Professional Documents

Culture Documents

Cellular Microsphere Filler: Standard Chemical Analysis

Cellular Microsphere Filler: Standard Chemical Analysis

Uploaded by

petersom 93Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cellular Microsphere Filler: Standard Chemical Analysis

Cellular Microsphere Filler: Standard Chemical Analysis

Uploaded by

petersom 93Copyright:

Available Formats

Cellular Microsphere Filler

Sil-Cell is an ultra-light, naturally Sil-Cell is an excellent

Overview

Structure

occurring, Aluminum Silicate, functional filler because of its

microcellular filler that is inert, inert properties, low density

inorganic, non-toxic and pH and structure. The multicellular

neutral. Particles are formed by structure provides greater

creating a structure of multicellular tensile strength versus other

spherical bubbles. types of micro fillers.

Sil-Cell is exclusive to Silbrico Due to its low effective specific

and manufactured at our facilities gravity (E.S.G.), it is an

in Illinois and Pennsylvania, exceptional density reducing

as well as in Australia. agent for composites. Sil-Cell’s

E.S.G. ranges from 0.17 to

0.336 g/cm3 compared to

calcium carbonate type fillers

Uses

Sil-Cell has been found that range from 2.5 to 2.8

to be cost effective in the g/cm3.

manufacturing of joint

compounds, adhesives, auto

Trace Elements

body putty, cultured marble, Manganese <0.3%

wall patching compounds, Sulfur <0.2%

Standard Chemical Analysis Titanium <0.1%

stucco, ready mix gypsum

plasters, resins, plastics and Barium <0.1%

Gallium <0.05%

a variety of other composites.

Boron <0.01%

Chromium <0.0075%

It can also be treated with Zirconium <0.003%

unique proprietary surface Molybdenum <0.002%

coatings to modify the Nickel <0.002%

particle’s surface. In both Copper <0.0015%

organic and inorganic Lead <0.001%*

composites, these coupling Arsenic <0.001%*

agents improve adhesion. Chlorine <0.0005%

All analyses are shown in elemental form even

though the actual forms present are mixed glassy

silicates. Free Silica may be present in small

amounts, characteristic of the particular ore body.

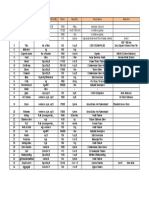

Representative Particle Percent Retained by Weight (U.S. Sieve) *By Food Chemicals Codex Method

