Professional Documents

Culture Documents

Jis B 2220-2004

Jis B 2220-2004

Uploaded by

ANDERSON NERES100%(1)100% found this document useful (1 vote)

74 views58 pagesOriginal Title

JIS B 2220-2004

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

74 views58 pagesJis B 2220-2004

Jis B 2220-2004

Uploaded by

ANDERSON NERESCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 58

JIS

JAPANESE

INDUSTRIAL

STANDARD

Translated and Published by

Japanese Standards Association

@® JIS B 2220:

(JPF/JSA)

Steel pipe flanges

ICS 28.040.60 : 77.140.99

Reference number : JIS B 2220 : 2004 (B)

PROTECTED BY COPYRIGHT

B 2220 : 2004

Foreword

This translation has been made based on the original Japanese Industrial

Standard revised by the Minister of Economy, Trade and Industry through

deliberations at the Japanese Industrial Standards Committee, as the result

of proposal for revision of Japanese Industrial Standard submitted by the Japan

Pipe Fittings Association (JPF)/the Japanese Standards Association (JSA) with

the draft being attached, based on the provision of Article 12 Clause 1 of the

Industrial Standardization Law applicable to the case of revision by the

provision of Article 14:

Currently, to revise the International Standard of steel pipe flanges (SO

7005-1:1992), the International Organization for Standardization (ISO) has

started with its deliberation. In the process of the deliberation, the

Organization intends to issue the standard as a new one through deviding the

relevant International Standard into the European type, the United States

type, and the Japanese type, with each of them being set at the part

‘organization (part system).

In Europe, a draft for submission based on the EN Standard is beig

arranged, and in the United States, based on the ASME Standard.

‘This Standard has been prepared through the integration of the existing JIS

B 2220:2001 Steel welding pipe flanges and JIS B 22381996 General rules for steel

ipe flanges for arrangement as a draft for submission from Japan.

By the result, this standard shall be replaced, revising JIS B 2220:2001 and

withdrawing JIS B 238:1996.

Attention is drawn to the possibility that some of the elements of this

Standard may conflict with a patent right, application for a patent after

opening to the public, utility model right or application for registration of

utility model after opening to the public which have technical properties. The

relevant Minister and the Japanese Industrial Standrds Committee are not

responsible for identifying the patent right, application for a patent after

opening to the public, utility model right or application for registration of

utility model after opening to the public which have the said technical

properties.

Date of Establishment: 1984-10-1

Date of Revision: 2004-01-20

Date of Public Notice in Official Gazette: 2004-01-20

Investigated by: Japanese Industrial Standards Committee

Standards Board

‘Technical Committee on Machine Elements

JIS B 2220 ; 2004, First English edition published in 2004-05

Translated and published by: Japanese Standards Association

41-24, Akasaka, Minato-ku, Tokyo, 107-8440 JAPAN,

In the event of any doubts arising as to the contents,

the original JIS is to be the final authority.

© JSA 2004

All rights reserved. Unless otherwise specified, no pact of this publication may be reproduced or utlized

in any form or by any means, electronic or mechanical, including photocopying and microfilm, without

permission in writing from the publisher.

Printed in Japan Mer

PROTECTED BY COPYRIGHT

B 2220 : 2004

Contents

Page

Introduction »

1 Scope s+

2 Normative references +-+¥+---*~

3 Definitions »-----

4 Classification of flange and their designations ~ 8

5 Classification of gasket faces and their designations -------~

6 Designation of flanges according to zine plating ~~

7 Materials

8 Relationship between fluid temperature and maximum working

a an os

9 Nominal size of flange and application of pressure-temperature rating

10 Dimensions . oe

10.1 Dimensions of gasket face - 9

10.2 Dimensions of flanges «~~

10.3. Thread -~ severe

10.4 Dimensional tolerance --~

i Appearance *~ 10

12 Surface finishing --- 10

12.1 Gasket face soe

12.2. Welded portions ~~

12.8 Facing subjected to hot-dip zine coating

13 Soundness *~

13.1 Liquid penetrant testing and magnetic particle testing ~ el

13.2 Ultrasonic flaw detection oo

cy Zine coating * i

@

PROTECTED BY COPYRIGHT

B 2220 : 2004

15.1

15.2

16

16.1

16.2

16.3

16.4

Manufacturing method «

Flange“

Zine coating ~~

Test methods «

Liquid penetrant testing

Magnetic particle testing -

Ultrasonic testing ~

Cupric sulfate test --~

Inspection ~

Inspection for shape and dimensions ~~

Appearance inspection ~~

Surface finish inspection ~

Inspection by liquid penetrant testing +--+ sre resreerererenrrneerenee DB

Inspection by magnetic particle testing

Inspection by ultrasonic testing ---------~ ~

Hot-dip zine coating inspection ~

Material inspection

Acceptance inspection

18 Designation ~~

19 Marking ~~ soe seeeeeed

Annex 1 (normative) Flanges processed by flash butt welding ~~~

Annex 2 (informative) Outside diameter of steel pipes -~

Annex 3 (informative) Standards of ASTM materials and ISO materials 40

Annex 4 (informative) Small raised faces 42

Annex 5 (informative) Details of welded portion of welding flanges **--+--+--++--"-43

Annex 6 (informative) Flanges of nominal pressure 2K, 40K and 63K ~

Annex 7 (informative) Calculated mass of flanges ~~~

Annex 8 (informative) Table of relationship between JIS and corresponding

international standards --

Gi)

PROTECTED BY COPYRIGHT

JAPANESE INDUSTRIAL STANDARD @JIS B 2220 : 2004

Steel pipe flanges

Introduction This Japanese Industrial Standard has been prepared based on ISO

7005-1 Metallic flanges—Part | : Steel flanges published in 1992 as the first edition with

some modifications of the technical contents. A list of modifications with the

explanations is given in annex 8 (informative).

1 Scope This Standard specifies steel pipe flanges (hereafter referred to as

“flanges") of nominal size 10A to 1500A for nominal pressure 5K, 10K, 10K light type,

1GK, 20K and 30K which are used to join parts for piping, such as steel pipes and

valves, in ordinary (*), pressure (, high pressure (), high temperature (9, alloy steel

pipes ©), strainless steel pipes ©) piping for steam, air, gas, water, oil, ete. ().

