Professional Documents

Culture Documents

Indus Plant Engineering - Labra

Indus Plant Engineering - Labra

Uploaded by

Ryan Calica0 ratings0% found this document useful (0 votes)

73 views31 pagesOriginal Title

INDUS PLANT ENGINEERING - LABRA

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

73 views31 pagesIndus Plant Engineering - Labra

Indus Plant Engineering - Labra

Uploaded by

Ryan CalicaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 31

INDUSTRIAL RANT

ENGINEERING

oa

a>

ah

LAB, EAN

2020

IN THEORENC>L COMAITEMONS, PUNIP WORK IS NEGLECT?

IN ACTUAL, WORK SHOUNT BE NEGIECTED BECAUSE “WE SNIAL

CONTINUOUS WORK 6 WHAT WILL BRING YOU FAR.

— LABRA (PANDEMIC, 2020)

HEAT TRANSFER

TYPE DEFINITION a a

BODIES IN CONTACT. MOLECULAR ee a

CONDUCTION | conmunicarton THROUGH SOLID

MATERIALS 08 STAGHANT FLUIDS An# Re 44

/NXING AND MOTION OF PARTICLES OF

Convection | (nm

ELECTROMAGNETIC WAVES ARE Q=

Sec

RADIATION PASSED FROM ONE BODY TO ANOTHER [a+ Gal

THROUGH A SPACE a 4

C= be (kArt keAz)

CONDUCTION Bs

CONDUCTION THROUGH WALL

PLANE WALL CONDUCTION THROUGH PIPE

a em! ee CYUNDRICAL E

= ,

a

Todos

Ve ie oe T

mane Y= Re

mows ake Ab me

8= TW

a

oot

K

a wea

4

we c

ss ee

At is EOD ek

am Kaa wien a)" wan)

lit ci A=ZirL

ONECUN EIR ER GRRE CONVERSION: tle 18

CONDUCTION THROUGH SPHERE

HOWOW SPU

At

Q° ae ek

WA 41G%Ka fitsteke hehe

THERMAL DIFFUSIVITY

DEFINES THE SPEED OF HEAT PROPAGATION BY CONDUCTION

DURING CHANGES OF TEMPERATURE. THE HIGHER THE THERMAL

DIFFUSIVITY, THE FASTER THE HEAT PROPAGATION.

CONVECTION

CRITICAL RADIUS

USED FOR SMALL DIAMETER SYSTEMS

FOR CYUNPERS | FoR SPIEKES

t2'%nr t=2/n

BIOT NUMBER

IF THE BIOT NUMBER IS VERY SMALL, THEN THE CONDUCTION

RESISTANCE IS NEGLIGIBLE COMPARED TO THE CONVECTION

RESISTANCE

Bit RESCTANUE TO CONDUCTION

KEENE TO CONVECTION

oven

Bir Cia) me jemates Yt

7m

Lune. LENT ~ AREA!

REYNOLD'S NUMBER

= = 0

N ee ae

k k= THERMAL CON?

“a 2 = HEEL

Poa paren opr tee

PRANDTL NUMBER (RoRmeDS FREE COWECTON

DIMENSIONLESS PARAMETER REPRESENTING THE RATIO. OF

DIFFUSION OF MOMENTUM TO DIFFUSION OF HEAT IN A FLUID

R-VALUE

[MEASURE OF INSULATOR’S ABILITY TO REDUCE THE RATE OF LOW

Nee= “t

K

NUSSELT NUMBER (FORCED CONVECTION)

RATIO OF HEAT CONVECTION To HEAT CONDUCTION

2 2

: VAUE = Bee ave THERA. CONPICITY

Nu

Md = o/NoNue viscosity |0 = VIANETER

cp weomc vest =| P = DeNomy

Wi= dear reanrer coer.| = COEF, THERM. EXPRNEON

Ke TueaMal Conateniny | 9 = ceAVTEONAL AxceL.

GRASHOF NUMBER CREE CONNECTION)

NNONDIMENSIONAL PARAMETER USED IN THE CORRELATION OF HEAT

AND MASS TRANSFER DUE TO THERMALLY INDUCED NATURAL

CONVECTION AT A SOLID SURFACE IMMERSED IN A FLUID

Nuer Zerbeot

Mae

RADIATION

STEFAN-BOLTZMANN LAW Eoct4

ANYTHING WHOSE TEMPERATURE IS ABOVE THE SURROUNDING WILL

ALWAYS RADIATE A SIGNIFICANT AMOUNT OF HEAT

Q=e0A(T*-T)

= Get xo® Wires

T= ONG x® Bye gt et

ete +

G.62SX\0'S-s

ames he rc = WE = women

+ PLANCK'S LAW

= ALL SUBSTANCES EMIT RADIATION WHICH DEPENDS UPON THE

ABSOLUTE TEMPERATURE AND MATERIAL

+ KIRCHHOFF'S LAW

~ REFERS TO WAVELENGTH-SPECIFIC RADIATIVE EMISSION AND

ABSORPTION BY A MATERIAL BODY IN. THERMODYNAMIC

EQUILIBRIUM, INCLUDING RADIATIVE EXCHANGE EQUILIBRIUM,

+ EMISSIVITY

~ THE RATIO OF RADIATION FROM AN ACTUAL BODY TO THE

RADIATION FROM A BLACK BODY

+ BLACK BODY

~ IDEALIZED SURFACE THAT ENTS RADIATION AT THE MAXIMUM

RATE

+ GRAY BODY

~ ACTUAL BODY THAT RADIATES LESS HEAT THAN A BLACK BODY

HEAT EXCHANGERS

= ANY DEVICE WHICH AFFECTS THE TRANSFER OF HEAT FROM ONE

SUBSTANCE TO ANOTHER

LOGARITHMIC MEAN TEMP. DIFFERENCE

ARITHMETIC MEAN TEMP. DIFFERENCE

PARALLEL WS. COUNTER FLOW

STEAM CONDENSER

FLUID AT CONSTANT TEMPERATURE GIVES UP HEAT TO A COLDER FLUID,

THE FLUID'S TEMP. GRADUALLY INCREASES

STEAM BOILER

= FLUID AT CONSTANT TEMPERATURE RECEIVES HEAT FROM A WARMER

FLUID CTEMPERATURE IS DECREASING)

CONDENSER. Boilee

2 eco + QO

a

HEAT TRANSFER

QQ = Ve Ar (LMT)

heel CY)

VOLUME FLOW RATE

“te ena

=e

THE PURPOSE OF A PUMP 1S TO TRANSFER A FLUID FROM A REGION OF LOW

PRESSURE TO ANOTHER REGION AT THE SAME OR HIGHER PRESSURE.

Raiden POSITIVE DISPLACEMENT WS. DYNAMIC 2?

POSITIVE DISPLACEMENT

TMPELLERS PASS ON VELOCITY FROM THE MOTOR TO THE LIQUID WHICH MOVES

THE FLUID TO THE DISCHARGE PORT

PRODUCES FLOW BY CREATING PRESSURE

DYNAMIC (KINETIC)

TRAPS CONFINED AMOUNTS OF LIQUID AND FORCES IT FROM THE SUCTION TO THE

DISCHARGE PORT

PRODUCES PRESSURE BY CREATING FLOW

Korky RECIPKOCATING — LINEA. oben ad : L

PUINGER AXIAL FLW

“me PN mons

RECIPROCATING PUMPS USES A PISTON. AND CYLINDER ARRANGEMENT

WITH SUCTION AND DISCHARGE VALVES

risennkce

INTEGRATED INTO THE PUMP.

Reuer

Gg ADDITIONAL INFORMATION:

COMMONLY USED AS BOILER FEED PUMP

FOR STEAM

Suction was

ee ee

TISEVAIGE «CON SIMPLEX, DUPLEN, TRIPLEX ‘A RECIPROCATING PUMP DESIGN

THAT UTILIZES (N)_ SEPARATE

AIR CHAMBER — USED TO SMOOTHEN THE ee pane ty opive THE

FLOW DUE TO THE NATURE OF FLOW OF

LiQUID. THIS 1S PLACED ELTHER ON THE Opie 9

SUCTION SIDE OR DISCHARGE SIDE. TRIPLEX - 3

+ TN NEW PUMPS, SLIPPAGE IS WITHIN 25,

ROTARY PUMPS

EXTERNAL GEE PUMP WRIA Genk PUNP

a

ope PUN?

~

CENTRIFUGAL PUMPS

POWNSTREAN

0 A aaa,

oo

CPOING

(MPL

MPELEKS

i

DRIVESHAFT iPSTKEAM

PIPE FLANGE

(Guction)

DEEP WELL PUMPS

TURBINE PUMPS

= PUMPS FOR HIGH SUCTION LIFT UP TO 305M.

PLUNGER PUMPS

GEAR PUMP DISCHARGE Low

= TT MOVES A FLUID BY REPEATEDLY ENCLOSING A

FIXED VOLUME USING INTERLOCKING cogs or | HEAD Low

‘GEARS, TRANSFERRING IT MECHANICALLY USING A APPLICATION:

CYCLIC PUMPING ACTION.

eat VISCOUS FLUIDS (OIL)

~ A POSITIVE-DISPLACEMENT PUMP THAT CONSISTS: :

OF VANES MOUNTED TO A ROTOR THAT ROTATES areas

INSIDE A CAVITY. IN SOME CASES THESE VANES. GAM aNp PISTON

CAN HAVE VARIABLE LENGTH AND/OR BE TENSIONED . guyTTLE BLOCK TYPE

‘TO MAINTAIN CONTACT WITH THE WALLS AS THE

PUMP ROTATES

~ A-PUMP IN WHICH THE PRESSURE IS DEVELOPED impeuLeRs:

PRINCIPALLY BY THE ACTION OF CENTRIFUGAL . yroHeR HEADS — LOW

es cna KINETIC ENERGY INTO PRESSURE ENERGY See sree

‘THROUGH DIFFUSER VANES: . eee Nish

DISCHARGE

SPECIFIC SPEED ?'

IN RPM, IMPELLER WOULD

OPERATE TO GIVE 1 GPM

FOR A TOTAL DYNAMIC

HEAD OF 1 FOOT.

