Professional Documents

Culture Documents

ARG Belt Conveyors For Bulk Materials

ARG Belt Conveyors For Bulk Materials

Uploaded by

Easy Energy SAC100%(1)100% found this document useful (1 vote)

170 views338 pagesOriginal Title

ARG Belt Conveyors for Bulk Materials

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

170 views338 pagesARG Belt Conveyors For Bulk Materials

ARG Belt Conveyors For Bulk Materials

Uploaded by

Easy Energy SACCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 338

Prepared by the Engineering Conferance of the

Conveyor Equipment Manufacturers Association

Belt Conveyors

for

Bulk Materials

SECOND EDITION

:

(CBI Publishing Company, Ine.

51 Sieeper Street

seston, Massachusetts 02210

=

Cy

Contents

Prifece

Acknowledgment 31

Introduction 30

Chapter Bet Conveyor General Aplications and Economics 1

Conveying ofa variety of materns, Wide range of eapacies.

Saamcdiny vo path oftravel. Loading, dicherging, and

ae ar ayant. Procts functions. Rebcbilty nd

stoekpling oP ironmental avaniages, Safety. Low

erm, and memtenance Coss. Long-Aistance

labor Pendons examples of conveyor systems, Investment

Transport sonveyors verdus treks: Owning and opzating

(one present wort.

Chapter 2 Design Considerations a

Conveyor arrangements. Resumes of Chapters 33.

Chapter} Characeitis and Conveyablity of Bulk Materials Po

ate) eharaceriies:behevior of materials on 2 noving belts

fect of inclines and decines; material class.

CChapter# Capaciles, Belt Widths, and Speeds st

‘Bet wide, Lump size considerations, Belt sped:

ae mended snasmm speeds Yor specie teri

Saraveyor capaci, Troughed belt oad ares.

Pie el load reas Capacity tables and thei we,

= =

a ow es oe es

os os

= 6 ow aD

coma

snd Accessories ur

Chapter 10. elt Takeups, Cleaners,

elt takeupe: bet stretch; takeup movement; manual akeups

Bet eecmyakeups. Cleaning devies: types of bel cleaners;

utorat pt leaner, el turnover scheme; pulley w prs

Tosation pal cleaning. Aseessry equipment: weather

‘team: spillage protection; tramp iron detectors: sa

Esmpling devices.

Chapter 11 Conveyor Loading and Discharge I

Toading te be: direction of loading; transverse belt

‘retactnent leading an Inclined bek conveyor impact at leading

deere eet eding cules and skrtbords. Feeder.

poi gs of discharging! dicharge ovewihevend pulls,

Towering chutes, THippers. Plows,

"Blulaing and ploting normal materia

Wek comeyor

tdscharge ete

Discharge trajectories:

Pajares; hozontal, ineind, and de

trast,

Chapter 2 Motors and Controls 3

‘Torque characteristics. Reduced

Miage maring, Accelerating time and starting

Fear Spegenertive braking. Wound-rotee

fregueneys able-speed drives. Ambient condition and

Motor enclosures. Electrical

Computer contol and multiplexing.

Motor seen

temperature

interlocking.

Chapter 13. Operation, Matotenance, and Safely au

Operation, Maintenance, Safety: gileline for sae

fperation and maintenance

Appendices 33

"A. Guide fr Use of SU (Metre) Units

BL Nomenclature

: 23

33

Indes 339

: Chapter 5 Belt Conveyor idles o

Requirements and claciestons. General types of belt

conveyor idles troughing eareying Idlers; Impact ides; bet

traning suspended idler, return idler; two-roll °V" return

fale, Idler spacing. Idler selection, ler rating,

Bel alignment

(Chapter § Belt Tension, Power, and Drive Engineering %

asic power requirements. Blt tension calculations,

CEMA horsepower formula. Drive pulley relationships.

Drive arrangements. Maximum and minimum bel tensions

‘Tension relationships and Belt sag between idles. Acceleration

and deceleration fores, Analysis of acceleration and

fecsleration forces. Design considerations. Conveyor

honepower determination—raphieal method. Example of

belt tension and horsepower calculations: 6 problers. "Bet

Conveyor dive equipment, Backstops. Brakes. Braker and

beckstops in combination, Device fr acceleration, ectleraton,

nd torque control Brake cequirement determination

(Gectleration calevlations)

Chapter? Belt Selection 1

Factor in the composition of conveyor belting: covers: adhesion

ales belt caren; breakers. Grades of conveyor beling and

(Conveyor belt splices: vulcanized versus

iy fastened; applicable sevice conditions. Conveyor

tet selection: tension trghabilty, pulley consideatons; load

support impact resistance; cover considerations loacing

‘onsieratons;exonamic considerations.

Chapter Pullysand Shatls 204

CConveyor pulley: types: Ingzing: weights; load ratings

diameters face widths crowa; overloads. Shaftirg

esutant radia loud; selection; deflection.

Chapter Vercal Curves m0

‘Concave verte curves! design; erapicalconsncton:

precautions for design, Convex vertical curve: design; ier

{pacing: se of bend pulleys.

Chapter 1

Belt Conveyor General

Applications

and Economics

Contents

Conveying of a variety of materials.

Wide range of capacities.

Adaptability to path of travel.

Loading, discharging, and stockpiling capabilities

Process functions.

Reliability and availability.

Environmental advantages.

Safety.

Low labor, power, and maintenance costs.

Long-distance transportation.

‘Examples of conveyor systems

Investment decision—belt conveyors versus trucks.

‘Owning and aperating costs. Present worth: required rate

of recun

“The subject of bet conveyors is. of primary interes to all engineers

managers and sihers who are responsible for selecting equipment for ban-

‘Tune Bak atari, This book is primarily a design manual, but Chater

a ete acount the reader with the many uses of bell eonveyors and

‘hac advantages under widely varying conditions of opertion.

Sar creyors have stained s dominant postion intransporsing bulk

rmateiie Soe to fuch inherent advantages a8 their economy and safety of

Bon, realy, vetsaiity, and practically unimited range of

crete! tn addon, they are autable for pesforming nanerous processing

enetion in connection with thee normal purpose af providing a continuous

TOES fara) between operations. Recently, ther conformity to

fo einen! requirements has provided a frther incentive for selection of

‘a conveyors over other means of transportation.

reeehor tnd low energy requirements are fundamentl with belt

conveyors compared with other means of tansporsaior. The dramatic in-

cae eeeipperning, costs hee placed conveyors in an extremely

TRESS poston for applications that Were not considered afew years ago.

Sek Conveyor manufacturers have consistently aniipate the needs

cofindusiy with improvements in designs and with components that have

CEBer a known requirements, Relbiliy and safety arz outstanding now

Gee Slike and more durable belts are avilable, as well as greatly im:

ea nee ania pars and highly sophisticated clecrcal controls and

Safety davies.

Shacied and deserbed inthis chapter re some of the advaniages of

bet conveyors, which ate performing a wide variety of intraplan functions

ea cordon ina more innovative manner than is possible with other means

aerermportng bulk materials, Algo included are examples of relative long

Roane eet eS qwayor systems which are being used extesivly because they

Saree eth ipeant benefits a relly safety, and low cos er ton

of material ansprted.

Conveying of a Variety of Mate

-Thesize of materials that ean be conveyed is imited only bythe with of the

Ta aecrns can rane from vey fine, dusty chemicalsto large, lompy ore,

be ei or pulpwood logs, See Figure 1.1. Closely sized of {tiable

eres ace caried with minimum degradation, Becanse rubber bel ae

Tidy teistant to corosion and abrasion, maintenance costs are com

ahi Siew when handling highly corrosive materils ar those that ae ex,

Ftemely abrasive, such es alumina and sinter.

‘atari that might eause sticking or packing if ansported by other

means ive often handled successfully on belt conveyors, Even auch Bet

eeteals us foundry shakeout sand, coke, sinter, and iron ore pellets are

onveyed sucessfully

|

[ee hr of abate reo inne

‘Wide Range of Capacities

Currently availabe belt conveyors ae capable of handling hourly capacities

in excess of any practi! requiement, See Fgute 1.2. Yet thay are alo wed

‘eb spay soloing fact.

18 canoe Cent Appin td Eon

economically in plants for transporting materials between process unit at 8

(ide range of rater—somedimes a ite as a mere debe,

‘Bet conveyors operte cntinuovsly—around the clock and around

tne calendar when resuired—without los of time for loacng and unloading

Ce Shaty return tips, Seheduling and lgpstcing are necessary a8 the

itera i loaded to and vnloaded from the belt conveyor automaticaly.

Goeraing Iabor costs difer litle, repardess of eapaciyy ratings. Overall

Ceirpertion decrease Gramatialy, however, as annval tonnage haadled in

{fesien, Such economie considerations are Mutated Inte in this chapter.

ior these reasons, bel conveyors are capable of handling tonaages of

bulk spteral thet mould be more cory and often impractical to transport

by other means

Path of Travel

Path of Travel

Adaptabilty

‘elt conveyor systems provide the means of wanspotirg materials via the

{howe latanee between the requied loading and unloading points They

an follow existing terrain on grades of 30 co 35%, compared withthe 6 10

fu eilectve limits for truck haulage, Ser Figure 13. Trey ean be provided

sath structures ‘which prevent the escape of dust to the surrounding at-

tere and are weather protested, Sveh structures areeconomial and are

‘Mpable to special requirements, See Figures 1.4 and 1.5. Belt conveyors

provide « continuous flow of atrial while avoiding the confusion, delays,

Bie safety hazards of ral and motor traffic in plants and other congested

‘nvanmesel protection.

