Professional Documents

Culture Documents

Carbomastic 15 LT: Selection & Specification Data

Uploaded by

srinath vOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbomastic 15 LT: Selection & Specification Data

Uploaded by

srinath vCopyright:

Available Formats

Carbomastic 15 LT

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Two-components, high solids aluminium pigmented, low temperature curing modified epoxymastic.

Carbomastic 15 LT is a high build coating with excellent adhesion to rusted steel and most aged

Description

coatings.

• Surface tolerant

• Recommended for painting over rusted steel where hand cleaning only is possible

• Carbomastic 15 LT penetrates through rust to steel substrate and stops further corrosion and

undercutting

Features

• Fast curing at low temperatures

• High solids give good coverage and reduced solvent emission

• Excellent maintenance primer for piping, bridges, tank exteriors, ships and offshore structures

etc..

Color Aluminium

Finish Semi-Gloss

Wet Film Thickness 115 – 350 µm per coat, normally 175 µm.

100 - 300 microns (3.94 - 11.81 mils) per coat

Dry Film Thickness

Normally 150 µm.

Solid(s) Content By volume: 86 ± 2%

Theoretical Coverage 5,7 m²/l at 150 µm.

Rates Allow for loss in mixing and application.

Continuous: 120°C (248°F)

Dry Temp. Resistance

Non-Continuous: 150°C (302°F)

Limitations Not recommended for immersion service in acids, alkalies or solvents.

May be topcoated with most generic types. Some alkys or oil modified paints exhibit poor adhesion.

Topcoats

Topcoat should be applied within 14 days.

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

May be used over most generic types of coatings which are tightly adhering to the substrate

General

including organic- and inorganic zinc primers.

Preferably blasting however hand- or power tool cleaning is acceptable standard in many cases to

Steel remove non adhering paint and rust. Alternatively, ultra high pressure water jetting to Nace No. 7

min. C Vis WJ-2. Max flash rust; C Vis WJ-2M.

MIXING & THINNING

Mixing Power mix separately, then combine and power mix.

May be thinned up to 15% with Thinner # 2. Use of thinners other than those supplied or

Thinning recommended by Carboline may adversely affect product performance and void product warranty,

whether expressed or implied.

May 2020 8622 Page 1 of 3

Carbomastic 15 LT

PRODUCT DATA SHEET

MIXING & THINNING

Ratio 1:1 Ratio (A to B) by volume.

Pot Life 1½ hours at 20°C and less at higher temperatures.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

The following spray equipment has been found suitable and is available from manufactures such as

General

Binks, De Vilbis and Graco:

Pump Ratio: 30:1 (minimum)

GPM Output: 3.0 (minimum) 12 liters/min.

Material Hose: 3/8” I.D. (minimum)

Tip Size: .023” - .027”

Airless Spray

Output PSI: 2000 - 2400

Filter Size: 60 mesh

Teflon packings are recommended and available from the pump manufacturer.

Brush & Roller Recommended for small areas and touch-up only

(General)

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 5°C (41°F) 2°C (36°F) 2°C (36°F) 0%

Maximum 35°C (95°F) 75°C (167°F) 40°C (104°F) 85%

Industry standards are for substrate temperatures to be 3°C above the dew point. Special application techniques may be required

above or below normal application conditions.

CURING SCHEDULE

Surface Temp. Dry to Recoat Final Cure

5°C (41°F) 18 Hours 7 Days

10°C (50°F) 10 Hours 5 Days

20°C (68°F) 6 Hours 3 Days

25°C (77°F) 4 Hours 2 Days

These times are based on recommended DFT. Higher film thickness, insufficient ventilation or cooler temperatures will require

longer cure times and could result in solvent entrapment and premature failure.

CLEANUP & SAFETY

Use Carboline Thinner #2 or #25. In case of spillage, absorb and dispose of in accordance with

Cleanup

local applicable regulations.

Read and follow all caution statements on this product data sheet and on the MSDS for this

Safety product. Employ normal workmanlike safety precautions. Hypersensitive persons should wear

protective clothing, gloves and use protective cream on face, hands and all exposed areas.

May 2020 8622 Page 2 of 3

Carbomastic 15 LT

PRODUCT DATA SHEET

CLEANUP & SAFETY

When used in enclosed areas, thorough air circulation must be used during and after application

Ventilation until the coating is cured. The ventilation system should be capable of preventing the solvent vapor

concentration from reaching the lower explosion limit for the solvents used.