Notes (®) Piping using Carbon steel pipes for ordinary piping of JIS G 3452 and

are welded carbon steel pipes of JIS G 3457.

© Piping using Carbon steel pipes for pressure service of JIS G 3454.

© Piping using Carbon steel pipes for high pressure service of JIS G 3455.

© Piping using Carbon steel pipes for high temperature service of JIS G

3456.

©) Piping using Alloy steel pipes of JIS G 3458.

©) Piping using stainless steel pipes of JIS G 3459 and large diameter

welded stainless steel pipes of JIS G 3468.

(®) Integral flange, which is to be used as part of some other equipment. or

components, shall also be within the scope of this Standard.

Remarks 1 The International Standard corresponding to this Standard is as

follows.

In addition, symbols which denote the degree of correspondence in

the contents between the relevant International Standard and JIS are

IDT (identical), MOD (modified), and NEQ (not equivalent) according

to ISOMEC Guide 21.

ISO 7005-1 : 1992 Metallic flanges—Part I : Steel flanges (NEQ)

2 The outside diameters of JIS steel pipes are shown in annex 2 infor-

mative).

3 The pressure used in this Standard indicates gage pressure.

2 Normative references The following standards contain provisions which, through

reference in this Standard, constitute provisions of this Standard. The most recent

editions of the standards (including amendments) indicated below shall be applied.

PROTECTED BY COPYRIGHT

2

B 2220 : 2004

JIS B 0151

JIS B 0203

JIS B 0601

Remarks :

JIS B 0621

JIS G 0303

JIS G 0565,

SIS G 8101

JIS G 3201

ISI G 3202

JIS G 8203

JIS G 3214

JIS G 3452

JIS G 8454

JIS G 3455

JIS G 3456

JIS G 3457

JIS G 3458

JIS G 3459

JIS G 3468

JIS G 4051

JIS G 4304

JIS G 4305

IS G 5101

JIS G 5121

JIS G 5151

JIS H 0401

JIS H 2107

JIS H 8610

Iron and steel pipe fittings Vocabulary

Taper pipe threads

Geometrical Product Specification (GPS) —Surface texture: Profile method—

Terms, definitions and surface texture parameters

ISO 4287:1997 Geometrical Product Specifications(GPS)—Surface texture +

Profile method—Terms, and definitions and surface texture parameters is

identical with the said standard.

Definitions and designations of geometrical deviations

General rules for inspection of steel

Method for magnetic particle testing of ferromagnetic materials and

classification of magnetic particle indication

Rolled steels for general structure

Carbon steel forgings for general use

Carbon steel forgings for pressure vessels

Alloy steel forgings for pressure vessels for high-temperature service

Siainless steel forgings for pressure vessels

Carbon steel pipes for ordinary piping

Carbon steel pipes for pressure service

Carbon steel pipes for high pressure service

Carbon steel pipes for high temperature service

Arc welded carbon steel pipes

Alloy steel pipes

Stainless steel pipes

Large diameter welded stainless steel pipes

Carbon steels for machine structural use

Hot rolied stainless steel plates, sheets and strip

Cold rolled stainless steel plates, sheets and strip

Carbon steel castings

Corrosion-resistant cast steels for general applications

Steel castings for high temperature and high pressure service

Methods of test for hot dip galvanized coatings

Zine ingots

Electroplated coatings of zinc on iron or steel

PROTECTED BY COPYRIGHT

3

B 2220 : 2004

JIS Z2241 Method of tensile test for metallic materials

JIS Z 2343-1 Nondestructive testing —Penetrant testing—Part 1 : General principles —

Method for liquid penetrant testing and classification of the penetrant indication

JIS Z3001 Welding terms

JIS Z3121 — Methods of tensile test for butt welded joints

JIS Z3122 — Methods of bend test for butt welded joint

3 Definitions For the purposes of this Standard, the definitions of the principal

terms given in JIS B 0151 and JIS Z 3001 apply.

4 Classification of flanges and their designations Flanges and their designations

shalll be classified according to their shapes as shown in table 1.

‘The types of slip-on hubbed flanges (SOH) for nominal pressure 20K and 30K shall

be as described in table 2.

PROTECTED BY COPYRIGHT

4

B 2220: 2004

Table 1 Classification of flanges and the designation

Glassfcaton of lange Designation Figure

Welding fangs] Slip-on plate ange]

soP

Slipon habbed

Mange

SoH

Socket welding

‘ange +

i

sw

Welding neck

‘ange

wy LY

Tap joint ange

ce

i ait

"Threaded Dange

™ i A By

PROTECTED BY COPYRIGHT

5

B 2220 : 2004

Table 1 (concluded)

Classification of lange Designation

Figure

1 | ch

Tatogral flange

lank Tange

BL

Table 2. ‘Types of nominal pressure 20 K and 30 K slip-on hubbed flanges

(SOH)

Ciastcation of amas Tine Fine

Sivan baba Mange

‘Type A :

Type B

| mmc a J

|

5 Classification of gasket faces and their designations Gasket faces and their

designations shall be as shown in table 3. Male-female face gasket (MF) indicates a

combination of male seat (MF-M) and female seat (MF-F) and tongue and groove (TG)

indicates a combination of tongue seat (TG-T) and groove seat (TG-G).

PROTECTED BY COPYRIGHT

6

B 2220 : 2004

Table 3 Classification of gasket face and the designation

asain sea Te Taran Fie

Palace

awa vA

fais

aw yu

i

AYA | Yau

wea

wr

veo) ata

Tonga a anoe] Tomes

ror| {YA wi

to

Tom

:

wea) CoA

PROTECTED BY COPYRIGHT

7

B 2220 : 2004

6 Designation of flanges according to zinc coating Designation according to the

presence of zine coating shall be as given in table 4

Table 4 Designation according to the presence of zinc coating

Designation Definitions

Black flange Flanges not subjected to dine coating

Witte Hango GND ‘Flanges subjected to hat-dip zine coating or electroplated zine coating

7 Materials Materials of the flanges shall be the ones given in table 5 or those at

least equivalent to them in both the mechanical properties and corrosion resistance.