Frome 1. Gable supended rie provide spp for comarar

Paths of travel canbe quite Gexble, and the length af the routes can

be extended repeatedly, ax required. In some open-pit mining opertions,

‘conveyors thousands of feet fong are shied latrallyn the bench to fll’

the progress of excavation at the face,

Loading, Discharging, and Stockpiling Capabilities

Belt conveyors are very Mexible in their capabilites for receiving materia)

‘rom one of mare locations and for delivering it to points er areay as te-

‘quired by pant flaw shets. They can provide the main aneporation artery

hile being loaded at several points (Figure 1.6) or anywhere along thee

Tength by equipment which providers uniform feed to tie bl Figure 1-7).

5

fms ead ape i

fn son al ath

tang, urn and Scion Comming

“They ate particulary uefa in tunnel beneath stockpiles, trom which they

an tela and, where required, blend materials fom varios ples (Figute

418). Material can simply be discharged over the head end ofeach conveyor

(gure 1.9) or anywhere along its length by means of plowsor traveling tip-

pers (Figure 1.10,

b ooeer ed pul

ene 1. Maile fers ua

eh cir cen

‘elt conveyors, with thee stackers and reclalers have become the

only practical means for latge-sealestockpling and recaiing of such bulk

atrial as coal oe, and taconite pellets. See Figures 11 and 1.12. The

‘Combination tackerreclaimer in Figure 112 Mustrates the trend tn mogern

7

ct neers fhe ig conor

apy fed vo sted coneyr em

allo ship terminals. Even the shiplders are equipped with conveyors For

{ling and trimming the holds of vessels at controled rae, See Figur 113.

‘Sttunloading ships and lake vessels (iguse 1-14) equipped with belt

conveyors ean be unloaded in all ports, even those which do not have

‘Sockside unloading equipment (Figure 1-15). Unloading cspacties of such

‘Shaan are ually greater than thore of several rab bucket unloaders, re

uitng les turnaround time and lower labor and other operating costs,

‘fe contrast win he sbovemeativud. hishsapacty unlonding

systems, cerain matelale, such a8 foundry sand, can be plowed from the

BIS leur 16) a1 specie locations in quantiles corrolled by the re

{uirements of the application

=

‘eres Eater

led fed inch conveyor pater a sand from fat eit conveyor

Process Functions

ein 16, Suni i is

repli 1800

ene 1.16: Yop plow diets fry

‘Although belt conveyors are generally ured to transport and distribute

‘materiale, they are also tne with atliary nqipnest lor performing

‘umerous funesons during vavlousstager of processing. A hgh degree OF

blending i accomplished as materials are bedded into sad relamed from.

stockpiles, See Figure 17, Several desinlar materials can te proportioned

continuously onto a eomsnon collecting bl.

>

el acaimer roves 8 fee Of

Und row rare plone

“Accurate samples ofthe material conveyed can be cbiained by devices

: which Qitesegh the tyeam of material ast lows from one conveyor 10

aac ca aie objects ean te removed from the material. While being

wae peered om the conf, Tails can also be weighed accurately and

carly or they eo: sorted, picked, or sprayed. many cases, such

contjgns are nt onl jtformed more effectively In ecnnection with belt

Conveyors but ae the only practi! means.

Reliability and Availability

“The reliability of bet conveyor ha been’ proved over decades end in peas

ray yaousey. They are operating with ee wimestrlalliy, many

cay thal process units whore very suczss depends on continous ope:

seins va Pipandng coal in power plants, and transporting raw Bulk

‘ions eae tel plans, in cement plats, and to and ‘rom ships in ports,

Were downtime is very soy.

Se eons ar operated atthe touch of «buton (Figure 118), 2

any time af tne day ox week, When required, they ca and often do operate

20y nuowaly shift after shift, They can be housed so that both they and cht

cae betie transported are protected from element that would impede

aan ane of tks and cerin oer means of Usnsportation.

&

Esra fro cota eer tk

fovbe dupiy pon ond puto

=

Environmental Advantages

at conveyors are environmentally more acceptable dan other means of

: itasporting bul mateals; they neither pole the sit nox defen thee

i “They operate quiet, often in thelr own ensures which, when desirable,

E anbe located above the confusion and snfetybaacds of ace aio in

{eval tunels—out of sight and hearing, See igure 119. Furthermore, they

a Abnot contaminate the air rh dust orhyrocarbons. Ai waster, dust can

4 be contained within transfer chutes or coeed with suitable equipment, if

pecrsay. Finally, overland bel conveyor stems ean be eid (ond

f inothe landscape, ling a nacared, qu, and polton re operat

ton See Figure 120.

cin 1.18. Coneer in comply ened galery Few 1.20. Ovid contro se ng ¢

Er I fod fy ovr avg anprnce Sone ppt sue roi» Pn ppearnce

From ghey oa aie Blending wi hence

”

safely

‘net conveyors operate with an extremely high degree of tlt. Few person-

Bal omweyor for operation and they are exposed 10 fever hazards than

Bea rears of wrensporation, Mterial is contined onthe bel and

rae int arent endangered by fling lumps or the maluntion of hugs

are comport vehicles, Such vehicles also involve polis lability,

apetner thy operate over highways o nother areas acesbe to the public

dae ercjon offer les hazard ( careless personnel tunis inerent in

Also, conveyor ore dng bull materiale The conveyor exuipment itself

eens Mrotected from overload and malfonction by bult-a mechanical and

‘ecarial afey deve

‘Low Labor Costs

“The labor hour per ton required to operate bel conveyor tems are usa

Ter fines of any method of transporting bulk mateies. Like other low

eae Gre, nigh automated operations, bek conveyors have Tow

BpSting con and provide a igher return on fnvestmert than competitive

aera Mort functons ofthe system can be monitored. rom & central con

Tat pare! or controlled by computer, allowing a misimum mumber of

el Ring perenael to inspect the equipment and report ondtons that may

quire attention by the maintenance department

sree ioe rained for maintenance personnel is also minimal. As

‘oted below in egatd to maintenance cots, tepals and weplacements ofthe

pene ivelyemall pans can be made quickly atte site. Most belts can even Be

raed sone altand sore bes have conveyed wd oer 100,000,000

‘enlacsfone wearing out. Later in this chapter several examples of long

Soest soveyor systems ilsrate the effet ef lov labor costs.

‘Low Power Costs

“The increasing coe of energy emphases the importance of power and its

‘Rhation tothe om per ton for transporting bulk materia, Because belt con

were re operated by eletse power, they are lst aleced by the prices

Tee ees abs other Hitations of Uguid fuel. They eonsume power only

rao are being wed. Ther sap need for empty retro trips or idling

Weta ke nex oad, On Jong eyems the declined portion often assist in

aoe ae am ncined or horizontal portion. Some enveyer ssi a

crometelyrgtnertve. See Figre 1.3. The cost of pover for belt conveyor

Paar tis ays contibuted to thet exremely low operating costs, a5

Tree muse har pcrensed substantially with the rsein the cost of guid

fuel

Low Maintenance Costs |

Maintenance cout for belt conveyors ae extremely low compared with most |

‘other means of transporting bulk mates. Extensive suppar systems, such

45 those commonly associated with tuck haulage, are nt required. Compo-

‘ent parts are wuly housed and have very long life compared with that of

] motor vehicles. Usually, they need only scheduled Inspetion and tubrica

tion. Any reptce or replacements can be anticipated and unscheduled

downtime avoided. Parts are small and sccesible so ceplacemeats can be |

‘made on the site quickly and with mininal service equipeent. Also, ade

‘quate inventories of spare parts san be muintained ata low ext and require |

Felaively le sorage space,

[Long-Distance Transportation

‘The economic beefs of low operating cst for Ibor and energy, a well as

some ofthe other advantages outlined above, have led 108 widespread edop-

ton of belt conveyor syetems ara mesne of teneportng ble mata over

Increasingly long ditanes. Not only were these systems the best investments

atthe time they wer installed, but the recent dramatic increases in the costs

cof both labor and liquid fuel have greatly enhanced their present value. A

few of these systems ate deserbed below.

Seattle, Washington

a ‘The system shown in Figure 1.21 established a landmark inthe use of belt

conveyors for longistance transportation of bulk mater. In the late

j

i

L2fly mover ected mater rough

rari sco ef 0 see

B

Pela, lovers 2,00 ph of 0 do

Sip ae wale ppg eerie

18205 contractor pioneered the use of belt conveyors for relatively longs

lstace haulage by transporting $,000,000 yards of excavated materia fom

Denny Hil downtown Seattle to scows Waiting inthe harbor. It was so

ighly profitable sd dependable that such systems were later adopted by

tthe contactors, Now they are commonplace in the construction industry

in cases where large tonnages must be transported economically,

Lost Creek Dam

‘A recent example of belt conveyor haulage on a construction projec isthe

{1d instalation at Lost Creek Dam on the Rogue River near Bedford,

Greeon, (See Figure 1.22.) Army Corps of Engineers plas had indicated &

fo,o0o-foot, 8% haul road down steep mountaiside Tor handling

7,000,000 tons of shat rock fram the quarry to the dam ste. However, the

Satzactor used one St-Inch wide by 3,000 feet centers bt conveyor down a

1M decline to underbid his competitors by several milion dollars. The

following benefits were revealed by his economie sud

1. An inal saving of $1,800,000 investment in traces was celled,

‘idan entiated 1.37800 gallos of diesel fue ove theif of the

Drojet wat nat required,

2. The cost of constructing the haul rosd was avolde, as wells the

tnuch greater cst of restoring the terrain as requirsé by the Corps

ff Engineers specifications.