This product contains flammable solvents. Keep away from sparks and open flames. All electrical

equipment and installations should be made and grounded in accordance with applicable

Caution

regulations. In areas where explosion hazards exist, workmen should be required to use non-

ferrous tools and wear conductive and non-sparking shoes.

PA C K A G I N G , H A N D L I N G & S T O R A G E

Shelf Life 24 months at 24°C

Storage Temperature & 5°- 45°C

Humidity 0 - 95% relative humidity

Storage Store indoors.

Part A: 10 litres

Packaging

Part B: 10 litres

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

May 2020 8622 Page 3 of 3

You might also like

- Green Mark Manager 6 May 2019Document1 pageGreen Mark Manager 6 May 2019Haider Tyebally TyeballyNo ratings yet

- Intergard 740Document4 pagesIntergard 740Josevi Jiménez MerinoNo ratings yet

- PARATHERM 600 HEAT RESISTING FINISHDocument2 pagesPARATHERM 600 HEAT RESISTING FINISHyarth880% (1)

- Valve Seat Lathe Type VSL: Instruction ManualDocument25 pagesValve Seat Lathe Type VSL: Instruction ManualAmiya100% (4)

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Thermaline 400 Finish PDSDocument3 pagesThermaline 400 Finish PDSQuy RomNo ratings yet

- Thermaline 400 Primer PDSDocument3 pagesThermaline 400 Primer PDSQuy RomNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Carboguard 703 GF PDSDocument4 pagesCarboguard 703 GF PDSDuongthithuydungNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Carboweld 11P PDSDocument4 pagesCarboweld 11P PDS이선엽No ratings yet

- Interzinc 22Document4 pagesInterzinc 22dexterisNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Thermaline 1248 PDSDocument3 pagesThermaline 1248 PDSGudang PagardewaNo ratings yet

- Royalthane 450GLDocument2 pagesRoyalthane 450GLSyed FaridNo ratings yet

- Intergard 276: Epoxy Undercoat/ Tie-CoatDocument4 pagesIntergard 276: Epoxy Undercoat/ Tie-CoatAhmed IbrahimNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Carbothane+134+HG+PDS+3 11Document2 pagesCarbothane+134+HG+PDS+3 11James Everett AbdulNo ratings yet

- Carbothane 134 HPDocument4 pagesCarbothane 134 HPsrinath vNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- Sanitile 655: Selection & Specification DataDocument3 pagesSanitile 655: Selection & Specification DataIndraNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Interzinc 12: Inorganic Zinc Rich SilicateDocument4 pagesInterzinc 12: Inorganic Zinc Rich SilicateSubham SahuNo ratings yet

- Carboguard 891 Product Data SheetDocument4 pagesCarboguard 891 Product Data SheetPrakashNo ratings yet

- Carbomastic 15 PDS 2013Document2 pagesCarbomastic 15 PDS 20134508366279No ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- KCC DataSheet LT313ENGDocument2 pagesKCC DataSheet LT313ENGNasir AnsariNo ratings yet

- Thermaline 400: Selection & Specification DataDocument3 pagesThermaline 400: Selection & Specification DataJalaluddinNo ratings yet

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- Intersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingDocument4 pagesIntersleek 1100SR: Advanced Fluoropolymer Foul Release CoatingYanyan2009No ratings yet

- Carbozinc 858 (3K)Document4 pagesCarbozinc 858 (3K)DuongthithuydungNo ratings yet

- Ultracote Ultracote Ultracote Ultracote: Ultrazinc 2120Document3 pagesUltracote Ultracote Ultracote Ultracote: Ultrazinc 2120Cherbee FerrerNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- TDS - Resist 65Document5 pagesTDS - Resist 65Teknik produksi wikonNo ratings yet

- E-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - A4 - 20160729Document4 pagesE-Program Files-AN-ConnectManager-SSIS-TDS-PDF-Interspeed - 6200 - Eng - A4 - 20160729Erwin MalmsteinNo ratings yet

- Interzinc 2265: Product DescriptionDocument4 pagesInterzinc 2265: Product DescriptionIsabelo AbaoNo ratings yet

- Interzinc 75V: Zinc-Rich EpoxyDocument4 pagesInterzinc 75V: Zinc-Rich EpoxyTrịnh Minh KhoaNo ratings yet

- Zinc Anode 304 MZV Protects Steel Against Severe CorrosionDocument2 pagesZinc Anode 304 MZV Protects Steel Against Severe CorrosionMANIMARAN QCNo ratings yet