Ce DESCAPTION PRESSURE | DISCHARGE

DOUBLE SUCTION PUMPS 22

. -— eB -

_ = on = a

~ EMPLOYED WHEN THE FLOW

ARATE REQUIRED BECOMES

TOO LARGE FOR THE INLET

(CROSS-SECTIONS OF ONE

IMPELLER

WHEN THE FLOW VELOCITY

(OF THE FIRST IMPELLER HAS

TO BE REDUCED TO PREVENT

CAVITATION.

WHAT TO DO?

WHEN. GIVEN DOUBLE SUCTION

RELATIVELY RELATIVELY N

at ga PUMPS. DIVIDE GIVE caraciTY

(WOLUME FLOW RATE) BY 2

AIR LIFTS

~ COMPRESSED AIR BEING ADMITTED TO THE WELL TO LIFT

THE WATER TO THE SURFACE

= MODIFICATION OF THE OLD HAND. THIS IS BEST SUITED WHERE THE

LIFTS IS 7.6 M OR OVER AND CAPACITIES UP TO 190 LITERS PER SHALLOW WELL PUMP UPTO 25 FT.

Leela DEEP WELL PUMP up 10 420 FT.

EJECTOR — CENTRIFUGAL PUMPS

~ COMBINES A SINGLE —STAGE CENTRIFUGAL PUMP AT THE TOP of TURBINE PUMP UP TO 300 FT.

THE WELL AND AN EJECTOR/JET LOCATED DOWN IN THE WATER

= USED FOR SMALL CAPACITIES SUBMERSIBLE FOR HIGH HEAD

~ IS THE SPONTANEOUS VAPORIZATION OF THE FLUID,

RESULTING IN A DEGRADATION OF PUMP PERFORMANCE,

~ THE FORMATION OF CAVITIES OF WATER VAPOR IN THE

SUCTION SIDE OF A PUMP DUE TO LOW PRESSURE

NPG = Hs + Hp - He

ater

tr ‘Below 2 CENIERUNE

ie

ASSDUNE PRESSUREON THE=UAWI?

He TOTAL Fricnon=Hen@uoss IN SUCTION

GUREACE OF PUMP SUCTION SUPPLY

FRICTION HEAD

~ THE HEAD REQUIRED TO OVERCOME THE RESISTANCE TO

FLOW IN THE PIPE AND FITTINGS.

STATIC HEAD

~ IS THE HEIGHT OF THE SURFACE OF WATER ABOVE THE

GAUGE POINT.

PRESSURE HEAD

~ IS THE STATIC HEAD PLUS GAUGE PRESSURE ON THE

WATER SURFACE PLUS FRICTION HEAD.

VELOCITY HEAD

~ IS THE HEAD REQUIRED TO PRODUCE A FLOW OF THE

WATER.

SUCTION LIFT

~ THE VERTICAL DISTANCE FROM THE LIQUID SUPPLY LEVEL

TO THE PUMP CENTER LINE WITH THE PUMP PHYSICALLY

LOCATED ABOVE THE LIQUID LEVEL SUPPLY.

SUCTION HERD

~ THE VERTICAL DISTANCE FROM THE LIQUID SUPPLY LEVEL

TO THE PUMP CENTER LINE WITH THE PUMP PHYSICALLY

LOCATED BELOW THE LIQUID LEVEL SUPPLY.

STATIC DISCHARGE HEAD

~ THE VERTICAL DISTANCE IN BETWEEN THE PUMP CENTER

LINE AND THE POINT OF FREE DISCHARGE ON THE

SURFACE OF THE LIQUID IN THE DISCHARGE TANK.

vea7 — VOUME

wrt

INQREASE ei

veap (Mthet.| Qe

iS | INCREASE

a Wehe |Q4Qrt-

i voune' nad | 7h |e

CAUSES OF CAVIATION

OO

N PSH (net positive suction HEAD)

— DIFFERENCE BETWEEN ACTUAL SUCTION PRESSURE AND SATURATION VAPOR

PRESSURE

‘SUCTION NOZZLE ON THE OPPOSITE SIDE OF THE

END SUCTION CASING FROM THE STUFFING BOX AND THE FACE OF

PUMP THE SUCTION NOZZLE PERPENDICULAR TO THE

‘LONGITUDINAL AXIS OF THE SHAFT.

‘A CENTRIFUGAL PUMP WHOSE DRIVE UNIT IS

INLINE PUMP ‘SUPPORTED BY THE PUMP HAVING ITS SUCTION AND

DISCHARGE FLANGES ON APPROXIMATELY THE SAME

CENTER.

eS ‘SHAFT NORMALLY IN A HORIZONTAL POSITION

PUMP

‘HAS ONE OR MORE IMPELLERS DISCHARGING INTO ONE

VERTICAL SHAFT | OR MORE BOWLS AND A VERTICAL COLUMN PIPE USED

‘TURBINE PUMP TO CONNECT THE BOWLS TO THE DISCHARGE HEAD ON

WHICH THE PUMP DRIVER IS MOUNTED.

PUMP PARALLEL TO THE SHAFT

TAKES SUCTION FROM A PUBLIC OR PRIVATE WATER

‘BOOSTER PUMP ‘SYSTEM FOR THE PURPOSE OF INCREASING THE

‘EFFECTIVE WATER PRESSURE.

‘SUBMERSIBLE ‘A VERTICAL TURBINE PUMP WITH PUMP AND MOTOR

PUMP CLOSED COUPLED AND INSTALLED UNDERGROUND

THE LEVEL, WITH RESPECT TO THE PUMP, OF OF WATER

ran ae FROM WHICH IT TAKES SUCTION WHEN THE PUMP IS

NOTIN OPERATION.

THE LEVEL, WITH RESPECT TO THE PUMP, OF WATER

a prs FROM WHICH IT TAKES SUCTION WHEN THE PUMP IS

TN OPERATION.

If DIFFERENCE BETWEEN THE PUMPING WATER LEVEL

Daa ‘AND THE STATIC WATER LEVEL

a (e NOTE: CONIBNE FORNULA BELOW, IF NOE

IS. CONSTANT,

wis

a7 | n= m (A) SAME PUMPS

SPECIFIC SPEED

VOLUME FLOW RATE

Ol=ARER x VELOLAY

TOTAL HEAD/ TOTAL

DYNAMIC HEAD (TDH)

PUMP EFFICIENCY

THz (2a-23. (2) (We

mer ene

veo W080 ea

Py=sah

wae

PUP WORK Wee Me

Ne = NS.

a

SPEED, rpm A. CONSTANT DIAMETER VARIABLE SPEED

= PELHARGE CPM a ae toon, {* 2 8 {Sy

@, \Ni) Wy x) Pm \N

SIMILAR PUMPS

NI@, . NIG

B. CONSTANT SPEED VARIABLE DIAMETER

(e)

-& Blt

Meeeeisemal| oe ee ee

. ay ow +R

o-(F ae) e ~(

C. CONSTANT SPEED VARIABLE DENSITY

a pe m ph

PISTON DISPLACEMENT VOLUMETRIC EFFICI

PoP NEGECTED A

w= 2(5)07)N eye

ROP CONSIERED f

We HOO)N + Fa) Bye 1 Zesur

SLIP

Sup = \o-Q

PERCENT SLIP (% SLIP)

Loar = x 100%

No-&

o

FANS AND BLOWERS

+ FAN

~ APPLY POWER TO A GAS TO INCREASE TTS ENERGY CONTENT

THEREBY CAUSING I 0 FLOW oR MOVE. FANS PRESSURE RISE EQUAL TO OF BELOW 4 PSI.

+ BLOWER

~ AAV USED To FRE aR UNDER pressure winch wemis BLOWERS RESCUE PETE OS

RESISTANCE TO GAS FLOW 1 IMPOSED UPN DISCHARGE. COMPRESSORS — PRESSURE RISE ABOVESO PIG.

+ EXHAUSTER

FAN LAWS

~ AFAN USED TO WITHDRAW AIR UNDER PRESSURE WHICH MEANS

RESISTANCE TO GAS FLOW IS IMPOSED UPON SUCTION

AXIAL FANS

PROPELEZ “TWEAXIAL == VANEAXIAL

+t ek ol

PoxtvEN SeveN —RDMTVEN See ved WIVES VEN

CENTRIFUGAL FANS

AL FAN SPEED VARIATION

FANS IN SERIES/PARALLEL

SERIES | Q, 2@2|han=hishe

PARALLEL |am=024e I= he

STATIC HEAD STATIC FAN EFFICIENCY

Puianer = Powe | hg = Behe Pm eg = SMC AIR POWER _ Feo. ove

Bwhw = Baho ‘SHAFT FaneZ Pb

WELOCITY HEAD MECHANICAL EFFICIENCY

hy= es oF Ae em = Ait Foe Paw

W= 2g |No= ouner vetoary SAT OUR

TOTAL HEAD BERNQULLI’S EQUATION FOR FAN

h= hs + hv

CAPACITY OF FAN

Q= Ao* Vo

POWER OUTPUT OF A FAN/ AIR POWER

Pan = SanQ*h = One %9*h

STATIC AIR POWER

Forme aie = Cae X 9 xhs

COMPRESSORS

COMPRESSORS WS. PUMPS???

~ COMPRESSORS ARE SINILAR TO PUMPS, BOTH INCREASE

THE PRESSURE ON A FLUID AND TRANSPORT THE FLUID.

~ HOWEVER, GASES ARE COMPRESSIBLE, THUS COMPRESSORS

REDUCE THE VOLUME OF THE GAS

CLASSIFICATIONS OF COMPRESSORS

Penne DISPLACEMENT

‘ARE THOSE IN WICH SUCCESSIVE VOLUMES OF AIR ARE

CONFINED WITHIN A CLOSED SPACE AND ELEVATED TO A

HIGHER PRESSURE

+ RECIPROCATING COMPRESSORS

~ PISTON OR DIAPHRAGM HAS A RECIPROCATING MOTION.

‘+ SCREW (HELICAL OR SPIRAL LOBE) COMPRESSORS

= TWO INTERMESHING ROTORS, EACH IN HELICAL

CONFIGURATION DISPLACE AND COMPRESS THE AR

+ SLIDING-VANE COMPRESSORS

= AXIAL VANES SLIDE RADIALLY A ROTOR MOTOR MOUNTED

ECCENTRICALLY WITHIN A CYLINDRICAL CASING,

‘+ TWO IMPELLER STRAIGHT-LOBE COMPRESSORS

~ LOBES IMPELLERS TRAP THE AIR AND CARRY IT FROM

INTAKE TO DISCHARGE.