3, The conveyor was reeneralive and its motor generators supplied

Enough sleseca energy for the projest and returned the exess 10

the local public uty.

4, A substandal saving in manpower enabled the corracor to bid &

price 33,200,000 below his next competitor.

5. The project was completed ahead of time becaute tie conveyor

handled 2000 sph, whereas che Schedule was based cn 1200 tp.

6. Thesafty hazards and maintenance cot for trucks operating down

‘an 8% winding road were eliminate.

One man monitored al exitcal points of the system on dased-irauit TV

from his staion on the loadout hoppec. The system was protected by

humerous safety devies, including magnetic braker whch stopped the

loaded conveyor within 23 feet fom 450 fp.

(Oklahoma Cement Plant

‘Another example ofthe economy and adap: ability to terris ofthe belt cone

‘eyor Is use in this Simi sytem (rm quarry to ml st an Oklahoma

cement plant (Figuge 1.23). The eximated total ditect and fret cots per

ton for flload, truck, and conveyor haulage areas showe below

atimated Cost Per Ton

Belt conveyors Truck allroad

Half prodvetion base ae

Full production 26 ates 3

‘Trucks were ruled out not only because of thee higher costs but because of|

hilly terain and the necessity for eossing two railroads an two highways.

‘The disadvantage of rail ransportation Was the need for exeasive trackage,

‘witeers, loading and unloading, and storage. Also, eeheduling and dis-

etching would pose problems for full production,

ene 123. 34 me reson comer gate allows materia

{Si mans imecone fom gary fo een ma

|

‘After the fst year of operation it was found thatthe cost per ton for

conveyors for ful production was only 13.3 cents, compared with aa

tstimated 21.6 cents or 2.4 cents per tonsmilel For half production it was

Ss cents pr ton. This was doe fo an extended depreciation petiod and the

fact thatthe enti eystem was operated and maiatloed by ely two men and

supervisor.

‘Texas Iron Ore Mine to Stel MAI?

‘A Texas see! plait was faced with mounting costs for eranoportg sky,

brasve iron ore from the nearby mine to an ore-washing plant adjacent to

the ml. When the operation began in 1946 the mine was about a mile from

the plant, but by 1964 te haol had Increased to 5.5 miles. At that distance

the haul lone wae costing 6 cets pe ton-mile which represtted 55% of the

total est pr ton for mining and delivering the are othe washer. Te was then

that an eaaustive feasibility study was made of all operitons, from ex-

‘avating and loadiag inthe pit through transportation tothe washer.

"The elimination ef trucks sea shutle between loadig machines and

mainline haulage war not considered, cue 1 the rapid prozess ofthe min-

ing machines In the shallow ore bodies andthe need fo mx ores from severl

Toeations The problem was to determine the best method of ransporting the

ore from trek dumping station atthe mine to the washer A rll was

fled ut because of the lege capital investment in equipment and terminal

Facts a5 well anticipated eiffcues ia handing the sicky lumpy ore

“pipeline for the mala transport appeared promising aetording to

preliminary estimates, but further consideration was abandoned because of

1 The dificlis of eruhing the sticky ore to minus 2 or 3 inches at

the mine

2, Unavallabity of water and reservoir sits.

3, The problem of desiging pump suitable for such coarse, sbrasive

fore, a wel se Wear and mafntenance costs Of pipe and pumps.

4 Undesrabiity of eeating exces fines and the need for ther subse.

quent agglomeration

Dewatering ane storage of ore at che rill

{Gearing the pipeline in cate of mil stoppages

‘An alltruck haulage operation, with an-investmeat in nev, lrser

trucks, was eslimated to be much mare cosdy than belt conveyor haulage

‘Aso te ditference would increase athe shallow ore bodes were mined out

fnd the length of haul increased (Figure 1.24), Inezeases in he costs of labor

fd ig fusle could not be sntepate atthe time this study was made, or

the estimated economic vantage of belt conveyors would have been much

reser,

Jamaican Bausite Mine to Seaport

“The adaptability and economy of belt conveyors for tansporting bulk

‘haterlals over rugged train derpite adverse weather cond fons is Mustrated

vag of te

‘roe ng of ht eer en as

eae eee id

by this system designed to deliver 130 ih of bauite frm are dryers tthe

mine to port fcity in Jamalea, Se Figure 1.25,

“Tae investment decision for this system was based on an intensive

‘economic stidy when was derided to incense production a the mine, The

"ammo 30 ph of ut er

‘sed ein om mn pt ly

”

aoe ont Art

existing tran was inadequate forthe increase so the economies of truck,

SERRE Stumling, pipeline, and conveyor haulage were analyzed and such

arte eras api, reliably, and the effects of weuther wee 2on-

Sidereds The eesls ofthe sudy are summarized below,

Economic Comparizon*

Conver Rairoad—Trumlng Truck.

Distance from mine 0 or ils) 6s 140) 6s We

Relsvewansporaion east per tnvmile 1.00 te oe 10

[elas anoperen sot parton 10 13s 26

Bele api cost 100 a

“The pipeline method was rected besause ofthe serious problem of

dewatering ihe sured bauxite, Truck eosis per ton were not only higher

sree SSnveyor cons but operating problems were anticipated due to tropical

ae teen sanfall of six inches per month and frequent dense fogs). A

WSvead Grould also ental high operating cots because ef the ereitous

rant own long erades and over deep gles subject. floating. The profile

veeie conveyer route (Figure 1.26) soguess the considerably Tonger

lsances that would have bean required for both trucks andrairond because

criti inablty to neyotiate steep grades. The resulting higher costs are

seo pave, Actual power consumption by the belt conveyors i low since

RS'ny Toned system fe virally in balance, The power generated by the

PRnT escent ofthe material is about equivalent tothe power demands 10

onsale belts Spare pars are minim beease al belts are identical and

aoe ae ni tuo aes of speed reducers and thre sites or types of motors

‘Par jt re covered to protect the dried bauxite from the weather and the

se pelts are of the "turnover" type to prevent buldep of ore on the

eum ile

‘Ove and Waste Haulage from an Arizona Copper Mine?

CCharactristc ofthe open-it copper mines in Arizona ander parts of the

nee Gide pret depth. Often tis necessary to remove several

seat fet of wane fock and alloval gravel 1o reach the uppermost ore

andi ay operaens employed raloads to haul th ore and waste over 2

aa eae geo the trface, Then orks became more economies! fr the

decree Iading shovels up 80k grades to thecres of thepit, and on tothe

primary crushers.

gab cgew mine was opened in Aszona where the ore was overlaid

with 700 feet of waste rock and alluvial gravel. Based ou cahausive

wren ree feasnlty studies, bet conveyors were installed to vansport

seenemg inch waste and ore from primary rushers nth pit wo the surface

mittjon to waste dump and ml. See Figures 1.27 and 16, The sytem sue

ree tals justifies peetmvestment calculations. A fringe tenefit of the belt

ee

B a ee

a

i

pio ts

i Fame 126 conor patie

‘conveyor system eit environmental dsrailisy—there i pracealy no dust

i ischarged to the air and noise pollution is practically nonexistent. This is

particulary important because of nearby relrement commusiy

ewe 1.2 Agdacpacy conser ote ft 3.00 ph of ato

oper oe frm prnary eases pt pond anor moa

|e Campa Cann peo ad Ewan

night ofthe experience at ths min, a study was conducted in 1973

to comeuttsnveyor and irk baulage for a similar but hypothetical opra=

+e cor coy rae based on recovering in 20 years 200 milion tons of re

‘ion oe ih 20 fet of waste rock and gravel, where the wase rock/Ore

ore il Individual studies were made fr ore and waste a5 well s for

cs ee nd trek mses. The combined resus are summarized in the

Soret am fe heures foreach sytem Include & 40D-foot haul from pit

tae acme dump and a 1000-fo0t haul for ore to mil, The adverse grade

tobi ret for tucks was figured at 8% and for conveyors 25%

“comparsn of irk vss conveyor Maalag pit with annual rma af 30 ition

‘Samifton waste 10 lion oe 108)

sone ised

rrcincay commen “anno i

cin ena th Sale

ne eer re a

S ghee BSE oh eRe ee

2 Soe i ESS ik ee ie

a ee

Cbviously, for these tonnages the conveyor was the best veskmet for ait

Sv eso fet: and would become more proftableas the depth ofthe

pit Increased,

reir comparison today would be more faverale 10 conveyors

‘peeause of ineeassin the costs of tabor and mor fuel aswel a the efTect

bestiaton on the replacement cost of trucks. Repaciment costs for the

aoa would te limited to beking anda few reatvey small mechanical

Sand eletieal components.