- Carboguard 1340 PDSDocument4 pagesCarboguard 1340 PDSSaefuddin OrtegaNo ratings yet

- 135Document2 pages135Abdullah SahlyNo ratings yet

- Carboguard 885 PDSDocument2 pagesCarboguard 885 PDSsyazwanjohnmazlanNo ratings yet

- Interplate 317: Zinc Silicate Shop PrimerDocument4 pagesInterplate 317: Zinc Silicate Shop PrimerMohamed NouzerNo ratings yet

- Intertherm 50: Silicone AluminiumDocument4 pagesIntertherm 50: Silicone Aluminiumnoto.sugiartoNo ratings yet

- Carbo Zinc 11 HsDocument2 pagesCarbo Zinc 11 Hstyto_rmzNo ratings yet

- Interzinc 22 Tds EngDocument4 pagesInterzinc 22 Tds EngFounder TarihoranNo ratings yet

- Interclene 175: TBT Free AntifoulingDocument4 pagesInterclene 175: TBT Free AntifoulingTrịnh Minh KhoaNo ratings yet

- Carbocoat 8215 PDS 6-10Document2 pagesCarbocoat 8215 PDS 6-10Mayur PatelNo ratings yet

- Intertherm 79: Temporary Protective PrimerDocument4 pagesIntertherm 79: Temporary Protective PrimerNassim Ben AbdeddayemNo ratings yet

- Interplus 1180: Protective CoatingsDocument4 pagesInterplus 1180: Protective CoatingsAnindya Aulia PratiwiNo ratings yet

- Technical Data Sheet for Unsaturated Vinyl Ester CoatingDocument5 pagesTechnical Data Sheet for Unsaturated Vinyl Ester CoatingBiju_PottayilNo ratings yet

- Interclene 165Document4 pagesInterclene 165Trịnh Minh KhoaNo ratings yet

- KCC - DATASHEET - Koramel Enamel LT313 - EngDocument2 pagesKCC - DATASHEET - Koramel Enamel LT313 - EngNguyen1987 TrungNo ratings yet

- Cathacoat 302 Zinc Silicate PrimerDocument4 pagesCathacoat 302 Zinc Silicate PrimerAhmed IbrahimNo ratings yet

- Interzinc 22: Product DescriptionDocument4 pagesInterzinc 22: Product Descriptionchristian210789No ratings yet

- Rust O Cap: Surface Tolerant EpoxyDocument3 pagesRust O Cap: Surface Tolerant EpoxySanthana SaravanaNo ratings yet

- TDS-PDF-Interzinc 22 EngDocument4 pagesTDS-PDF-Interzinc 22 Engapde06No ratings yet

- Interzinc 2280 Product BrochureDocument4 pagesInterzinc 2280 Product BrochureAshish Raul CIENo ratings yet

- Ul Ul Ul Ultracote Tracote Tracote TracoteDocument3 pagesUl Ul Ul Ultracote Tracote Tracote TracoteJenniferValleNo ratings yet

- Hempadur Zinc 17360Document2 pagesHempadur Zinc 17360Bang OchimNo ratings yet

- Carbothane 8832: Selection & Specification DataDocument4 pagesCarbothane 8832: Selection & Specification Dataluisbarrios104No ratings yet

- High Solids Coal Tar Epoxy Product SpecificationsDocument2 pagesHigh Solids Coal Tar Epoxy Product SpecificationsAbuhurairah MunshiNo ratings yet

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- RC Series Wet Cooling Tower Leaflet - v1Document2 pagesRC Series Wet Cooling Tower Leaflet - v1srinath vNo ratings yet

- PolicyDocument 337753093Document5 pagesPolicyDocument 337753093SAGAR ADHAONo ratings yet

- Kotak Long Term Two Wheeler Insurance Policy DetailsDocument4 pagesKotak Long Term Two Wheeler Insurance Policy Detailssrinath vNo ratings yet

- Protective & Marine Coatings: Zinc Clad Iv EuDocument2 pagesProtective & Marine Coatings: Zinc Clad Iv Eusrinath vNo ratings yet

- Technical Data Sheet for Barrier 80 Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 Zinc Epoxy PrimerBalaji GuruNo ratings yet

- Carbothane 134 HPDocument4 pagesCarbothane 134 HPsrinath vNo ratings yet

- Particulars िववरण Deposit जमा Withdraw िनकासी Pension contribution पेंशन अंशदानDocument5 pagesParticulars िववरण Deposit जमा Withdraw िनकासी Pension contribution पेंशन अंशदानsrinath vNo ratings yet