Materials of welding flanges shall be suitable for welding.

Remarks: ASTM materials and ISO materials admitted that they are equivalent

or superior to the materials given in table 5 are shown in reference

table 1 and reference table 2, respectively.

Table 5 Materials

Wolled seis Steal forgings ‘Seool castings Material

Namberat | Symbotat | Namberat | —Symbotar | Namberof ] Symboror |? N®

standard | material | standard | material | standard | material

Carbon seal] JISGSI01 | S8400 | JiSGami | SFA | JiSasio1 | sca0 | 001

ascas | s20c | mscsz2 | srvci | mscsis1 | scrHt

wisewsr | Sac | aisaasr | sreoa | aisasior | soso | 002

= = wiscsme | Sivoan | sisGbisi | SCPHZ | 0030

Taw alloy = = wis Ga20s | SFVAFT | JISGsisi | SCPHIT | Oide

steel

= wis Gs208 | SFVAFIIA | JiSGsi6I | SCPH2I | Olbe

Buainless | JISGaa08 | SUSs01 | sISGaua | SUSFS0a | WSGSIa | SCSIsA | O2le

— ais a.4305 | SUS 304

= aiscain | ScSisa | 02ib

Wsaia | SUSsI6 | sisGsa4 | SUSFaIe | JSGsiZ | SCSI4A | Ooze

gis G4s05 | susai6

= wisGsiai | SCS1sA | 0aab

FisGs04 | SUSs0aL | JISGaaa | SUS Food = Oia

ais.G.4s05 | sussoaL

Wis Gaor | SUSaIEL | JISGaai | SUSTaIeL

ais g.4305 | sUSsi6L

= 0a

Remarks 1 S$ 400 of JIS G 3101 and SF 390A and SF 440A of JIS G 3201 shall be

those which have a carbon content of 0.35 or less.

2 The inspection of S20C and $25C of JIS G 4051 shall be conéucted as

specified in JIS G 0303, and the tensile strength of $20C shall be 400

Nimm* or greater and S25C, 440 N/mm? or greater.

PROTECTED BY COPYRIGHT

8

B 2220 : 2004

Reference Table 1 ASTM materials

oe Stel fringe Sie anings Nara]

Nowberaf | Symbilat | Namberet | Syminlat | Namberot | Symialat | eroun

andard | tare) | standard | mtaricl | sendara_| material | Number

Cosas cans | AN = ane] WoB TH

cor | ee | a ae | ou

asr | cu

Taw aley | Aa x miei a mae [wer is

tod | nae B fisat ot

‘ast | ica | ame incia | an] wos i

ais_|_Fizcta

aaa | ease | (amen |e fee ce Zr

emt pa as] cen | nee |r

20] a1] asa] Fate] asi] cram za

amo | sion | aise | rater | aan | cron

amo _|_sin ass_| coast

irae oer) ae | oo z a aa

a0 | se | are | sae

Remarks: For standards shown here, see annex 3 (informative)

Reference Table 2 ISO materials

Wait : mm.

Material Rolled steele Stool forgings ‘Stool castings | Material

[Number of] Symbol of [Thickness|Nambor of Symbol of| Thickness [Namber of] Symbol of |group No

standard | material standard | material standard | material

180 | PH200_|60erless| 180 | Fis | eaorless iso 40m] cass2n | 11

9328-2 | PHa15 [over 60 to] 26041 | Fis | over éato

and ine land ime 2

100.

Habs, Fi2_| GSorless

180 | 16Mo3 [G0orles| 180 | Fas = |isoseor] cas | 15

Tow alley | gane-2 2604-1

= = = = = = = _|isose01|csan [19

180 ecm) — 180 | Fao 180 4991 |_ cas 21

sa2e-s_f 2604-1 cat

180 {6 GNiMo 180 |_ Fez = fiso sor |__os7 22

9328-5 hiv 12 2600-1 | P64 = 60.

TCNiMe| — cot

712 CeiLe

Stainless [ISO fr2ceits | — 180 |_rus = = = 2a

steel | 90285 fio 26081 | Foe =

KeaceNiMe | —

hr a2

Racine | —

hrs

Remarks: For standards shown here, see annex 3 (informative)

PROTECTED BY COPYRIGHT

9

B 2220 : 2004

8 Relationship between fluid temperature and maximum working pressure Rela’

tionship between fluid temperature and maximum working pressure (hereafter refer-

red to as “pressure-temperature rating”) shall be as given in table 1. While the light

flange of nominal pressure 10K shalll generally be used for steady flow at a tempera-

ture of 120 °C or less and a pressure of 0.7 MPa or less.

‘The working temperature for white flanges shall be maximum 300 °C.

9 Nominal size of flange and application of pressure-temperature rating ‘The appli-

cation of the pressure-temperature rating to the nominal size of flanges, each type and

nominal size of flanges shall be as given in attached table 2, However, the nominal size

of light flange for nominal pressure 10K shalll be as given in table 6 regardless of its

temperature-pressure rating.

Table 6 Nominal size of light flanges for nominal pressure 10K

Nominal | Type of Nominal size A

pressure | Manges

10] 18] 30]5] 99] «o]50 65] s0]50] 100 [125 | 180 | 176 | 200] 328 [B50 [300] 350 | 400

sor [ofofofofofojofojojo| oF of oO] oO] oo

SoH |=

oo

10K light type

10 Dimensions

10.1. Dimensions of gasket faces The dimensions of gasket: faces of the flange shall

be as described in attached table 3.

Remarks: ‘The dimensions of the small raised face are shown in annex 4 (infor-

mative).

10.2 Dimensions of flanges The dimensions of flanges for each nominal pressure

shall be as given in attached tables 4 to 9,

Remarks 1 Inside diameter of the integral flange (IT) (d) and the diameter of hub

(2) and the radius of fillet (2) given in attached table 4, attached table

5, and attached tables 7 to 9 are given for reference. Inside diameter

(d complies with JIS B 2001. In the case of other dimentions, the

strength of the flange shall be calculated.