Moving a Mountain 19a Cement Plant

tn contrast withthe sbove examples of conveyor systems operating Ove UE

In sontin’and fom deep pit res, this 4mile sSiem operas Over

ed eave Adtona desert, See Figure 1.28, The system haul the stone,

te ad lc atx substantially Tower cost per ton thantrocks, eventhough

‘REC are excellent rads between mine and plant

Te esGhign 1a tz economic advantage over tucks, the conveyor

system has inereang design fetures:

1L The system consists of only two conveyors one. vonveyor

pide to the design ofa high percentage of conveyors which are required to

Dictate under retsonably normal conditions. However, some conveyors

CRerate under conditions for which complete data are beyond the scope of|

‘ie Book, These design problems usualy require brosd expesience for &

‘htisfactorysoluon. A CEMA member should be consulted in such eases 5

Te erin he denign of very large conveyors or complex conveyor systems

DNasutance from CEMA members in meeting special design requirements will,

insure optimum economy and performance.

{uit conveyor design considerations and the leaton of dts pertain-

ing to them are outlined below.

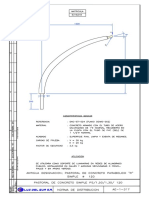

Conveyor Arcangements

Bek conveyors can be arranged to follow an infinite numberof profiles oF

paths of trwvel, Among theze are conveyors which ae horizontal, inclined

er eatingd or; wih ihe inclusion f concave and convex curve, any com

ination of ese, also, numerous atrangements are posse fo loading 1°

land digehrging from the conveyor.

The Romencatue of typical belt conveyor components is strated

below in Figure 2.1, Various arrangements are iiustated in Figures 2.2

ewe 21. Nomen of componns ofa pi Bl omer

a

a through 2.9; loading and discharging arangements are shown in Figures 2.10

‘hrough 2.18. In addon, belt conveyor stackers can be connected {0 a

Inainline conveyer to stockple material several hundred feet on ether of

both sides into pies of any practical length, as shown in Figure 1.1 in

Chapter |. Ore combination stacker elalmer (Figure 112) an be wsed (0

‘stockpile material oo resaim and return it tothe man bel conveyor.

‘Belt conveyors can be designed for practically any dered path of|

travel, limited nly by the strength of bel. angle of ineine or decline, oF

a Svalabe space, Some ofthe profes shown below ate more desirable than

t thers, For example, ransfers beteen conveyors should be avoided where

possbiedveto acdional wear on the ella he Hoang pois, Justis,

Ena possible plugging in the transfer eles. For Cree reason, the arrange.

tment in Figue 23 i preferable to those shown In Figute: 2.$ and 27.

= =

‘TYPICAL BELT CONVEYOR TRAVEL PATHS

——— = —

Fee 26. Arceaig and Rou

Jat hes vane Oo oer

— =

ran 23, Hone on cme

Gent utlanton, and reasonable if expectancy ofthe equipment.

Chapter 3

Characteristics

and Convyeyability

of Bulk Materials

Contents

Material characteristics.

Behavior af materials on a moving belts

Effect of inclines and declines; Materla cass

“The succesful design of a belt conveyor must bepia with an secure

“ppmanal of the characterises of the material to be tanspored. A few

l Jimpoctant characteris require definition.

‘The angle of repose of material i the angle which the scface of a

normal, freely formed ple makes tothe horizontal. A

‘The angle of surcharge ofa materials the angle to the horizontal

‘which the sutface ofthe material assumes while the mati i at rst on &

Tnoving conveyor bel, Tie angle usually is 5" to 15" esr than the angle ot

fepose though in some material it may be as much as [0° less

“The lowabily of a materi, mr mestured by sang of repose and

angle of surcharge, determines the cross-section of the material Lond which

{ay can be carted ona el Italo is an index ofthe safe ange of incline

(ofthe bet conveyor.

‘The lowabiityis determined by suek material characterises as: size

1 and shape ofthe fine patces and lumps, roughness or smoothness ofthe

Mitac of the material patie, proportion af fines and lumps present, and

mole cootent ofthe materia.

| ‘Table ol ilustrates and defines the normal relationship ofthe fovea9~

ing properties andthe general characterises of materia

y | Sanu3-L_ maby Ange of Sersege—Anale of Repo

rahe

4 FES | runnin |__ aversion mai

Le ated | Wagar | ie aeaee |i age?

ple areca [arene |e ree

I me er

Poe | eat | etme | Pyro | “ormoa

Ta hrc

1 aon | set] rr, wn- | Toa co | i,

Galore Ree aa | tee anay | menue | wine rs,

[ane | Sens, | Soeirel | Sth ca | ng ie

1 cater naar] maa, | Mcrae || Gaerne

wae See Speen

Seo Smuce we

1 cae =

11 »

1 charcttad Con Mat

Consideration should alzo be giv. tothe weight per eubie foot ofthe

material; Ha Gusiness, wees, ste sess, abrasivents; its chemically

Corrosive action; and its temperatore. ovine general information concerning

‘hore properties of many materials Is given in Table 3-2. Table 33 gives alist,

ff materials wih ther piyscal characteristics and clasification code

‘esignatons, Ie must be understood the: the data given inthis table ae for

Sverage conditions and average mates. Each characteristic may vary in

Specific instances, especially angles of repose and maximum conveyor

inclinations

Proper consideration must pe givew to these materials, the

characterates of which vary under various conditions of handling,

Stmosphere humidity, age, or long storage. In some eiss, accuracy may

Fequire chat carefully conducted tests be run t establish the materiel

Characteristics under the required conditions.

‘Materials or characterises omitted from Table -3 may be roughly

appeared by comparison wth sted materials ofthe same general type

Behavior of Materials on « Moving Belt

‘Autention must be drawn to he fact thet the normal characterise of

saterals ae considerably influenced by the movement, slope, and speed of

the conveyor belt that caries them.

‘As the conveyor bel pastes successively over each carrying ile, the

material onl correspondingly agitated, This agitation tends to work the

Inrger pices tothe surface of the load and the smaller particles or fines othe

‘potions I alo tends io fatten the material surface slope (Le. the angle of

Surcharge) and explains why this angle let than the angle of repose

"Any cfernce between the forward velocity of th materia sits be-

ing loaded snd he conveyor bel that i receiving it must be equalized bythe

Ssecceration of the material This acceleration cause: turbulence in the

materia.

“Any vertial velocity of the material sit is beingloaded mst be ab

sorbed in the eesilent construction ofthe conveyor bell nd the impact ilers

{eed uader the loading pont. In this proces, a further inrease in material

‘urbulence is produce.

“These ive influences are emphasized when the conveyor belt igon an

Incline o dcine, and azo when the eonveyor bel is opeated at high speeds

‘These influences are emphasized ern more when the matetlal banded is

Tbuce and contains ree rounded | ng, such ar cone washed gravel, he

tendency of which ist Bounce an= all on the eonveyor bel.

fect of Inclines and Delioes

“The nominal eros section of the material on a horizontal conveyor bet is

‘measured ins plane normal to the bs". On an inlined or declined conveyor

Deli gravity necesiates thatthe asual eross section of the load be eo

int Cuts

sidered in a vesteal plane. To maintin the total width of te materi oad

on the bel and to mainiala unchanged surcharge angles, the sross section of

te load pouble onan inclined or declined belt most be les than that on &

horizontal bel-Referting to the diagram wed inthe derivation of belt con-

Noyoreapacty (Figure 42) the area A, doesnot change although thearea 4,

‘does decree athe cosine ofthe conveyor sone.

‘The total effects fafluenced by the surcharge ange at which the

material will ie on the conveyor belt. However, in most eases, the actual

Tose of capacity i Tess than 3%,

Si folowing three precautions may well be obseved: lumps are

more ley terol aff the efgreof inclined conveyor belts than horizontal

‘es; for bells of constant slope, the spillage of material x more likely to

‘cast immediately beyond the loading point, materials which aerate ex-

keavey, suchas some very fine ground cements, o materials in which the

Sraporon of water fs high that a slurey is ereate, must be eared on in-

nes and at such a conveyor bet speed that the tendency ofthe material (0

tlie back is uly offset.

Tone33._ Maver Cas Deseoion

Material harris aa]

"Wey fine 100 mesh ad under

Fint—I/Sineh ad under

Sie Granale—Under 1/2 inch

impyesonalning lamps ove 172 inch

Iireguareingy, eek, mate topes

Fowablig | Very trelowingange of repo les than 9

semen | Fr owing ane af repose 20" 1029"

fepese IAveaueMowingeanle of repore 30" 1 39°

Siogat—sogle repose #0” and over

‘Nonsbeave

JAbrasinenes | Very abrasive

"yary sharp gure bl covers

UAraes and develops Sid characters

Consing exsist

Micelinecus | Contamina, affecting or saleby

‘Ghoraensics | Degeadabl, feng ue ot slesiiy

dcuangwzzr|esaulaens|mooe>

(Goneiines Gives off barmulfures or das

“more thon one | Highly corosve

Gritee | Milly ease

Choractertir | Hygroseone 8

‘mar apei) | Ineloeks or mats

‘iso chemin present may afet rubber

‘ery Hgbt ane ty maybe windswept

Elves temperature :

