Professional Documents

Culture Documents

Valve Clearance (1Hd Fte) : Inspection

Uploaded by

Arief SoehartoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Clearance (1Hd Fte) : Inspection

Uploaded by

Arief SoehartoCopyright:

Available Formats

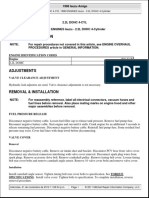

EM−9

ENGINE MECHANICAL − VALVE CLEARANCE (1HD−FTE)

VALVE CLEARANCE (1HD−FTE) EM0W1−01

INSPECTION

HINT:

Inspect and adjust the valve clearance when the engine is cold.

1. REMOVE CYLINDER HEAD COVER

(See page EM−77)

2. SET NO.1 CYLINDER TO TDC/COMPRESSION

(a) Turn the crankshaft pulley clockwise, and align its groove

with the groove of the timing gear cover.

(b) Check that the valve rocker arm on the No.1 cylinder are

loose and valve rocker arm on the No.6 cylinder are tight.

If not, turn the crankshaft 1 revolution (360˚) and align the

mark as above.

Turn P22808

3. INSPECT VALVE CLEARANCE

(a) Check only the valves indicated in the illustration.

S Using a feller gauge, measure the clearance be-

tween the adjusting screw on the valve rocker arm

and the valve bridge.

S Record the out−of−specification valve clearance

IN EX EX IN EX IN measurements.

Valve clearance (Cold):

P23268 Intake

0.17 − 0.23 mm (0.007 − 0.009 in.)

Exhaust

0.47 − 0.53 mm (0.019 − 0.021 in.)

(b) Turn the crankshaft pulley 1 revolution (360˚) and align

the mark as above. (See procedure step 2)

(c) Check only the valves indicated as shown. Measure the

valve clearance. (See procedure in step (a))

IN EX IN EX IN EX

P23269

4. ADJUST VALVE CLEARANCE

(a) Loosen the lock nut on the valve bridge, and loosen the

adjusting screw until the adjusting screw and valve stem

Loosen Adjusting

Screw are completely separated.

Loosen NOTICE:

Hold the valve bridge with a wrench, and loosen the lock

Valve nut. Do not apply torque to the valve bridge.

Bridge

Hold

P23273

1HZ, 1HD−T, 1HD−FTE ENGINE (RM617E)

EM−10

ENGINE MECHANICAL − VALVE CLEARANCE (1HD−FTE)

(b) Loosen the lock nut on the valve rocker arm, and loosen

the adjusting screw.

Turn Adjusting (c) Insert a 0.20 mm (0.008 in.) feeler gage for intake or 0.50

Screw mm (0.020 in.) feeler gage for exhaust between the ad-

Lock

Valve justing screw on the valve rocker arm and the valve

Rocker bridge.

0.20 or Slide Arm

0.50 mm (d) Turn the adjusting screw on the valve rocker arm until the

Feeler feeler gauge slides with a very slight drag, and lock the

Gauge P23271 adjusting screw with the lock nut.

(e) With the feeler gauge inserted, check that the resistance

of the feeler gauge remains the same when the adjusting

screw on the valve bridge is loosened.

Loosen

Adjusting If the resistance of the feeler gauge changes, repeat from

Screw step (b).

Slide

Valve

Bridge

P23274

(f) Tighten the adjusting screw on the valve bridge, and lock

the adjusting screw with the lock nut when the resistance

Tighten Adjusting of the feeler gauge begins to get stronger.

Screw NOTICE:

Hold the valve bridge with a wrench, and lock the adjusting

Slide Lock

screw with the lock nut. Do not apply torque to the valve

bridge.

Valve Hold

Bridge P23275

(g) Loosen the lock nut on the valve rocker arm.

(h) Tun the adjusting screw on the valve rocker arm until the

Turn Adjusting feeler gauge slides with a very slight drag, and lock the

Screw

Lock adjusting screw with the lock nut.