DYNAMIC COMPRESSORS

= RAPIDLY ROTATING ELEMENT ACCELERATES THE AIR AS IT

PASSES. THROUGH THE ELEMENT, CONVERTING THE

VELOCITY HEAD INTO PRESSURE

(CENTRIFUGAL COMPRESSORS

[ACCELERATION IS OBTAINED THROUGH THE ACTION OF ONE

‘OR MORE ROTATING IMPELLERS

‘ANIAL COMPRESSORS

WERE ACCELERATION 1S OBTAINED THROUGH THE ACTION

‘OFA BLADED ROTOR, SHROUDED AT THE BLADE ENDS.

SINGLE-STAGE RECIPROCATING COMPRESSOR P, WV, T RELATIONS

Co el MC

RECIPROCATING

ROTARY

CENTRIFUGAL

ISENTROAC/ADABATIC

p ma Povyteore

@_reo

mi IsoTHEeNAL

1S A MACHINE USED TO

INCREASE THE PRESSURE OF AIR

(OR GAS) 8Y DECREASING ITS

VOLUME,

Low

Low HIGH

\ coup

Ne sears coup

tonne |e (h)

PISTON DISPLACEMENT

PISTON SPEED

V=2LN

VOLUMETRIC EFFICIENCY

| ey= Itc -c(B)F

CaCineONde = ¥E-

ACTUAL VOLUMETRIC EFFICIENCY

LESS THAN THE CLEARKE VOL, EFF. BECAUSE OF PRESSURE DROP AT

VALVES, HEAT LOSS, AND THE PRESENCE OF RESIDUAL GAS IN THE

CYLINDER AT END STROKE

COMPRESSOR EFFICIENCY

_ COMPRESSOR Powe

Ce =" BRAKE Powe

COMPRESSOR WORK

i” -c(B Ay Tam IDEAL INDICATED POWER

erstee-e (8) Ht

CAPACITY FOER; = PriiVo

Y= met ADIABATIC COMPRESSOR EFFICIENCY

fi ISENTEORIC WORIC

Ce ppaeane * ACTUAL FUND WORK

WORK FoR GENTROPIC COMPRESSION!

"ae NO CE 1]

EGO

i)

BWORK, FoR COMPRESSION

W= rina | °

+

ADIABATIC COMPRESSION

ISOTHERMAL COMPRESSION

MINIMUM WORK

ISENTROPIC PROCESS NO COOLING

ISOTHERMAL PROCESS

PISTON DISPLACEMENT

ROO NEGLECTED

Vo = (2) E07LN

ROD CONSIDERED

Vo> Ev*n + F(0*d?)IN

Vp=(2\(Bo*LN) ~ Fae un

Tee Ls

0

%

Se

f

Vv

COMPRESSOR WORK HEAT REJECTED IN THE INTERCOOLER

Be = mep-11)

week (nv[($) 1]

INTERCOOLER PRESSURE

b= Ihe %,

HEAT ABSORBED BY COOLING WATER

Q= Mepwlstn

we (BOE lo tok!

5 () |essath

MULTI-STAGE RECIPROCATING COMPRESSOR

welt re 7

wel . ee ee

\O rae Rh G e wt sierra Fi

ro &

t %

{

' &—

i &

v

COMERESSOR WORE PRESSURE RATIOS (IDEAL CONDITIONS)

GENERAL FORMULA

Note: "S” 5 No, oF Stages ee 4-4

ee or

Woe Jew 1A ] ara

TTL Le DL

CENTRIRIGAL ROTARY (VANE)

eB BASIC CONVERSION OF CONIPRESSION 95.

We (A) (@)*-1] CONVERSION FLOM SINGE-STAGE To Z- sPGE SYSTEM

Fowler swe = f5- Ky

“hott ste = BB wa,

2

CONVERSION FKOM 2-STAGE “D SINAE-SRGE SHSM

POWER INceEDSE = K-Fh

Za tower macerse = B-Po , ag%,

wv

Nome

Ps= SINE SIE

Py= POMBE SIE

REFRIGERATION:

~ IS DEFINED AS THE PROCESS OF EXTRACTING HEAT FROM A LOWER-TEMPERATURE HEAT SOURCE, SUBSTANCE,

‘OR COOLING MEDIUM AND TRANSFERRING IT TO A HIGHER-TEMPERATURE HEAT SINK.

METHODS:

MECHANICAL REF.

AIR CYCLE REFRIGERATION

ABSORPTION REF.

ICE REFRIGERATION

STEAM JET REFRIGERATION

WATER FIBA ony. 2OAB WY, y 2381-144

BRINE Op BAG Vox

uUQquIP = Ls. VEGETABLES op = 318 Yor

GER FREEING WATT APTER FREEZING pouty = SBI ign MIB Yn, AGL

A= Wt te + 40 LEAN BEEF = BIZBMYign UB Yige 1288,

A= mop (tif) 4CLg) + Mew Cg -t0)

Siteat SErORE FREEZING HEAT AFTER

~ COMPRESSES THE LOW-PRESSURE REFRIGERANT GAS TO A HIGH-

PRESSURE REFRIGERANT GAS AND CAUSE TO TO FLOW IN THE

SYSTEM.

= HEART OF THE VAPOR COMPRESSION SYSTEM.

TYPES OF COMPRESSORS

RECIPROCATING

| ROTARY | CENTRIFUGAL

CLASSIFICATION OF COMPRESSOR BASED ON ENCLOSURE

CRANKSHAFT =—-EXTENDS = THROUGH =—THE|

OPEN-TYPE COMPRESSOR HOUSING SO THAT THE MOTOR]

CAN BE EXTERNALLY COUPLED TO SHAFT

‘HERMETICALLY COMPRESSOR AND THE MOTOR ARE ENCLOSED IN}

‘SEALED THE SAME HOUSING:

H THE CYLINDER HEAD CAN BE REMOVED FR

Coleen ‘SERVICING OF THE VALVE AND PISTONS

EVAPORATOR

~ LIQUID PORTION EVAPORATES WHILE ABSORBING HEAT FROM:

TH suaouNDDGS

TYPES OF EVAPORATORS

COIL TUBING BETWEEN METERING DEVICE AND

COMPRESSOR

Fxpansion | "YES 0FORY eirouroRs:

(oY ‘A BEAR TYPE — PRIME SURFACE, SLMPLEST

{ire) | & materi seers woe Townes

C. FIN-TUBE

.SHELLAND Con — ALSO cRLLD cHTLER

FLOODED ONLY FOR WATER-COOLED CONDENSERS. HIGH

evap. | capacry siren,

Fish (Tuna) WEY. DB“, Soa

MILK Yok 05

MAGNOLIA 69-0985 Ye $9 =105

CONDENSER

~ RECEIVES THE HIGH-PRESSURE REFRIGERANT GAS AND THEN CONDENSES

WHILE REJECTING HEAT TO THE COOLING MEDIUM (AIR OR WATER)

= LIQUEFY THE REFRIGERANT

TYPES OF CONDENSERS

COMMON IN SHALL COMMERCIAL SYSTEMS

TYPES OF AIR-COOLED CONDENSERS:

A NATURAL DRAFT — AMBIENT AIR

FORCED DRAFT — PUSHED THROUGH COILS

INDUCED AIR DRAFT — PUSHED OVER OILS

EXPENSIVE AND CORROSIVE

TYPES OF WATER-COOLED CONDENSERS:

‘A. DOUBLE PIPE (TUBE-IN-TUBE) REFRIGERANT

THROUGH INNER TUBE AND WATER THROUGH

OUTER TUBE.

SHELL AND COIL — MADE OF STEEL WITH COPPER

TUBES INSIDE

VERTICAL SHELL AND TUBE

. HORIZONTAL SHELL AND TUBE

‘MUCH LIKE A COOLING TOWER, WATER IS spRRYED

(OVER THE CONDENSER AND COOLS IT.

AIR-COOLED

WATER-

COOLED n

EVAPORATIVE

ACCESORIES

1. SPRAY POND ~ WATER RECIRCULATING DEVICE. WARM WATER 1S

SPRAYED THROUGH NOZZLE.

2. COOLING TOWERS

TUBINGS

most. cons

| sveet awn tt)

| STAINLESS STEEL ooo pots, ama eck

THROTTLING | EXPANSION DEVICE FLOAT VALVE ~ MAINTAINS LIQUID AT CONSTANT LEVEL

~ REDUCES THE PRESSURE FROM CONDENSER PRESSURE TO = ASFLOAT SWITCH” CLOSES AT MAK, LEVEL

EVAPORATOR PRESSURE

CONSTANT = AINTAINS CONSTANT PRESSURE AT ITS_OUTLET

TE ceTee PRESSURE E.V. (TRANCE 10 evapoRATOR)

Pe eesee nnston DERICES, ~ MOST POPULAR FR MODERATESIZE REF. YSTEMS

CAPILLARY iwsive oaneree [0.S0mm= 2mm] sypcanent = THERMOSTATIC EN”

TUBE CONTROLLED Ev, ~ PEGULATES THE FLOW RATE OF LIQUID RerRteRANT

(SMALL REF exci Am -6m TIN PROPORTION TO THE RATE OF EVAPORATION IN

SYSTEMS), CAPACITY upto Jo KW THE EVAPORATOR

EXPANSION TYPES: TONS OF REFRIGERATION

_ AGATE VALVE = ISTHE AMOUNT OF HEAT THAT MUST BE EXTRACTED TO FREEZE TON

2 COSTA ESE EASE (SHORT) OF WATER AT 82 F INTO ICE AT 32 (AT ATH) 1 AY.

bed = ALSO CALLED REFRIGERATION TON

THERMOSTATIC EXPANSION VALVE

. THERMOSTATIC EXPANSION VALVE W/

Sega EQULER [TORE NSISICIRW, = Zi wi = 0.4 5- Zoo

FLOAT VALVE FOR FLOODED EVAPS.) vn 0)

REVERSED CARNOT CYCLE HEAT ADDED

TEs vincent” Qn = in = KOS

HEAT REJECTED

Qe= Qour = ThhS

COP (HEAT PUMP)

=

a shete

COP (REFRIGERATION)

VAPOR COMPRESSION SYSTEMS ARE THE MOST WIDELY ADOPTED REFRIGERATION.