Someta ene

nce

oa wa con psn wold

“Tame 3:3. Material Charis ond tight Per Cubic Fo

OO Aiea Recommended

Average weight “repose. maxima

Material fissperca])_(dewees)__inlinrian code

ifs weal 1” 4 er

‘fal pallets Aa 9 a

‘ais ed qos 2 B26

‘Atmonds, broken or whole 20 sone 80)

ime toe 50 so ms

‘um, ly soe a Bos

‘aura 065 2 os BM

“Ataris chins as & eae

‘Atuminor hyarate ® 4 no con

‘Riuminam ore

ies be -

‘Atuminam once » iam

‘Aluminum sete Soe Biss

‘Aluminom sulphate 2 ” By

‘Ammonium elo, crytaline so Boss,

‘Ammen nz so seasnus

‘Amvmonfum sulphate (rants) « sastu

‘Anuimonr powder soe ne

‘ple joe Rs

‘ater, plverictd 229 ory

Arsenic onde soe perry

‘ebro Fe or rock ne ome

‘arsests, seed & EasKy

Ath, nac, round 2 ” B35

‘Ashes omy. 3 ich & under & Deer

‘ones coal wet, Soe & under % bast

‘Rene, 9 a ms amt

‘Repl bade for Fain cas

‘Ripa rushes inch ender sou as

Bagase 6 Eesy

Bekele & sme plats

‘Gowsered) s Bas

Baste sot 26

Bevan erbonate 6 re

Burm enfbonate Mer eke 2 a6

asim Hysrate a he

Barium ove hes

Burk, wood fuse 6 » Easvy

Baer 2 ioas B25N

Basalt oe m6

Brow, grounds dey 09 » 2s

Basie mine Fi i Bt

Brute crushed, 3 ooh under joss 0 or

Bean, castor, wise 2028 bie ease

‘Beans, esr, eal Bi

Beans oar. 07 » es

Fees

ett Cmts;

poe Sine

gis of Recommended

Average wet “rouse” matimam

Marie spore) __Gegrec)___Ininion Cade

eas, ay steeped @ 340 Bs

Boe pulp iy ras Es

es pl, wet 254s 56

Bee, whe a 2 =

Bentonite crude 3540 aa Diex

‘Benoni, 100 mesh & under 50-8 a » de

Bone sso S te

Boneack, 109 mesh 2 wader nas 20 sy

Bonechar 0 sos im

Bonemea! 50-8 soos 26

Bors of fine o jose a

Boron, Velnch sreeinge $5.00 io oe

Borat 2 och snd under on jose Bs

Boreal ne Ss ne baer

Ban oan sos Bashy

ve ain, spent ey 3330 6 es

Brower rainy spent me 50 Pa oor

Brome chips 50-30 sr bo

Buckwheat moa 3s BIN

Cali aide (rushed 1-30 sow as

Grbon etvateds dy ae 20 a8 mst

Gatton viet pleted nas 3s md

Extson tack: powder a sos “as

ateorunum, 9 inch an under 100 m9 bar

Sceen 38 sos Bis

Gas on chips 3-120 ‘ os

oust soda oe 45 a6

Cement, Poland 99 sos 20-23 aM

emer, Porand, arated 7s net

Coren, rock Ge inestone) toostio bis

Cement anger 15098 so-so br

Sea ty 55 s Dis

Charcoal tas 35 sg

‘Chrome ore chromite) asst soe Dan

Cinder, ast tarnuee a Fi west

inde, coat “ 3s Ey a

Git Gre ato bentonite,

atomaceous earthy filles «

fark, Kalin, and Mat a 2

iy. ales 0-100 im

Gay, exami, de, Hes 0. sos as

Gay, dy cs foosi20 3s wa a

ay dr apy eos is e0, Bas

Ginter Cement Ge cement ines) E

Clover teed a 2 "

‘Coal antrate, river, or ln, me

1/8 inh ad unde o 3 6 mr

e

ume ad Cnn fo Mat

‘Fue cond

oe

Average weight “repose maximum

Moveril (iseper caf) (depes)___lnsinaion code

“Coa anit, sed ee

oat bwin, mined $0 mesh

‘ander soe 6 “ Bast

cont iinous, ined & Sed ass % is Dist

eat ituminons, mined,

‘mat ne ws s ” post

coat biruminens, mined, slack,

"inch der 0 o 2 ost

cou, borin, sipping,

"ot cleaned 0-60 ser.

os cy 2 ser

ws sos 330.

Eecoe avs 3s ne Gs

Corte, call 2 29 baswy

‘Coffe, een bean has iow oss esa)

Coffe, pound 2s B ra as

Cole, fasted bean as casPqu

‘Goffe, sble 8 BASF

eke, oose Bs wot ws BuIQVT

Cote pstleum clened sas fae Fy boey

(Coke eet, i neh and under 28 woe on cr

Eempost ie-50 East

Genera, cinder 0-100 1230 bie

Copper oe 120-180 most 2 “Da

Copper ulate Ts.88 Ff » Dae

Cork ranslated ims as

Gorm cached 4550 sw

Comm ea se

orm, sett & 2 o con

‘Corn 3 ary Bs

Gorm germ 2 BSW

Cora gt fos pst Baw

Sorneal m0 is a ssw

CContonsce, dey, deinted Zao » 16 sw

eironeed ry oe de-ted isas Fa 8 osw

‘Coonseat eae, crushed rary ou + B35

Coonseed eke, PY fous jou Disw

‘Couonseed pul 2 S *Bay

‘Coventet teal 30 3 2 Bas

avtoneed mets * cose BSW

racking ered,

inc der os0 6 pes

notte tus 350, soe 6

‘Chale my iv poe Bee

Gilet to-120 io » Bz

Dfatomacsous earth nae wots axa

20.50 s ies

Mant Che

in continued

eee

‘©

a Average weight “repose, aia

} Morait (ibaperce fe inelnation code

‘izodiam phospate 25-01 30-48 meQr

fy Bolom, try ‘e-00 ost n De

| atomite pulverize “ a bie

| ath as etcaated—ry 0-80 3s 20 mse

} Exh; we, conning cay too-10 & a Bas

Fi Btonits cuted ich & onder 65-70 ed cs

Eprom sats foo Sout as

© Retdspar, eine eeennas ros ss 1s Bs

elspa sto 3aneh lm sito ue a Bae

Feldepe, 200 mes foo soe ro

1 Ferrous eartonate i590 so B36

Ferove slate Sots os

Perouse oss 09 Gs

Filer pest med, soe factory 0 Als

ik meal 3540 basw

Fish evap 0 BW

f) Fsseed 6 a a msNw

sted mea s ow Bisw

Flour, west ss40 3 2 ASSEN

Flue dus, baller house, ry 30 co Aumre

Forepa, ich serecaines Sscios s 6

Forepary |i t0 Sick lamps Hota a bes

Founy flor sidan coer, ee, 70=100 soe baz

f) aes ear, iy sos » Bas.

Pls ene, oly ous no Bas

Flere eat oer, burned o mo 326

pp Palle eh oi iter, aw 40 as 30 +25

(lena (ead sue) 0260 sot a6

‘Giss batch exe ibe sla) roy o-10 ‘ism

‘Gass batch (woot & cone) ‘00 so on Dasz

‘Gein granted 2 a asa

‘Glue, ground 1/4 inch and under o oe ae

Shue peat o B ” es

luc, vxsable, powcered o fonts

lutca eal o sone asp

rain itr, spent, ey 0 soe Bay

Gain ly, spent, met a0 s cay

© Granta, eine sereeninas m9 ar

(Granite, 17-0 ne amps as-50 ce ber

Grae, broken 95-100 sot bar

Take o so 5

Graphite, our a na x

Grapite ore ss sos or

Grae seed tok. so BSN

Gave, ba |

Grave, dy, sharp

(Grave, pebbles

Gypsum, vine sreeings

Gypsum, (eto dneh lumps

Gane, ey

Honiey

Hops spt dry

Hops spent, wet

dee, rushed

Iron oe

Irom ponte

Iron suphate

Iron slice

Kaolin ay, 3 ach and under

Laie

Usd ene

Lind etvonte

Und oer

Lind odes

16 oes, avert

{end si, panaated

6 ta paver

a mae

Ups sicred

tiered 9 oh and under

me Sprated, 78 ch under

Une tert pulverized

ime pebble

Limestone earl

Tia neh ander

Lesions, estes

Uae ake, pense

Lines eal

Magnesium ehorde

eM tgr armed, 8 och and

‘nae

Mat dey, whole

ft per ef),

fe-00

8-10

a0

0

sr50

Sess

ass

toni60

"00.200

bets

275

faosias

e

2

imam

0

2

3020

woes

20

ss

5-50

3

fes0

2

oes

asle oT ‘Recommend

‘moose man

(days) __incnaior_ote_

3 Ey

oat iss

xo 2 Die

« a 6

x 5 Bae

das me

ost =

4 Es

‘ Est

8 bis

soe 5

us 20 bas

so Bas bsrq

sos

joe cas

jose Ed

as 8 ss

owe aasrx,

6 Bas

noe Aon

x 1s ie

6

Soe

dost

a 2

a a

you me

x is Sex

yout sw

x 0 Es

“ os

ot unk

ae av

6 os

=e

ome continued.