Valve 5. REINSTALL CYLINDER HEAD COVER

Rocker (See page EM−94)

Slide Arm

Z15468

1HZ, 1HD−T, 1HD−FTE ENGINE (RM617E)

You might also like

- International VT365 PDF Service ManualDocument102 pagesInternational VT365 PDF Service ManualZeck100% (10)

- Piston Engine TroubleshootingDocument30 pagesPiston Engine Troubleshootingkp subedi100% (1)

- 1KD FTV Injector Disassemble ReassembleDocument7 pages1KD FTV Injector Disassemble ReassembleAll Haul TransportNo ratings yet

- Caterpillar Engine FamilyDocument72 pagesCaterpillar Engine FamilyJesus Almanzar Santos100% (1)

- Isuzu 4JA1 Engine Product Knowledge TrainingDocument88 pagesIsuzu 4JA1 Engine Product Knowledge Trainingfernando aritonangNo ratings yet

- Em2008 PDFDocument407 pagesEm2008 PDFBeto GarciaNo ratings yet

- MAZDA Advanced Petrol Engine Management EnglishDocument142 pagesMAZDA Advanced Petrol Engine Management EnglishThuy Anh100% (2)

- Euro III BH117L Engine DL08 Operation Maintenance ManualDocument221 pagesEuro III BH117L Engine DL08 Operation Maintenance ManualLeticia Naranjo100% (5)

- 13C PDFDocument81 pages13C PDFKyaw Kyaw LinnNo ratings yet

- Fuel Injection Pump Technical Hint for Land CruiserDocument45 pagesFuel Injection Pump Technical Hint for Land CruiserВячеслав ГлушакNo ratings yet

- Sect 0 General 1kd Engine Ce302 PDFDocument28 pagesSect 0 General 1kd Engine Ce302 PDFDavit OmegaNo ratings yet

- Body Builder's Drawings and Supporting Data GuideDocument55 pagesBody Builder's Drawings and Supporting Data GuideTeddy Khant100% (1)

- Landcruiser Castor BushDocument1 pageLandcruiser Castor BushthailanNo ratings yet

- ASE Auto HRDocument78 pagesASE Auto HRRavi RanjanNo ratings yet

- Manual Formacion V3300-DI-TDocument20 pagesManual Formacion V3300-DI-TTerah PioNo ratings yet

- Engine Mechanical : Group 11CDocument36 pagesEngine Mechanical : Group 11CRomaNo ratings yet

- Ec QG16Document320 pagesEc QG16Mahmoud El-MeghenyNo ratings yet

- Diesel+code+toyota+ PDFDocument10 pagesDiesel+code+toyota+ PDFKumar HemrajNo ratings yet

- Y61 CRD X Sm7e-Y61kg1 emDocument22 pagesY61 CRD X Sm7e-Y61kg1 emDaniel BruceNo ratings yet

- Toyota in The World 2013Document26 pagesToyota in The World 2013evamcbrownNo ratings yet

- Volvo Engine TAD1341GE TAD1342GE TAD1343GE TAD1344GE TAD1345GE TAD1355GEDocument374 pagesVolvo Engine TAD1341GE TAD1342GE TAD1343GE TAD1344GE TAD1345GE TAD1355GENAMIK KEMAL ALTANNo ratings yet

- A320 engine and oil specificationsDocument4 pagesA320 engine and oil specificationsJoao Melo100% (1)

- Brochure A35g A40g t4f en 22 20050840 DDocument20 pagesBrochure A35g A40g t4f en 22 20050840 DRengga PratamaNo ratings yet

- Frontier d22 - Sist DireccionDocument43 pagesFrontier d22 - Sist DireccionrubenNo ratings yet

- Installation of Cylinder Head: Downloaded From Manuals Search EngineDocument6 pagesInstallation of Cylinder Head: Downloaded From Manuals Search EngineDavid QuispeNo ratings yet

- Mitsubishi Engine F9Q Series Workshop ManualDocument48 pagesMitsubishi Engine F9Q Series Workshop ManualAlexandru sNo ratings yet

- Defender MY2002 Wiring DiagramDocument108 pagesDefender MY2002 Wiring DiagramsmartstepNo ratings yet

- Injector Pulse WidthDocument3 pagesInjector Pulse Widthmsaad19103564100% (1)

- Twingo Electrical ManualDocument126 pagesTwingo Electrical ManualJose Bastidas75% (4)

- MPV Facelift PDFDocument33 pagesMPV Facelift PDFTony ChanNo ratings yet

- 4 JB 1Document60 pages4 JB 1Rex Palmitos100% (1)

- Calibracion de Valvulas Toyota 1nz YarisDocument11 pagesCalibracion de Valvulas Toyota 1nz Yariscpaolinod100% (3)

- Toyota 2L-T diesel engine specifications 1984-1988Document2 pagesToyota 2L-T diesel engine specifications 1984-1988Pencil neck100% (1)

- Sebp4195 44 01 All - 005Document694 pagesSebp4195 44 01 All - 005nerit0loco83100% (1)

- 1996 Toyota Land Cruiser Prado RJ ModDocument4 pages1996 Toyota Land Cruiser Prado RJ ModVincentius NikimNo ratings yet