‘SYSTEMS IN BOTH COMFORT AND PROCESS AIR CONDITTONING.

~ ALSO CALLED REVERSED RANKINE CYCLE.

COMPRESSOR WORK COP (COEFFICIENT OF PERF.)

so

» y

We= m(ltz- tn) = her coer _ 4h %

OP = oupeeman wi. “We | 2 * R

ENTHALPY AT EVAP. ENTRANCE (4) SUN

EER (ENERGY EFF. RATIO) zu

Wy= Infg + xhhfgy | x-auacrryye | PATIO OF ENERGY REMOVED AT THE EWP. TO THE = Sp a

baal ELECTRICAL ENERGY CONSUMED, SHALL CONFORM TO THE =

REFRIGERATING CAPACITY SEPATHENT Te BIER 3

Re EFFecT _ Ss...

Gu= (hi - ha) eRe —Powce war SZC] BE se

POWER PER TON REFRIGERATION EFFICIENCY 222

fowa? Pex Ton = —_We___ = CoPexsnen 22 8

"ON OF REF C= Sex 100% EES

+ x pa | sea VOLUMETRIC EFRCEY MECH’ EFFICIENCY

wt = Fi

Wwe en= A

COMPRESSORS ae 2

DISPLACEMENT RATE OF COMPRESSOR CLEARANCE VOLUMETRIC EFFICIENCY

12 ee aa Me

Vp 4VLNene omy yee Ge = 140-6 (tq) | C= PERCENT Coenen

y + (= CONWRESSION RATIO

VOLUME FLOW RATE AT SUCTION ve ) For? ANNONA,

[vicemvy | \=Sennc Voune @ |

Wem IW SPUR NOUINE F | Use k=44

COMPRESSOR AND THE EVAPORATOR TEMPERATURE

DEGREE SUPERHEATING AND

aaa TTT DEGREE SUPERHEATING

DIFFERENCE BETWEEN ACTUAL TEMPERATURE ENTERING THE

DEstEE

HN = ti-tevar

DEGREE SUBCOOLING

DIFFERENCE BETWEEN CONDENSER TEMPERATURE AND THE ACTUAL

TEMPERATURE ENTERING THE EXPANSION VALVE.

ADVANTAGES:

~ REDUCES QUALITY OF GAS VAPOR

~_INCREASES REFRIGERATING EFFECT OF SYSTEM

°%Ge = tow-ts’

W/ HEAT EXCHANGER HEAT EXCHANGERS

= PREVENT. NO LQUID

ENTERS

COMPRESSOR

~ PREVENT BUBBLES OF VAPOR

THROUGH EN.

ENERGY BALANCE

Wsthe = hth

cor

Se Se

THESE ARE REFRIGERATION SYSTEMS WITH TWO OR MORE LOW-SIDE PRESSURES,

~ LOWSIDE PRESSURE IS DEFINED AS THE REFRIGERANT PRESSURE BETWEEN EXPANSION VALVE AND COMPRESSOR INTAKE,

+ INTERCOOLER — REDUCES THE WORK PER KILOGRAM OF VAPOR BETWEEN TWO STAGES OF COMPRESSION; MAY BE ACCOMPLISHED BY A WATER-

COOLED HEAT EXCHANGER OR BY USING A REFRIGERANT.

+ FLASH TANK — EQUIPMENT IN WHICH VAPOR IS SEPARATED FROM THE LIQUID,

1. TWO STAGE COMPRESSOR, ONE EVAPORATOR

f= Thx

= ms (hha)

ENERGY BALANCE?

Agha + mghy= hg + wighy

My = my

Ms = me

COMPRESSOR WORK

We = mi (hah)

Wen = ms (1 -hg)

Wer = Wer + Won

CUO Le

“ARETE = my 4m

Mh = Moho + mshs

We = MChe-lv),

=m Ng- hy

%2=™(h- hy)

Tig = m4 me

th + mahi = wsles + mzh7

Oy = Me (she)

Oe, = Me (nhs)

Wenz ims (hi4~ has)

Wey = a (In - Ini)

= Mt he

OP = “loa ewe

HEAT BALANCE:

hy = Mis +(m-m hz

|OUNCTION

Wear BALANCE:

anh =(rm-my)hg + mine

Ss

~ COMBINE TWO-VAPOR COMPRESSION UNITS, WITH THE CONDENSER OF THE LOW-TEMPERATURE

SYSTEM DISCHARGING ITS HEAT TO THE EVAPORATOR OF THE HIGH-TEMPERATURE SYSTEM,

CED EU ee |

| CRYOGENICS — THE SCIENCE OF LOW TEMPERATURE

Mshs + Mhz = Mshg +mhz

ry ( -hg) = ms (ns - he)

A= Mm Cry-hg)

Wen = msChe-s) | Wror = Wer + Wen

Wer= mC he-h)

DIRECT CONTACT CASCADE

B=[Aee

HEAT BALANCE?

mg (hs -hs) = ,(n2-hs)

“TOTAL COMPRESSOR WORK:

We = mi(ng-hi) + ms (hg-hs)

Oe a

REFRIGERATION EFFECT

= IS OPERATING ON THE REVERSE BRAYTON CYCLE

~ TTIS THE ONLY ATR-COOLING PROCESS

DEVELOPED COMMERCIALLY WHEREIN A GASEOUS.

REFRIGERANT IS USED THROUGHOUT THE CYCLE

= IDEALLY SUITED FOR USE IN AIRCRAFT

EXPANSION WOR

A= MCpa(Ts- TH)

HEAT REJECTED

|

Og = mega (Te-Ts) NET WORK

ESSOR WORK Wer = We- We

COEFFICIENT OF PERFORMANCE

= oe

CoP War

OE a

GENERATOR HEAT

BANles Nus -W20" Sse,

= A REFRIGERATION WITHOUT COMPRESSOR AND

RATHER NO EXTERNAL WORK TO COMPRESS THE

REFRIGERANT.

‘A SUBSTITUTE TO THE COMPRESSOR 1S THE

[ABSORBER-GENERATOR SET-UP THAT PRODUCES A

SOLUTION OF REFRIGERANT AND THE

REFRIGERANT 1S SUPERHEATED BY AN EXTERNAL

HEAT.

COEFFICIENT OF PERF.

= Ge _Cuserus oma)

cor= — @g_ Cpu nese)

ABSORBER HEAT

Om +m = Mshs + mhz

izh2 + tzhe =Qat mh

CONDENSER HEAT

MASS AND ENERGY BALANCE

Ge= M36 hs- ha)

EVAPORATOR HEAT

© WAS BALANCE O ENERGY BALANCE

Mme mz+mg Ag+ Ge =n + Oe

Qe = M3(h5-h4)

a

WAM WATERS,

~ WATER IS USED AS REFRIGERANT

= PRINCIPLE OF OPERATION BASED ON THE FACT

THAT WATER WILL BOIL OR YAPORIZE RAPIDLY,

AT A-RELATIVELY LOW TEMPERATURE, IF THE

PRESSURE ON THE SURFACE 15 REDUCED.

MASS AND ENERGY BALANCE

EMPIRICAL EQUATION FOR FREEZING

TIME

Pana ae

pre | Ggesr

327 |e eene TaN *r

~ BRINE ~ 1S WATER PLUS SODIUM CHLORIDE

AND/OR CALCIUM CHLORIDE MIXTURE WHOSE

PURPOSE OF ADDITION OF LAPURITES 1S TO

DECREASE THE FLUID FREEZING TEMPERATURE

- HEAT OF RESPIRATION (HR)—

APPLICABLE ONLY FOR FRUITS AND RESPIRATION

TOTAL HEAT LOAD

ti= TEMPERATURE ENTERING

Es = SORAGE TeNPERATURE

R= HEAT OF RESPIEATION

HEAT REMOVED FROM WATER TO MAKE ICE

ere en |

Cbg & Cag -» WATER SPECIFIC HEAT

Ai yap MATER MAL

ti Se FINAL

ALLOWANCE OF HEAT LOSS

“USUALLY 10%-20% OF THE HEAT

REMOVED, USE HIGHER VALUE

Qam = 122

NUMBER OF ICE CANS PER TON OF ICE, N

ZOOOFT | Fr= FReEaNG Hares, Ie

24W ye | We = WEGHT Ge

REFRIGERANTS

WO TYPES OF REFRIGERANTS

PRIMARY REF.— REFRIGERANTS USED IN. VAPOR-COMPRESSION

sysTens

SECONDARY REF. — ARE LIQUIDS USED FOR TRANSPORTING LOW-

TEMPERATURE HEAT ENERGY FROM ONE LOCATION TO ANOTHER. ALSO

‘CALLED ANTI-FREEZERS OR BRINES.

PRIMARY REFRIGERANTS

CTT

~ CONTAINS ONE OR MORE OF THE THREE HALOGENS — CHLORINE,

1

FLUORINE, BROMINE

= STANDARDIZED BY RSHRAE

Rll R13 Ris

wie R-40 Rell4

AUMIBER OF FUIORINE ATOMS

HYPROGEN +1. CAoNS)

CARBON — 4 CAMS)

STANDS FoR RERACERANT

INORGANIC COMPOUNDS

R77 AMMONIA Naz

2-718 WATER H20

8-729 AIR 0, 4370N2

R-744 (CARBON DIOXIDE coz

R- 164 SULFUR DIOXIDE So2

Bane: F

wean ae HB

CTT

SUITABLE REFRIGERANTS ESPECIALLY FOR SERVICE IN THE PETROLEUM

‘AND PETROCHEMICAL INDUSTRY

RSQ METHANE CHa

R170 THANE Colle

— R-290 propane Coa

penis:

GON =| 924

Shree! or.

— Fuloewe —> 0

~ MIXTURE OF TWO DIFFERENT Tr

Ris2a

R-\70

i

a4

(es ee

eee) we eas

[Ree |e ee

~ ISA SUBSTANCE USED IN. REFRIGERATING MECHANISM, IT ABSORBS

HEAT IN EVAPORATOR BY CHANGE OF STATE FROM LIQUID TO GAS.