“le of ‘Recorded

Avwage wight “repore maximum

ert (is peru fi) (degre) Inelnaion cote

Wa, wal 16 soe ms

Manganere once © :

Manganese re as. 2 0

Mangsoese oxide ta sas

Manganese cllte 0 joe

Marbles cute, oss jou

Mew Sosy soot

takes roa i»

I: died, aked sé jos

yey power i s

ils sated eas &

Mik, whole, powdered a moe

Mat scale fons 6

Mil maize 6 caw

sMebyodenite, powdered io o as

Malyodenu ore i o

Monososism phoephte o ue

Masta sted ss a9 maw

Nephelene aye soutas so B36

Niacin 3s sot 26

Nickelcobal sft ore too so sort

Oats, rolled a0 Sota Gay

Steak 0 & Dew

ral sc cryatat o sous Bassu

Oyser sels ound, under och S40 joie csr

‘Oyster ses, whole » so bisty

Paper pulp sock om » ssisMv

Peanut, in els ise ose asq

Peanuts, shel sss oe cq

Pear ded is ‘aisng

Peirleum coke (ee coke) =

Phoephat ai, fern @. Pa a mast

Phosphate ipl super,

round etic sos 6 Py past

Phoepate roe, broken, dry iss 5.29 ins Dis

Phosphate rock, pulverted a o 3 Bis

Polyctsene piles ss B 32379

Polysyrene pels s a BasPQ

Polyvinyl corse ooo ‘ AGRE

Potash multe ey mo an

Potash (uit) ie ran 3 oe Br,

Potash sal, sie, ee. % 209 bast

,

“Tam cominue

Materia

Poussum elorie, pellets

Pres, von, 2 10 neh homps

yes, pallets

(quar, Ynchsrenigs

Gaara, eta Since

Rice, hlled or polhed

ie, rut

Rie wis

Rock crushed

‘Roky sot excavated with shovel

Rubber, poled

‘Robbe, ela

Bye

ye meal

‘Sstoner ake

‘Sitfower meal

‘Siler sect

Sabie acd

Sst, common dry, coarse

Sal common sy, ine

Sal cake, ay, cscs

‘Sa eake, dy, pulverized

Salpeter

Send, bank, éamp

‘Sina, bank dry

Send, core

‘Sind, foundy, prepared

Sing, foundry Hakeout

‘Sand, sie, ory

Senaione, broken

ge, diet

‘Some sae, ma

Site, broken

Shelae

‘Shes, powdered ar pranlaed

‘Sis ge lin ad, ry

Average welsh

{ibe perc 1)

o-10

tei0

ae

asias

0-00

90

seat

Bas

estes

too-ii0

30

aus

3500

0

oss

&

oats

Tos-t30

sito

6

f-00

$100

S100

50

pa

0

ass

50-100

190

0

3

Aone

aezres

2023

so

ne

ry

&

so

ms

oe

3029

s

2

iB

ou

sa

Pa

Xe

ne

&

a

»

29

5o

Pe

&

Recommrnded

incinion

na

a

Ey

nn

Ger

basruw

Berw,

Bent

ast

Br

By

Ba

De

ay

Bsw

Dasoz

ae

cas

Sispy

er

t

— > oy

= =

Materiat

Sine

Sg, Dat fornace, erated

Slag, furnace, ganar, dry

Sag, fernace, granular we

Sat, eushed ch under

Soap teas or granules

Sods ath, biquetes

‘Soda ath bears

Soda ah, abe

Sodium suminate, around

‘Sodium slaminum sue

Soclum antimonts, crushed

Sedlum arte

‘Sodium phospate

Seatum slit ry

Sorghum sed

Soybeans, racked

Soyoeans, whole

Soybean ce, ove 4 inch

Soybean fakes, ra

Soybean meal cold

Soybean meal, bot

‘arch

Stel chips, crushed

Ste riminge

Sugar a, ape

Sugar, fined, arama, dry

Sugar cefiod, pana, wet

Sugar beet pip ry

Sagar beet pul, wet

Sonar cane, soiog

Sulfate, ershed, Hach & under

Sulfate, powdered

‘Sulfate, 3 toh and under

‘Sonflower txt

“Taconite, pees

Tale, vein seeeings

‘Tle Weta Sach laps

Tnoay seed

Tian onde

Tianiun Sponge

‘Tobacio stems

Average weight

is perce

100-135

90

ass

0-100

tom

sas

Ey

2

%

ss

%

ina

soo

oe

«

*

25-50,

rid

65

5s

5565

2s

0-8

aoas

116.130

50

55.95

Fraleor

rnpose

ears

Fa

=

sot

2

sos

Soot

3

B

&

x

Bae

2

na

joe

ioe

3s

4

ma

ins

Sot

ioe

jose

ne

ne

co

%

%

%

bas

02

is

i»

2

saa

ra

1620

a

cote

‘az

cu

Be

a6

50)

Ge

Aer

Bae

6

“Das

336

Bis

eaeNw

con

basw

sy

as

Bist

Bs

barwe

BV

Basrx

Basu

casx.

ex.

Gsns

DasNs

pag

es

336

BAQy

base

Buy

or

Tame3- continued,

Gasie af Recommensed

Averoge weight “repose mania

Moree, (ibe per cat inetination code

“Trapror, 2-1 S.neh lamps 100-110 3044 ba

‘Taleium phosphate 21-30 ie as

eso phosphate o De

‘Teen phoepnate, eraser 2 vou " me

Tetum phosphate, puvered $0 © 2B Bas

‘Ui pile, ry as a Bs

ernie, expanded 6 s cosy

Vernet oe 80 2» Day

Walnut shel, rushed seas soe Bn

Went rar FA 2 sy

‘Wheat, cracked ss out Bsn

‘wheat gem, ry eas m2 Bas

nie le 3s.100 sos ASM

Wood cise 1030 & 2 easwe

Wood chips, hogae, fut 525 a Des

ood shavigs Bis sv

Zine concentrates sto Bas

Zine sre, crushed 1 2 :

Zin oe, roaee no x6

Zine oxide, peavy 50-35 nex.

Zine suse ame ons Aes

i

a

Chapter 4

Capacities, Belt Widths,

and Speeds

Contents

Belt widths.

Lump size considerations.

Belt speeds.

General recommended masimum speeds for specific matertals

Belt conveyor capacities.

Troughed belt load areas.

Flat belt load areas.

Capacity tables and their use.

F

j

:

1

Bele Wiethe

as eeeeeeeeeeeSSFSse

‘The width of eomunyne belts euttomaily i express in aches. The belt

widths treated in this manual—and which are avaiable (roms eeeeiny alt

‘manufactrersin the United States~are a follows: 1,24, 30,36, 42,96, of,

0, 72,84, and 96 inches,

(Generally, for given speed, the belt width and the bek conveyor

‘apaciy increase together. However, the width of the nareowerbeke mse

governed bythe size of lumps to be handled, Blt must be wide enough So

{at any combination of prevaling lumps and finer material does not load

the lumps too close cosh edge ofthe conveyer bel, Also he Inde diners

slons of loading chutes and the distance between sir boards ms be sal

‘ent fo pass vatlous combinations of lumps without jamming,

Lump Size Considerations

eens

‘The lump sine influences the bel specifications andthe choie of carrying

Sales. There is also an empirical relationship between lump sine aad beh

with.

‘The recommended maximum lump ste for vious belt widths is as

follows: Fora 20° surcharge, with 10% lumps and 90% fines, Ihe reco

‘mended maximum lump sie is 1/3 the belt with (0/3, With al loos aed

no fines, the resommended maximum lump sae i 1/5 the beh width (b/9),

For 2 30° surcharge, with 109% lumps and 90% fines, the recor,

‘mended maximum lump sie is 1/6 the belt with (0/6). With al longs aod

no fies, he recommended maximum lump sie ie 1/10 he bel width (3/10),

Another way to determine belt with fora specific hump ss f

luseated in Figure 4.1. This simple chart shows the belt width neecuy for a

sven sie lump, fr various proportions of lamps and ne, and for rarieus

{areharg loadings,

Batt Speeds

‘Suitable belt conveyor speeds depend largely upon the cheacteriatics of the

rxterial 19 be conveyed, the eapaciy deed, and the belt tensions

employed

Powdery materits should be conveyed at speds low enough 19

‘minimize dusting, particularly at the loading and discharge patos, Frage

eons. Bel ii ear fore een mp se Fines a2

‘Power tha 119 mena pe

‘materials also limi bel speeds. Low speeds are necessary so that degradation

Df teagile materials will not occur at the loading and discharge point a the

conveyor belt and the material being eatied move over the ier.

Heavy, sharp-edged materials shouldbe card at moderie speeds,

‘Thisis good practice because he sharp edges are kel to wear the belt cover

unduly, parculacy if the loading velocity ofthe materia ia the diection of

‘elt tov! i appredably lower than the ble speed,

(General recommendations for maximum speeds of tlt conveyors are

shown in Table 1 A

Under favorable loading and waster conditions, for troughed con

‘veyor belts wider than 30 inches, speeds in exces of those speed in Table

441 ae used for fine materials, damp sand, coal, earth wit no large lumps,

tnd ered sone, increase in bel speed permit decrezes in bet with

And tension, However, these benefite must be weighed sgsnst the possible

Gindvantage of increased belt Wear, material degracatio, windags loses,

lump impact on carrying idlers, and generally reduced Ue of all conveyor

‘components, Consulta CEMA member company when essiering opera

Hon at these higher speeds.

“The design of the loading area and the dscharge ofthe material over

the nead pulley algo must be considered when choosing the bel sped. If the

materiale dy and fine and the belt velocity is high dusting of the material

tay be intolerable, Also, i the material is henry or contais lege lumps, oF

if the partis edges are angular and sharp, a high velocity of seenarge may

fause undue wear on the discharge or transfer chutes

“Tamedt. Recommended Maximum Bel Speeds

‘Belt Beir

pects wit

Material Sing conveyed om) fines)

[Grin or eter free owe, 30 it

onabrasive mata 700 230

0 ica

100 i656

Gal, tap ey, 20 ore, 00 it

Serburden an eat, e- x0 atte

Shahed sone 00 a0

100 7256

eno, bard carpal oe, 30 7

oust-rued one so 236

@ over 36

. Foundry and, prepared or das

Enaceot send with smal cores, 330 Ay wi

vith or without mal castings

Gro hon enough to harm Belin)

Prepared Foundry sand aba inl

Esra (or dry sorasve) arias 200 any wit

duchraed from be by rbbet=

dae plows

Nonabraive mates ihartee 2, “ay wi

From bel by means of plows excep or

swood ple,

shore 3002

Foster bt, fat or wound,

For feding ie, nonabrasive, OF sarc | Any wisn

ately abrsive mater om

Belt Conveyor Capacities

ror given speed, belt conveyor capacities increase asthe bet width in-

Fadat Nios ine capaciy ofa bel conveyor depends on the surcharge angle

Sha on te Wctination ofthe side rolls of thre-rol toughing idler.

