Professional Documents

Culture Documents

039 WINS For Shading QC in Grading Department

Uploaded by

IffatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

039 WINS For Shading QC in Grading Department

Uploaded by

IffatCopyright:

Available Formats

LHT/3/039

LIBERTY Issue No. 06

MILLS LIMITED Page No. 01 of 01

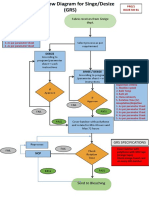

Work Instruction For Shading QC in Grading Department

1.0) Objective:

To check the shades and quality of fabric according to required / given standard.

2.0) Scope:

This work instruction covers all activities carried out by Shading QC in Grading Department.

3.0) Procedure:

3.1) It is mandatory for all Shading QC’s in Grading Department to have passed Munsell Hue Test / Eye Test

at the time of appointment and also once in each year

3.2) QC notes the continuity of every Target design in Grading Department.

3.3) Approved shade and hand feel standard is received from Marketing or from Processing Department and

receiving is written-down on Standard Log Sheet (LHT/04/055).

3.4) Fabric length in meters should be provided with machine number & table number where as Grading

checker makes sure that all designs & colors are included.

3.5) These stripes are then converted into continuity form from center of fabric where fabric should be on

front / top and also make sure that all bands are on same direction covering all designs / colors.

3.6) It is preferred that each fabric band is visible by having distance of 2” from other fabric.

3.7) QC makes width & continuity list wise continuity and clearly mentions width and meters on top front of

the continuity.

3.8) Continuity is checked under light source (specified by Target) & approved/ok product is called shade

band and is recorded in Thaan / Roll Delivery Status ( For Continuity ) LHT/04/146.

3.9) Continuity and hand feel of the fabric is checked against given standard. In case of flannel, raising is also

checked. If raising is found non-confirmatory then thaan / roll is marked and checked physically. If low

raising is found then fabric is sent back for re-processing.

3.10) If shade differences are found in continuity list then seek for approval from QAM. Also check

electronically in Delta E (If required). Also if fabric is re-process able then out shade fabric is sent for re-

processing otherwise keep the continuity list separate with marking “HOLD” and send the details to

printing for issuance of the replace fabric. Details are also provided to FFG with width and meterage to

keep those thaans separate.

3.11) All acquired information regarding shade bands is maintained under Shade Band Report (LHT/04/050)

3.12) Master list / summary of Shades family is made and considered as standard throughout the program.

3.13) QC provides the shade wise OK thaan / roll status Grading department on Thaan / Roll Delivery Status

(LHT/04/081)

3.14) NCP (LHT/04/016) is filled against any Non-Conformity found within the process.

3.15) Counter shade bands are circulated (when needed) to cutting department and receiving is written down in

Standard Log Sheet (LHT/04/055)

3.16) Shade bands are kept till the completion of order and after that Shade bands are discarded wholly by

cutting into pieces and sent to rejection area.

3.17) Shade bands are verified/checked in specified light source as per customer. If no light source is specified

by customer than D65 is used.

3.18) In grading department shading / Continuity procedure will be followed as per Customer Wise Continuity

Or Shading Procedure(LHT/04/145).

4.0) Related Document:

Shade Band Report LHT/04/050, Standard Log Sheet LHT/04/055,

Thaan / Roll Delivery Status LHT/04/081, Non-Conforming Product LHT/04/016,

Customer Wise Continuity Or Shading Procedure LHT/04/145

Thaan / Roll Delivery Status ( For Continuity ) LHT/04/146,

5.0) Circulation:

As per Circulation Record

Written By: Quality Assurance floorManager

Reviewed By: GM Quality

Approved By: Management Representative

Date:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- TAC LAC Mapping SessionDocument10 pagesTAC LAC Mapping SessionVaibhav TiwariNo ratings yet

- HR Internal Investigation Report TemplateDocument5 pagesHR Internal Investigation Report TemplateIffatNo ratings yet

- Appraisal Costs Are Necessary Costs To The Success of A CompanyDocument9 pagesAppraisal Costs Are Necessary Costs To The Success of A CompanyIffatNo ratings yet

- PFD GRS - Pre TreatmentDocument9 pagesPFD GRS - Pre TreatmentIffatNo ratings yet

- PFD GRS - FinishingDocument5 pagesPFD GRS - FinishingIffatNo ratings yet

- Naming Organic Compounds Practice: ExercisesDocument2 pagesNaming Organic Compounds Practice: ExercisesIffatNo ratings yet

- MCP - Curing and Steaming - Updated 23-12-2021Document10 pagesMCP - Curing and Steaming - Updated 23-12-2021IffatNo ratings yet

- MCP - Pretreatment - Updated 23-12-2021Document43 pagesMCP - Pretreatment - Updated 23-12-2021IffatNo ratings yet

- 006 WINS For Pre Final & Final Inspection QADocument2 pages006 WINS For Pre Final & Final Inspection QAIffatNo ratings yet

- Workbook SruDocument69 pagesWorkbook SruIffatNo ratings yet

- Chemical Process Control: Additional 30 Minutes To Complete and Submit This Paper. The Additional 30 Minutes Are ForDocument12 pagesChemical Process Control: Additional 30 Minutes To Complete and Submit This Paper. The Additional 30 Minutes Are ForIffatNo ratings yet

- Vapor-Liquid Equilibrium - WikipediaDocument8 pagesVapor-Liquid Equilibrium - WikipediaIffatNo ratings yet

- Understanding Process Safety ManagementDocument8 pagesUnderstanding Process Safety ManagementIffatNo ratings yet