REFRIGERANTS USED TO COOL A SUBSTANCE OR EVAPORATOR AND THE

REFRIGERATOR [S THEN RELEASED TO THE ATMOSPHERE

728 LiQUID NITROGEN

& 704 Liguin HELIUM

2-744 CARBON DIOXIDE

GROUPINGS AND CLASSIFICATIONS OF REFRIGERANTS

+ NRSC ~ NATIONAL REFRIGERATION SAFET CODE

= GROUPS ONE TO THREE (1-8)

GROUP 4 — SAFEST OF THe REFRIGERANTS

(GROUP 2 — TOXIC AND SOMEWHAT FLAMMABLE

(GROUP 3 — FLAMMABLE REFRIGERANTS

+ NBFU ~ NATIONAL BOARD OF FIRE UNDERWITERS

= CLASS ONE TO SIX (4-6)

CLASS ONEIS MOST TOXIC WHILE CLASS SIX IS LEAST TOXIC

RIB PLE

|

Riz SILVER

Riz WHITE

22 REN

R-34a ‘SKYBLUE

ese — [a

R502

R77 SILVER

R-13 PALE BLUE

[50s [roe

SECONDARY REFRIGERANTS

‘COMMONLY USED SECONDARY REFRIGERANTS

+ CALCIUM CHLORIDE

+ SODIUM CHLORIDE

‘ETHYLENE GLYCOL

+ PROPYLENE GLYCOL

AIRCONDITIONING

THE AUTOMATIC CONTROL OF AN ATMOSPHERIC ENVIRONMENT EITHER

FOR THE HUMALJANIMAL COMFORT OR FOR THE PROPER PERFORMANCE

OF INDUSTRIAL/SCIENTEFIC PROCESS,

FUNCTIONS

+ CONTROL THE TEMPERATURE

+ CONTROL THE HUMIDITY

‘+ CONTROL THE PURITY (REMOVAL OF DUST AND OTHERS)

+ CONTROL OF AIR CIRCULATION/ MOVEMENT

DEFINITION OF TERMS:

STUDIES THERMODYNAMIC PROPERTIES. OF

PSYCHROMETRY — | MOIST AIR AND THE EFFECT OF MOISTURE

ON MATERTALS AND HUNAN COMFORT.

A GRAPHICAL REPRESENTATION. OF THE

on, a THERMODYNAMIC PROPERTIES OF MOIST

AIR, PROCESSES, AND CYCLES

psvcunomerer | INSTRUMENT USED TO STUDY THE

PROPERTIES OF AIR

ATMOSPHERIC

‘A IMIXTURE OF GASES, WATER VAPOR, AND

AIR POLLUTANTS:

AIR WHERE ANY DECREASE IN TEMPERATURE

sarocren | ar ann one A

VAPOR INTO LIQUID.

meruRaTED AIR CONTAINING SUPERHEATED VAPOR.

MOIST AIR ‘VAPOR

aA NITROGEN AND OXYGEN.

WAPOR CONDENSABLE COMPONENT OF THE MIXTURE

AIR DRY AI- NITROGEN =78% By VOL.

aware var | OXYGEN = 21% BY Va.

2

21% 10 3%

DEPENDS ON WEATHER| 0S POF, 47g

AIR CONDITIONING PROPERTIES

1, PRESSURE

APPROXIMATE FORMULA

2. TEMPERATURE

‘DRY BULB + ACTUAL TEMP. OF AIR

TEMP. ‘tog + MEASURED BY ORDINARY THERMOMETER

+ TEMPERATURE OF AIR IF IT*S SATURATED

WET BULB + MEASURED BY WETTED WICK THERMOMETER

TEMP. + TEMPERATURE OF ATM. AIR IN AN ADIABATIC

we PROCESS

WET BULB _ -

DEPRESSION WoD = twe - te

DEW POINT WATER VAPOR IN AIR CONDENSES (CONSTANT.

TEMP. “eg PRESSURE COOLING)

SLING PSYCHROMETER — MADE UP OF TWO THERMOMETERS, ONE DRY

BULB AND ONE WET BULB SIDE BY SIDE

3. SPECIFIC VOLUME

GT

A -&

Yo . &T_ 2

VP ta = Pe

4. HUMIDITY RATIO

= RATIO OF THE MASS OF WATER VAPOR TO THE MASS OF DRY ALR

0.622

We™ 9622 |C\nwweo

(2 Fe-R |” tnwaie 23.97

MASS OF WATER VAPOR IS USUALLY MEASURED IN GRAINS

5. RELATIVE HUMIDITY

a Rhea @ VEWPONT TEM

Year > Poor @ vey eis TEMP

G. ENTHALPY

Pe = TOTAL PRESSURE oF ANR-VAPOIe

Ya > PARTIAL IRE OF DRY AN

Py PARTIAL PRESSURE OF WATER VAG

R= Pat &

r= hg ®

ne wt?

%

h= Op(tdb) + Whg>

DALTON’S LAW OF PARTIAL PRESSURE — TOTAL PRESSURE OF

ATMOSPHERIC AIR IS THE SUM OF THE PARTIAL PRESSURES OF DRY ALR

AND WATER VAPOR

APPROXIMATE FORMULA CPpaR= 1.0K

7. PERCENT SATURATION | DEGREE OF SATURATION | HEATING AND HUMDIFYING PROCESS

PERCENTAGE HUMIDITY

GATURATION = ACTUAL HUNT RATIO

ee Bunoiry Bano oF Sar. A poms, ‘wanes

Pen

%a samuRaTONn = eu[-f— 9] | 3 - |

A-Z WEDTING

aaa 2-3 HUNIAFYING

Becton “SRN

ADIABATIC PROCESS

3

Vinee

re aon

me “mostra \2 ANBAR

ALR MIXING

&

TAHEAT BANE

te MOISTURE BOLONGE

rs Nb we ens BALAN

Wi

ni

BYPASS FACTOR

o-1 | cane THE PORTION OF THE AIR THAT PASSES THROUGH THE COLL WITHOUT

0-2 | HEATNe (Heme) CONTACTING THE COWL SURAACE

0-2 | HUMIIFANG CisoTHERNA. eYER) pee nEsTIP cat

0-4 | venuwrrne te -by

0-5 | GOUNG 2 DewuNuIEMe (alecon) ee

0-6 | HEATING 2 HUNIDIFYNG CCOOUNG TONER) ta te-ta

0-7 | COOUNG ZB HUNI”IFYING CADABENC DAE)

0-8 | HEATING 2 VEINIDIFYING CCHEN'L DENuM!) BF OF COOLING COIL

to-te

ENTHALPY DEVIATION — DIFFERENCE BETWEEN THE ACTUAL/TRUE oy | OF Ke

SPECIFIC ENTHALPY AND THE SPECIFIC ENTHALPY OF SATURATED AIR AT

GIVEN WET BULB TEMPERATURE.

cou ractor | gp> ae

APPLICATIONS OF PSYCHROMETRY (METHODS OF AIR HANDLING TO A CONDITIONED SPACE

TW AREAS WHOSE OUTSIDE CONDITIONS ARE CLOSE IN TEMPERATURES AND

HUMIDITY TO THE SPACE BEING MAINTAINED.

EXPANSION

\PRESSOZ P =x ae.

Os

© ‘eonroeate © conmonce “™ a.

og

= OWERS TEMA &

Human OF AZ

. bach TIM IL MMR

te a Su= mac w-lte) | “yore ECONOMICAL THAN AL OUSIDE A, SINCE HE BECCUATED AR

RATE OF yj) TEMPERATURE 15 CLOSER TO THE CONDITIONED SPACE: OT FOR AREAS

Me meeuRe ma (WW) WHERE TOXIC ODORS ARISE.

Va= may)

— Pius

AIR CONDITIONING CALCULATIONS as

ve

Aue convmowae a

cont

Se

(Teeuwen

Ale ETT

PART OF THE RECIRCULATED AIR 1S CONTROLLED BY DAMPER. ACTION

‘MAKING IT BYPASS THE CONDITIONER,

g

a

AE CONDTONER

Nove sNesuE FAN Qe

‘Wor

SENSIBLE HEAT

Qs = mep (tz -t)

LATENT MEAT LOAD DEFINITION OF TERMS:

7 zi WSE5 RATIO OF ROOM SENSIBLE HEAT TO THE

= (WoW) * hy v= 24424 | Aeareneron | SUMMATION OF ROOM SNE aD Room

LATENT HEAT

TOTAL HEAT LOAD

RATIO OFTHE TOTAL SENSIBLE HEAT TO THE

Q1=As+Q vee GRAND TOTAL HEAT, INCLUDING THE

UTDOOR ATR HEAT Lonos.

SENSIBLE HEAT RATIO

a ese 90H | ne nee sa

DiR= asta ~ ar Fact HEAT TO THE EFFECTIVE TOTAL HEAT

AIRCONDITIONING CAPACITY

Ms=Mr+mo —> Mehz + Whe =msh4

Qwwacon= mC Mg- hi)

AIRCONDITIONING CAPACITY — NO MIXING PLENUM met

nM Cmormrihy +Qee.

Qpacon = Mo Chg -hi) + mC hg hi)

COOLING

REDECT HEAT BY REDUCING THE TEMPERATURE OF WATER

CIRCULATED THROUGH CONDENSERS.

‘+ RECIRCULATING WATER FROM A CONDENSER 15 EVAPORATIVELY

CCODLED BY CONTACT WITH ATMOSPHERIC AR

Ce ae CCU

‘CONDENSER WATER IS DISTRIBUTED AT THE TOP OF THE TOWER, INTO THE

SHELL, THEN COLLECTED AT THE Pau

HOT WATER,

AlZIN

He DRAFT TOWER

‘USES WATER EVAPORATION FOR COOLING, THE DIFFERENCE 15 THAT A FAN

PUSHES THE AIR INTO THE SHELL cel

OUT

Fant

Hot —>

20

AIR

cone, Ww

CT aes)

‘MOST POPULAR TOWERS USED IN THE CITIES. TWO OR MORE FANS

INSTAL O THE TOP OF TE

DRIFT EuMINABeS

air,

# Re

‘DRIFT ELIMINATORS ~ THE ELIMUNATORS PREVENT THE WATER DROPLETS

‘AND MIST FROM ESCAPING THE COOLING TOWER.