- No Go W38 Oi38-16 PDFDocument10 pagesNo Go W38 Oi38-16 PDFRonald Bienemi PaezNo ratings yet

- Volvo Penta D6-370Document2 pagesVolvo Penta D6-370Anonymous alQXB11EgQ100% (3)

- Adjustment of Valve Clearance: No. 1 No. 3 EX EXDocument11 pagesAdjustment of Valve Clearance: No. 1 No. 3 EX EXDavid QuispeNo ratings yet

- Differential CaseDocument5 pagesDifferential CaseOmar Jayson Siao VallejeraNo ratings yet

- Cylinder Head Bolt Tightening SequenceDocument2 pagesCylinder Head Bolt Tightening Sequenceອູ່ ໄຊ ອິນເຕີNo ratings yet

- Engine 3 0l Turbo Diesel - Specifications - TorqueDocument3 pagesEngine 3 0l Turbo Diesel - Specifications - TorqueAlex Sirgiovanni0% (1)

- The Ag Shop Product CatalogueDocument93 pagesThe Ag Shop Product Cataloguefireman100% (1)

- Service Manual Hyundai h35-45d-7 Brake SystemDocument9 pagesService Manual Hyundai h35-45d-7 Brake SystemПетрNo ratings yet

- Removal: Automatic Transmission (A750F)Document5 pagesRemoval: Automatic Transmission (A750F)joe nathanNo ratings yet

- Manual - de - Servicio - Isuzu - 2.2l (LUV) PDFDocument24 pagesManual - de - Servicio - Isuzu - 2.2l (LUV) PDFLuis ValenzNo ratings yet

- Check your charging system for proper operationDocument16 pagesCheck your charging system for proper operationAbu AliNo ratings yet

- Ford Ranger BrochureDocument8 pagesFord Ranger BrochureGabriel Andrew EstrellaNo ratings yet

- A51 A43 A34 A23 A22 A26 A24 A25 A32 A45: Position of Parts in Engine CompartmentDocument4 pagesA51 A43 A34 A23 A22 A26 A24 A25 A32 A45: Position of Parts in Engine CompartmentApril MckeeNo ratings yet

- BT-50 en OrganizedDocument40 pagesBT-50 en OrganizedPao RodNo ratings yet

- Disassembly and Assembly of Differential (With A.D.D.)Document24 pagesDisassembly and Assembly of Differential (With A.D.D.)frankhil ramosNo ratings yet

- Nissan CD17Document3 pagesNissan CD17jose luis calixto requisNo ratings yet

- Hydraulic brake booster disassembly guideDocument10 pagesHydraulic brake booster disassembly guideYannick de WalqueNo ratings yet

- Revise ZD30DDT Engine Valve LifterDocument9 pagesRevise ZD30DDT Engine Valve LifterJose Luis Jimenez HuashuayoNo ratings yet

- CJZC Engine Crankshaft GroupDocument28 pagesCJZC Engine Crankshaft GroupDaniel100% (1)

- GME TX4200 Owner's ManualDocument33 pagesGME TX4200 Owner's ManualHelen HelenopoulosNo ratings yet

- Especificaciones de Ajuste Toyota 2kd-ftvDocument3 pagesEspecificaciones de Ajuste Toyota 2kd-ftvyonth faiber rivasNo ratings yet

- Кардан Передний Задний Мосты LGPRO-WE-0554 - 1st - WSMW - 05 - N - G.Exp - 729Document188 pagesКардан Передний Задний Мосты LGPRO-WE-0554 - 1st - WSMW - 05 - N - G.Exp - 729Dmitry BondarNo ratings yet

- Sds Toyota vx100Document8 pagesSds Toyota vx100Ferry DarmawanNo ratings yet

- Hyundai HD78 Wheels and TiresDocument19 pagesHyundai HD78 Wheels and TiresBigfair HD78No ratings yet

- TATA Minibus 407 MaintainanceDocument13 pagesTATA Minibus 407 MaintainancePraveen Kumar ReddyNo ratings yet

- Fault Codes: Diesel (1KD-FTV - D-4D)Document2 pagesFault Codes: Diesel (1KD-FTV - D-4D)Oliver LealNo ratings yet

- Reassembly: 1. Assemble Piston and Connecting RodDocument7 pagesReassembly: 1. Assemble Piston and Connecting Roddolphi_742078No ratings yet

- Installation Guide DB3: 2015 Toyota Corolla (Smart Key) - 403.TL6 2.18 RSRDocument22 pagesInstallation Guide DB3: 2015 Toyota Corolla (Smart Key) - 403.TL6 2.18 RSRRaja Yasir 1No ratings yet