“The tommnal crows seton ofthe material ona belt is measured in a

plane normal to the belt On an inclined or declined conveyor, the material

Page co conform to its surcharge angle as measured in a vertical plane, Thi

sees he area, Ay, atthe cosine of the angle of conveyor slope. See

‘Bgure 4.2 However, fn most ces, the actual loss of eapacty is very smal.

Assuming a uniform feed tthe conveyor, the crossectional area of

the load onthe conveyor belt isthe determinant ofthe beltconveyoreapac-

1 In this manual, the cross-sectional area is based upon ie following two

Conditions Fs, the material loed onthe roughed belt doesnot extend to

he bet edges, The distance from the edges of the material oad tothe edges

ofthe belt is et at "standard edge cstance," which s defined a 0.0550 +

(9 inch, where bis the width ofthe belt in inches. Troughout his manval,

andar edge distance is presumed to be in effect unles otherwise specified,

‘Second, the top ofthe loa ofthe material ithe are of a cil tangent, at the

‘edges ofthe ond, fo the surcharge ange of loading

‘Areas—Slandard Rage Distance

Refering to Figure 42; the area of losd eros szation is dvided into wo

parts, Ones the trapezoidal area, A; the other Is the cesar segment area,

Fee vgn stermed the surcharge ren. The sum of hese wo areas (Ay +A)

‘Sats whi isthe total crosesetional are,

Diaper” rane

ele ‘ieaniaccpese

/ ‘fen ein i fee

ene 42. Are of oad er sen

‘Based on an analyse of the theee-equal-roll roughing idlers of eight

rmanufactorers, the length of the fat surface of te eener roll averages

‘O371D, wher bs the bee width in inches. raphieal fll-ale analysis of &

Sly ble with finch and 1/32Jneh covers, lying on an average three-

quaL-oll coughing idle, indicates thatthe Nat isance onthe bltearrying

SOeace over the center lds eol i 1/inch seater than center roll length:

Se:

Trapesoidl are, Ay

Let

4)

1 areatapeia asco), =( 4

2. Width beh, @ = f+ 2m + 26

B haley

f= mech

12031 + 0.25

c= 0058) + 09

§ Lose + 0.25 + 2m + 20.0856 + 0.9)

2m = b = 04816 — 2.05

r= 0.5985 ~ 1.025,

Fe mcos f= (0289Sb ~ 1.025) cos P

4p = 20.25950 ~ 1.025) cos

12 osnte + 0.25 + 20.2595b ~ 1.025) cos B

4, [t= GST 025 + o3Tb + 0.25 + 202598 — Lumeots

a z

= 03710 + 0.28 + (0.2595 ~ 1.025) cos F

5. j=msing

42 (0.25050 — 1.025) snp

6 ares oftrperois 4, = EH

7

TOsTib + 0.25 + (0.28956 ~ 1.025) cos A x

((62s880 ~ 1.025) sin A

Crculr segment (surcharge) area, A,

20

360

48. Area angle (ACD) = “#228

15, Acea whole setor (ABCD) =

9, Area segment (ABCE) A, - Aide

Aca A,

wre Eo rales :

pu BaTIb + 025"+ 2025950 — 1025) cos?

Tang

018556 + 0.25 + (02595 — 1.025) cos

ine

ve ae (eushsgu soa unas)

At,

a, Total Area, A + 4, (00) = 4

Flat Belt Load Areas—Standard Edge Distance

tier

Pre 43. at Dl ong

2u'e

1, Area sectot (ABCD) = G8. = AE

‘rea angle (coe) = CE S4eHOD _ ade

wit inde

? ?

i ~ "2

‘Atea wiangle (ACD) =

A, = Area secog

sch

2 h=28C=2rsine re phe

For standard edge distance, ¢ = 0.0550 + 0.9 inch.

[on b= 2e =D ~ 2.0880 +03) = 8905 — 18

0018 _ 488 — 09

zane sie

a= (astbe88) (op a)

4

or Mat bet, (fe) = AL since Ay

4. Forftarbet ,() = Ae

Belt Conveyor Capacity Tables and Their Use

“Teoushed and fle bet conveyor capacities are detailed is Tbles 42 crush

4:5. These tables ae setup for 20%, 35%, and 45 roughing idler shapes and

for Nat belts or various degrees of surcharge anges whieh corespond tothe

sumping characteristics ofthe materials o be conveyed an for belt speeds

‘of 100 fom.

a

TFomabe te bet oe of tase abe, he folowing steps should

be taken:

1 neering Tales 1 and33, determine De UGA 0 the

ering oT areal he averee, wa B10 15°

than the angle of revo

anne AES So cetemine he ey of heme in pounds

per eae fot tbe

aoe eps suite to he mates and co CONNER

(robin. Refer to Chaptet §-

1 robe Ra Senucmmened Mam Bel Ses" Se:

1 ute conveyor belt speed

5 an Set somane per out (9) 10 be comet 12 the

ce tfeat in cable per ROR (27).

sg = DX 2000

o/s = ates density

omen the dese cpu inci er Rour foe eS

Santry at a belt speed of 100 fom

seceeqanienn = 00 * area RTT)

4, sg te equlalen capac 29 foun, rf so TEES? through

eee Pind the appropriate bel width,

1 {St fad Spy, eek he secede wl a

2b Te amp te may GevermigSsBalt wth

core BN gtd bl speed tay regis revlon

rane e208 Touphed Tie Eu Ras Sndert Eee DE 028th + 09 Ink

‘Cepai 9 100 FP

eerie)

SurcharaeArsle

A= Cra Seton oF Load

(ei)

oe ee a) SS am

m8 hey Sap ap ee) th Se

Wo th a ls 9] eS oe

24 33 ae ie tee ma ES on Pear

<3 SE Soo sine 1amh 12) oe a

SB 28 A Von | a So STE |

ant 3897

CML BO LR 2S sine bon 2388) 22 TS soem at rons Was 13552

idm ane batt 2 bio namn 20i2| 108 2 1S ap ent 15205 16876

He L3tl 17 bon 3ane 2708 43RHOS Tey ats {bipp apare 22310 24607

page 30 2288 220) Sous sass |iamy WOR 28 She ssa) 5osit 33813

000 4551 £05 ai [pts 23ene 27781 316 987)

i ame, 35° Touhed Bel Tiree Equa Rol Standard Ege Distance © 0.0880 + 09 Inch

; Seimei ony IF

i ma ‘mii

o-|s a Tose

bs dinchess| O° 5°10" _15* 20" ase aoe] OF 5°10" is? m°_ 25°30"

aia aaa] 9 oe Th

f HE [SS So Sud foe 25 ne] scot sr 20m mat aon eo 07

* 30 | 455. 506 557 609 662 716.772] 2733 3039 3346 3658 395,

| BL SN Rl Sh So va vel ast on ot Ss

5 |S es cst cat be a] Soe ae att

|B [Se 13k 138 12a tas tg 2om| tor Bie sie re vas

@ i998 2429 26st 2876 3.107 3.345| 11966 13269 14880 15906 17257 18642 21058

i G2 |b5ts Saas dsr sam aor asnz dara] tree topo zizns aszis sien a7i96 2975

Bo |B fees 222 20 250 Site cle edu soar ase Sout rt osu

© |S SS SS8 Gas 30h alts alse So Joe ns tine ie Se

f

& “ane tt 48° oeed Be qu Rl Smid El ite = 0054+ 9 ch

: SS aim ond consi

| fe ‘ni

be

- mate Surcharge Anse ‘Surcharge Ana

SoS eee ee

i 2 a0 a6 2a] 1 SS aA SSE

a3) AS a] Be ie We Be Be a doe

$92 43 Ma[ an hue dn con doe an

i SR de sim chal fe hie at st Geo at an

or fe le tea ce ete er tse rt oe

(ms LS Line Su] Sos auc uy sos i cae

4 YEE 100 20S Esl ate ot tet oy Li hi

225 U3 Hy|ige ins tora oe tt a at

EELS) Sib|oat ia aor kes Sty devo Snr

: S2E-G23 CA fal sac nso da aoe te

351 Sino iy Salons cot Gon tu tnt 0

Tosue 5. Flt Bet Capciy Standard Ed

Diance = 0550 + 69 Inch

1am of Dod ra

= mn ‘nin

. = Saco a Sashone ge

Bees ee ee

rn ‘i 508108 ae a GOT

a yoy in an se ei oor ane ws

% os lw ie tse a) on ine fo

= te ho he ee ian lan aa au 80

& ta st an mo oe Se la aim io ioe ame

3 10 30 jn ae sae ost so tit Sas ie

a 23 ois vos 1303 (2 jim San fan fro ssn

. 2 Sr 2 clu 12 toy Lea] im at fue fos eo send

: = Bb colp (ais bite dose 30] an am fr its tne ost

x St tay ios guns fa eae ate ce tae 0 280

»

Chapter 5

Belt Conveyor Idlers

Contents

Requirements and classifications.