COOLING POND

‘A-MAN-MADE BODY OF WATER FORMED FOR THE PURPOSE OF COOLING

HEATED WATER TO A NEARBY POWER PLANT OR INDUSTRIAL FACILITY

a

hor —>

Hao tala

ta Our

AR

copuse 1

Orn

TOWERS

ANALYSIS:

NAKE-UP

WATE; |

RANGE te

TENP. DIFFERENCE OF WATER ENTERING OR LEAVING THE TOWER

te= RANGE = ta- tp

APPROACH ts

TEMP, DIFFERENCE OF WATER LEAVING THE TOWER AND WET BULB TEMP.

OF ENTERING ALR

ta = APPROACH = th - tw

[RATE OF MOISTURE REMOVED | MAKE-UP WATER REQUIREMENT

WOISTIKE _ a Mm = Ma-mo

Rencven= MeN) Nance — en

REMOVED

HEAT BALANCE

a= Su

MMi Cz -hn) = Mg Cpy Cta-ty)

ENERGY BALANCE

mh + Maha +Mmhm = Mzhe + Moly

QUANTITY OF WATER LOST BY BLEED OFF

|pverme ”

G52 Se us

QUAY OF Ngo Lost BY EED-OFF

COOLING TOWER SPECIFICATION

oneans ta = 40°C

zw ty = Bee

bwloy> 20°C

DRYERS

‘MOST COMMONLY USED DRYER

‘+ CONSISTS OF A ROTATING CYLINDER WHERE

MATERIALS FLOW WHILE GETTING IN

CONTACT WITH THE HOT GASES; THE

CYLINDER IS TILTED AT A SLIGHT ANGLE

+ COPRA, SAND, WOOD CHIPS

ROTARY

DRYER

‘+ WET FEED IS INTRODUCED AT THE TOP AND

FALLS DOWNWARD WHILE COMING IN

CONTACT WITH THE HOT AIR

‘+ PALAY, WHEAT, GRAINS

TOWER DRYER

‘+ MATERIAL TO BE DRIED IS SUPPORTED ON A

FLOOR THROUGH WHICH THE HOT GASES

PASS

‘+ COPRA, COAL, ENAMEL WARES

HEARTH

DRYER

+ CENTRIFUGE REVOLVING AT HIGH SPEEDS

CENTRIFUGAL CAUSING THE SEPARATION, BY CENTRIFUGAL

DRYER FORCE, OF THE WATER FROM THE MATERIAL

‘+ DRYING FERTILIZER, SALT, SUGAR

+ TRAYS, CARRYING THE WET MATERIALS,

TRAY DRYER PLACED IN COMPARTMENT CONVEYOR

‘+ TPIL-IPIL LEAVES, GRAINS

‘+ INFRARED LAMPS. ARE DIRECTED TO. THE

INFRARED RAY | ” sericies 10 Be DRIED

oven ‘+ DURING PAINTED ARTICLES LIKE CARS

FREEZE- + SUBLIMATION OF WATER VAPOR FROM ICE

DRYING UNDER HIGH VACUUM AT TEMP. BELOW O

DEGREE CELSWS.

‘+ HEATED ETAL ROLLS ON THE OUTSIDE OF

WAICH A THIN LAYER OF LIQUID 1S DRYED.

HYGROSCOPIC MATERIALS

ARE SUBSTANCES WHICH ARE VARIABLE IN THE MOISTURE CONTENT

THEY CAN HOLD AT DIFFERENT TLMES.

BANA: SPONGE

DRUM DRYERS

BONE ORY WEIGHT

FINAL CONSTANT WEIGHT ATTAINED BY ANY HYGROSCOPIC SUBSTANCE

ATER BEING DRIED OUT.

GROSS WEIGHT

Gees weictt (Wr) = Sm +6W

REGAIN

THE HYGROSCOPIC MOISTURE CONTENT OF A SUBSTANCE EXPRESSED AS

THE RATIO OF THE MOISTURE WEIGHT TO THE BONE DRY WEIGHT.

MOISTURE WeicuT WE

REGAN = Gone Oy Welalt ~ — 2p

MOISTURE CONTENT

ISTURE WI,

hostute contest = area ~ “We

TYPICAL LAYOUT OF DRYING A PRODUCT

Fees

oO

PROPUCT Wg

BENON-AIABATIC.

DevER CACTUAL)

WADIABATIC Dever

BRISOTHERNAL h2= Am=ma(Ws-Wa)

DRYER

DRY BASIS WET BASIS

A NosuRE

Mnge ne Samy = OL

eM mg +B7N

“TotaLmass <~

MOISTURE BALANCE

MATERALS MOISUIZE REMOVED = AIRS MOIST APVED

Vea — Wie = Ma (Ws - Wa)

HEAT SUPPLIED IN THE HEATER

Qa = maChe-m) ;

EFFICIENCY

eFricieny oF HER ABsOR_ he

DRYER HEAT suru nz - hy

ARE USED EITHER TO REMOVE THE WATER

FROM A LIQUID SUBSTANCE, LIKE SUGAR

SIUICE, OR TO PRODUCE DISTILLED WATER BY

CONDENSING THE STEAM,

DR ANALYSIS: DOUBLE EFFECT EVAPORATORS

CL TaD

h@ hs 1ST ERE vame

+ FoR NON-VISCOUS LIQUIDS THAT DO

a RTE NOT DEPOSIT SALT OR SCALE

STANDARD + FoR LIQUIDS THAT DEPOSIT SALT oR

VERTICAL TUBE ‘SCALE DURING EVAPORATION.

+ CONSISTS OF LONG TUBES SO THAT

THE LIQUOR PASSES THROUGH THE

LONG TUBE,

EVAPORATOR BUT ONCE

Nar ccuTOn | Ti IN SLIGO

EVAPORATOR SCALING LauIDs (rep) . 4 +e,

+ CAN BE USED WITH HIGH VISCOSITIES @ STE aM CiNLET) ed

+ OME OF THE CHEAPEST TYPES Kaw ware (ae 7 tow

@ vara cpeonucr) hy > hfs,

SPRAY OF WATER FALLS ON HIGH fy 2 hg Otn

FILM TYPE TEMPERATURE TUBES BECAUSE OF STEAM Reine

ON THE msiDe. heh Sh@ oe

WHERE THE TUBE BUNDLE 15 SUBMERGED

SUBMERGED TYPE | WERE TI

MASS BALANCE ON FIRST EFFECT

Mshe + Merwe, = my hy, + ma\My,

GUT, ms = MW, 5 my, = Moy

ims Chg = hw)

i cena

RELIEVING RATES y= OF

= THE VELOCITY AT WHICH THE VAPOR LEAVES THE WATER SURFACE MASS BALANCE ON 2ND EFFECT

RELIEVING SURFACE

= THE WIDTH OF THE WATER SURFACE IN THE SHELL MULTIPLIED By Maloy, + Mews lee = Myghvg + Mwe hie

THE DISTANCE BETWEEN THE TUBE SHEETS eur, m= mae > ney mew,

rin hvi~ he

Pisenepaine pitch = (ABET OF Het) 5 sper. youn We = hg - Pg

UEVING SURFACE

= EVAPORATOR ECONOMY

HEAT HEAD aL

~DIFERENCE BETWEEN. THE SATURATION. TEMPERATURE OF THE | EyaraqeatoR Exonanny= XABERROPUED, MMi + MW

NNOTIVATING FLUID AND THE SATURATION TEMPERATURE OF THE SreAM SUPPLY mg

vapor

SO Le

msERes aFARAWeL var,

AST EFEX vam

cy

DRAINS ROW WATER DEANS eon wore INS

CONVEYORS

EITHER FIXED OR PORTABLE DEVICES FOR MOVING MATERIALS BETWEEN

‘TWO POINTS AT THE SAME OR DIFFERENT ELEVATIONS, WITH CONTINUOUS

‘OR INTERMITTENT FORWARD MOVEMENT

TT oa

+ THEY LENE THE BOILER AISLE FREE FROM

OBSTRUCTION

BELT ‘CONTINUOUS SYSTEM BELT USUALLY TROUGHED

+ HIGH CAPACITIES POSSIBLE

+ CONL COPR, OARS, PRCKAGES

SPIRAL | + EoLESs HELICOID ScREW IN A TROUGH

ScREW — | = puvezizeD com, Lou, GRAINS

FLIGHT / | + LOW IN FIRST COST BUT LARGE ENERGY

SCRAPER CONSUMPTION. CONSTDERBLE WEAR, CAUSED BY

ABRASION

+ SERIES OF METAL FLIGHTS: ATTACHED aT

INTERVALS TO CHAIN

+ PREKAES, BOXES, OPRR

PIVOTED — | + wATERINL 1S. CARRIED AND BUCKETS ARE

Buck SUPPORTED ON ROLLERS

CARR + THE PIVOTED BUCKET CARIES CAN BOTH ELEVATE

An conve,

+ COPRA, COAL, GRINS

LARRIES | SUSPENDED RAIL TYPES ARE GENERALLY USED

Re FORCE TO NOE:

eeu OF mats

B= TOTAL CHAIN PULL

BR+ e+e |, oe

fOWER= TOTAL CHAIN x VELoUTY | 2.2

fa TAL Cuan Sageeage

‘SCREW CONVEYORS DESIGN CONSIDERATION

‘+ SCREW CONVEYORS SHALL BE GUARDED TO PREVENT PERSONNEL FROM

‘COMING INTO CONTACT WITH THE SCREW. GUARDS OF HORIZONTAL

BARS SPACED TO ALLOW MATERIAL TO BE FED INTO THE CONVEYOR

SHALL BE NOT MORE THAN 2,440 MIM APART.

‘+ 2,100 MIME OR LESS ABOVE FLOOR OR OTHER WORKING LEVEL SHALL BE

‘COMPLETELY COVERED WITH SUBSTANTIAL LIDS.

+ BOO MM OR LESS ABOVE THE FLOUR MAY BE GUARDED BY STANDARD

RAILING GUARDS 08 SUBSTANTIAL COVERS OR GRATINGS.