Distribution

Sil‐32 Sil‐42 Sil‐35 Sil‐43 Sil‐50

+50 Mesh +300 μm 1% 0% 0% 0% 0%

-50+100 Mesh -300+150 μm 8% 1% Trace Trace Trace Physical Properties

-100+200 Mesh -150+75 μm 26% 16% 12% 11% 4%

-200+325 Mesh -75+45 μm 22% 26% 24% 21% 13% 6.5 -7.5

-325+450 Mesh -45+32μm 12% 12% 18% 19% 10%

-450+635 Mesh -32+20 μm 6% 18% 13% 15% 23%

-635 Mesh -20 μm 25% 27% 33% 34% 50%

100% 100% 100% 100% 100%

Typical Specifications (Grade) Sil‐32 Sil‐42 Sil‐35 Sil‐43 Sil‐50

Effective Particle Density‐ESG (lbs/ft3) 10.5 13.5 15.0 16.0 21.0

Effective Particle Density‐Range (lbs/ft ) 3

10.0‐11.5 12.3‐14.4 14.2‐15.6 15.2‐17.3 19.3‐21.5

Dry Bulk Density (lbs/ft3) 7.0 8.5 9.0 10.5 13.0

Dry Bulk Density Range (lbs/ft ) 3

6.5‐7.5 8.0‐9.0 8.5‐9.5 10.0‐11.0 12.5‐13.5

Effective Particle Density‐ESG (g/cm3) 0.170 0.216 0.240 0.255 0.336

Effective Particle Density‐Range (g/cm ) 3

0.160‐0.184 0.197‐0.231 0.228‐0.250 0.244‐0.277 0.310‐0.345

Dry Bulk Density (g/cm3) 0.112 0.136 0.144 0.168 0.208

Dry Bulk Density Range (g/cm ) 3

0.104‐0.120 0.128‐0.144 0.136‐0.152 0.160‐0.176 0.200‐0.216

Average Particle Size (μm) 75 45 40 37 32

Particle Size Range (μm) 1‐300 1‐220 1‐150 1‐150 1‐110

Thermal Conductivity (BTU-in/hr/sqft/°F) 0.36 0.40 0.41 0.43 0.45

Proprietary Surface Treatments are Available to Improve Performance

Type Ordering Code(s) Molecular Structure Hydrophobic Oleophobic

Uncoated BC No No

Silane 23 Monomer Yes Yes

Silicone 34 (18) Polymer Yes Yes

• Is an organometallic silane type • Is an organometallic silicone type

34 (18) Coating

23 Coating

reactive monomer reactive polymer

• Creates a monolayer film on the • Creates a multiple layer formation on

surface of the particle the surface of the particle

• Demonstrates moderate hydrophobic • Demonstrates significant hydrophobic

and oleophobic properties and oleophobic properties

• Significantly reduces the surface • Moderately reduces the surface

viscosity of perlite viscosity of perlite

• Improves the Rheological properties of • Improves the Rheological properties of

composites composites

• Demonstrates moderate resistance in • Demonstrates significant resistance in

temperature and pressure temperature and pressure

For more information or to arrange for samples,

please call: 800-323-4287 or email: info@silbrico.com

You might also like

- Caolin C. Britex 95 Qpros PDFDocument3 pagesCaolin C. Britex 95 Qpros PDFEduardo Pérez100% (1)

- Aluminum-Beryllium Alloys For Aerospace Applications: Materion Corporation Materion Beryllium & Composites 14710Document7 pagesAluminum-Beryllium Alloys For Aerospace Applications: Materion Corporation Materion Beryllium & Composites 14710roshniNo ratings yet

- Almatis Reactive Alumina Brochure PDFDocument2 pagesAlmatis Reactive Alumina Brochure PDFLuis OteroNo ratings yet

- GMA Garnet Blast Cleaning Product Data SheetDocument2 pagesGMA Garnet Blast Cleaning Product Data SheetBakhtiyar PaizullayevNo ratings yet

- Cracking EvaluationDocument17 pagesCracking Evaluationهوا عجلون-المهندسNo ratings yet

- Metallographic Specimen Preparation Basics: by Donald C. Zipperian, Ph.D. Pace TechnologiesDocument14 pagesMetallographic Specimen Preparation Basics: by Donald C. Zipperian, Ph.D. Pace Technologiesrazor75apNo ratings yet

- Precipitated SilicaDocument5 pagesPrecipitated SilicaLong An ĐỗNo ratings yet

- Features and Benefits Dessel, BelgiumDocument2 pagesFeatures and Benefits Dessel, BelgiumPhạm ViệtNo ratings yet

- Study On Fly Ash and GGBS Based Geopolymer Concrete Under Ambient CuringDocument6 pagesStudy On Fly Ash and GGBS Based Geopolymer Concrete Under Ambient CuringkarskotNo ratings yet

- Zinc Chloride Sol and Solid DataDocument4 pagesZinc Chloride Sol and Solid DataAnonymous jDvJoTNo ratings yet

- M25 Mix DesignDocument1 pageM25 Mix DesignRøshän Kumar PatelNo ratings yet

- Effect of Silica Fume On The Properties of Concrete: (Ijerat)Document5 pagesEffect of Silica Fume On The Properties of Concrete: (Ijerat)Ohnmar OmNo ratings yet

- Attapulgite: Natural Occuring Clay MineralDocument1 pageAttapulgite: Natural Occuring Clay Mineraladitya imansyahNo ratings yet

- Fouling Control For RO & NF SystemsDocument66 pagesFouling Control For RO & NF SystemsPrem MishraNo ratings yet

- Sisal Fibre Reinforced ConcreteDocument7 pagesSisal Fibre Reinforced ConcreteSathish PandiyarajanNo ratings yet

- Technical Data - Ecoflat PDFDocument1 pageTechnical Data - Ecoflat PDFManuel Castillo NoleNo ratings yet