General types of belt conveyor idle

roughing carrying idlers; Impact idiers; Bele trainings

Suspended idlers; Return idlers: Twovoll “V" return idler

Idler spacing.

Ialer selection.

Idler rating.

Belt alignment.

So

on

= oo os

= = eo oe oe

a

{alee Requirements

Important requirements for ders are proper supper ané protetion forthe

belt and proper support for the load being conveyed.

Bat conveyor idlers for bulk materials are designed to incorporate

rolls with various dlameters, The rolls ae fited with antivaion bearings

fnd seals and are mounted on sats

Frictional restance of te fet wil iafucaces be tenon and, com

sequently, the horsepower requirement. Roll dlameter, bearing design, and

Seal requirements constitute the major components affecting frcional

"Tit manual does not discuss the elative merits ofthe various ante

friction bearings used, nr the merits Of the sal to protect these beatings

from dit and moistare and to stain the ubriant. Each bet conveyor idler

Imanufactorer chooses a particular beating and seal arrangement. Much ine

enulty has been excised by thee fler manufacturers to provide depend

Able ielers

Selection ofthe proper rol diameter and siz of bearing and shafts based on

the type of service, operating condition, lad exried, and bet speed. For

fare and aectracy of lr election, the various ile designs ean be grouped

Into clesifeations ae shown in Table 5-1

ToS fer Clacton

Former | comer .

ctasipeation | sever. | inches) | _Duserison

aM t * ght dy

a t 5 oa

a u 4 :

Bs i 5 not

ce a 4 | eam ey

Ss ut 5 ee

& W é ae

Bs SA. 5 :

26 SA. é 2G

es v ‘ eae dy

Er vt i we

—_—<—<<

1. comer en

General Types of Belt Conveyor Tilers

there are two basi types of belt conveyor idles: carrying idler, which s4p-

Toe fie londed rum ofthe conveyor belt and return les, which suppor the

pets seta run of the conveyor be. See Figures 3.1 through $3.

Caring Idlers, Caeyngiders are of two general configurations. One is

Cerne Tae rand urvally sone thee rls, The two outer rolls

eae tOjnea pwards the center rll is borizonal. The ater configuration is

a ane oping Mat belts, This idee generally consists of @ single

ree cetacean positoned between brackets which attach gree 10 the

conveyor frame

‘Return flrs, Return ilers usally are horizontal rols, positioned be

Rare ei, nih normally are attached to the underside ofthe support

ae eee ahieh the carrying idles are mounted, Twe-oll “V" return

‘ies are alo usd for Utter leaning and higher load rings.

ewe $2. Ft Bl ier

“Troughing Carrying les

‘as the capacity tables in Chapter 4indieate roughed telts cary far greats

ne reek ar bel, fr the same with of bet and tel speed Troughing

eens ders are therefore very important components of belt Conveyors

SP LER Soveyor aytems,warranng detailed discussion,

[cent ot Commer ten

[eles with end ols set t 35° and 45° angles, while affording seater

carrying caparity fora given width, necessitate a preatertrarsvece flex

t inthe conveyor be. Sich idler bave a shorter history of application than

a 20° teoughing ier, However, improvements in bet exeass design and

‘materials have contibuted to wider accepance and greater we of 35° and

8 45" roughing icles

"Troughing ides are made in two general syle, indine and offset.

“The most commonly used is composed of thee in-line ols of equal length

Fora given width of bet end-all inclination, and material surcharge angle,

{hedhvcesauablngtvrll trvghing ler frm the bet in the bo toughed

‘shape to cary a maxim load eros section, ©

‘An offic (roughing llr is shown in Figuce 5.8. nih le, the n=

cline falls are located ins plane alongside the plane of the horizontal ell.

“These are popula inthe ran industry, where very thin else used, and a

underground mining, where low head room isa problem. Another inline

4 {rousing idler has song horizontal roll and two chor ince roll, While

thie ler doe not form 4 piven belt nto trough for maximum oad cross

‘ection, its useful where the load must be spread for manu inspection,

Picking or sorting. The Inetined end rolls turn up the bel edges to prevent of

nine spillage: Ths i known a 8 picking bet ile, Ser Figure 5.6

Pent SA, 20° roughing ier

E im 55. 35 fe woh iar

‘ean 6, 30% ping bt ir, :

6

|

impact Iles

Impact trovghing idles, sometimes referred to at “aishion ier," have

rolls made ofa resilient materia, They are used at loacing points where im

pect cesling from limp size and weight of the material hancled could

eioutly damage the belt fit were rigidly supported. One type frequently

{sed consis of 2 threroll assembly, each roll being made of spaced,

reilen cs. Similar impact Slers are made to suppor fat belts. See thea

ompanyngisrations, Figures $.7 and 5.8. Load ratings of impact idlers

_ sremo highes than thoee of standard ies. The een diss usually are ex-

pended in favor of belt peotecion.

Peo 5. 25" wou

Puchi np! i

Igoe ier with Fed safe

‘elt Training Iles, Carrying

Generally speaking, wll designe, carefully construct and maintained bet

‘Sonveyors wll continue to run with prope ligament without the need for

Special belt raining idler. There are transient condition, however, that may

hose conveyor bels to become misaligned despite all efforts to assure pro-

pet installation and maintenance. For this reason, conveyor manufcurers

Eso farish special belt taining ilrs, which, if prozerly maintained, will

help to stein belt alignment in aiffiuk situations,

"The usual rnin lr has the earring rll frame mounted on 8 een

tral pivot appronimately perpendicular tothe conveyor belt. Means are pro-

‘ide to cause the earring cll (o become skewed with respect co the center

Tine of the conveyor. As the belt traverse tbe skewed rolls, they urge the

{loplced belo seur to the conveyor centerline snd, in doing x, the rolls

fre urged to return to proper alignment. See Figure £9.

ised guide rolls placed perpendiular tothe edze ofthe conveyor belt

sre not recommended beraute continuous contact with the conveyor belt

ge accelerates bell edge wear, appreciably ceducing belt ife, See Figure

S10,

the es efecive the raining

tn genera, the greater the belt ensions,

tates.

une 49, 1° woud bl nine

‘ar

cine $30, Type fed eile,

Sroning side pe rer

Suspended Iles

tn this type of ile, the rls (sualy 3 or ) are Ke together and 8,

Je. om tn cowveyr frame singers Ts suspended 0 hanging les

Pen egpape somewhat ike that of a atenary and is thus sometimes

Sse a nary or salané, lr, Ics popula for heacy-uy ert and

cae ar yorn Thre cl les are usualy used for the carrying ru,

ae in there me sometimes used at lading oins, Relient ics are

anc Five enended on these idles at Leading points. See Figure 3.11

Sr ereaded rs tolerant of bath poor algrment and abuse by

tmps Bocuse ofthe eile consetion betveen rolls, (ca be furnish

sum Mick rlease type of mounting whieh permis the entire Her 0 be

ee At. Suspended hero er

>

ee

quel lowered and removed fom sve in ae of fue). Training

au generally not wsed with suspended fer

are general 2 be mounted on (suspended From) ether iid frame

stringers (chanel) of Wire-rope SIRT

Return ters

“Tes ler are set suppor the eur ron ofthe be They usally 76

‘hese le Ste wer Flanges of the ssnges hin support the cars

res eferabitha retin ls be So mounted hat Me UT

ingles. se below the conveyor fame, Figee 5.12 Uhsraes &

Vor!

"riaearmiccamrani

“pos Reurn flere, The fat rtur der consss ofa ong ingle Tl, ie

Fete, mounting bracket ales fll length bracket desi, and

2h ng sol allow for adequate varsers Belt movement

mounting eee contact ay satinary part f the com

‘eyor or ts frame.

“sepsCleaning Return eles. a mpc cone wih Tre

Set arnt ie pderence fein othe czryng sree of tb)

application oe avai and wear he shell ofthe return et 8, Or,

Sueh materi ey Oe icy and adhere to the retum ile rolls: A ae

ths put use misalignment ofthe return run of te Bl.

pay caf earn ier cll are avaliable to overcome these dif

seien anes icky materials are 4 problem, rbbersie, oF Bbes

Seat Ty shape. w-cteaning return ils can be used. Die 408

ca ery oar surfaces fr adhesin and thus reduc

etl rl eval bull up. Tis type of ern ler rometimes He

sen ee Ciaing let” Eve thou sch ers do "rac

roneousy clef ering tte bal surface om he eu ty 40 DOC

ot pat leaning devies. See Figures 5.13 and 5.14

ean 4 Halal or

Soy seonng ern ie

“

enon igi

‘On shor conveyors, it may be necessary to equip the complete return

‘run wit slf-leaning flrs, On Tong return belt runs, it necessary to use

‘these idles only tothe point where the material on the bel surface no luge

‘vl sdere to and bold up on normal feturn ler rol. Beyond ths polnt,

‘ondard return ides can be ured.

‘Revura Belt Traloingfdlerz. Retua belies canbe ivtally mounted to

tea or align the return belt in a manner similar to the training ile

previously described forthe eatryng run ofthe belt Se Fgute 515.

‘Two-Roll “Y" Retwe fers

‘Wich the increased use of heavy, bgh-tension fable and ste! cable bets, the