CRANES AND HOISTING

EQUIPMENT

BOOM | TELESCOPIC 08 FIXED AR, USED TO MOVE OBJECTS

BUFFER | CUSHIONING DEVICE, MININIZE SHOCK OF COLLISON

BUMPER | STOPS THE MOVING PART AT THE LINIT OF TRAVEL OF A

CRANE, PREVENTS MOTION BEYOND A POINT

cae HOUSES THE OPERATOR, HOISTING MECHANISH, AND

EQUIPMENT CONTROLLING THE CRANE

CAGE | HOUSES THE OPERATOR, AND EQUIPMENT CONTROLLING

THE CRME

OVERHEAD * ON A PAIR OF PARALLEL ELEVATED RUNWAYS,

TRAVELING/ LIFTS AND LOWERS A LOAD AND CARRY IT

BRIDGE CRANE HORIZONTALLY PARALLEL TO, OR AT RIGHT

ANGLES TO

+ TTS. OPERATION LIMITED TO THE AREA

BETWEEN THE RUNWAYS

‘+ MAINTENANCE SHOPS, ICE PLANTS

FOR HOISTING, DOES NOT INCLUDE A

HOISTWAY WOR A CAR OR PLATFORM

TRAVELING THROUGH GUIDES

LOADING IN SHIPS, HANDLING MATERIALS IN

SHIPS

DERRICK CRANE

JIB CRANE + FIXED CRANE, SUPPORTED BY A VERTICAL

MEMBER FROM WHICH EXTENDS HORIZONTAL

SWINGING ARMS CARRYING A TROLLEY HOIST

‘CONSTRUCTION WORKS, MATNTENANCE SHOPS

GANTRY CRANE | + SIMILAR TO AN OVERHEAD TRAVELING,

EXPECT THAT THE BRIDGE FOR CARRYING THE

TROLLEYS 1S SUPPORTED ON TWO OR MORE

MOVABLE LEGS:

+ MINING, PIERS

PILLAR CRANE — | + FIXED CRANE, VERTICAL MEMBER HELD. AT

THE BASE, WITH HORIZONTAL REVOLVING

ARM CARRYING A TROLLEY

+ MAINTENANCE SHOPS, PERS

J1B

~ A HORIZONTAL ARM, FOR SUPPORTING A TROLLEY OR FALL BLOCK. ARM

EXTENSION OF THE HERD OF THE BOOM

TROLLEY

= A TRUCK OR CARRIAGE ON WHICH THE HOISTING MECHANISM 15,

MOUNTED AND WHICH TRAVELS ON AN OVERHEAD BEAM OR TRACK.

PIPE — 1S A TUBE WITH A ROUND CROSS SECTION CONFORMING TO THE DIMENSIONAL

REQUIREMENTS FOR NOMINAL PIPE SIZE AS TABULATED IN TABLE FOR PIPE SCHEDULES.

MEDIUM PRESSURE Fimnes, vaves sec.

BLACK PIPE

(CARBON STEEL PIPE

GALVANIZED PIPE

WROUGHT PIPE

BELL AND SPIGOT

JOINT

BUTT WELD

JOINT

COMPRESSION

JOINT

‘SOCKET WELD

BULL HEAD TEA

MANIFOLD

‘CROSS-OVER

EXPANSION LOOP

STREET ELBOW

‘SADDLE FLANGE

CHECK VALVE

GATE VALVE

GLOBE VALVE

RELIEF WALVE

‘STEEL PIPE THAT HAS NOT BEEN GALVANIZED

STEEL PIPE WITH PROPERTIES CHIEFLY OF CARBON

CCORTED WITH ZINC TO RESIST CORROSION

REFERS TO BOTH WROUGHT STEEL AND WROUGHT

‘IRON, WROUGHT IN THIS SENSE MEANS WORKED.

COMMONLY USED JOINT IN CAST-IRON PIPE

EACH PIECE 1S MADE WITH ENLARGED DIAMETER OR

‘BELL AT ONE END INTO WHICH THE PLAIN OR SPIGOT

END OF ANOTHER PIECE 1S INSERTED

JOINT IS THEN TIGHTENED BY CEMENT, OAKUM,

LEAD oR RUBBER,

WELDED PIPE JOINT. WHERE ENDS OF THE TWO

PIPES BUTTING EACH OTHER (AROUND PERIPHERY)

‘A-MULTI-PIECE JOINT WITH CUP SHAPED THREADED

NUTS. WHEN TIGHTENED COMPRESS TAPERED

SLEEVES SO THAT THEY FORM JOINT (PERIPHERY)

USE OF A SOCKET WELD FITTING WHICH HAS A

PREPARED FEMALE END OR SOCKET FOR INSERTION OF

THE PIPE THEN WELDED.

BRANCH OF WHICH IS LARGER THAN THE RUN

LARGE PIPE OR DRUM WHERE EACH OF A GROUP OF

BOILERS 1S CONNECTED

FITTING WITH BRANCHES IN LINE CONNECTING TO A

SMALLER PIPES

‘AU INTERCHANGEABLE TERM WITH HEADER

‘WITH DOUBLE OFFSET, OR U — SHAPED WITH ENDS

TURNED OUT.

LARGE RADIUS BEND IN A PIPE LINE TO PREVENT

EXPANSION IN THE PIPE LINE DUE TO HEAT

MALE AND FEMALE THREAD ON EACH ENDS

FLANGE CURVED TO FIT A BOILER/TANK AND

ATTACHED TO A THREADED PIPE, RIVETED/WELDED

To BOILER/TANK.

SO THE FLUID TO PASS IN ONE DIRECTION ONLY

‘ALLOWS FLUID TO FLOW WHEN THE GATE 15 LIFTED

FROM THE SEAT. LESS RESISTANCE TO FLOW THAN

GLOBE VALVES.

GLOBE SHAPED BODY WHICH WHEN CLOSED RESTS

ON A SEAT SO AS TO PREVENT PASSAGE OF k FLUID

OPEN AUTOMATICALLY TO RELIEVE EXCESS PRESSURE

WORKING PRESSURE : | Be2 = 1207 Kha (125-175)

STANDARD PRESSURE Primes’ Wteere ex.

Max. STEAM WORKING PRESAKE = (262 Ke

MILL LENGTH

~_ALSO KNOWN AS RANDOM LENGTH

RIN- OFF ILL PE 714) 8800m|=(GOOOmm

eae Nia”; 9,450 mm = 10,6750

FLUID FLOW VELOCITIES

Eee

Gauss

Dae cee)

ON ao

IDENTIFICATION COLOR FOR PIPES

WATER GREEN

STEAM SILVER-GRAY

OIL-MINERAL (VEGETABLE/ANIMAL) J sown |

GASES (GASES/LIQUID FORM), FUMES | YElLOW OCRE

AIR LUGHT BLUE

OTHER FLUIDS, DRAINAGE

FIRE FIGHTING MATERIALS

HAZARDOUS SERVICES Samer ELON

ELECTRICITY

COMMUNICATIONS

SCHEDULE NUMBER

LUGHT ORANGE

WaITE

700 +P

CHED, Now

SCHED. No. =

Po

2s5+yP

WE WAWL THCK. 5 Tam

AX. INTERNAL. SERVE PRES. 5

m= +c

D> ounsive B 5 min .

S= ALONABLE ‘STRESS; KFa

C= ALLOWANCE FoR THREADNG £0.

‘Suayecr

" izis* vara

+ USED FoR DRAINAGE

GRST IRON | gesisTMr To cotastN a ARATON

STEEL + LOM-COST AND STRONS

+ OWE THEIR SPECIAL PROPERTIES TO ALLOYING ELEMENTS OTHER THAN

ARON

WROUGHT + TWO-COMPONENT METAL CONSISTING OF TRON ADDED WITH 4% TO

IRON ‘354 OF FINELY DIVIDED AND UNIFORMLY DISTRIBUTED IRON SILICATE.

COPPER AND | + USED WHERE FLEXIBILITY, APPEARANCE, OR CORROSION RESISTANT 1S

WROUGHT | + MOST POWER PLANT PIPING

ALLOY STEELS |

BRASS IMPORTANT. HOWEVER, COSTLY.

PIPE CONNECTIONS (JOINTS)

PACKED LEADED BELL-AND-SPIGOT, PLAIN AND COUPLING

‘SCREWED ‘COUPLINGS AND UNIONS

FLANGED COMPANION FLANGES (LOOSE OR SCREWED), SHRUNK, RIVETED, OR WELDED

TO PIPE

WELDED ‘FUSION PROCESS USING GAS OR METAL ARC WELDERS:

SPECIAL WALWES

SAFETY WALVES -BOILER SAFETY VALVES, THE ULTIMATE LINE OF DEFENSE AGAINST THE

‘OCCURRENCE OF HAZARDOUS STEAM PRESSURES IN THE BOILER.

+ RELIEF VALVES —A FORM OF SAFETY VALVE, GUT USUALLY INTENDED FOR LESS SEVERE

SERVICE,

+ BLOW-OFF VALVES —10 RID THE MUD DRUMS OF SEDIMENT ACCUMULATIONS, TO DRAIN

‘THE AND REDUCE CONCENTRATION OF BOILER, AND TO RAPIDLY LOWER THE BOILER WATER LEVEL

+ CONTROL AND REGULATING VALVES — aXe FOR WATER LEVEL, STEAM PRESSURE,

‘WATER FLOW, ETC, (THERNOSTATICALLY OR MECHANICALLY CONTROLLED)

+ BOILER OUTLET VALVES —STOP-CHECK OR AUTOMATIC NON-RETURN TYPE. TO PREVENT

BOILERS IN PARALLEL RECEIVING BACKFLOW FROM THE OTHERS WHEN ITS PRESSURE BECOMES

‘SUBSTANDARD.

te LL

CONTINUOUS FLOATS | FLOAT-OPERATED VALVE, SIMPLE IN PRINCIPLE AND OPERATION,

INTERMITTENT FLOATS | THE BUCKET TAP ISA WELL-KNOWN EXAMPLE

UPRIGHT BUCKET FLOATS ON THE INCOIAING CONDENSATION AND HOLDS. THE

DISCHARGE VALVE CLOSED UNTIL THE WATER RISES IN THE TRAP

BODY FAR ENOUGH TO SPILL INTO THE BUCKET.