- Prot - Act Broschuere A4 Ortlinghaus en Web 1Document9 pagesProt - Act Broschuere A4 Ortlinghaus en Web 1srinath vNo ratings yet

- Adobe Measuring ToolDocument6 pagesAdobe Measuring Toolsrinath vNo ratings yet

- RENK Marine Symposium 2016Document228 pagesRENK Marine Symposium 2016srinath vNo ratings yet

- An Overview of Aluminum Foam Production MethodsDocument8 pagesAn Overview of Aluminum Foam Production Methodsgouhua yuanNo ratings yet

- Structural CalculationDocument5 pagesStructural CalculationEze NonsoNo ratings yet

- C&I Engineering Field Cabinet SpecificationDocument6 pagesC&I Engineering Field Cabinet Specificationishu vohraNo ratings yet

- Man l32 44Document274 pagesMan l32 44Tran Duy NamNo ratings yet

- 2SK2663Document1 page2SK2663hectorsevillaNo ratings yet

- Yogesh Kumar Garg Resume Mechanical EngineerDocument3 pagesYogesh Kumar Garg Resume Mechanical EngineerYogeshGargNo ratings yet

- Philips MDK 900Document2 pagesPhilips MDK 900Heri MunirNo ratings yet

- LG LED TV Owners ManualDocument44 pagesLG LED TV Owners ManualBa humbugNo ratings yet

- Thanda Matlab Coca-ColaDocument11 pagesThanda Matlab Coca-ColaANIRBAN28No ratings yet

- Project Management Assignment 2 - Soichiro HondaDocument7 pagesProject Management Assignment 2 - Soichiro HondaGladwin SamuelNo ratings yet

- The Effect of Inrush Current On Transformer ProtectionDocument9 pagesThe Effect of Inrush Current On Transformer Protectionbigsteve9088No ratings yet

- Eromobil Er230 Manual1Document14 pagesEromobil Er230 Manual1Станислав НиколовNo ratings yet

- SAP PM Best PracticeDocument55 pagesSAP PM Best PracticesachinWebDNo ratings yet

- Industrial VisitDocument22 pagesIndustrial VisitInvincible GamerNo ratings yet

- Electrician job hazard analysisDocument1 pageElectrician job hazard analysisZaul tatingNo ratings yet

- 12 HOUSEKEEPING Q1 W2 M2 FinalDocument20 pages12 HOUSEKEEPING Q1 W2 M2 FinalWyn Ave CagakitNo ratings yet

- Oracle BOM Mass Changes - Oracle Functionality - ManojDocument29 pagesOracle BOM Mass Changes - Oracle Functionality - ManojVijay PawarNo ratings yet

- Safety PrecautionDocument1 pageSafety PrecautionSJ Chua100% (1)

- Larsson Quotation Sample Lsh320m-0.4-VvvfDocument7 pagesLarsson Quotation Sample Lsh320m-0.4-VvvfvinayNo ratings yet

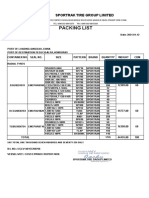

- Packing List: Sportrak Tire Group LimitedDocument1 pagePacking List: Sportrak Tire Group Limitedissa lamarNo ratings yet

- Python3 Tutorial PDFDocument26 pagesPython3 Tutorial PDFferronatto11100% (1)

- Unit I Acoustics Planning For Noise, STC, NRCDocument9 pagesUnit I Acoustics Planning For Noise, STC, NRCKavya DesaiNo ratings yet

- Medical Equipment MaintenanceDocument6 pagesMedical Equipment Maintenancever_at_workNo ratings yet

- 1.2. Modular Programming - En-UsDocument12 pages1.2. Modular Programming - En-UsChandrasekhar K100% (1)

- Dam PluggingDocument104 pagesDam PluggingMpho Vince MatlouNo ratings yet

- 106 TOP Control Systems - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsDocument18 pages106 TOP Control Systems - Electrical Engineering Multiple Choice Questions and Answers - MCQs Preparation For Engineering Competitive ExamsRian RiveraNo ratings yet

- PMAS-Arid Agriculture University RawalpindiDocument3 pagesPMAS-Arid Agriculture University RawalpindiAli AzanNo ratings yet

- Civil HandbookDocument24 pagesCivil HandbookShubham Aggarwal100% (1)