- Environmental Quality Standards For Water and Effluent Standards WEPADocument13 pagesEnvironmental Quality Standards For Water and Effluent Standards WEPApeguy diffoNo ratings yet

- Study of Properties of Self-Compacting Concrete With Cement Replaced With Aluminum Oxide and Silica FumeDocument10 pagesStudy of Properties of Self-Compacting Concrete With Cement Replaced With Aluminum Oxide and Silica FumeIJRASETPublicationsNo ratings yet

- Adblue Diesel Exhaust Fluid-PI SheetDocument2 pagesAdblue Diesel Exhaust Fluid-PI SheetAntonio AriasNo ratings yet

- Element Brochure E71uDocument8 pagesElement Brochure E71uVijo JoseNo ratings yet

- Blastrite Glass Bead - Starbead - Industrial BeadsDocument1 pageBlastrite Glass Bead - Starbead - Industrial BeadsYoutube For EducationNo ratings yet

- Cenospheres TDSDocument1 pageCenospheres TDSizzybj100% (1)

- 1993 - Recycled LeadDocument9 pages1993 - Recycled LeadgutobegaNo ratings yet

- Properties of Powders and Sintered MaterialsDocument4 pagesProperties of Powders and Sintered MaterialsPanda983No ratings yet

- Paints and Coatings: Safsil ProductsDocument4 pagesPaints and Coatings: Safsil Productskensley oliveiraNo ratings yet

- (IJETA-V8I6P3) :mehtab Alam, Hemant Kumar SainDocument7 pages(IJETA-V8I6P3) :mehtab Alam, Hemant Kumar SainIJETA - EighthSenseGroupNo ratings yet

- EFFECT OF SISAL FIBRE IN FLY ASH BASED .ProjectDocument26 pagesEFFECT OF SISAL FIBRE IN FLY ASH BASED .ProjectSuriya PonrajNo ratings yet

- Unit 5Document5 pagesUnit 5Nikhil DeolNo ratings yet

- TDS Polyester WiperDocument1 pageTDS Polyester WiperacaiNo ratings yet

- Mechanical Characterization and Microstructure Analysis of AlDocument7 pagesMechanical Characterization and Microstructure Analysis of AlMoh Hafizh KNo ratings yet

- Mineral Fillers: DescriptionDocument1 pageMineral Fillers: DescriptionForeverNo ratings yet

- Celulosa MicrocristalinaDocument5 pagesCelulosa MicrocristalinaPaola LopezNo ratings yet

- Envirobent Dam Seal AB50Document1 pageEnvirobent Dam Seal AB50BtsibandaNo ratings yet

- Jetblast™ Copper SlagDocument4 pagesJetblast™ Copper SlaglambtranNo ratings yet

- Contaminated Land - Stratford - GCA - 180530 - Issue - 05 - Part7Document212 pagesContaminated Land - Stratford - GCA - 180530 - Issue - 05 - Part7Rahat Ali SiddiquiNo ratings yet

- Exxon™ Butyl 268: RubberDocument2 pagesExxon™ Butyl 268: RubberMaram YasserNo ratings yet

- BNi-7 TDSDocument2 pagesBNi-7 TDSQuang Thuận NguyễnNo ratings yet

- H12326974 PDFDocument6 pagesH12326974 PDFYuliantari YuliantariNo ratings yet

- Irjet V5i6236Document4 pagesIrjet V5i6236PRAVEEN KUMARNo ratings yet

- AMBERLITE™ HPR550 OH Ion Exchange ResinDocument4 pagesAMBERLITE™ HPR550 OH Ion Exchange ResinFabio Pereira de CarvalhoNo ratings yet

- Application Guide CAB O SIL Fumed Silica For Silicone RubberDocument8 pagesApplication Guide CAB O SIL Fumed Silica For Silicone RubberNoah JohnsonNo ratings yet

- An Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteDocument5 pagesAn Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteAnonymous kw8Yrp0R5rNo ratings yet