2 For slip-on welding flange (plate flange) (SOP) for nominal pressure

5K and blank flange (BL) of nominal size 400A or larger given in

attached table 4, slip-on plate flange (SOP) for nominal pressure 10K,

and blank flange (BL) of nominal size 250A or larger given in

attached table 5, full face gaskets should be used instead of ring

gasket, so as to prevent flanges from being applied excessive bending

moment,

3 The details of welded portion of welding flange are shown in annex 5

(informative).

PROTECTED BY COPYRIGHT

10

B 2220 : 2004

4 The pressure-temperature rating and basic dimensions of flanges of

nominal pressure 2 K, 40 K and 63 K are shown in annex 5

(informative).

5 The calculated mass of the flange is shown in annex 7 (informative).

10.8 Thread The thread of threaded flange (TR) shall be described in JIS B 0203.

10.4 Dimensional tolerance The dimensional tolerance on flanges shall be as

specified in attached table 10. Each axis line of socket of flange, socket of slip-on flange

(SOP and SOH), and the socket of socket, welding flange (SW) shall be perpendicular to

the gasket face enough for practical use.

Perpendicularity to the gasket, face of the axis line of the thread of threaded flange

(TR) shall be within 0.9 mm per 100 mm of the axis line. Perpendicularity shall be as

described in 5.8 of JIS B 0621.

‘The axis line of the thread of threaded flange (TR) shall be perpendicular to the

gasket face within tolerance of 0.5°

11 Appearance The flanges shall be free from any cracks or flaws detrimental to

use.

12 Surface finishing

12.1 Gasket faces The gasket faces of the flanges shall be finished in accordance

with table 7. Gasket faces of full face (FF), raised face (RF), and male-female face (MF)

shall be finished by turning with a round-end tool. The turning condition for 3.2 pm

and 6.3 ym Ra shall be as described in table 8.

‘The gasket face may be finished otherwise under an agreement between the parties

concerned.

Table 7 Finishing on gasket face

Unit: gam

Gasket face Fa

| Full face (FFY 32063

Raised face (REY 326s

‘Male-Temale face (MF) (Male seat and female seat) 3.2 or less

| “Tongue and groove (TG) (Tongue seat and groove sea) Sor Toss

Remarks: The value of Ra dependes on the definitions of JIS B

0601.

PROTECTED BY COPYRIGHT

un

120: 2004

Table 8 Turning condition for gasket face

Fa “Turning condition

= Radius of Blade edge Pitch of serration

: mm mm

Bz 08 035 10 0.30

16 0.35 10.042

e 08 0.35 to 0.42

16 0.52 40 0.60

122 Welded portion Welded portion of welding flange with steel pipe shall be

appropriately machined.

12.8. Facing subjected to hot-dip zinc coating ‘The inside diameter surface of flanges

subjected to hot-dip zine coating [excluding the smaller inside diameter of socket

welding flanges (SW) and the inside diameter of welding neck flanges (WN)] may be of

grinded or machined to remove the coating as required.

13 Soundness

1 Liquid penetrant testing and magnetic particle testing Cast steel flanges shall

satisfy the requirements for the soundness by means of liquid penetrant testing and

magnetic particle testing specified in standards for individual steel castings.

18.2 Ultrasonic flaw detection Forged steel or cast steel flanges shall satisfy the

requirements for the soundness by means of ultrasonic testing specified in standards

for individual steel forgings or steel castings.

14 Zinc coating Zinc coating shall be made as given in the following

a) Flanges subjected to hot-dip zinc coating shall not attain the final point in a cupric

sulphate test even when the immersion is carried out for 5 cycles.

b) The electroplated zine coating shall be grade 2 of JIS H 8610 or at least equivalent

thereto in corrosion resistance.

15 Manufacturing method

15.1 Flange Flanges shall be manufactured through the necessary machinings after

forging by the following method a), or after casting by b).

The plate flange (SOP and LJ without hub) may be manufactured through the

necessary machining after forming by c) or

Blank flange (BL) may be manufactured through the necessary machinings after

forming by 0).

a) Tobe hot-forged from a steel ingot or billet. In this case, a heat treatment specified

in the corresponding standards for the individual forgings shall be applied.

b) To be cast using appropriate melting and casting equipment. In this case, a heat

treatment specified in the corresponding standards for the individual castings shall

be applied.

PROTECTED BY COPYRIGHT

12

B 2220 : 2004

© To be manufactured from a steel sheet by press-work punching, gas cutting,

plasma are cutting, ete. Where the gas or plasma arc cutting is applied, the cut

surface of the flange shall be eliminated at least 2 mm by machining.

@) Tobe processed with flash welding as specified in annex 1 (normative).

15.2 Zinc coating When applying zinc coating to the flange, the following shall be

applied.

a) Zinc coating shall be applied after machining. In the case of applying hot-dip zine

coating, and the coatings on the inside diameter surface, welding area, etc. of the

flange are to be removed thereafter, the application may be on estimating the

necessary working allowances.

b) Flanges shall be coated after cleaned well by sandblasting, pickling and the like.

© Zine materials used for the hot-dip coating shall be distilled zine of JIS H 2107 or

zine ingots at least equivalent thereto in quality.

16 ‘Test methods

16.1 Liquid penetrant testing The liquid penetrant test shall be performed, as

specified in the individual steel castings standards.

16.2 Magnetic particle testing The magnetic particle test shall be performed, as

specified in the individual steel castings standards.

16.3 Ultrasonic testing The ultrasonic test shall be performed, as specified in the

individual steel forgings or steel castings standards,

16.4 Cupric sulfate test The cupric sulphate test on hot-dip zine coatings shall be

carried out according to the requirements of clause 5 in JIS H 0401

17 Inspection

17.1 Inspection of shape and dimensions ‘The shape and dimensions of flanges shall

be inspected by direct measurements, limit gaugings or other means, and shall meet

the requirements of clause 10.

17.2 Appearance inspection The appearance of flanges shall be inspected visually

and shall meet the requirements of clause 11.

