Professional Documents

Culture Documents

012 WINS Initial Production QA

Uploaded by

IffatOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

012 WINS Initial Production QA

Uploaded by

IffatCopyright:

Available Formats

LHT/3/012

LIBERTY Issue No. 03

MILLS LIMITED Page No. 01 of 01

Work Instructions For Initial Production

1.0) Objective:

To assure that the product is according to the specifications.

2.0) Scope:

This work instruction covers all activity carried out by the Inline Q.C.

3.0) Procedure:

3.1) Q.C has customer specifications / chopped / seal samples.

3.2) Q.C makes sure that only specified labels are distributed among the machine operators.

3.3) Before start of any bulk production Q.C checks from the initial production, direction /

pattern, style, shade, zip, elastic/dori, Velcro attach, z-hem ,shoulder tucking, opening,

kaj/button, hand hole, bar tucking, bottle neck, overlap/flange in sham, piping, tie, hand

feel, raising, peaching, sewing, label and label placement, Teyvek Label, Hanger

Direction, Sewing thread, elastic pull ratio, fitted drop, SPI & Velcro (whichever

applicable).

3.4) Q.C picks at least one (01) piece per machine per operation and checks thoroughly

against pre-approved pieces/specifications and take 03 pieces measurements.

3.5) Q.C has to check the goods thoroughly even SPI and measurements according to the

pre-approved piece / specification.

3.6) If any defects found (according to DCL LHT/04/025) then Q.C informs the concerned

machine operator and supervisor.

3.7) Performs the button pull test (whenever applicable) through Lab Report SDL/4/002.

3.8) In case any critical issues are found, QC stops the production and informs the

supervisor, Q.A Manager and Production Manager.

3.9) Wherever applicable if customer required perform the seam slippage test through Lab

Report SDL/4/002 once per lot

3.10) We use separate MCP and PFD for all Target Product.

4.0) Related Document:

Trial and Initial Inspection Report LHT/04/021

Defect Classification List LHT/04/025

MCP LHT/04/068

PFD LHT/04/045

Lab Report SDL/4/002

Measurement Report (Fitted) LHT/04/193

Measurement Report (General) LHT/04/014

5.0) Circulation:

As per Circulation Record

Written By: QMS Executive

Reviewed By: Quality Assurance Manager

Approved By: Management Representative

Date:

You might also like

- Appraisal Costs Are Necessary Costs To The Success of A CompanyDocument9 pagesAppraisal Costs Are Necessary Costs To The Success of A CompanyIffatNo ratings yet

- PFD GRS - Pre TreatmentDocument9 pagesPFD GRS - Pre TreatmentIffatNo ratings yet

- PFD GRS - FinishingDocument5 pagesPFD GRS - FinishingIffatNo ratings yet

- Naming Organic Compounds Practice: ExercisesDocument2 pagesNaming Organic Compounds Practice: ExercisesIffatNo ratings yet

- MCP - Curing and Steaming - Updated 23-12-2021Document10 pagesMCP - Curing and Steaming - Updated 23-12-2021IffatNo ratings yet

- MCP - Pretreatment - Updated 23-12-2021Document43 pagesMCP - Pretreatment - Updated 23-12-2021IffatNo ratings yet

- 006 WINS For Pre Final & Final Inspection QADocument2 pages006 WINS For Pre Final & Final Inspection QAIffatNo ratings yet

- Workbook SruDocument69 pagesWorkbook SruIffatNo ratings yet

- Chemical Process Control: Additional 30 Minutes To Complete and Submit This Paper. The Additional 30 Minutes Are ForDocument12 pagesChemical Process Control: Additional 30 Minutes To Complete and Submit This Paper. The Additional 30 Minutes Are ForIffatNo ratings yet

- Vapor-Liquid Equilibrium - WikipediaDocument8 pagesVapor-Liquid Equilibrium - WikipediaIffatNo ratings yet

- Understanding Process Safety ManagementDocument8 pagesUnderstanding Process Safety ManagementIffatNo ratings yet

- (ESP Merit and Needs Based Scholarship Program) : Instructions For Filling Out The Scholarship Application FormDocument9 pages(ESP Merit and Needs Based Scholarship Program) : Instructions For Filling Out The Scholarship Application FormIffatNo ratings yet

- Eq of ContinuityDocument5 pagesEq of ContinuityIffatNo ratings yet

- GAP ANALYSIS OF PRETREATMENT (28-February-2022 TO 1-MARCH-2022)Document5 pagesGAP ANALYSIS OF PRETREATMENT (28-February-2022 TO 1-MARCH-2022)IffatNo ratings yet

- Its All Baout SulfurDocument12 pagesIts All Baout SulfurIffatNo ratings yet

- Process Control - Instrumentation and Control Engineering Interview QuestionsDocument11 pagesProcess Control - Instrumentation and Control Engineering Interview QuestionsIffatNo ratings yet

- Automatic Control SystemsDocument3 pagesAutomatic Control SystemsIffatNo ratings yet