- Sand BrochureDocument4 pagesSand BrochureKTSivakumarNo ratings yet

- Syahrial 2019 IOP Conf. Ser. Mater. Sci. Eng. 547 012021Document9 pagesSyahrial 2019 IOP Conf. Ser. Mater. Sci. Eng. 547 012021Nafis Dhaffarul HannanNo ratings yet

- Çimsa Eco White TDS (EN)Document1 pageÇimsa Eco White TDS (EN)Babu NysemereNo ratings yet

- How To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition ConditionsDocument2 pagesHow To Get The Most Out of Orbis Micro-Xrf Measurements With Multiple Acquisition Conditionstaufiq_hidayat_1982No ratings yet

- Materials For Newer ConcreteDocument33 pagesMaterials For Newer ConcreteAkshaykumar RathodNo ratings yet

- 170430162420Document37 pages170430162420Sahithi .MNo ratings yet

- TDS Sibelite M3000 M4000 M6000 PDFDocument2 pagesTDS Sibelite M3000 M4000 M6000 PDFLe PhongNo ratings yet

- Comparative Study of Conventional Concrete With Micropozz Based Geopolymer Concrete Along With GGBSDocument3 pagesComparative Study of Conventional Concrete With Micropozz Based Geopolymer Concrete Along With GGBSVivek PatvaNo ratings yet

- TDS - Zeolite PowderDocument1 pageTDS - Zeolite PowderErik YerzyNo ratings yet

- The Effects of Silica-Based Fillers On The PropertDocument11 pagesThe Effects of Silica-Based Fillers On The Propertánh nguyễnNo ratings yet

- Silica Sand 1Document1 pageSilica Sand 1krishna sharmaNo ratings yet

- Synthesis and Characterization of Alumina Zirconia Composite Material Doped With SilicaDocument7 pagesSynthesis and Characterization of Alumina Zirconia Composite Material Doped With SilicaAdvanced Research PublicationsNo ratings yet

- AdBlue Aus32 Din 70070Document2 pagesAdBlue Aus32 Din 70070JeSuSkopjeNo ratings yet

- Aluminium TrihydrateDocument1 pageAluminium TrihydrateprchnandagawaliNo ratings yet

- Cab o Sil Fs in Unsat Pes Resins 118548 16p EngDocument16 pagesCab o Sil Fs in Unsat Pes Resins 118548 16p EngJorge D. VarelaNo ratings yet

- Specification CZS100Document1 pageSpecification CZS100jackNo ratings yet

- MIN U Sil 5 Ground Silica TDSDocument1 pageMIN U Sil 5 Ground Silica TDSCharles OlsenNo ratings yet

- Baxxodur EC 201: Technical InformationDocument2 pagesBaxxodur EC 201: Technical Informationpetersom 93100% (1)

- Silicone Oil PDSDocument2 pagesSilicone Oil PDSpetersom 93No ratings yet

- Silicone Oil MSDSDocument3 pagesSilicone Oil MSDSpetersom 93No ratings yet

- LATICRETE 317 SDS - US EnglishDocument7 pagesLATICRETE 317 SDS - US Englishpetersom 93No ratings yet

- LATAPOXY 300 Adhesive Part B SDS - US EnglishDocument7 pagesLATAPOXY 300 Adhesive Part B SDS - US Englishpetersom 93No ratings yet

- Latapoxy SP 100Document3 pagesLatapoxy SP 100petersom 93No ratings yet

- LATAPOXY 300 Adhesive Part C SDS - US EnglishDocument7 pagesLATAPOXY 300 Adhesive Part C SDS - US Englishpetersom 93No ratings yet

- LATAPOXY 300 Epoxy Adhesive Part A SDS - US EnglishDocument7 pagesLATAPOXY 300 Epoxy Adhesive Part A SDS - US Englishpetersom 93No ratings yet

- Matrix Science Academy: Chemistry MHT CET L1 2022-23 Hints and SolutionsDocument2 pagesMatrix Science Academy: Chemistry MHT CET L1 2022-23 Hints and SolutionsLight MayNo ratings yet

- Bolt CalculateDocument6 pagesBolt CalculateBahtiar YudhistiraNo ratings yet

- Discharge Heads and SubsDocument1 pageDischarge Heads and Subsamir shoushtariNo ratings yet