17.3 Surface finish inspection Finishing of gasket face shall be inspected by an

appropriate method such as comparison between it and the reference sample that

agrees with the numerical values of Ra given in table 7, and shall meet the

requirements of table 7.

The surface finishing of the welded portion where a welding flange is jointed with a

steel pipe shall be inspected visually, and meet the requirements of 12.2

174 Inspection by liquid penetrant testing The liquid penetrant testing on cast

steel flanges shall be carried out as specified in 16.1, and the result shall meet the

requirements of 13.1

PROTECTED BY COPYRIGHT

13

B 2220 : 2004

17.5 Inspection by magnetic particle testing The magnetic particle testing on cast

steel flanges shall be carried out as specified in 16.2, and the result shall meet the

requirements of 13.1

17.6 Inspection by ultrasonic testing The ultrasonic testing on forged steel or cast

steel flanges shall be carried out as specified in 16.8, and the results shall meet the

requirements of 13.2.

17.7 Hot-dip zine coating inspection The hot-dip zine coating of the flange shall be

tested as specified in 16.4, and the result shall meet the requirements of 14 a).

17.8 Material inspection ‘The material of the flange shall be tested as specified in

requirements of the individual material standard unless otherwise designated by the

purchaser and the result shall meet the requirements of clause 7.

17.9 Acceptance inspection The acceptance inspection of the flange shall be

performed on the following inspection items. In this inspection, the sampling plan for

Jot inspection shall be subjected to the agreement between the parties concerned,

a) Inspection of shape and dimensions

b) Appearance inspection

©) Surface finish inspection

@ Inspection by liquid penetrant testing of cast steel flanges (as required by the

purchaser)

e) Inspection by magnetic particle testing of cast steel flanges (as required by the

purchaser)

Inspection by ultrasonic testing of forged steel or cast steel flanges (as required by

the purchaser)

8) Material inspection

18 Designation Flange products except integral flanges (IT) shall be designated by

the number of this Standard or title of this Standard, name or classification of flange,

name or classification of gasket faces (®),nominal pressure, nominal size and symbol of

material.

In the case of the white flange, classification according to the presence of zinc coating

(2N) shall be appended.

The following information shall be appended.

a) Light type (L) for light type flange for nominal pressure 10K.

b) Welding neck flanges (WN) with substitutional dimensions of nominal pressure 5K

and 10K, products with substitutional dimension (iD.

©) Distinction between type A (A), type B (B) and type C (C) for slip-on hubbed flanges

(SOH) for nominal pressure 20K and 30K

Note @) With lap joint flange (LJ), there are no gasket faces.

PROTECTED BY COPYRIGHT

14

B 2220 : 2004

Examples 1

Examples 2

Examples 3

Examples 4

Examples 5

Examples 6

Examples 7

Examples 8

Examples 9

JIS B 2220 SOP FF ZN 5K 800A SS 400 or Steel pipe flange, slip-on

plate flange, full face, white flange, 5K, 300A and SS 400.

JIS B 2220 LJ 5K 450A SF 390A or Steel pipe flange, lap joint

flange, 5K, 450A and SF 390A.

JIS B 2220 TR FF 10K 80A SCS 13A or Steel pipe flange, threaded

flange, full face, 10K, 80A and SCS 138A.

JIS B 2220 WN RF 10K H 1000A SFVC1 or Steel pipe flange,

welding neck flange, raised face, 10K, and products with

substitutional dimension, 1000A and SFVC 1

JIS B 2220 SOP FF 10K L 150A $20C or Steel pipe flange, slip-on

plate flange, full face, 10K, light flange, 150A and S20C

JIS B 2220 BL FF 16K 200A S25C or Stee! pipe flange, blank flange,

full face, 16K, 200A and S25C.

JIS B 2220 SOH RF 20K A 50A SUS3IGL or Steel pipe flange,

slip-on hubbed flange, raised face, 20K, type A, 50A and SUS 316L

JIS B 2220 SOH MF-M 30K C 65A SFVC2A or Steel pipe flange,

slip-on hubbed flange, male seat, 30K, type C, 654 and SFVC2A

JIS B 2220 TG-G 30K 100A SFVAF1 or Steel pipe flange, welding

neck flange, groove seat, 30K, 100A and SFVAFI

19 Marking Flanges excluding integral flange (IT) shall be marked the following

information on the periphery surface by such an indelible means as stamping, die

marking, etching or spraying.

a) Nominal pressure, nominal size and symbol of material—symbol of the nominal

size, A may be omitted.

The following shall be marked after the symbol of the nominal pressure

1) Symbol L for the light flange for nominal pressure 10K.

2) Symbol H for those of the substitutional dimension for nominal pressure 5K and

10K welding neck flanges (WN)

3) Distinction of type A (A) type B (B) and type C(C) for slip-on hubbed flanges

(SOH) for nominal pressure 20K and 30K

Examples 1

Examples 2

Examples 3

Examples 4

Examples 5

Examples 6

5K 300 SS 400

5K 450A SF 390A.

10K 80 SCS 13A

10K H 1000A SFVC1

10K L150 S20C

16K 200A S25C

PROTECTED BY COPYRIGHT

Examples 7 20K A 50 SUS 316L

Examples 8 30K C 65A SFVC 2A,

Examples 9 30K 100 SFVA F1

15

B 2220: 2004

b) Melting or casting number, or, an appropriate quality control number in which

melting or the casting number can be traced.

e

Manufacturer's name, its abbreviation or trademark

@) Other necessary information not confusable with those specified in a) to ¢)

Attached Table 1

Pressure-temperature rating

vine Pa

‘Nominal — group No. Divi Fluid temperature C_

proven |Special Boterence| soo | Tove TBO) BO HO] 360 [aan | a5 We | TE]