- HR Internal Investigation Report TemplateDocument5 pagesHR Internal Investigation Report TemplateIffatNo ratings yet

- Cascade Control System 1Document20 pagesCascade Control System 1IffatNo ratings yet

- Petroleum 20short 20Q A 20complete 20Document10 pagesPetroleum 20short 20Q A 20complete 20IffatNo ratings yet

- Sulphur Recovery Units (SRU) - Conversion ReactorsDocument22 pagesSulphur Recovery Units (SRU) - Conversion ReactorsIffatNo ratings yet

- Lect-5 FurnaceDocument60 pagesLect-5 FurnaceIffat0% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Holy Spirit Mass SongsDocument57 pagesHoly Spirit Mass SongsRo AnnNo ratings yet

- Berghahn Dana ResumeDocument2 pagesBerghahn Dana ResumeAnonymous fTYuIuK0pkNo ratings yet

- Boomer L2 D - 9851 2586 01Document4 pagesBoomer L2 D - 9851 2586 01Pablo Luis Pérez PostigoNo ratings yet

- KITZ - Cast Iron - 125FCL&125FCYDocument2 pagesKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroNo ratings yet

- Solution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan MchughDocument36 pagesSolution Manual For Understanding Business 12th Edition William Nickels James Mchugh Susan Mchughquoterfurnace.1ots6r100% (51)

- Some Sunsickday - Kitchenro11Document356 pagesSome Sunsickday - Kitchenro11Spencer HNo ratings yet

- Sabre V8Document16 pagesSabre V8stefan.vince536No ratings yet

- Rural Marketing MergedDocument146 pagesRural Marketing MergedRishabh HemaniNo ratings yet

- Power - of - Suffering 2Document21 pagesPower - of - Suffering 2jojiNo ratings yet

- I. Errors, Mistakes, Accuracy and Precision of Data Surveyed. A. ErrorsDocument53 pagesI. Errors, Mistakes, Accuracy and Precision of Data Surveyed. A. ErrorsJETT WAPNo ratings yet

- 1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineDocument1 page1 Raven's™ Standard Progressive Matrices Plus (SPM Plus) - PSI OnlineVINEET GAIROLANo ratings yet

- PQS Catalogue 4 2Document143 pagesPQS Catalogue 4 2sagarNo ratings yet

- Bilge Günsel TEL531E Detection and Estimation Theory W #1-2Document25 pagesBilge Günsel TEL531E Detection and Estimation Theory W #1-2ahmetNo ratings yet

- Tadano450xl PDFDocument12 pagesTadano450xl PDFmunawar0% (1)

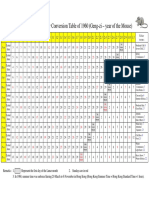

- Gregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Document1 pageGregorian-Lunar Calendar Conversion Table of 1960 (Geng-Zi - Year of The Mouse)Anomali SahamNo ratings yet

- Syllabus EM1Document2 pagesSyllabus EM1Tyler AnthonyNo ratings yet

- Apspdcl PDFDocument21 pagesApspdcl PDFK.sanjeev KumarNo ratings yet

- Introduction To Hydraulic System in The Construction Machinery - Copy ALIDocument2 pagesIntroduction To Hydraulic System in The Construction Machinery - Copy ALImahadNo ratings yet

- ElectricityDocument196 pagesElectricityjingcong liuNo ratings yet

- Free DMAIC Checklist Template Excel DownloadDocument5 pagesFree DMAIC Checklist Template Excel DownloadErik Leonel LucianoNo ratings yet

- FS1 Worksheet Topic 6Document2 pagesFS1 Worksheet Topic 6ALMALYN ANDIHNo ratings yet

- Amlodipine Besylate Drug StudyDocument2 pagesAmlodipine Besylate Drug StudyJonieP84No ratings yet

- Worship Aid - May Crowning 2020Document5 pagesWorship Aid - May Crowning 2020Kevin RyanNo ratings yet

- Wec14 01 Rms 20230112Document23 pagesWec14 01 Rms 20230112Shafay SheikhNo ratings yet

- Evelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Document290 pagesEvelyn Arizpe - Teresa Colomer - Carmen Martínez-Roldán - Visual Journeys Through Wordless Narratives - An International Inquiry With Immigrant Children and The Arrival-Bloomsbury Academic (2014)Lucia QuirogaNo ratings yet

- AMST 398 SyllabusDocument7 pagesAMST 398 SyllabusNatNo ratings yet

- Dispersion Relation of Electromagnetic WavesDocument2 pagesDispersion Relation of Electromagnetic WavesFidel SouzaNo ratings yet

- Negotiation Homework AssignmentDocument3 pagesNegotiation Homework AssignmentEunice Lourenço TanganeNo ratings yet

- Chapter - 01 Geography The Earth in The Solar SystemDocument10 pagesChapter - 01 Geography The Earth in The Solar SystemKarsin ManochaNo ratings yet

- Omran WalidDocument196 pagesOmran WalidDébora AmougouNo ratings yet