- (ESP Merit and Needs Based Scholarship Program) : Instructions For Filling Out The Scholarship Application FormDocument9 pages(ESP Merit and Needs Based Scholarship Program) : Instructions For Filling Out The Scholarship Application FormIffatNo ratings yet

- Eq of ContinuityDocument5 pagesEq of ContinuityIffatNo ratings yet

- GAP ANALYSIS OF PRETREATMENT (28-February-2022 TO 1-MARCH-2022)Document5 pagesGAP ANALYSIS OF PRETREATMENT (28-February-2022 TO 1-MARCH-2022)IffatNo ratings yet

- Its All Baout SulfurDocument12 pagesIts All Baout SulfurIffatNo ratings yet

- Process Control - Instrumentation and Control Engineering Interview QuestionsDocument11 pagesProcess Control - Instrumentation and Control Engineering Interview QuestionsIffatNo ratings yet

- Automatic Control SystemsDocument3 pagesAutomatic Control SystemsIffatNo ratings yet

- Cascade Control System 1Document20 pagesCascade Control System 1IffatNo ratings yet

- Petroleum 20short 20Q A 20complete 20Document10 pagesPetroleum 20short 20Q A 20complete 20IffatNo ratings yet

- Sulphur Recovery Units (SRU) - Conversion ReactorsDocument22 pagesSulphur Recovery Units (SRU) - Conversion ReactorsIffatNo ratings yet

- Lect-5 FurnaceDocument60 pagesLect-5 FurnaceIffat0% (1)

- C & C++ Sem 2 Practical SolutionsDocument13 pagesC & C++ Sem 2 Practical SolutionsShiva Krishna KondaparthiNo ratings yet

- Project Report FullDocument60 pagesProject Report FullFaraz AnsarNo ratings yet

- Grammar Test (Conditionals) 5415661Document5 pagesGrammar Test (Conditionals) 5415661Mike OkkNo ratings yet

- Remote Access StandardDocument3 pagesRemote Access StandardMagda FakhryNo ratings yet

- Critical Ops Circuit - Season 3 RulesDocument10 pagesCritical Ops Circuit - Season 3 RulesThiên Hà 4 ChiềuNo ratings yet

- 2-Hw Descr OMSN R4.3-5Document100 pages2-Hw Descr OMSN R4.3-5znesroNo ratings yet

- GED Test PreparationDocument592 pagesGED Test PreparationDean KimNo ratings yet

- EICS Engine Integrated Control SystemDocument2 pagesEICS Engine Integrated Control SystemAlejandroMuñoz100% (1)

- New Features in Oracle ApexDocument15 pagesNew Features in Oracle ApexAwais MajeedNo ratings yet

- Aeg Brochure Railway enDocument12 pagesAeg Brochure Railway enfouedNo ratings yet

- Machine Translation Spanish-To-English Translation System Using RNNsDocument9 pagesMachine Translation Spanish-To-English Translation System Using RNNsIJRASETPublicationsNo ratings yet

- View Your Typing Test ResultsDocument1 pageView Your Typing Test Resultsthealenlen921No ratings yet

- GNS 430/430A: Quick ReferenceDocument22 pagesGNS 430/430A: Quick ReferenceWangNo ratings yet

- Manual Marantz - MCR610 NA ESDocument130 pagesManual Marantz - MCR610 NA ESimmavNo ratings yet

- Math 6 Q2 Summative TestDocument8 pagesMath 6 Q2 Summative TestRowena Galon0% (1)

- Manual Spectro-GuideDocument74 pagesManual Spectro-GuidenasikroadNo ratings yet

- Second Step For Jee (Main & Advanced) - 2023 E-Caps - 07: Mathematics (Engineering-Classroom Assessment Practice Sheet)Document5 pagesSecond Step For Jee (Main & Advanced) - 2023 E-Caps - 07: Mathematics (Engineering-Classroom Assessment Practice Sheet)Saumya KhatriNo ratings yet

- CMake ListsDocument3 pagesCMake ListsWhitney ParsleyNo ratings yet

- TCL 40-E461c4-Pwc1xgDocument3 pagesTCL 40-E461c4-Pwc1xgEhduard VehovNo ratings yet

- Review IrecosDocument15 pagesReview IrecosRizwan PashaNo ratings yet

- Introduction To It - Ites Industry Unit-1 Part-B: Shivalik Public SchoolDocument5 pagesIntroduction To It - Ites Industry Unit-1 Part-B: Shivalik Public SchoolSohit RanaNo ratings yet

- Meanwell ProductDocument112 pagesMeanwell ProductMor4nt3No ratings yet

- UhhhhhDocument35 pagesUhhhhhjasonNo ratings yet

- MEESEVA User Manual For KIOSKS - Local Candidate Certificate Ver 1.1Document7 pagesMEESEVA User Manual For KIOSKS - Local Candidate Certificate Ver 1.1Sri HarshaNo ratings yet

- Graphing The Voltage Across An LRC Circuit Using PythonDocument10 pagesGraphing The Voltage Across An LRC Circuit Using PythonJose Enrico MaxinoNo ratings yet

- AV Systems BOQDocument20 pagesAV Systems BOQabul abbasNo ratings yet

- Uart Core With ApbDocument31 pagesUart Core With Apbujwala_512No ratings yet

- BAS 301 DetailsDocument2 pagesBAS 301 Detailsjohnoke.workNo ratings yet

- SAP Basis-Daily Health Check ReportDocument11 pagesSAP Basis-Daily Health Check ReportrgNo ratings yet