Sol | Saari

% Saag [eogefnggfecaeae ==

vor, 00% |. efreage roe toterfecefecefas SE

ee a

-_

eta, on

aaa pcos pose =p =p =p = p=

pe, 0228 cE = oan as

eto = a

ose, oom» 2a ee ee

pot, 908 tat Wp eee

= i 1.0) = = = = = = = a

oaaa actos pos =p

ae, cat ae Pio Pos

ee ge epg oer

casa, cas» fos tore fod fogs fero oe arealae

fae eg

me oa as pa eee

coe, oose |. re epee feed eee ete ea

es ae te ference [afer

Deere eta lege tener ena | celal

pate, 28a ae Re te =

cose, 02s [2a tre ote ere terete

PoE tt

a I Stas tae testa =

ae refer gorge pra r

alee a

a

ate, oat aa og act

ee peel eee et oe

ae =

TR Tp ae af a8 paar

pas par parp pp

Notes (*) Not applicable to JIS G 5101 SC 480 of material group 002, and ASTM A

587 CLI and ISO 9328-2 PH356 of material group 1.1

PROTECTED BY COPYRIGHT

16

B 2220 : 2004

Attached Table 1 (concluded)

Unit: MPa

Max working reanare

Material group No,

Nominal Dar Fiaid temperatare T

pressure | Sroatiod | Raforonce | °°" | Fuso] 320] B00] 350 | a00 | aS] a0] ae] a0

‘raterial | ‘oaterial 130

0K a

oe fis

13a] aa Pas | aa are aaO] SAT] BOUT | ——

TY] 81 as as aa ae ae] aa | 32] a

os fis

cc

FF TPB] aa aE] BT BEY BE] SAD [SONOS | SOOT

oa, oa, 22 SP ae] aa PaO] Be | BS [aaO | RIOT TON

0224, 0220

my 33-7 == -P- =) = ee

T[8i | a8 | 45 | 30] a8 | 38 [sa] —— -

0204, o2ab]2.3 Tse] ao ae] ae] ar | 0 zoe] —— J

Hel oo (eee ee ee eee S

Notes (Not applicable to ASTM A 852 LCI of the material group 1.5

Remarks 1

(©) Not applicable to ASTM A 351 CF3 and ISO 4991 C46 of material group

021b and 2.1

(2) Not applicable to ASTM A 351 CF3M of material group 022b and 2.2, ISO

4991 C57, ISO 4991 C60, ISO 4991 C61 and ISO 4991 C61LC.

@3) Not applicable to ASTM A 240 304L of material group 023a and 2.3, ASTM

A182 F304L and ISO 9328-5 X 2CrNi 1810.

Pressure-temperature rating of light flange for nominal pressure 10K

shall comform to clause 8.

For the specified materials in the column of material group No., see

table 5, and for the reference materials, see reference table 1 and

reference table 2

Division IT is the rating with some limitations put on that of Division |,

while Division IIT is the rating with further limitations put on that of

Division 11. Application of these divisions shall be as given in attached

table 2 depending on the type of flanges and their nominal size

71,is a minimum working temperature which is the normal temperature

or below. The minimum working temperature lower than the normal tem-

perature shall be subjected to the agreement between the parties concerned.

Maximum working pressure is at a temperature in the middle of the

temperature shown in the table shall be obtained by the proportional

interpolation method.

PROTECTED BY COPYRIGHT

Attached Table 2. Application of nominal size and

pressure-temperature rating of flanges

17

B 2220 : 2004

Nominal =

pressure

Moria [ 001,002, 0088 foRta, OBIb, Olde, Ob Gaia, 02

eroup No

tT Br Be zs

trot |, |e ale =e

=|, AR z 5 Zz

fonges 15 12 18 [3 le 1 le |e [2 1S (2 le |e [= [ee |e |e le |e fe le

=. =f =P yt py tty pt-pt

a) eto f a Sel etic na

S)oafr]-frfrfrfafrfrfafefrfefrfrfayef=fafafa] acta

Sa Uae Vesa esata ate feed aze sta ead eta aera) eta) ate] eaten alone reel

é| m1 Slee tren ats

2} afif-fitafafafafaftaf-fafafafaftafafofafadafada

Is) gaat eee an eel ae evecare [alr ne |g [anal

er{—frfr}r Paes) clr la

eo aa eri ett nea

eo) ae eeeh te se fete glee eel sedated

wof tf] =Jrfrfafafafr=]=frfafalrfa Sfrfifafa

ae Sells Belen Sale

eee aoe eel

sft} -]-]-|-falafrfay-]-f-fafefafeds}if-fafada

oot eae ee eles ein als

wrt t-}-1-1-|2) 21171 1-1-1-1 2) Pe

aoli}-|-frl-fifafrfr}-|-f-frfetedat-f-fefapede

Oe ul eee ele en teeters

mT] -|-Tt T=] PTT PTT 1) Pd

woof | |= fr] = Bre Sfifafafada =fifififa

cele rat ee pee Palos ale al

mT I-Tt T= TTT tpt

coo Utsler |e ere in| | |e le rm

soft fr] =fr}=[rfrfafrfrf=f-fafatmfrye]=]-fafefm

de ee

roofer ee lee er lam |r| een aan feet fer |

volt fr}-|-]-Jafafmfatal-|-fala}mfafafo]-faf afm

Boop T | TST a

sso] 1 | 1 =] = ec eee lle i

soft ff =]=f=fafafafafa}=f=fafcfmfr fa] =|=fafa fm

sooo eg fe femal eee grees fel cme cman | are fa oa fo [ee] ||

roof fr f= f=fofarfafatards Tce date || ala an

ram} cfr f= f=]ofafafafar|s r{a}mfafa]=]sfada fm

soo 1) Ue set eae ou fears fetal fea anf foams fev fea

rol t} rf -f=]=farfrfafrf a] = rfo}maia] =| ofr fafa

Remarks 1 The upper column of the column of “Material group No.” shows specified

materials and the lower one, the reference materials. For information, see

table 5, reference table 1 and reference table 2, respectively.

For the type of flanges, see table 1.

For the pressure-temperature rating symbols I, II and III, see attached

table 1.