- Toyota Tundra (2UZ FE) 2002Document16 pagesToyota Tundra (2UZ FE) 2002Isaac Castillo100% (1)

- H 100 ManualDocument262 pagesH 100 ManualMurat CanNo ratings yet

- p5 5S-FE+ENGINE+REPAIR+MANUALDocument23 pagesp5 5S-FE+ENGINE+REPAIR+MANUALkavindaNo ratings yet

- CH-40 MULTI-MODE MANUAL TRANSMISSION SYSTEM RESETTINGDocument3 pagesCH-40 MULTI-MODE MANUAL TRANSMISSION SYSTEM RESETTINGAlan Ghon100% (2)

- Diesel Engine and Components: Series Paragraphs 51-53Document9 pagesDiesel Engine and Components: Series Paragraphs 51-53Branko MikulinjakNo ratings yet

- Common Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMDocument1 pageCommon Rail Injectors Repairing Table: MM Bar M M M NM NM NM NMakhmedNo ratings yet

- Adjust Valve Clearance on 2002 ECHO RM884UDocument6 pagesAdjust Valve Clearance on 2002 ECHO RM884UBoncu BoncuNo ratings yet

- 1 AzDocument7 pages1 AzEdU RECTIFICANo ratings yet

- Calibracion Valvulas Toyota 1GRFEDocument9 pagesCalibracion Valvulas Toyota 1GRFEJose Antonio Rivero ReyesNo ratings yet

- C783 - Intake Manifold 1 Temperature-Abnormal Rate of ChangeDocument4 pagesC783 - Intake Manifold 1 Temperature-Abnormal Rate of ChangeLucas CamposNo ratings yet

- Volvo Engine MY04B5254T2-S40 PDFDocument29 pagesVolvo Engine MY04B5254T2-S40 PDFJohn DeenyNo ratings yet

- Cobb Tuning Nissan GTR A PORT Map NotesDocument3 pagesCobb Tuning Nissan GTR A PORT Map NotesturbojloNo ratings yet

- JiangdongDocument51 pagesJiangdonghlflorekNo ratings yet

- How To Set Ignition TimingDocument8 pagesHow To Set Ignition Timingbogdanxp2000No ratings yet

- Test Fiat 680Document3 pagesTest Fiat 680Claudio LopezNo ratings yet

- 319 Mod 4-4 SBC Brake Pads (WJB) 5-9-02Document4 pages319 Mod 4-4 SBC Brake Pads (WJB) 5-9-02Stefan KonyanNo ratings yet

- Program Files/WS - FTP/astra: Jack SobelmanDocument32 pagesProgram Files/WS - FTP/astra: Jack SobelmanJose Lara100% (1)

- Qashqai-Om j12 En6 November-2022Document536 pagesQashqai-Om j12 En6 November-2022gaurav_g9No ratings yet

- EC250D BRIC - Hyd - eng-GB20025770B - HDocument30 pagesEC250D BRIC - Hyd - eng-GB20025770B - Hفتحي الجمل فتحي الجملNo ratings yet

- B737-200 ADV: Flight Control Computer ADocument1 pageB737-200 ADV: Flight Control Computer Ajames kirkNo ratings yet

- Study of Piston Manufacturing and Completion of A Project On"Understandinng Piston Manufacturinng Process " in Piston PlantDocument26 pagesStudy of Piston Manufacturing and Completion of A Project On"Understandinng Piston Manufacturinng Process " in Piston PlantSambhav Jain100% (1)

- YMMS: 1996 Peterbilt 379 Inoperative Cruise ControlDocument10 pagesYMMS: 1996 Peterbilt 379 Inoperative Cruise ControlAbdelbagiNo ratings yet

- DC13 073A. 438-487 KW (503-553 kVA) : EU Stage II, China Phase II and CPCB-IDocument2 pagesDC13 073A. 438-487 KW (503-553 kVA) : EU Stage II, China Phase II and CPCB-IJulio SullaymeNo ratings yet

- Cat Electronic Technician 2015A v1.0 Product Status ReportDocument4 pagesCat Electronic Technician 2015A v1.0 Product Status ReportbejoythomasNo ratings yet

- Ashutam Fuel Lines Price List 2020Document12 pagesAshutam Fuel Lines Price List 2020Amit Chopra AmitNo ratings yet

- Riley 2.5 - ADocument26 pagesRiley 2.5 - Ahead_masterNo ratings yet

- Expt 3 Study of Energy Recovered Using Regenerative BrakingDocument10 pagesExpt 3 Study of Energy Recovered Using Regenerative BrakingYash BhangaleNo ratings yet