- Dept Sanitation RecyclingDocument6 pagesDept Sanitation RecyclinggwendolynNo ratings yet

- MSDS - KI25X Transformer OilDocument5 pagesMSDS - KI25X Transformer OilBrion Bara Indonesia100% (1)

- Concrete HistoryDocument4 pagesConcrete Historytest100% (1)

- CW20 Recycling EvergreenDocument23 pagesCW20 Recycling EvergreenHyodae KimNo ratings yet

- 5-NaMgF3 Under Pressure EffectsDocument13 pages5-NaMgF3 Under Pressure EffectsMuhammad UsmanNo ratings yet

- Viscoelasticity PDFDocument14 pagesViscoelasticity PDFNani DeskaaNo ratings yet

- Polymer Modified Asphalt EmulsionsDocument26 pagesPolymer Modified Asphalt EmulsionsdodifaisholNo ratings yet

- Gabriella Logue - Topic 4 Chemistry-Hodder (Practice Questions)Document2 pagesGabriella Logue - Topic 4 Chemistry-Hodder (Practice Questions)yesNo ratings yet

- Unimoly HTC Metallic: Product InformationDocument2 pagesUnimoly HTC Metallic: Product InformationregisNo ratings yet

- Chemsheets GCSE 1135 Acids Bases and Salts 1Document1 pageChemsheets GCSE 1135 Acids Bases and Salts 1Kenneth SorraNo ratings yet

- Dental CementsDocument159 pagesDental Cementsdrbaraa93100% (6)

- Ameerpet: Tender Boq For Interior Works - R-IiiDocument4 pagesAmeerpet: Tender Boq For Interior Works - R-Iiiyamanta_rajNo ratings yet

- Rockwool SeriesDocument12 pagesRockwool SeriesUsamah AhmadNo ratings yet

- CHAPTER I MaboloDocument18 pagesCHAPTER I MaboloZayn RauiNo ratings yet

- Adopting Multifunctional Material SystemsDocument197 pagesAdopting Multifunctional Material Systems_AniMuS__No ratings yet

- CHAP 1 Yellow Book PharchemDocument9 pagesCHAP 1 Yellow Book PharchemFaye CortezNo ratings yet

- Ejercicios de Transferencia de Calor Cond. y Conv. - OUIIDocument26 pagesEjercicios de Transferencia de Calor Cond. y Conv. - OUIIAntonio MoralesNo ratings yet

- S.No. Materials Units of Measurement (UOM) Rates Quantity Shop Name RemarksDocument1 pageS.No. Materials Units of Measurement (UOM) Rates Quantity Shop Name RemarksAMARNATH PSNo ratings yet

- Test Bank For General Organic and Biochemistry 8th Edition Katherine Denniston Download Full DownloadDocument19 pagesTest Bank For General Organic and Biochemistry 8th Edition Katherine Denniston Download Full Downloadmarcjohnstontsbgmqofip100% (35)

- Corrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemDocument6 pagesCorrosion Failure Analysis of Galvanized Steel Pipes in A Water Irrigation SystemC_rovere100% (1)

- Chemistry PPT Template 0001Document30 pagesChemistry PPT Template 0001arenestarNo ratings yet

- Unistrut General Engineering Catalogue No.17Document244 pagesUnistrut General Engineering Catalogue No.17Angelo FranklinNo ratings yet

- 5 Kiln Bearings PDFDocument60 pages5 Kiln Bearings PDFBülent BulutNo ratings yet

- Pert/CpM For Tower and Pipeline ConstructionDocument3 pagesPert/CpM For Tower and Pipeline ConstructionBen Daniel GamutanNo ratings yet

- Reduction of Chemical Effects of Swelling and ShrinkageDocument22 pagesReduction of Chemical Effects of Swelling and ShrinkageAkshay SetlurNo ratings yet

- المواصفة الفنية لطبقة سطحية فنيلDocument4 pagesالمواصفة الفنية لطبقة سطحية فنيلpaulaNo ratings yet

- NCEM 1.62.002 - EN-merged PDFDocument244 pagesNCEM 1.62.002 - EN-merged PDFCK ChioNo ratings yet