INVERTED BUCKET | VENTS BOTHTHE CONDENSATE AND ALR THROUGH THE MAIN VALVE

THERMOSTATIC USES. TEMPERATURE-SENSITIVE ELEMENT TO DETECT WHETHER

STEAM OR CONDENSATE SURROUNDS IT

EXPANSION, ORIFICE | HAVE A FLASH CHAMBER, OR EXPANSION CHAMBER, BETWEEN TWO

TRAPS RESTRICTIONS IN THE FLOW LINE.

FIRE PROTECTION SYSTEM

FRE PROTECTION ENGINEERING — INVOLVES DESIGNING DEVICES,

SYSTEMS AND PROCESSES TO PROTECT PEOPLE, PROPERTY AND BUSINESS

OPERATIONS FROM THE RESULTS OF FIRE

COMMODITY CLASSIFICATION

CLASS 1

IMeTAL PRODUCTS,

Fooos

CLASS 2

INCANDESCENT LAMPS.

BEER/WINE UP TO 20

PERCENT ALCOHOL

CLASS 3

WOOD DRESSED WITH

PLASTIC DRAWERS, ETC

ESSENTIALLY NON COMBUSTIBLE PRODUCT ON

‘WOOD PALLETS, OR IN ORDINARY CARTONS, 08

{IN ORDINARY PAPER WRAPPING, ALL ON WOOD

PALLETS

PRODUCTS IN. SLATTED WOODEN CRATES,

SOLID WOODEN BOXES, OR EQUIVALENT

COMBUSTIBLE PACKAGING MATERIALS ON

‘WOOD PALLETS

‘WOOD, PAPER, NATURAL FIBER CLOTH, PLASTIC

PRODUCTS ON WOOD PALLETS, PRODUCTS MAY

CONTAIN A LIMITED AMOUNT OF PLASTICS.

CLASS 4 PRODUCTS CONTAINING AN —APPRECIABLE

SMALL APPLIANCES AMOUNT OF PLASTICS IN PAPER BOARD

WITH PLASTIC PARTS | CARTONS ON WOOD PALLETS

DEFINITIONS

AVAILABLE MAXIMUM, HEIGHT AT. WHICH COMMODITIES

HEIGHT FOR (CAN BE STORED ABOVE THE FLOOR AND STILL

STORAGE MAINTAIN CLEARANCE STRUCTURAL MEMBERS

AND SPRINKLERS

EXPOSURE THE EXTERIOR PRESENCE OF COMBUSTIBLES

WHICH, IF IGNITED, COULD CAUSE DAMAGE TO

THE STORAGE BUILDING OR ITS CONTENTS

FIRE WALL PREVENT THE SPREAD OF FIRE. HAVING A FIRE

RESISTANCE RATING OF NOT LESS THAN 4

HOURS

HORIZONTAL ‘ANY UNINTERRUPTED. SPACE IN EXCESS OF

CHANNEL 1524 M I LENGTH BETWEEN HORIZONTAL

LAYERS OF STORED COMMODITIES

ORDINARY HAVE HEATS OF COMBUSTION SIMILAR TO

COMBUSTIBLES

EXTRA

COMBUSTIBLE

MODERATE

COMBUSTIBLE

KON-

COMBUSTIBLES

‘WoOD, CLOTH OR PAPER ANID WHICH PRODUCE

FIRES THAT CAN BE EXTINGUISHED BY THE

‘COOLING EFFECT OF WATER.

HIGHLY SUSCEPTIBLE TO TGNITION AND WILL

CONTRIBUTE TO THE INTENSITY AND RAPID

‘SPREAD OF FIRE.

WILL CONTRIBUTE FUEL TO FIRE

NOT IGNITE, BURN OR LIBERATE. FLAMMABLE

GASES WHEN HEATED TO A TEMPERATURE OF

745 C FOR FIVE MINUTES.

LOCAL FIRE CODE (PD. NO. 1185)

IRE CODE OF THE PHILIPPINES

FIRE CLASSIFICATION

(ORDINARY COMBUSTIBLE MATERIALS SUCH AS WOOD,

CLOTH, PAPER, RUBBER AND PLASTICS

CLASS B FIRE IN FLAMMABLE LIQUIDS AND GASES

CLASS FIRE INVOLVING ENERGIZED ELECTRICAL EQUIPMENT

CLASS D FIRE INVOLVING COMBUSTIBLE METALS, SUCH AS

MAGNESIUM, SODIUM, POTASSIUM, TITANIUM, AND OTHER

SIMILAR METALS

DRY STAND PIPE | pipes ARE NOT NORMALLY FILLED WITH WATER

FIRE SERVICE — | AN ORGANIZATION OF THE PHILIPPINE

NATIONAL POLICE FIRE DEPARTMENT

PERSONNEL —IN-CHARGE CISSION: FIRE

PROTECTION)

MEANS OF ‘A CONTINUOUS AND UNOBSTRUCTED ROUTE OF

EGRESS EXIT FROM ANY POINT IN A BUILDING

OCCUPANT LOAD | THE MAXIHUM NUNBER OF PERSONS THAT MAY

BE ALLOWED TO OCCUPY A PARTICULAR

BUILDING

BITTE era ae

TYPE ‘+ STORED OVER 4,550 MM BUT NOT MORE THAN 6,400

IMM HIGH IN SOLID PILES

+ OVER 9650 MM BUT NOT MORE THAN 6,400 MM

HIGH IN PILES THAT CONTAIN. HORIZONTAL

CHANNELS,

‘STORED NOT OVER 4,500 MM HIGH IN SOLD PILES

+ NOT OVER 3,650 MM HIGH IN PILES THAT CONTAIN

HORIZONTAL CHANNELS,

TYPES IS THAT IN WHICH THE STORED COMMODITIES ARE

NONCOMBUSTIBLE OR CONTAIN ONLY A SMALL

CONCENTRATION OF CONBUSTIBLES WHICH ARE

INCAPABLE OF PRODUCING A FIRE THAT WOULD CAUSE

APPRECIABLE DAMAGE

TYPE2

‘+ WET PIPE SYSTEM — A SYSTEM EMPLOYING AUTOMATIC SPRINKLERS

ATTACHED TO A PIPING SYSTEM CONTAINING WATER AND CONNECTED

TOA WATER SUPPLY. MOSTLY USED IN OUR COUNTRY

+ DELUGE SYSTEM — USING OPEN SPRAY HEADS ATTACHED TO A

PIPING SYSTEM THAT IS CONNECTED TO A WATER SUPPLY THROUGH A

VALVE THAT IS OPENED BY MEANS OF A DETECTION SYSTEM.

INSTALLED IN THE SAME AREA AS THE SPRAY HEADS,

HALON 1301 (BROMOTROFLOURROMETHANE CBaF3)

~ COLORLESS, ODORLESS, ELECTRICALLY NOM-CONDUCTIVE. GAS, AN

EFFECTIVE MEDIUM FOR EXTINGUISHING FIRES

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- What Is Fuel Injector Spray PatternDocument8 pagesWhat Is Fuel Injector Spray PatternRyan CalicaNo ratings yet

- The Pull UpDocument2 pagesThe Pull UpRyan CalicaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- MODULE V Draft SystemDocument12 pagesMODULE V Draft SystemRyan Calica100% (1)

- Final Examination Me 155 Power Plant Engineering: Something To Ponder OnDocument1 pageFinal Examination Me 155 Power Plant Engineering: Something To Ponder OnRyan CalicaNo ratings yet

- Aggregates in Civil Engineering: Base and Subbase Environmental Filters Fillers Dams CoresDocument48 pagesAggregates in Civil Engineering: Base and Subbase Environmental Filters Fillers Dams CoresRyan CalicaNo ratings yet

- Fans and Blowers: Learning OutcomesDocument17 pagesFans and Blowers: Learning OutcomesRyan CalicaNo ratings yet

- Constants and ConversionsDocument32 pagesConstants and ConversionsRyan CalicaNo ratings yet

- Ilocano Dictionary and Grammar Ilocano EDocument7 pagesIlocano Dictionary and Grammar Ilocano ERyan CalicaNo ratings yet

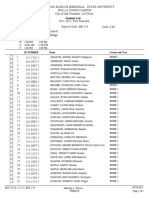

- Student List: Id Number Name Course and YearDocument2 pagesStudent List: Id Number Name Course and YearRyan CalicaNo ratings yet

- Experiment No. ME 153 05Document7 pagesExperiment No. ME 153 05Ryan CalicaNo ratings yet

- Group 1 - Report 2Document19 pagesGroup 1 - Report 2Ryan CalicaNo ratings yet

- Report No. Me 153 02 For ModuleDocument8 pagesReport No. Me 153 02 For ModuleRyan CalicaNo ratings yet

- Learning Outcomes:: Minor Trouble Shooting: For Non-Qualified TechniciansDocument13 pagesLearning Outcomes:: Minor Trouble Shooting: For Non-Qualified TechniciansRyan CalicaNo ratings yet

- 3x2 GuidelinesDocument2 pages3x2 GuidelinesRyan CalicaNo ratings yet

- Report No. ME 153 04Document8 pagesReport No. ME 153 04Ryan CalicaNo ratings yet

- Report No. ME 153 03 For MODULEDocument7 pagesReport No. ME 153 03 For MODULERyan CalicaNo ratings yet

- CamScanner 10-03-2021 12.59Document6 pagesCamScanner 10-03-2021 12.59Ryan CalicaNo ratings yet

- Learning Outcomes:: Some Other Ways of Classifying CompressorsDocument18 pagesLearning Outcomes:: Some Other Ways of Classifying CompressorsRyan CalicaNo ratings yet

- Ni P F Year Per I Year N IDocument5 pagesNi P F Year Per I Year N IRyan CalicaNo ratings yet

- Aqw Grimoire Fix For All Servers! Working Artix & Gravelyn Servers!Document2 pagesAqw Grimoire Fix For All Servers! Working Artix & Gravelyn Servers!Ryan CalicaNo ratings yet

- HelloDocument2 pagesHelloRyan CalicaNo ratings yet

- Sciences: Scope of Political ScienceDocument3 pagesSciences: Scope of Political ScienceRyan CalicaNo ratings yet