PROTECTED BY COPYRIGHT

18

B 2220 : 2004

Attached Table 2 (continued)

Tonia a

a

aa Tie Tae Tae

—

i a as =

Type of aie ea lz i‘

overs [8 {3 [e [rs le [2 fe le [8 (3 [ele [2 le fe [8 |S le le [2 |e |e

Septet ee ep pp yt

eel alata

aboalriitrfrdrdeyt ef rsetiisdi rtrd cert ida da dt

shen HT Thy Th

a| reltiiitit(il-delateli(erit|ctiyeleii ls

BH oSirdcitfcdr ery ria fey ctey aay aay a cia fad eqa es

arto eee eee ete

shift fedattyifrfctete pita eya la ya yi a

melee lenient a lie

TTT epee ee ee

ee,

meds fcdeet erty et aye fete fa af ay eye fep adalat

wT pepe pape ete tee tet

mt y-l-(ef etter life ete fete alt [ee fey alr i

s(t PePoer {tpt Pe cecec pie ep ere yep cf ayayi

Sea ee na

feet lola ele le feelin adeae a ila

ee ee eS eee

wart TT tT ete pepe pe ett

volt lt (ete trle{elelitele(tli leit lele(i lila

mer flyrplf idee cyte eyeee yaya y titty c yey tit

sop papa pate te

merle ete ima leds dtm leet (ala

doef fens eel a jie aan tele es alialim | ail a lee) a

SPT Pepe pepe ep

ote eed t la tl ele lama leet la

mle Sele lela eles) claim nln) ) eae la

sop ppp ee pep pee ee

soe Pfft ft ya( ala | 2] res filed =| ofall

soled t{frfofrfepayal oft fa faa] 2] a | fan

woe EET Tee PTT pi

Remarks 1 The upper column of the column of “Material group No.”

shows specified materials and the lower one, the reference

materials. For information, see table 5, reference table 1 and

reference table 2, respectively.

2 For the type of flanges, see table 1.

3 For the pressure-temperature rating symbols I, II and III, see

attached table 1.

PROTECTED BY COPYRIGHT

21

B 2220 : 2004

Attached Table 2 (concluded)

Nominal a

pressure

Material (aie, 0216, 0238, 7

Natori) ]o02, oose 13a ota cele 0280, 02%b

i iB 7 Zi 22 ze

Typeot |= = E 7 =

ZlelelBlz Ble Slelelelelzle le

Menges 13 [2 |e |e 18 12 [es [2 8S fe |e 8 LE Je ee |S |e le

=) r{-7-Tt)]-1-11/41-1- 11 Teeee

wr frfrfrfrfrfrfrfefrfafafafrfrfafada 1

gs} oofrfrfrfafrfafcfafafefafafapefafafadafada

=D =rypaqe T T ; eyes te (ae gate et | etal

S) ee) rata) | 1 Pyare |r ae cir da

ES} afrfrfrfafafafrfafrfrfefefrfefefafafafada

mT yT}IT}T}i}iyi}i}iyifi{i{i}i}iiayr|r|r|o

wfrfaf}atafaftafafafafafatatafatafafafifada

sflifrpatatrfatafrfrfrfrtrtafalafale ifn

OF gfe feta gl ates Ue ts sate [etal teats [ana tte] ata] tet ee

boo} tet lere |r| tele reer at (ert | ne ee) | te] 0 |

wsftfrf}rfafataftrfafafafalafafatatafrfafata

wo) TT {T}T]T]T{T]T]T]T]T]/ 1/1] 1,1, aya] Tle

solr frfrfrfrfrfafafafefafafafafrfalayryi fa

aolrfatrfafrfrfafafafefafafafafrfafafrla ta

0 | Ueah sets] mh |e a tH] Un ae | sae ee |e | et

solr fafafafrfafrfafrfafafafmfafr fo) afa fs fm

sof frfafafrfafafafafafafmfa} afc fo] pepe po

Remarks 1 ‘The upper column of the column of “Material group No.” shows

specified materials and the lower one, the reference materials. For

information, see table 5, reference table 1 and reference table 2,

respectively.

For the type of flanges, see table 1.

For the pressure-temperature rating symbols I, II and III, see attached

table 1.

PROTECTED BY COPYRIGHT

22

B 2220 : 2004

Attached Table 3 Dimensions of gasket face

aw Yn a Pas

iD. 8 eS

Full face(FF) Raised face(RF)

i

— ed

— ‘Nominal pressure

= i = = =

i

go va 9 iz 9 f g z g =

Vee ae ee

eee ea

Bp

eee ee eee

SU eee

BR

Sete ele toe ole

Se ee:

= DE ca Da DO OSD s | o

a

i | 0s | 28 | i | a2 | me | ima | a [>] > | = | >

ooo_| sso | oo | is | iz | sas | ziso | go | =| >| = | =

eas sso [si Po] ta Mie | zat | a0 PP

wo | ao | ss | as | iz | mao | ams] a |=] = | =

oo_| tus | ico | as | ts | mao | sero | sp | =| =| = | =

so] ao0-| ais Pas] te] Mao] ase | at J =] =]

foo_| seo | sto | as | te | Mae | “too | ot |e aia | oe

PROTECTED BY COPYRIGHT

29

B 2220: 2004

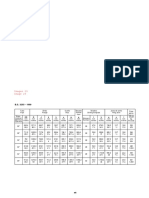

Attached Table 7 Dimensions of flanges for nominal pressure 16K

$e

$2

22, |j—#ee_

‘SOH of nomi SW of nominal size 10A to 80A

LJ of nominal size 15A to 600A. ‘TR of nominal sizo 10A to 160A

Unit : mm

[Nominal Teined dimension Tnside diameter Depth [Nominal | Raised face

lize | Outside Diameter] Diameter] Number] Nominal ‘of | designa’ [Diameter] Height

liameter| ofbolt | of bole {of bolts {designe sockot| tion of

joflange| hole | hole tion of Gar thread

contre thread | mai)

