage Mapping - Desal AreaDocument1 page26071-203-V61A-MWD0-00252-009 - Drainage Mapping - Desal AreacostonzNo ratings yet

- Croquis Bodega RESPEL.Document1 pageCroquis Bodega RESPEL.Bastián Salvador BotelloNo ratings yet

- 1-2B2C GF LIGHTING FIXTURES EXACT LOCATION-ModelDocument1 page1-2B2C GF LIGHTING FIXTURES EXACT LOCATION-ModelMuhammad BilalNo ratings yet

- Prancha ElétricoDocument1 pagePrancha Elétricomarco.754marNo ratings yet

- Carta Catastral Urbana: Departamento de Santander Municipio de BarrancabermejaDocument1 pageCarta Catastral Urbana: Departamento de Santander Municipio de BarrancabermejaCarlos Mario MezaNo ratings yet

- Lek Kitchen Drainage LayoutDocument1 pageLek Kitchen Drainage Layoutsavanth jayaramNo ratings yet

- TopodivaDocument1 pageTopodivamauricio san martinNo ratings yet

- Leidy Dayana Montenegro Ing. Esp. Vías Terrestres M.P. 52202-322412 C.C. 1.085.290.998Document1 pageLeidy Dayana Montenegro Ing. Esp. Vías Terrestres M.P. 52202-322412 C.C. 1.085.290.998Gustavo MartinezNo ratings yet

- ComarcasDocument1 pageComarcasrafaNo ratings yet

- Plano 1Document1 pagePlano 1Anonymous 9MMBH5oNo ratings yet

- 25 Los Vilos 18.12.2013Document1 page25 Los Vilos 18.12.2013comarkaliderNo ratings yet

- FTD003 FTD004: Turpo Pacha Marcelino Propuesta SFR - 2Document1 pageFTD003 FTD004: Turpo Pacha Marcelino Propuesta SFR - 2hernan ticona laricoNo ratings yet

- 400me 00004Document1 page400me 00004EstebanNo ratings yet

- Proiect NichitaDocument1 pageProiect NichitaTatiana CotirsevNo ratings yet

- 3e1p - 101Document1 page3e1p - 101Tomas CalabriaNo ratings yet

- Replanteo Fecales-ModeloDocument1 pageReplanteo Fecales-Modeloeafventuceli2No ratings yet

- REPLANTEO FECALES-ModeloDocument1 pageREPLANTEO FECALES-Modeloeafventuceli2No ratings yet

- 03 Replanteo Linea Aduccion Rev.02-La 03Document1 page03 Replanteo Linea Aduccion Rev.02-La 03LEONARDO BENITES MEZANo ratings yet

- Mapa Xy Maduros-CensoDocument1 pageMapa Xy Maduros-CensoMiluska SantosNo ratings yet

- Carta Catastral Urbana: Departamento de Santander Municipio de BarrancabermejaDocument1 pageCarta Catastral Urbana: Departamento de Santander Municipio de BarrancabermejaCarlos Mario MezaNo ratings yet

- 05-12-22 ContrapisoDocument1 page05-12-22 ContrapisoYonathan Melquiades Arrieta LedesmaNo ratings yet

- Plano Actual de La EstacionDocument1 pagePlano Actual de La EstacionJuan Luis Vermejo GonzalesNo ratings yet

- Cartografia POT 2009 Bello Comunas BarriosDocument1 pageCartografia POT 2009 Bello Comunas BarriosNataly Falla Valderrama57% (7)

- D. Gaya Batang Akibat Beban Hidup (Berat Orang P KG) : KeteranganDocument1 pageD. Gaya Batang Akibat Beban Hidup (Berat Orang P KG) : Keteranganjahiras siringoringo7No ratings yet

- Adapter: Circuit Diagrams and PWB LayoutsDocument3 pagesAdapter: Circuit Diagrams and PWB LayoutsnelsonNo ratings yet

- 4 DWG HighlightDocument1 page4 DWG Highlightthura mgNo ratings yet

- AP Pisiga CarpaDocument1 pageAP Pisiga Carpachristiam rojasNo ratings yet

- Els PortsDocument2 pagesEls PortsFrancesc MartiNo ratings yet

- Layout Nha Xuong Chu Lai (2023) V2 - 3Document1 pageLayout Nha Xuong Chu Lai (2023) V2 - 3ngocNo ratings yet

- Plano UbicacionDocument1 pagePlano UbicacionSidgar German Condori QuispeNo ratings yet

- Plano Techo Parabolico-ModelDocument1 pagePlano Techo Parabolico-Modeleduardo gabriel santos ballartaNo ratings yet

- 1.-Perimetro Matriz-Ul-01 (A2)Document1 page1.-Perimetro Matriz-Ul-01 (A2)Arturo Pazsoldan MartinezNo ratings yet

- Estado Actual - OkDocument1 pageEstado Actual - OkDAVID FERNANDO HEREDIA ASTETENo ratings yet

- Camino - Huarangal - Chico - en Proyecto - Camino 10Document1 pageCamino - Huarangal - Chico - en Proyecto - Camino 10Albino A. Gómez JaraNo ratings yet

- GBR AC Baranahan 2022-Model 6Document1 pageGBR AC Baranahan 2022-Model 6jayasemanggiNo ratings yet

- HEA260 IPE270: Escalera Escalera Escalera Escalera Escalera EscaleraDocument1 pageHEA260 IPE270: Escalera Escalera Escalera Escalera Escalera Escaleracarloscruz16No ratings yet

- Sencico Pisco PTDocument1 pageSencico Pisco PTjjc.topografiageomaticaNo ratings yet

- Rampa PeatonalDocument1 pageRampa PeatonalGuadalupe Isabel Merino RiofrioNo ratings yet

- 40 Estudio Paisaje Plano Ep 08 Seccion Paisaje Del Catalogo Abril 2017Document1 page40 Estudio Paisaje Plano Ep 08 Seccion Paisaje Del Catalogo Abril 2017yiiyolon00No ratings yet

- Tde T.ups TdaDocument3 pagesTde T.ups Tdarandolph castillejoNo ratings yet

- Pp-SistemaDocument1 pagePp-Sistemacesar cerna nievesNo ratings yet

- CA350 Comarcal 2023 v4Document1 pageCA350 Comarcal 2023 v4Manuel PortolesNo ratings yet

- TMB8 6 18-ModelDocument1 pageTMB8 6 18-ModelthamNo ratings yet

- Mapter PDFDocument1 pageMapter PDFPaulaRamirezNo ratings yet

- Plànol Nova Xarxa de Bus PDFDocument1 pagePlànol Nova Xarxa de Bus PDFDimu EliNo ratings yet

- PLANOS 2022-Layout1Document1 pagePLANOS 2022-Layout1Melady Rossy Perca CondoriNo ratings yet

- Combined Power Boiler Drawings PDFDocument29 pagesCombined Power Boiler Drawings PDFEnzo CutarNo ratings yet

- Sistema Vial Primario PDFDocument1 pageSistema Vial Primario PDFSOVEYDA AVILA ESPICHANNo ratings yet

- 3 ZonificacionDocument5 pages3 ZonificacionAndrés Orduña MartínezNo ratings yet