‘ire ofbolt

p|ic h | lao} «| s £

ISOH, SW, LI, TR, WN, IT, BL Ison, fi sw. fir Sw [TR [WwNr

lsw WN

A

1 | | ] 8 | 4 | Mafia] -|a7[o | io |e) «© | ot

w | a | 3 ws | 4 | mz [2z2]ase{iei| 15 | 10 Re | st | 1

20 | 100 | 7: ws | 4 | mz |or7| aso] ora} 20 | 13 [re | 56 | 1

2s | azs [so [|e | 4 | mis [ass aso] 272] 25 | is | Ret | a7] 1

sz | 135 | 1oo | 19 | 4 | mae faz} aaa} ass] a2 | 13 frei] m | 2

so_| uo | ios | io | 4 | mis |aoitsos| siz] ao | is [revel oo | 2

30] 158 120 | 19 | —# | Mas |eit}o27} 527] 50 | 16 | Re2 | 6 | 2

es | as | vo | io | 8 | mus |7r1]7a7]ono] os | is |Rea's| us | 2

so_| 200 | 1 | 23 | 8 | m0 |soolors| rai} go | 16 | Res | 12 | 2

90] 210] 170 | 23 | 8 | M20 ]i0z6]i04.1) 902] 90 | - | - | 48 | 2

roo | 225 | 185 | 23 | 8 | mzo |1154J1169]1023] 10} - | Rea | 160 | 2

i25_| 970 | 295 | 95 | 8 | mzz |rara|iasolize6| 125 | — | res | 95 | 2

150] aos] 260] 25] 12 | Maz |1666]108.4]151.0] 150 | - | Ree | 230 | 2

200 | aso | 305 | 25 | 12 | mae Jaisol2ios|ieo9] 200} - | - | 25 | 2

250_| 430 | 380 | 27 | 12 | nos |26e5]orsa|ouse| 50 | — | — | 35 | 2

‘300 | aso] 4a0 | 27] 16 | Ma [s21.0]s228[ 2079] 300 | - | - | a3 | 3

aso | sao | 480 | 33 | 16 |maoxs{s581]s602} 393.4] 335 | - | - | a0 | 3

4o0_| cos | 540 | ss | 1s |waoxs| ao0 Jars2{asro| ago | — | — | a5 | 3.

450 | 675] 05] a3} 20 [Maoxs| 460 [4023] fa] |e

Notes (®) With IT flanges, this dimension is shown for reference.

(@) This may be rounded off with the dimension cas a radius,

PROTECTED BY COPYRIGHT

31

B 2220 : 2004

Attached Table 8 Dimensions of flanges for nominal pressure 20K

re

$0 a $e 1

#, [te a a #, [ta],

* 7] =] ea

z TT 3 = +

ry | |

$6 Somme

$0 $0

SOF type Aof nominal size SOT type Bof nominal size SOH type C of nominal size

TOA to 600A 10A to 50A {5A to BO0A

te

feacedennee] te $o

2 ee =. on [ae

t i ZW

cI tau

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (347)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Hydratight LP-Series FlyerDocument4 pagesHydratight LP-Series FlyerANDERSON NERESNo ratings yet

- Socket 600# AnsiDocument2 pagesSocket 600# AnsiANDERSON NERESNo ratings yet

- Slip On Anel 600# AnsiDocument2 pagesSlip On Anel 600# AnsiANDERSON NERESNo ratings yet

- Socket Weld 1500# AnsiDocument2 pagesSocket Weld 1500# AnsiANDERSON NERESNo ratings yet

- Slip On Anel 400# AnsiDocument2 pagesSlip On Anel 400# AnsiANDERSON NERESNo ratings yet

- Slip On Anel 300# AnsiDocument2 pagesSlip On Anel 300# AnsiANDERSON NERESNo ratings yet

- S Jb01 Fire Extinguisher CabinetDocument2 pagesS Jb01 Fire Extinguisher CabinetANDERSON NERESNo ratings yet

- Socket 150# AnsiDocument2 pagesSocket 150# AnsiANDERSON NERESNo ratings yet

- Socket 300# AnsiDocument2 pagesSocket 300# AnsiANDERSON NERESNo ratings yet

- Couplings: Storz B and CDocument2 pagesCouplings: Storz B and CANDERSON NERESNo ratings yet

- Fiberbond Fiberglass Piping Systems Series 20FR16-C: DescriptionDocument2 pagesFiberbond Fiberglass Piping Systems Series 20FR16-C: DescriptionANDERSON NERESNo ratings yet

- The Fiberbond Fittings GuideDocument23 pagesThe Fiberbond Fittings GuideANDERSON NERESNo ratings yet

- 11 - OrificeDocument7 pages11 - OrificeANDERSON NERESNo ratings yet

- 7 - LWNDocument8 pages7 - LWNANDERSON NERESNo ratings yet

- 5 - MSSDocument5 pages5 - MSSANDERSON NERESNo ratings yet

- Class 150 - 2500 Reducing FlangesDocument2 pagesClass 150 - 2500 Reducing FlangesANDERSON NERESNo ratings yet

- Drip Rings STD - Tb.Dri.5011 FF RFDocument1 pageDrip Rings STD - Tb.Dri.5011 FF RFANDERSON NERESNo ratings yet

- 9 - HubDocument4 pages9 - HubANDERSON NERESNo ratings yet

- Thermoplastic Flanges: Technical Information Weights & DimensionsDocument11 pagesThermoplastic Flanges: Technical Information Weights & DimensionsANDERSON NERESNo ratings yet

- Cálculo de TubosDocument3 pagesCálculo de TubosANDERSON NERESNo ratings yet

- Schedule 80 PVC/CPVC Unions: UNION (Old Style)Document6 pagesSchedule 80 PVC/CPVC Unions: UNION (Old Style)ANDERSON NERESNo ratings yet

- S Storz Couplings DatasheetDocument2 pagesS Storz Couplings DatasheetANDERSON NERESNo ratings yet

- 5" DN125 5" DN125: Nominal Size Nominal SizeDocument3 pages5" DN125 5" DN125: Nominal Size Nominal SizeANDERSON NERESNo ratings yet

- Measuring DFT According SSPC PA2Document15 pagesMeasuring DFT According SSPC PA2ANDERSON NERESNo ratings yet

- 5" DN125 5" DN125: Nominal Size Nominal SizeDocument3 pages5" DN125 5" DN125: Nominal Size Nominal SizeANDERSON NERESNo ratings yet